Installation method for water cannon platform on chimney block in ultra-large container ship

A technology of container ships and installation methods, which is applied to ships and other directions, can solve the problems of wasting gantry crane resources, low installation efficiency, and affecting shipbuilding progress, etc., and achieve the effects of shortening the dock cycle, avoiding high-altitude operations, and improving double integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

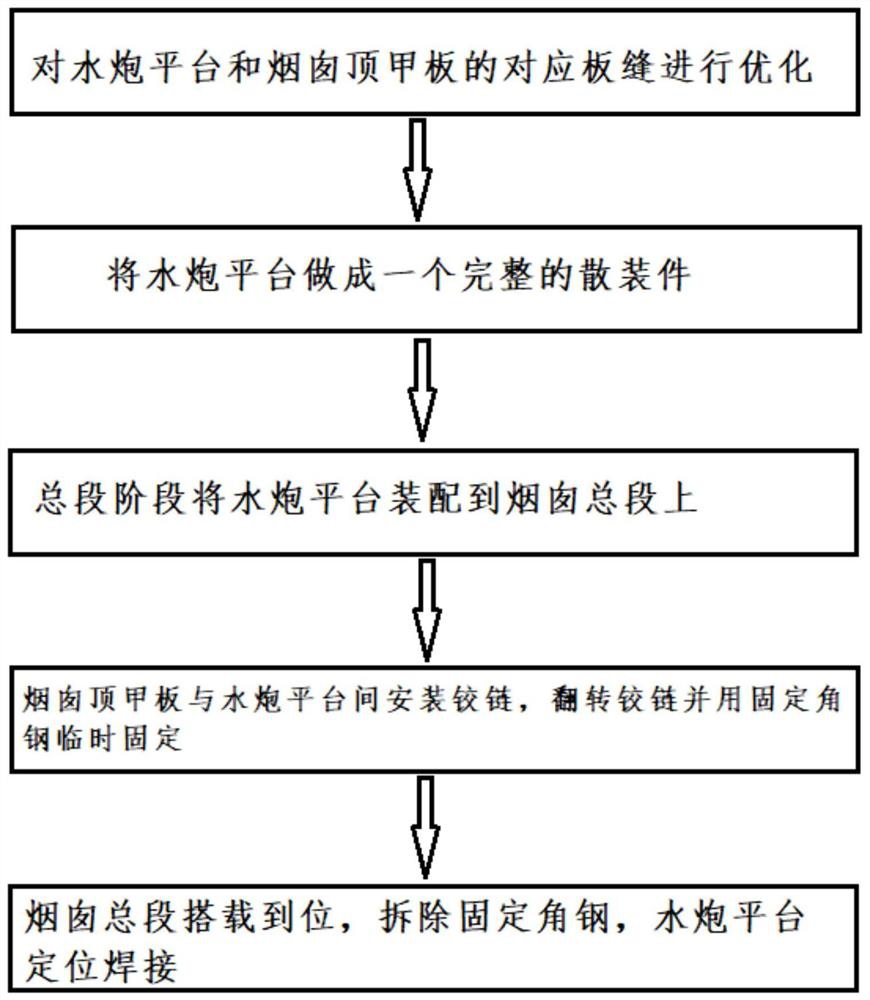

[0025] Below in conjunction with accompanying drawing, the installation method of a kind of ship chimney general section water cannon platform of the present invention is described further, in order to understand the application process of the present invention method more clearly, but can not limit protection scope of the present invention with this.

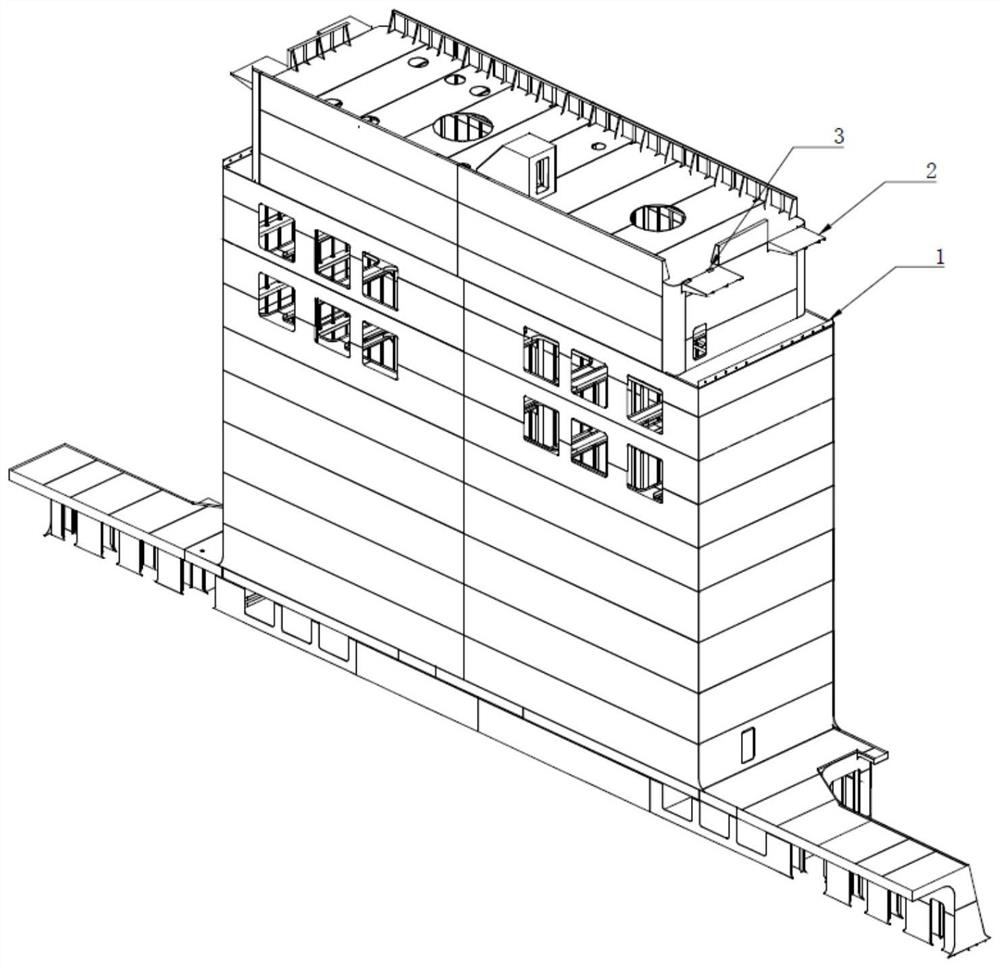

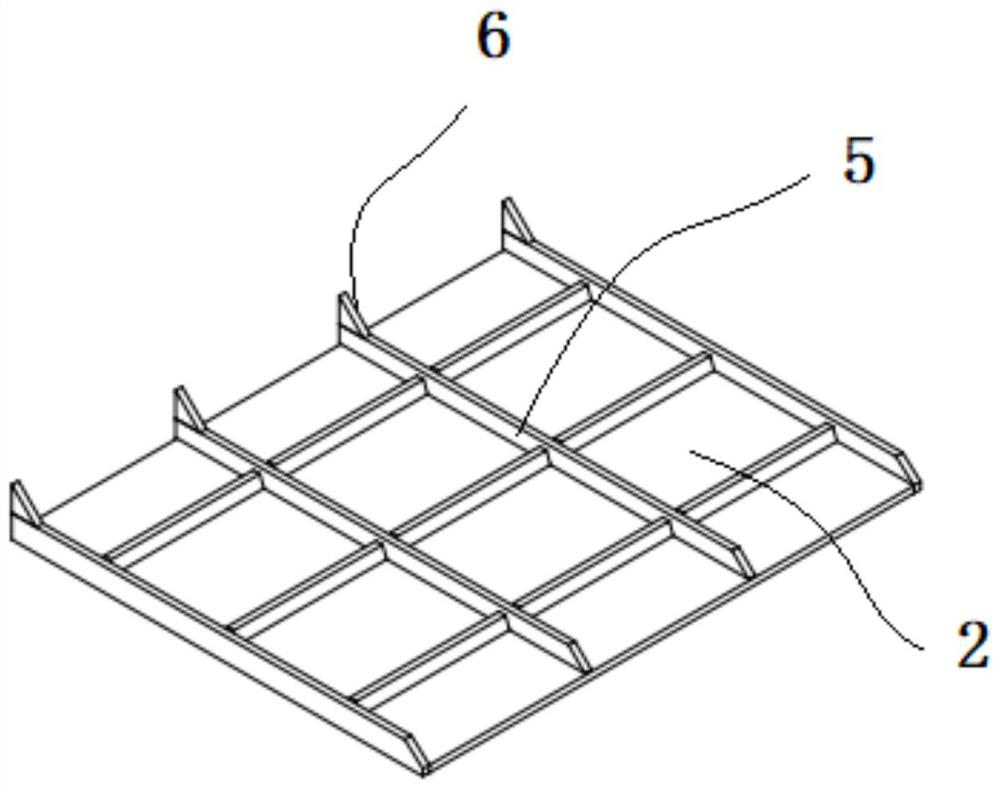

[0026] like figure 1 As shown, the height of the chimney general section is 30 meters, and the height of the chimney general section 1 is 80 meters from the bottom of the dock after hoisting to the ultra-large container ship, and the four water cannon platforms 2 are respectively fixed on the chimney general At the protruding position of the end walls on both sides of the top deck of the chimney at the top of the section 1, the four water cannon platforms 2 protrude to the outside of both sides after being fixed and installed on the general section 1 of the chimney. Since the highest point of the chimney section 1 is as high as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com