Extruder

A technology for extruders and processing units, applied in the field of extruders, can solve problems such as interference, and achieve the effects of simplified loading and light cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

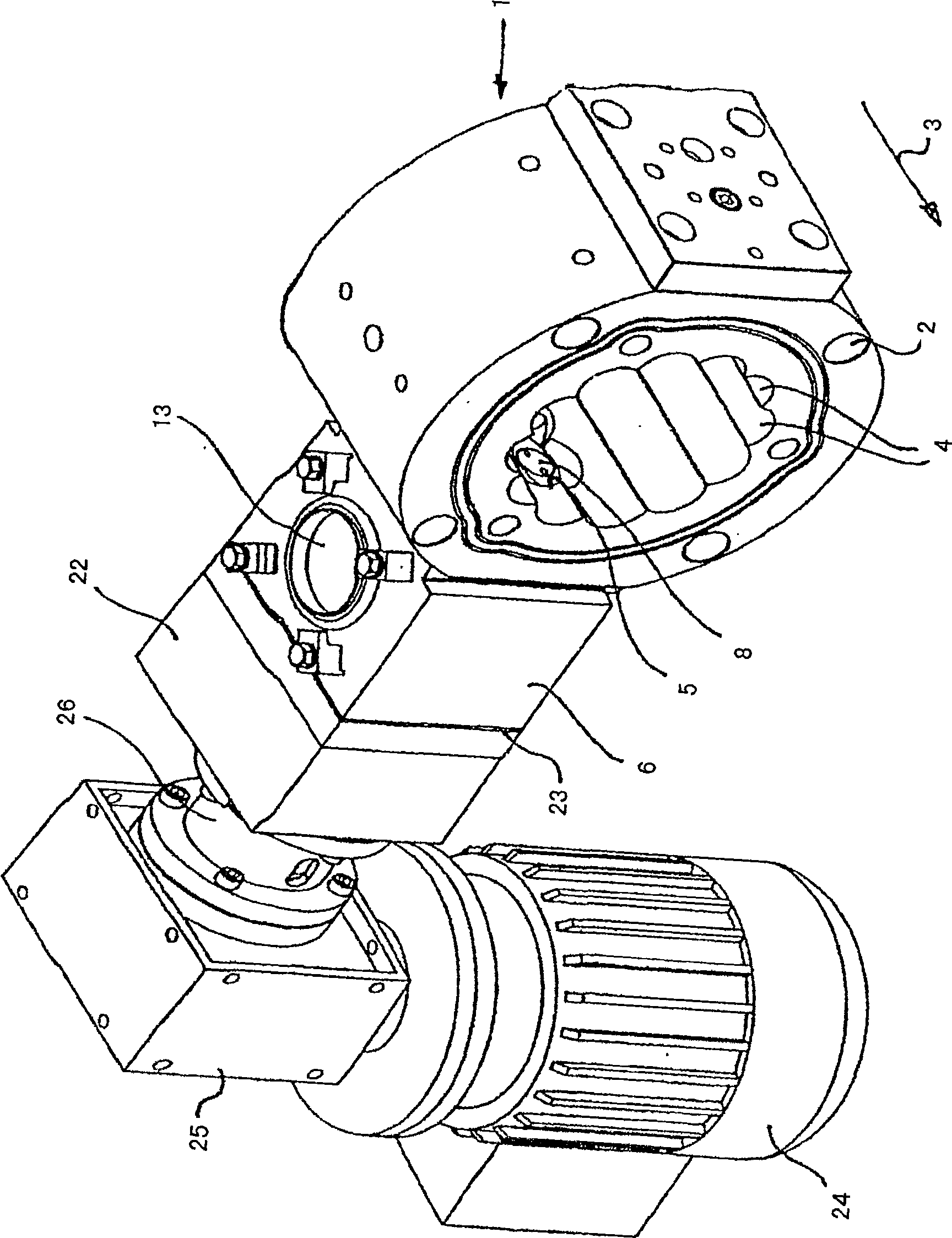

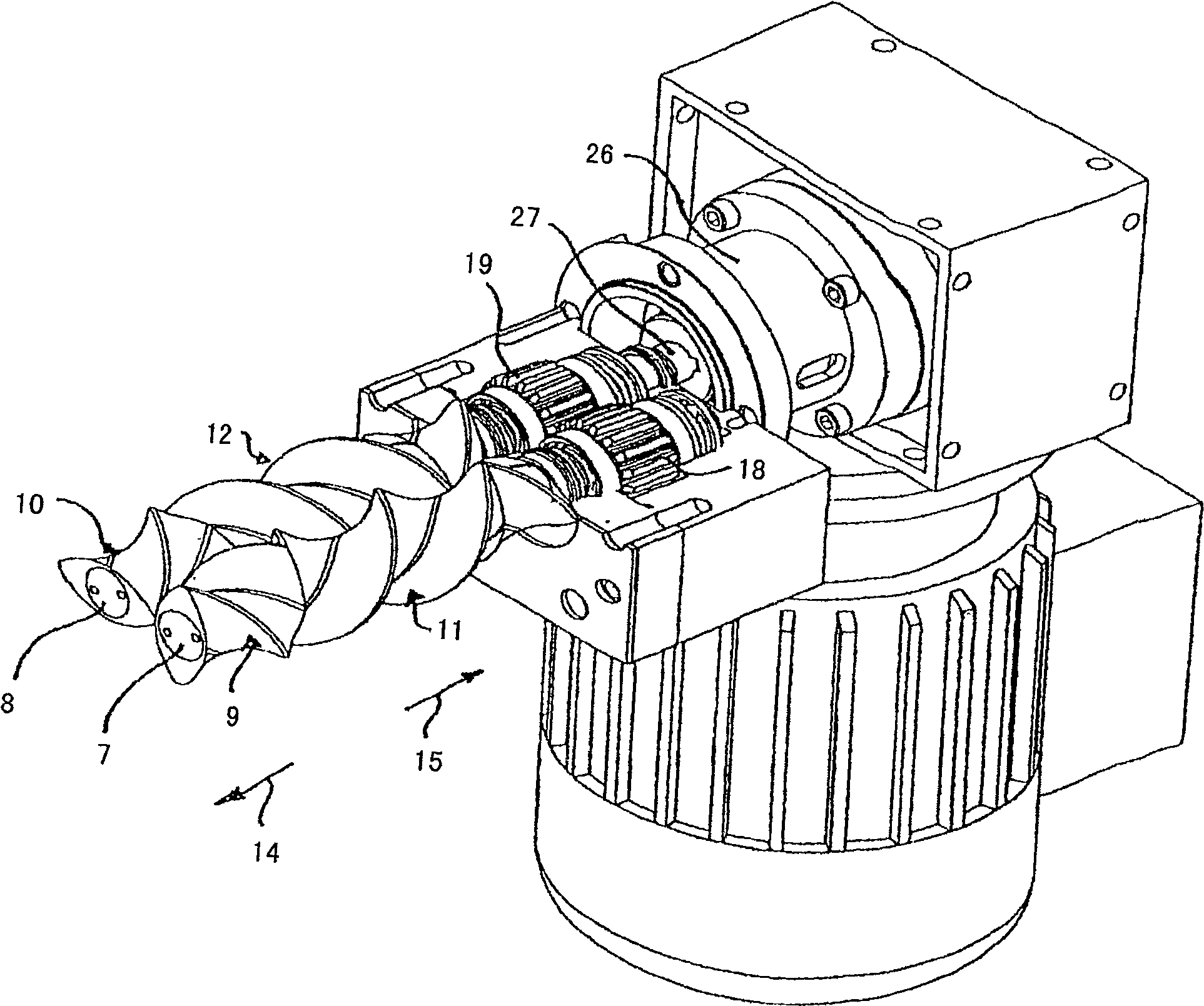

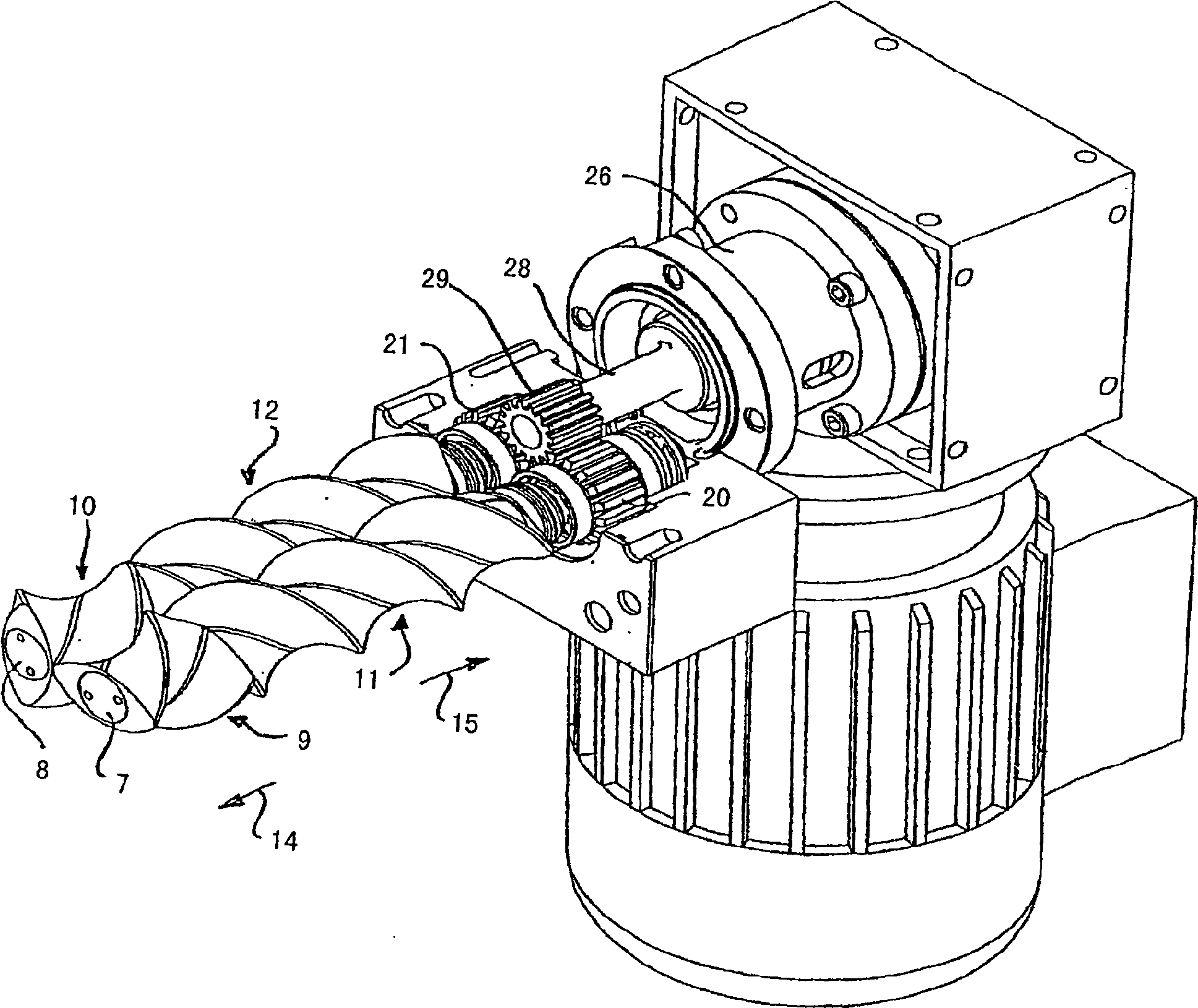

[0024] according to figure 1 Only one housing section 1 of the processing section of the extruder is shown. The treatment part consists of a plurality of such housing sections connected in series, which can be pulled together by tension rods, not shown, which pass through holes 2 in the housing section 1 .

[0025] The transport direction of the treatment section is indicated by arrow 3 . A housing section (not shown) with a material inlet opening is arranged upstream of the delivery of section 1 and a housing section (not shown) with a material outlet opening of the extruder is arranged downstream of the delivery.

[0026] The processing section is configured as an annular extruder, for example as described in EP 0 788 867 B1. That is to say that an inner core, not shown, extends axially through the housing section 1 of the treatment part and the remaining housing sections, not shown. An annular space is formed between the inner core and the housing section, in which space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com