Functionalization method for modifying surfaces of magnetic particles with gold nanoparticles

A technology of gold nanoparticles and surface modification, which is applied in the field of preparation of multifunctional nanoparticles, can solve the problems of separation of magnetic particles and gold nanoparticles, variability, and high cost of antigen and antibody, and achieves simple steps, simple operation and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

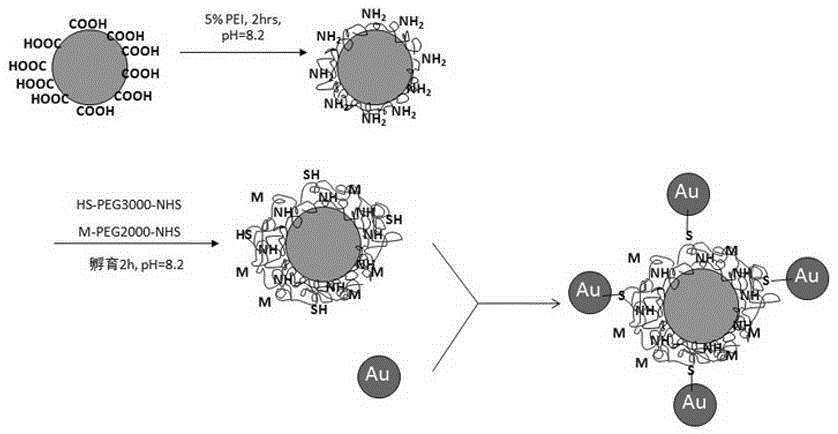

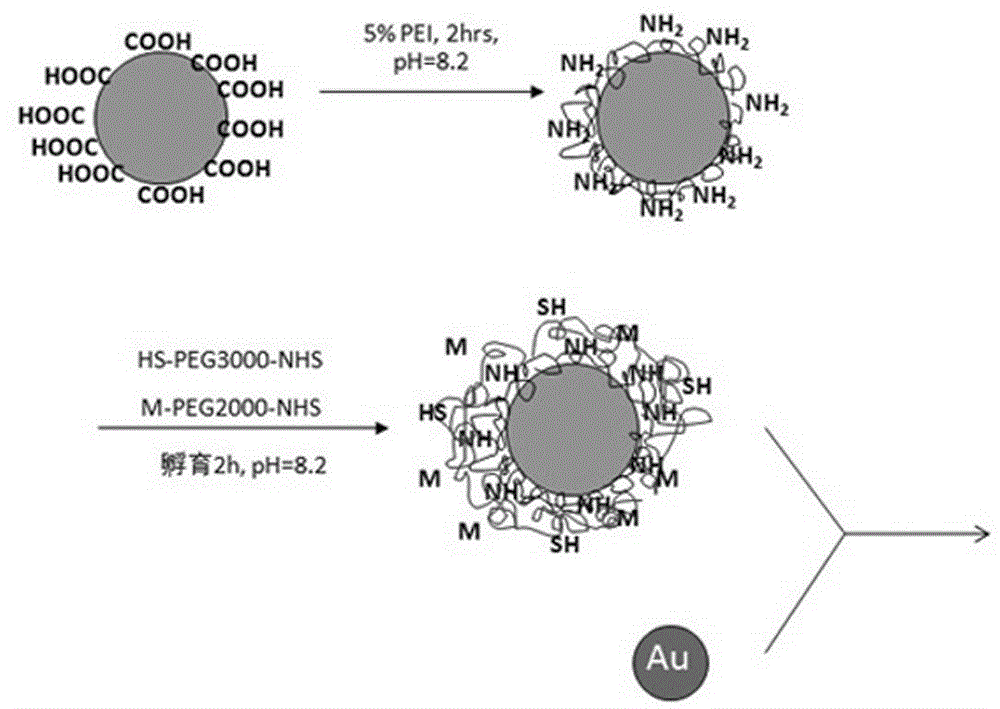

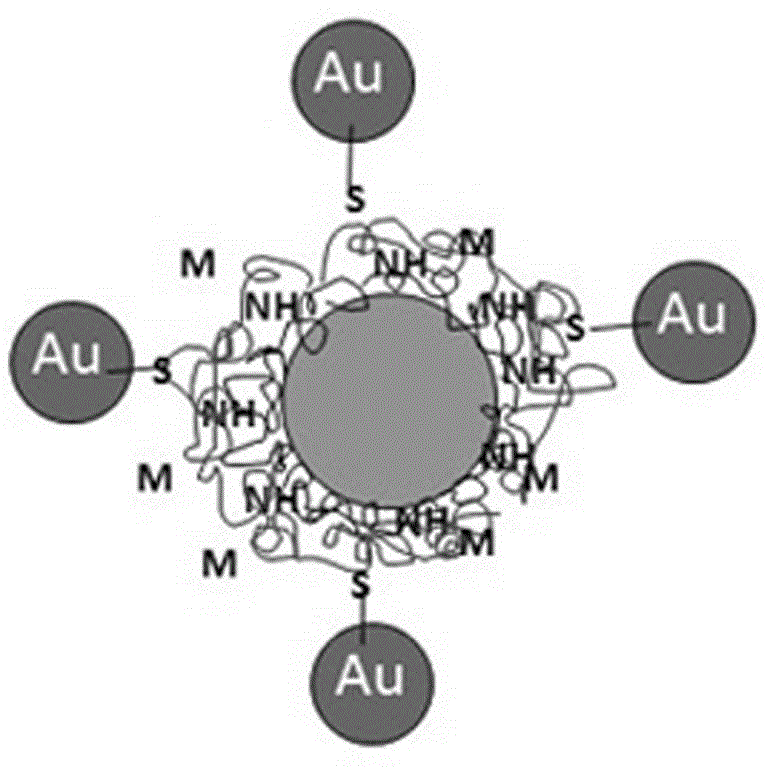

[0021] 1) Surface amination of magnetic particles: take 1mL of magnetic particle solution carboxylated on the surface, attract it to the wall of a 1.5mL centrifuge tube with a magnet, remove the liquid with a pipette gun, and add 0.05mol / L carbonate buffer (pH8.2 ), ultrasonic vibration to disperse the magnetic particles, repeat the above cleaning process twice, then add 5% polyetherimide carbonate buffer, and react for 2 hours. The magnetic particles were washed three times with carbonate buffer to remove excess polyetherimide.

[0022] 2) Pegylation on the surface of magnetic particles: add 1 mL of mercapto-polyethylene glycol (molecular weight: 3000)-N-hydroxysuccinimide (HS-PEG-3000-NHS) to the magnetic particles obtained in step 1) and methoxy-polyethylene glycol (molecular weight 2000)-N-hydroxysuccinimide (mPEG-2000-NHS) mixed with carbonate buffer (total PEG concentration of 40mM, HS-PEG-3000-NHS with mPEG-2000-NHS molar ratio is 1:4), reacted for 2h. The magnetic pa...

Embodiment 2

[0025] 1) Surface amination of magnetic particles: take 1mL of magnetic particle solution carboxylated on the surface, attract it to the wall of a 1.5mL centrifuge tube with a magnet, remove the liquid with a pipette gun, and add 0.05mol / L carbonate buffer (pH8.2 ), ultrasonic vibration to disperse the magnetic particles, repeat the above cleaning process twice, then add 5% polyetherimide carbonate buffer solution, and react for 1 h. The magnetic particles were washed three times with carbonate buffer to remove excess polyetherimide.

[0026] 2) Pegylation on the surface of magnetic particles: add 1 mL of mercapto-polyethylene glycol (molecular weight: 3000)-N-hydroxysuccinimide (HS-PEG-3000-NHS) to the magnetic particles obtained in step 1) Mix carbonate buffer with methoxy-polyethylene glycol (molecular weight 2000)-N-hydroxysuccinimide (mPEG-2000-NHS) (total PEG concentration is 20mM, HS-PEG-3000-NHS with mPEG-2000-NHS molar ratio of 1:9), reacted for 2h. The magnetic par...

Embodiment 3

[0029] 1) Surface amination of magnetic particles: take 1mL of magnetic particle solution carboxylated on the surface, attract it to the wall of a 1.5mL centrifuge tube with a magnet, remove the liquid with a pipette gun, and add 0.05mol / L carbonate buffer (pH8.2 ), ultrasonic vibration to disperse the magnetic particles, repeat the above cleaning process twice, then add 5% polyetherimide carbonate buffer, and react for 2 hours. The magnetic particles were washed three times with carbonate buffer to remove excess polyetherimide.

[0030] 2) Pegylation on the surface of magnetic particles: add 1 mL of mercapto-polyethylene glycol (molecular weight: 3000)-N-hydroxysuccinimide (HS-PEG-3000-NHS) to the magnetic particles obtained in step 1) and methoxy-polyethylene glycol (molecular weight 2000)-N-hydroxysuccinimide (mPEG-2000-NHS) mixed with carbonate buffer (total PEG concentration of 10mM, HS-PEG-3000-NHS with mPEG-2000-NHS molar ratio is 1:4), reacted for 2h. The magnetic pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com