Preparation method of wide pure titanium foil coiled tape

A pure titanium and foil technology, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problem of destroying the integrity of the oxide layer of pure titanium foil coils, unable to strictly control the distribution of rolling pressure, reducing coiling and striping. problems such as production efficiency and yield, to achieve the effect of low impurity element content, inhibition of corrosion, and fewer internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

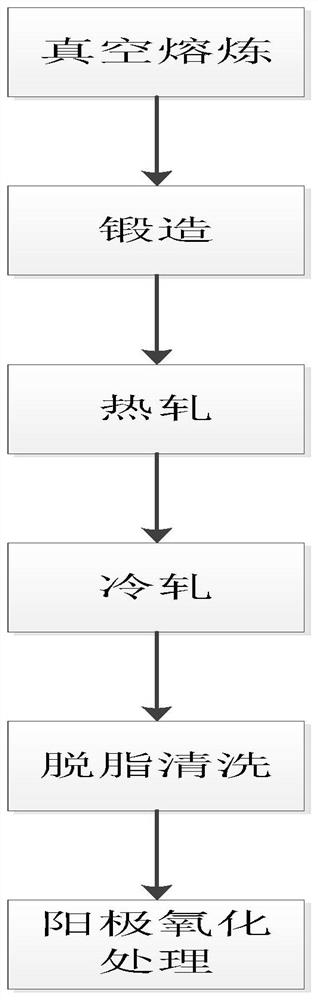

[0033] Such as figure 1 Shown, a kind of wide-width pure titanium foil strip preparation method comprises the following steps:

[0034] S1. Vacuum melting

[0035] 0A grade sponge titanium is used for batching production. After being fully stirred by the Consac mixing system, the density is 3.5g / cm3 prepared by an 8000-ton hydraulic press. 3 The electrode block is then smelted in a 10-ton vacuum consumable furnace twice to prepare a density of 4.51g / cm 3Finished pure titanium casting, the finished pure titanium ingot prepared by the above pressing and smelting has high specific strength and good corrosion resistance, which meets the requirements of use; the chemical composition of the finished titanium ingot is O≤0.05wt.%, Fe≤0.03 wt.%, N≤0.007wt.%, H≤0.005wt.%, C≤0.012wt.%, Al≤0.015wt.%, the prepared finished titanium ingot has low content of impurity elements, high purity, no pores, no Inclusions significantly improve the quality of finished pure titanium ingots and meet ...

Embodiment 2

[0047] Such as figure 1 Shown, a kind of wide-width pure titanium foil strip preparation method comprises the following steps:

[0048] S1. Vacuum melting

[0049] 0A grade sponge titanium is used for batching production. After being fully stirred by the Consac mixing system, the density is 3.5g / cm3 prepared by an 8000-ton hydraulic press. 3 The electrode block is then smelted in a 10-ton vacuum consumable furnace twice to prepare a density of 4.51g / cm 3 Finished pure titanium casting, the finished pure titanium ingot prepared by the above pressing and smelting has high specific strength and good corrosion resistance, which meets the requirements of use; the chemical composition of the finished titanium ingot is O≤0.05wt.%, Fe≤0.03 wt.%, N≤0.007wt.%, H≤0.005wt.%, C≤0.012wt.%, Al≤0.015wt.%, the prepared finished titanium ingot has low content of impurity elements, high purity, no pores, no Inclusions significantly improve the quality of finished pure titanium ingots and meet...

Embodiment 3

[0061] Such as figure 1 Shown, a kind of wide-width pure titanium foil strip preparation method comprises the following steps:

[0062] S1. Vacuum melting

[0063] 0A grade sponge titanium is used for batching production. After being fully stirred by the Consac mixing system, the density is 3.5g / cm3 prepared by an 8000-ton hydraulic press. 3 The electrode block is then smelted in a 10-ton vacuum consumable furnace twice to prepare a density of 4.51g / cm 3 Finished pure titanium casting, the finished pure titanium ingot prepared by the above pressing and smelting has high specific strength and good corrosion resistance, which meets the requirements of use; the chemical composition of the finished titanium ingot is O≤0.05wt.%, Fe≤0.03 wt.%, N≤0.007wt.%, H≤0.005wt.%, C≤0.012wt.%, Al≤0.015wt.%, the prepared finished titanium ingot has low content of impurity elements, high purity, no pores, no Inclusions significantly improve the quality of finished pure titanium ingots and meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com