Double-cone rotation vacuum drier internally provided with water spray pipes and scrapers

A vacuum dryer and drying machine technology, applied in the field of machinery, can solve the problems of hidden safety hazards, troublesome cleaning of drying equipment, troublesome operation, etc., and achieve the effects of eliminating hidden dangers, shortening drying time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

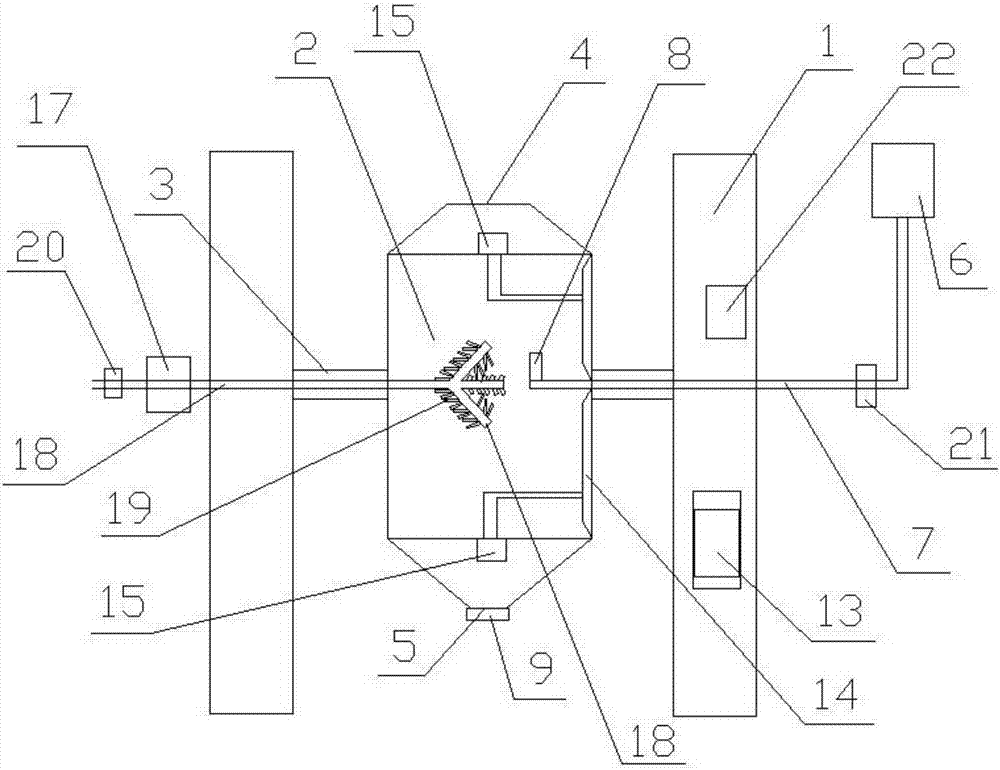

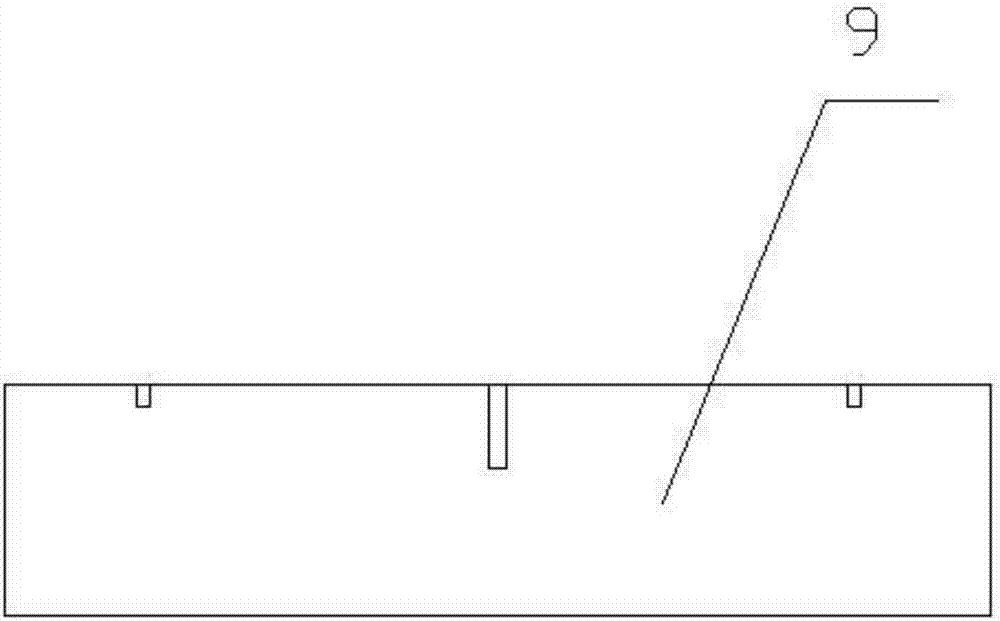

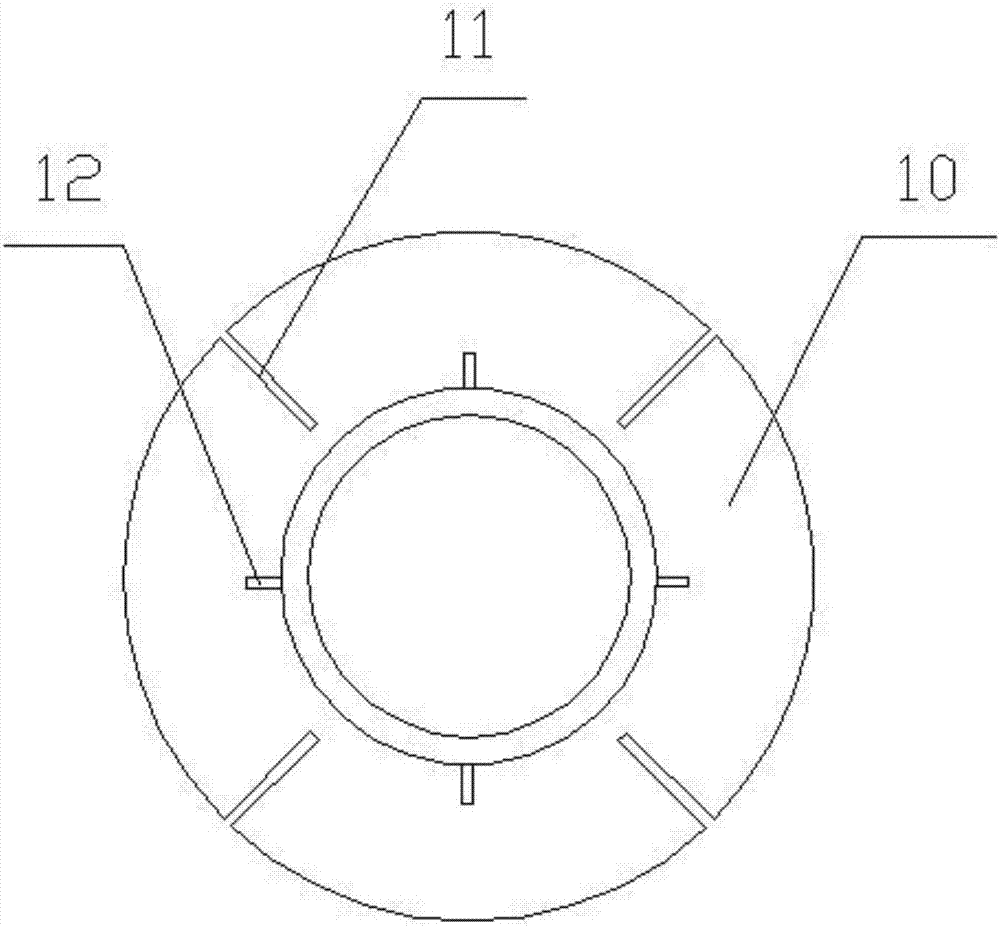

[0018] like Figure 1-3 As shown, a double-cone rotary vacuum dryer with a built-in water spray pipe and a scraper includes a support frame 1, one end is provided with a feed port 4, the other end is provided with a discharge port 5, and the middle is a double-cone hollow cylinder. The main body 2 of the dryer is set on the support frame 1, fixedly connected with the main body 2 of the biconical dryer, used to support the main body 2 of the biconical dryer, and is a rotating shaft 3 driven by the main body 2 of the biconical dryer , the vacuum pump 6 located on one side of the biconical drier main body 2, one end is connected to the vacuum pump 6, and the other end extends into the vacuum filter tube 7 in the biconical drier main body 2 through the rotating shaft 3, and is arranged on the vacuum filter tube 7 The filter head 8 extending into one end of the double-cone dryer main body 2 is arranged on the discharge device 9 connected to the discharge port 5, arranged on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com