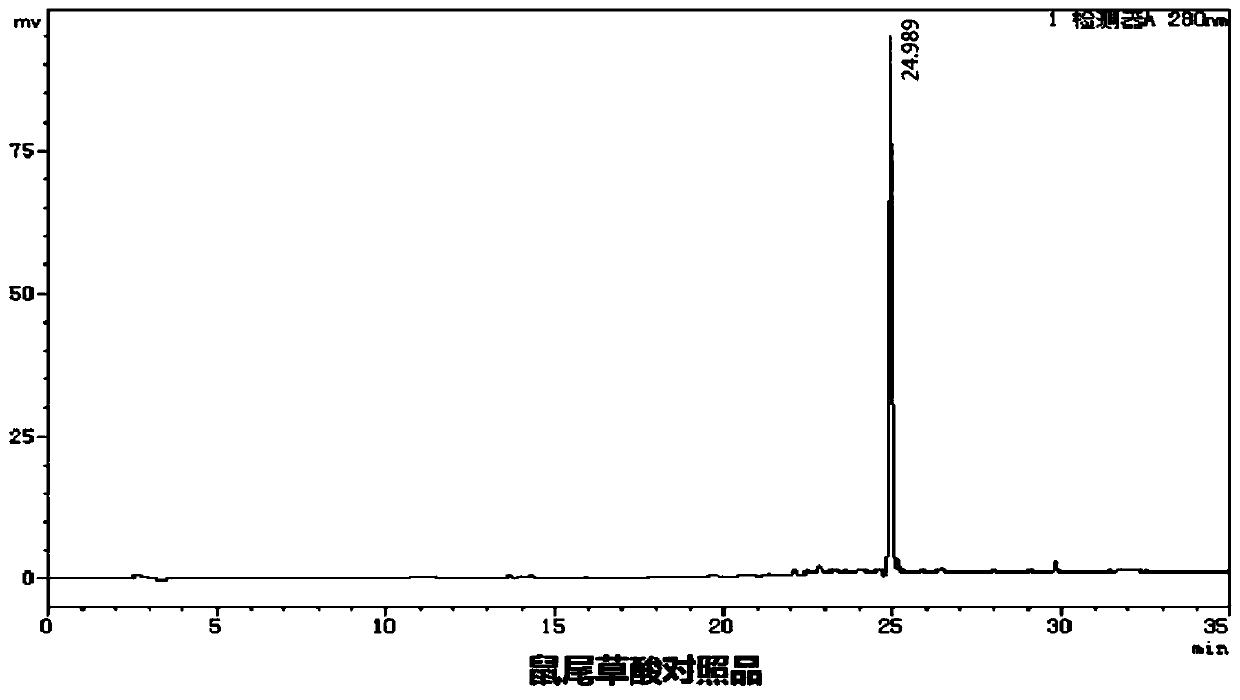

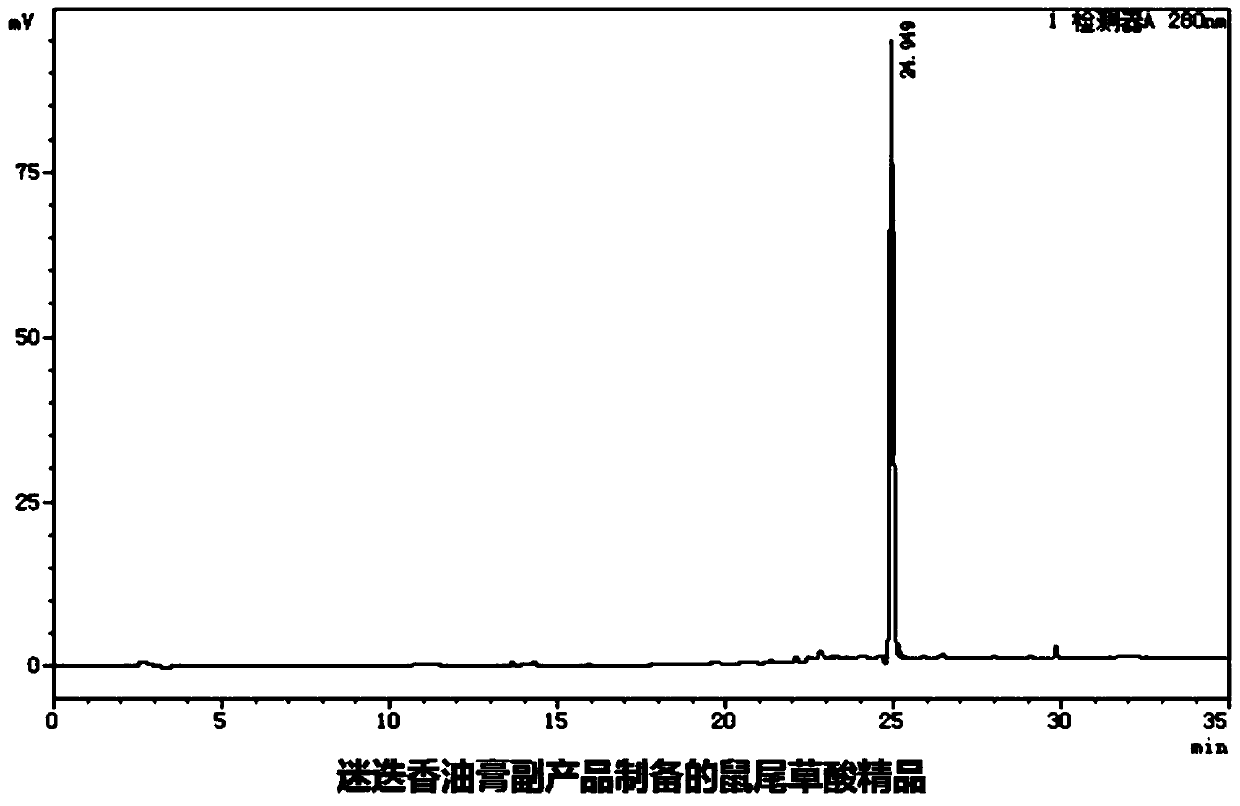

Method for preparing high-purity carnosic acid from rosemary oil paste byproduct

A technology for rosemary oil and carnosic acid, which is applied in the field of preparing high-purity carnosic acid, can solve the problems of structural change of residence time, no industrialized production, and complicated preparation process, and achieves great social and economic value and low production cost. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The method for preparing high-purity carnosic acid from the by-product of rosemary ointment, the specific process steps are as follows (see Figure 4 ):

[0051] (1) Prepare R67 extract

[0052] Mix ethyl acetate and absolute ethanol solvent according to the volume ratio of 95:5, and then mix it with No. 6 solvent oil according to the volume ratio of 5:95 to prepare the R67 extract as the first ( 4) Step prepare carnosic acid extract phase.

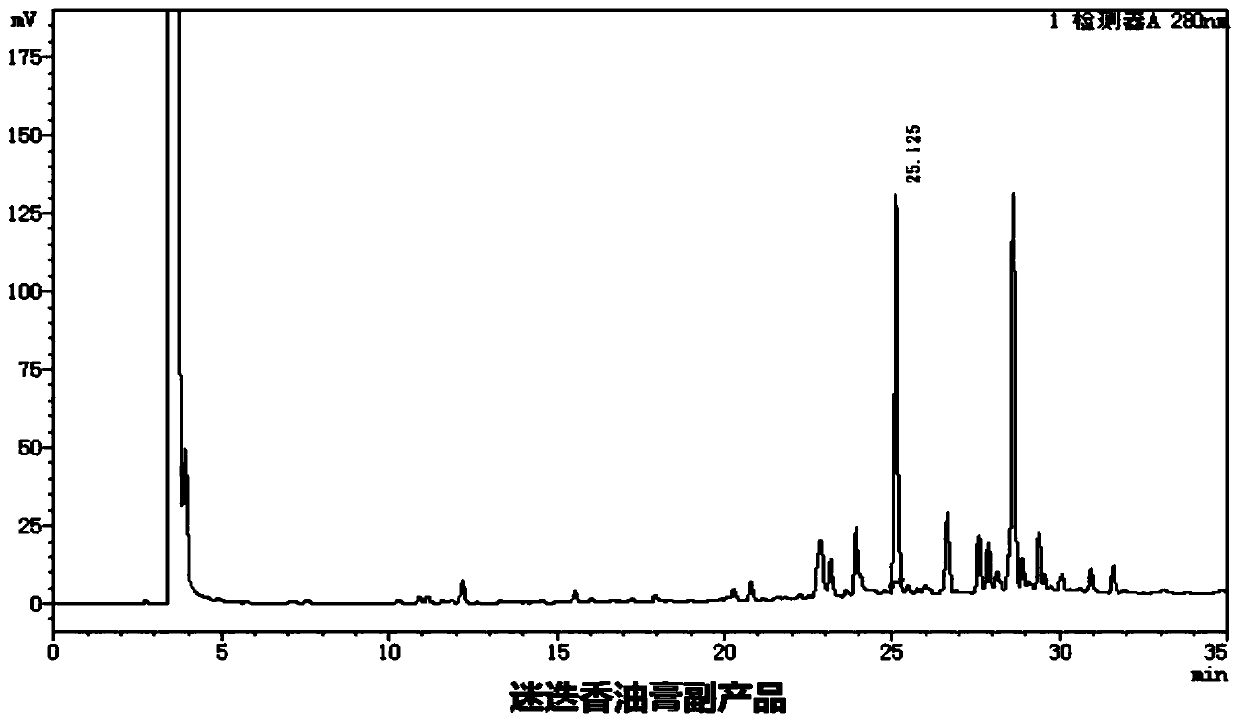

[0053] (2) Preparation of by-product of rosemary ointment

[0054] The dried or fresh rosemary leaves are subjected to steam distillation to prepare rosemary essential oil. The dried rosemary leaves are crushed into a coarse powder of 10-20 mesh, and 85-90% ethanol and 1% citric acid (stabilizer) are added to the ultrasonic countercurrent extraction at room temperature. The extract was concentrated under reduced pressure to recover ethanol, and then centrifuged to obtain a centrifugal liquid and precipitate. The centrifugal liquid is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com