Manufacturing method of anti-infrared high-energy heat-insulation goggle lens

A manufacturing method, infrared technology, applied to other household appliances, optical components, household appliances, etc., can solve problems affecting product quality, troublesome production, unevenness, etc., to avoid black spots and impurity spots, simple manufacturing method, and production The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 20

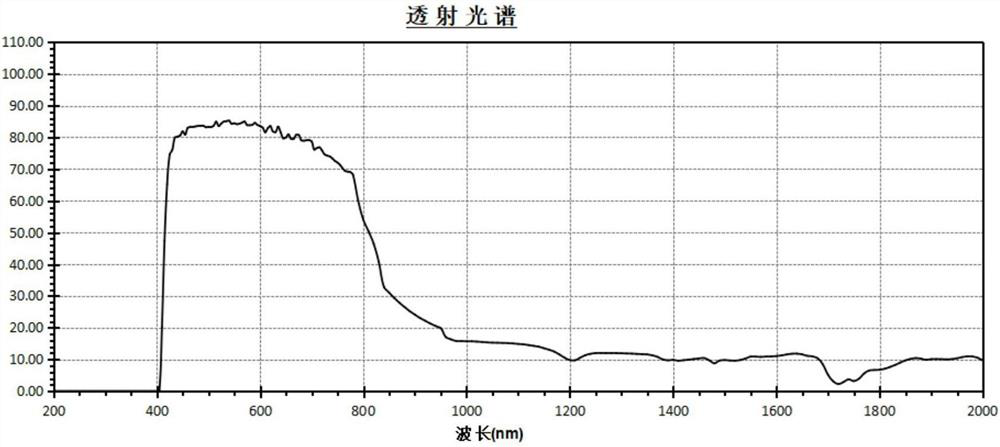

[0071] Example 20 is to use the masterbatch of Example 10 in Table 1 and the PC material to mix and stir at a ratio of 1:4, and inject molding. As shown in Table 6 and Figure 4 , the results show that the infrared transmittance (780nm-2000nm) is 6.38%, the visible light transmittance is 76.96%, the haze is 2%, the surface quality is good, there are no black spots and impurities, and it has passed the American standard, European standard and Australian standard. Compared with the best example 18, the anti-infrared effect of example 20 is better, but the haze value is relatively higher, and the visible light transmittance is also lower.

[0072] Table six

[0073]

[0074]

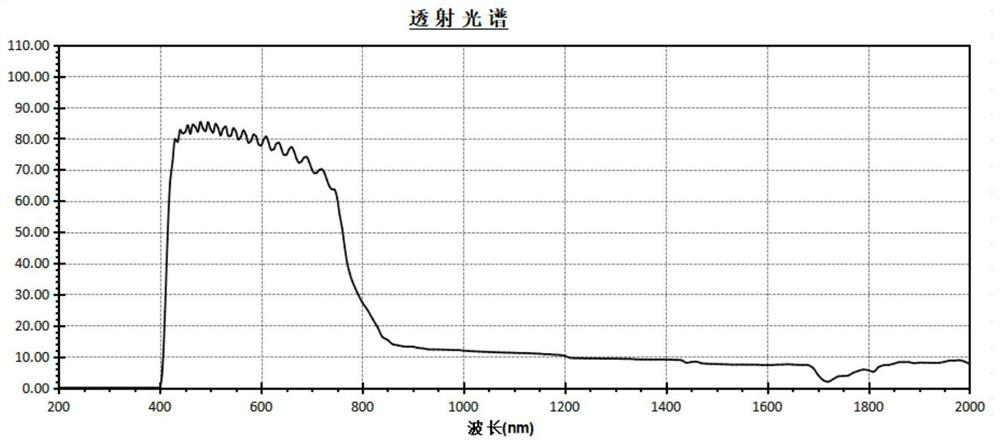

[0075] For comparative examples 7-9, the masterbatch and PC material of comparative examples 1-3 in Table 1 were mixed and stirred at a ratio of 1:4, and then injection molded. The best data in comparative example 7-9 is comparative example 8, detects as table seven and Figure 5 , the results show...

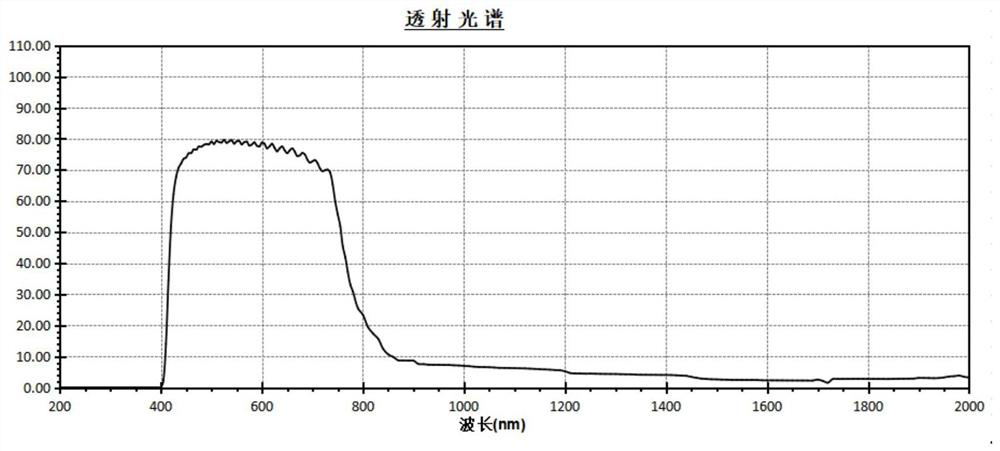

Embodiment 18

[0089] Example 18 After the lens is irradiated by infrared rays, the temperature difference between the environment below the lens and the lens above is the smallest, and the heat insulation effect is the best.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| barrier rate | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com