Manufacturing method of display substrate, display substrate and display device

A technology for display substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as dark spots and isolation failures in display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

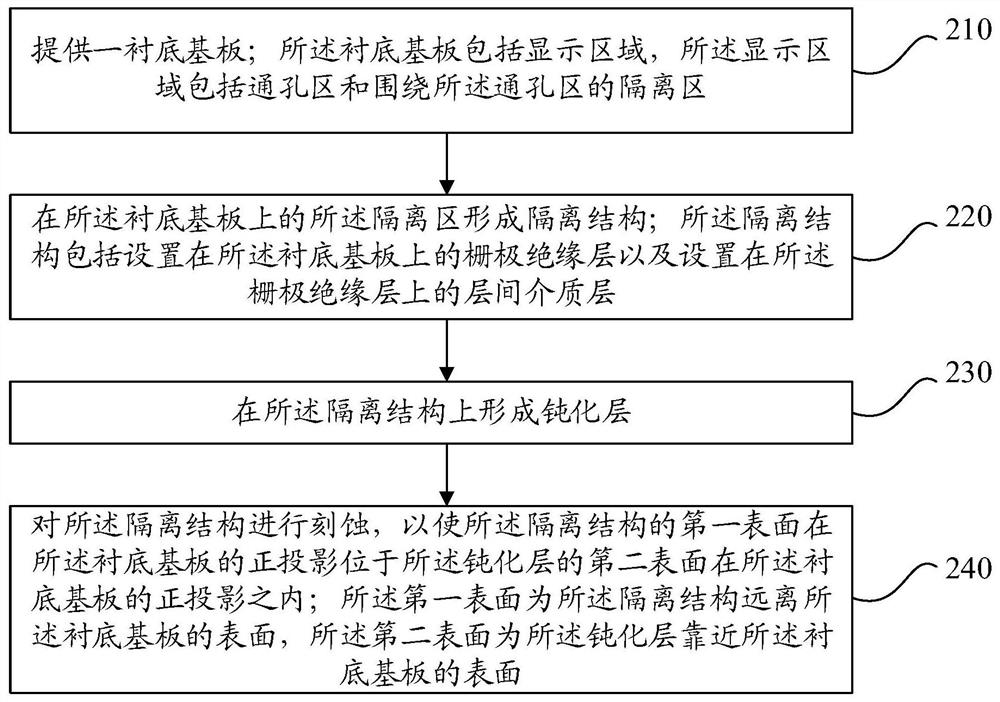

[0067] refer to figure 2 , which shows a flow chart of a method for manufacturing a display substrate according to Embodiment 1 of the present invention, which may specifically include the following steps:

[0068] Step 210, providing a base substrate; the base substrate includes a display area, and the display area includes a via area and an isolation area surrounding the via area.

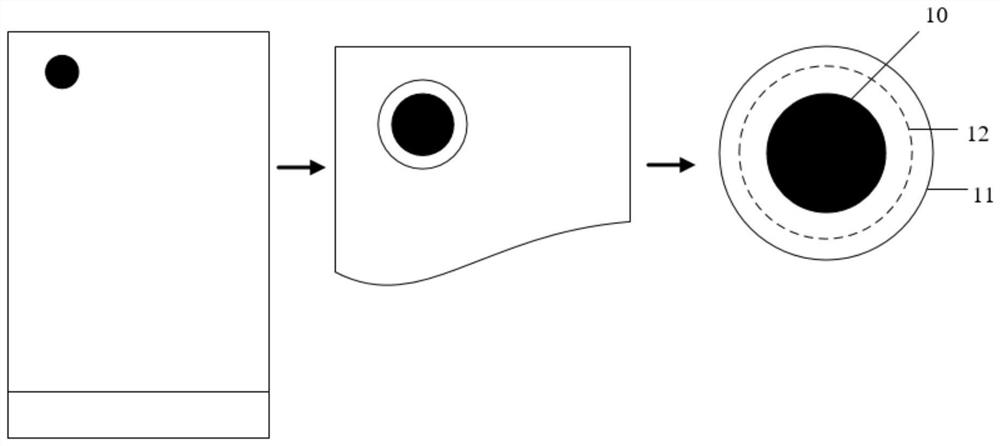

[0069] In an embodiment of the present invention, a base substrate is provided, the base substrate includes a display area, and the display area includes a through-hole area 10 and an isolation area 11 surrounding the through-hole area 10, such as image 3 As shown, it is a schematic plan view of a display panel formed by using the display substrate of the embodiment of the present invention. The through-hole area 10 in the display substrate refers to the display panel formed by the display substrate for installing a camera or an infrared scanning device. and other functional device areas, the ...

Embodiment 2

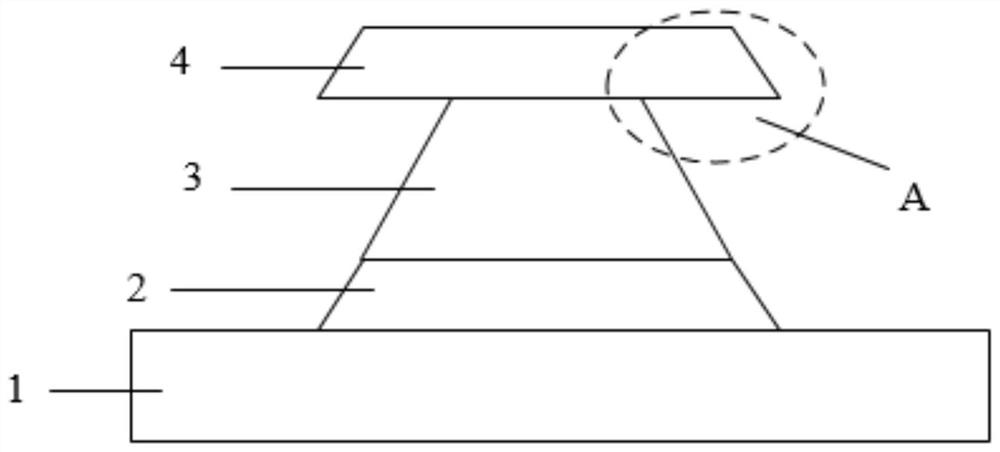

[0108] Embodiment 2 of the present invention provides a display substrate, including:

[0109] The base substrate 20, the base substrate 20 includes a display area, and the display area includes a through hole area 10 and an isolation area 11 surrounding the through hole area 10;

[0110] The isolation structure 30 of the isolation region 11 formed on the base substrate 20, the isolation structure 30 includes a gate insulating layer 103 disposed on the base substrate 20 and an interlayer dielectric layer 104 disposed on the gate insulating layer;

[0111] a passivation layer 105 formed on the isolation structure 30;

[0112] Wherein, the orthographic projection of the first surface of the isolation structure 30 on the base substrate 20 is located within the orthographic projection of the second surface of the passivation layer 105 on the base substrate 20; The second surface is the surface of the passivation layer 105 close to the base substrate 20 .

[0113] The display sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com