Biconical rotary vacuum drying main machine

A vacuum drying and host technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve problems affecting product quality and drying efficiency, uneven moisture and fineness of finished products, and unsuitable lithium iron phosphate materials. Drying and other problems, to achieve the effect of convenient replacement, uniform fineness, and improved energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

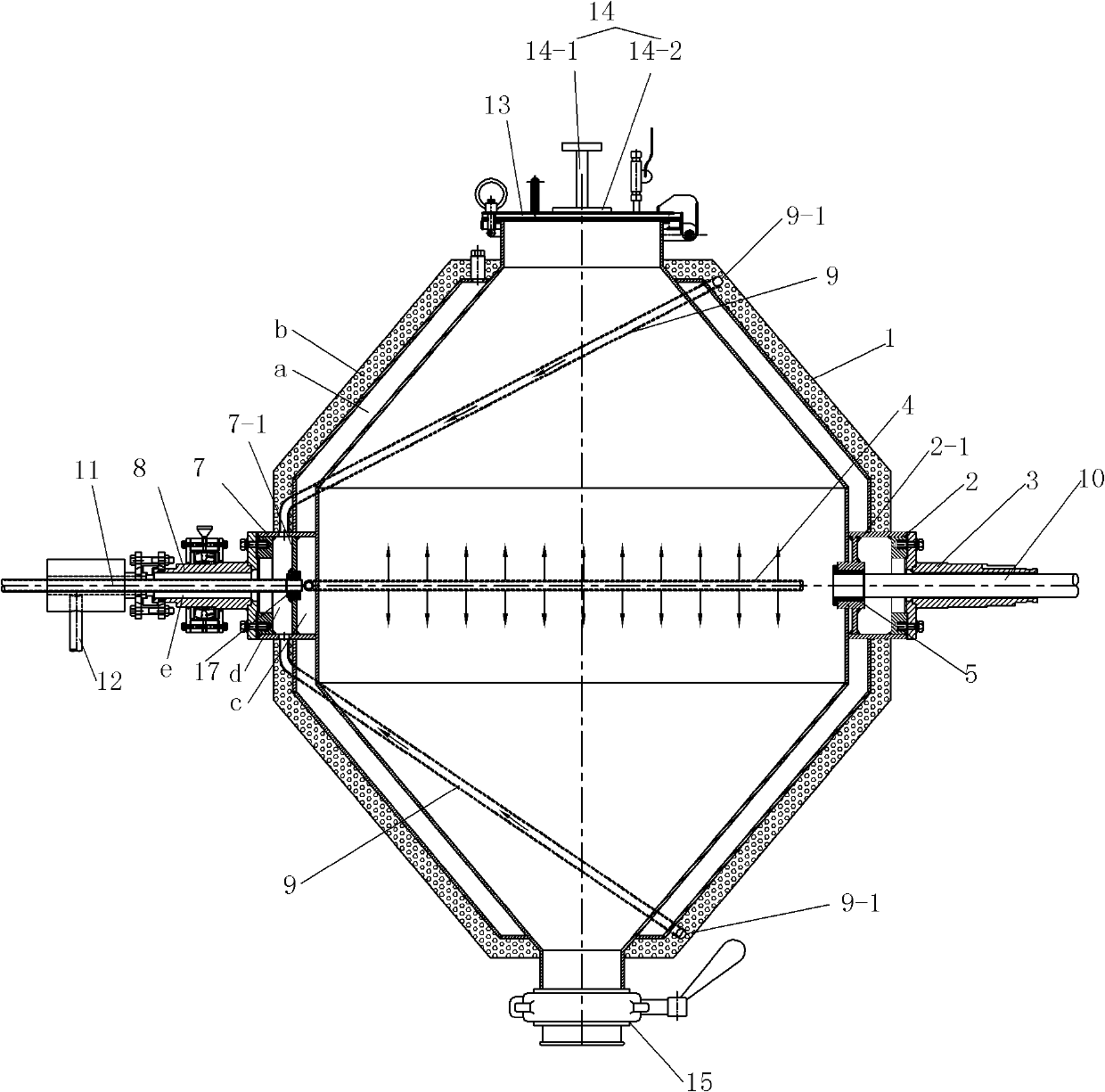

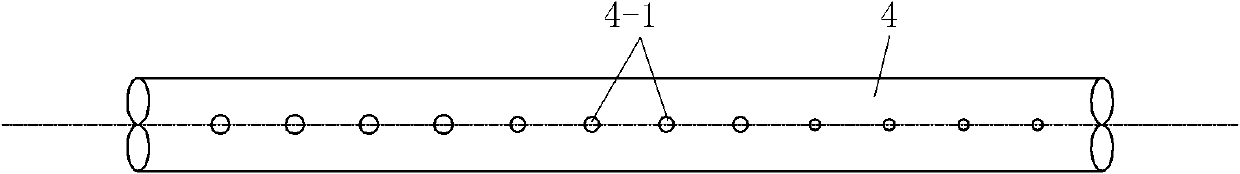

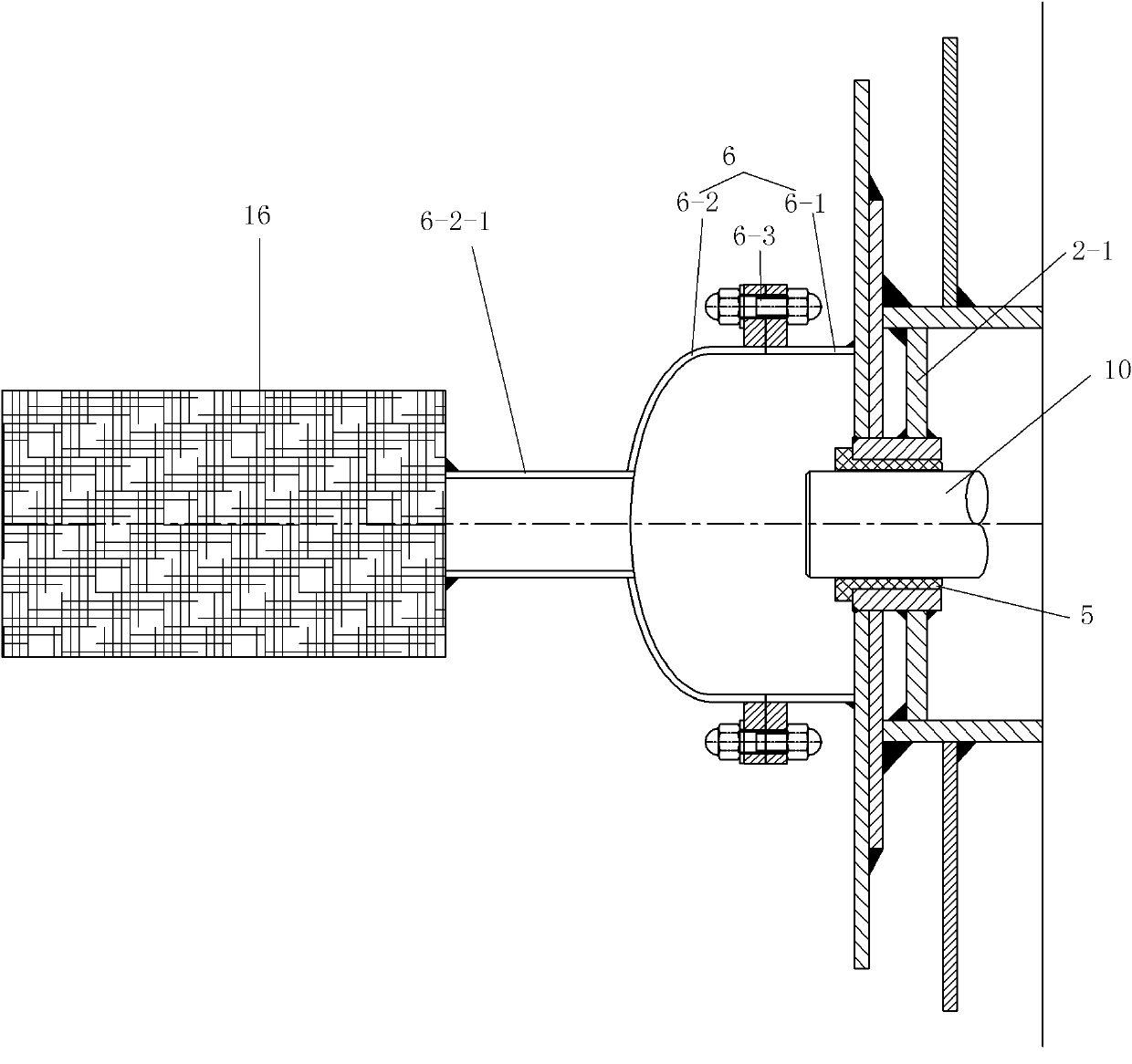

[0016] See Figure 1 to Figure 4 , this embodiment includes a jacketed cylinder body 1, the cylinder body 1 is provided with a feed pipe, a discharge pipe, a driving shaft seat mounting hole and a driven shaft seat mounting hole, and the feed pipe is provided with a feed cover 13, A discharge device 15 is provided on the discharge pipe. The driving shaft seat mounting hole and the driven shaft seat mounting hole are respectively fixed with the driving shaft seat 2 and the driven shaft seat 7 . The main shaft is composed of a hollow driving half shaft 3 and a hollow driven half shaft 8, and the driving half shaft 3 and the driven half shaft 8 are respectively fixed in the driving shaft seat 2 and the driven shaft seat 7. The driving shaft seat 2 is provided with a support plate 2-1, and a tube hole is provided on the support plate 2-1, and the vacuum tube 10 extends into the cylinder body through the inner cavity of the driving half shaft 3 and the tube hole on the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com