Packaging cover plate and preparation method thereof, display panel and display device

A technology for encapsulating cover plates and cover plates, which is applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., to improve the display effect and service life, avoid black spots, and avoid erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

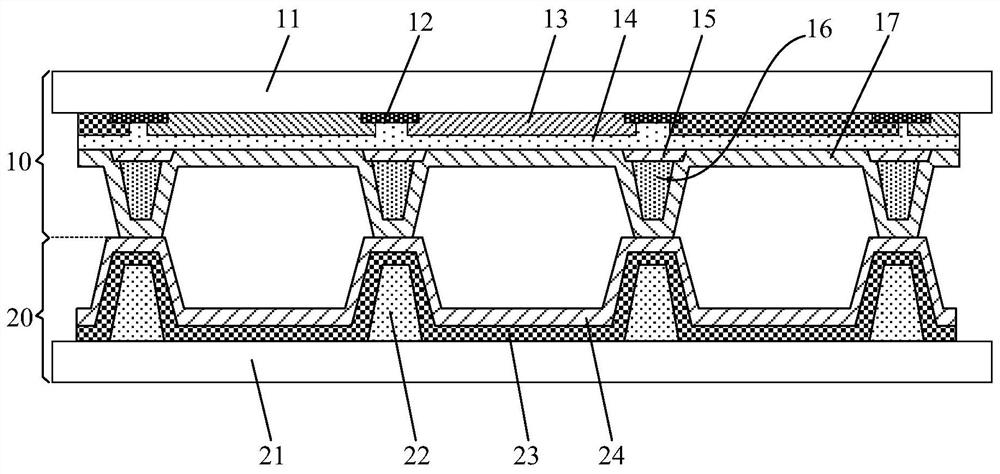

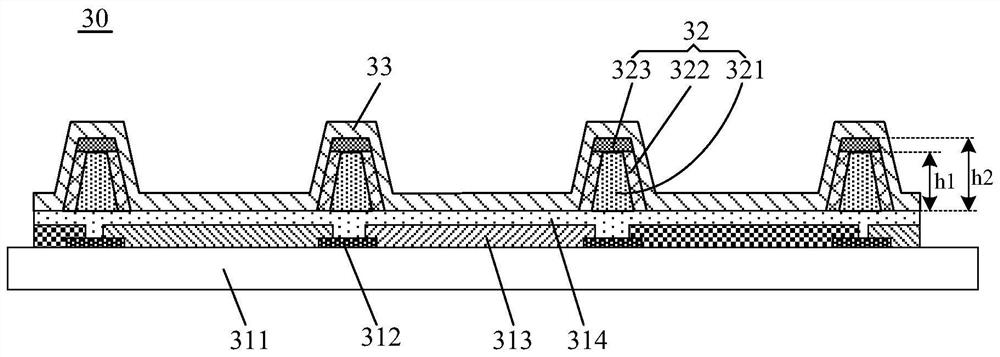

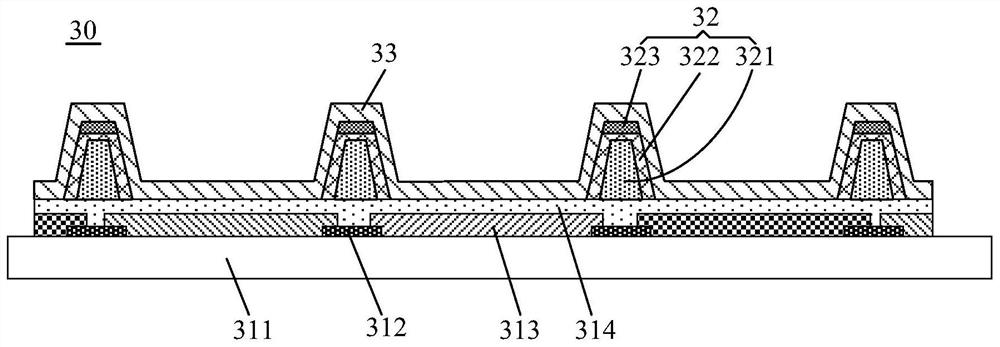

Examples

preparation example Construction

[0092] Figure 4 It is a schematic flow chart of a method for manufacturing a package cover in an embodiment of the present disclosure. Such as Figure 4 As shown, the preparation method of the package cover plate may include:

[0093] S41, forming a cover plate structure layer;

[0094] S42. Form a spacer column structure on one side of the cover plate structure layer, the spacer column structure includes a first spacer column located on one side of the cover plate structure layer, and the first spacer column includes a water absorption structure;

[0095] S43, forming an auxiliary electrode layer on the side of the spacer structure away from the cover plate structure layer,

[0096] Wherein, the spacer column structure is configured to block water vapor from diffusing along the spacer column structure toward the auxiliary electrode layer.

[0097] In one embodiment, forming the spacer column structure on one side of the cover plate structure layer may include: forming a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com