A copper foil surface treatment machine with self-adaptive tension

A surface treatment machine and tension force technology, applied in the field of copper foil processing, can solve the problems of black spots on the surface of copper foil, cumbersome hoisting operations, and increased replacement time, so as to reduce the formation of acid mist and save the installation workload. , the effect of preventing black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

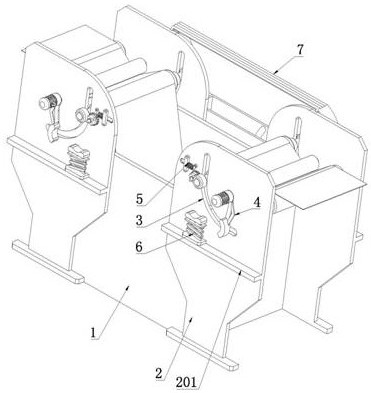

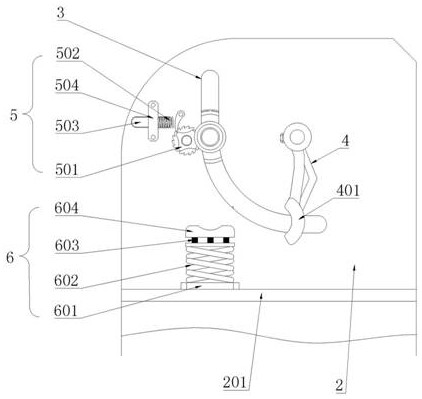

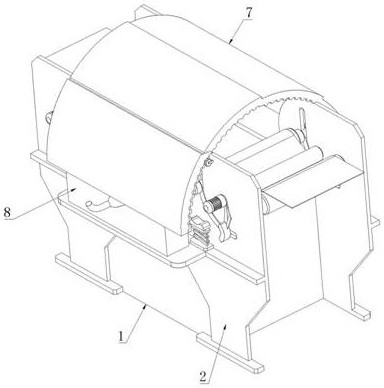

[0025] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] Depend on Figure 1-8 Provided, a copper foil surface treatment machine with self-adaptive tension, including a pickling tank 1 and a tension roller 9, is characterized in that, the two inner walls of the pickling tank 1 are sealed and rotated with clamping shaft seats 101, the clamping shaft seat 101 is clamped with a submerged roller 102, the length of the submerged roller 102 is set to be shorter than the inner wall distance of the pickling tank, and the contact part between the clamping shaft seat 101 and the submerged roller 102 is made of elastic material or elastic The structure is such that the submerged roller 102 contacts the clamping shaft seat 101 and is embedded in the clamping shaft seat 101 by an external force, and when rising, the submerged roller 102 is separated from the clamping shaft seat 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com