A non-contact swing granulation device for materials and bearings

A non-contact, oscillating granulation technology, applied in the direction of raw material extrusion granulation, etc., can solve the problems of affecting quality, increasing internal friction of bearing devices, reducing lubricant lubrication effect, etc., to ensure reliability and safety, Improve work efficiency and avoid black spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

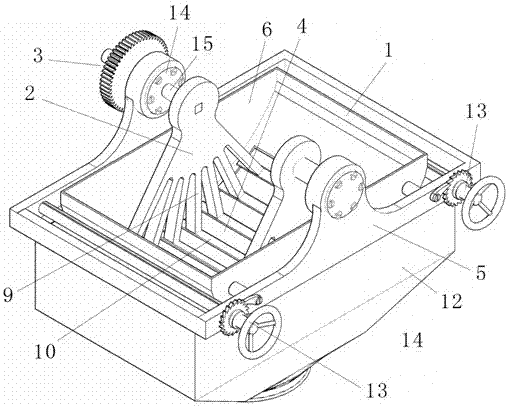

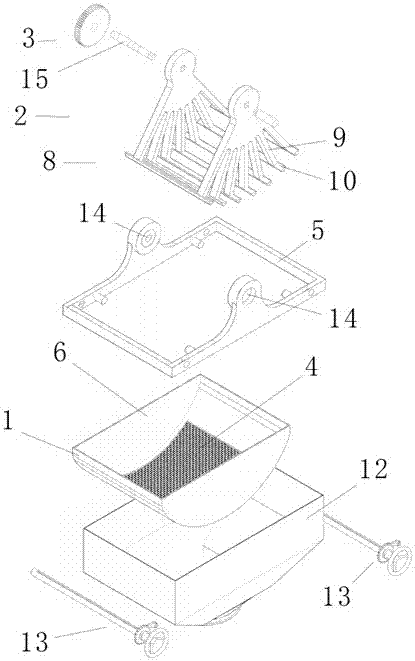

[0046] Embodiment 1, as attached figure 1 , 2 and 3,

[0047] A non-contact swing granulation device for materials and bearings, comprising:

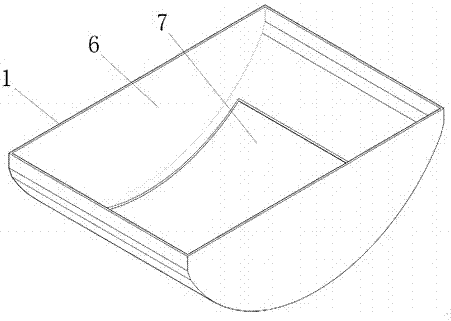

[0048] Material hopper 1: used to hold materials, the material hopper 1 has a material inlet 6 and a material outlet 7, and the material outlet 7 is provided with a sieve plate 4;

[0049] Extrusion assembly 2: cooperate with the sieve plate 4;

[0050] Driving part 3: arranged outside the material hopper 1, used to drive the extruding assembly 2,

[0051] The extruding assembly 2 extends out of the material hopper 1 to cooperate with the driving part 3. On the material hopper 1, the position where the extruding assembly 2 protrudes is in line with the position where the material is contained in the material hopper 1. The locations are separated.

[0052] In the above scheme of this embodiment, since on the material hopper 1, the position where the extruding assembly 2 protrudes is separated from the position where the material is ...

Embodiment 2

[0053] Embodiment 2, as attached figure 1 , 2 and 3 as shown:

[0054] As in the granulation device described in Example 1, the extrusion assembly 2 protrudes from the material hopper 1 through the feed inlet 6, and the sieve plate 4 is detachably arranged on the material hopper 1, so The sieve plate 4 is arc-shaped, and when the driving part 3 drives the extruding assembly 2, the movement track of the part of the extruding assembly 2 that cooperates with the sieve plate 4 matches the arc of the sieve plate 4 , the sieve plate 4 is arc-shaped.

[0055] In the above scheme of this embodiment, the extruding assembly 2 protrudes from the material hopper 1 through the feed port 6, that is, in the scheme of this embodiment, there is no need to re-set the extruding assembly 2 on the material hopper 1. The notch, first of all, simplifies the structure of this embodiment, at the same time, it also ensures the integrity of the material hopper 1, makes it have fewer gaps, and ensures...

Embodiment 3

[0059] Embodiment 3, as attached figure 1 , 2 , 3 and 4 show:

[0060] As in the granulation device described in Embodiment 1 or 2, the extruding assembly 2 includes an extruding part 8 cooperating with the sieve plate 4 and a swing arm 9 for connecting the extruding part 8 and the driving part 3, so The driving part 3 drives the swing arm 9 to make the extruding part 8 reciprocally swing along the sieve plate 4. The extruding part 8 includes a plurality of spaced apart pressing blocks 10, and each pressing block 10 is respectively connected to the sieve plate 4. The sieve plate 4 is matched, and the side of the pressing block 10 facing and / or facing away from the material is an inclined surface 11, so that the pressing block 10 can exert pressure on the facing material toward the sieve plate 4 during the swing process. The granulation device of the example also includes a hopper 12, the material hopper 1 is set in the hopper 12, the hopper 12 is provided with a gap correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com