Patents

Literature

79results about How to "Suitable for drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

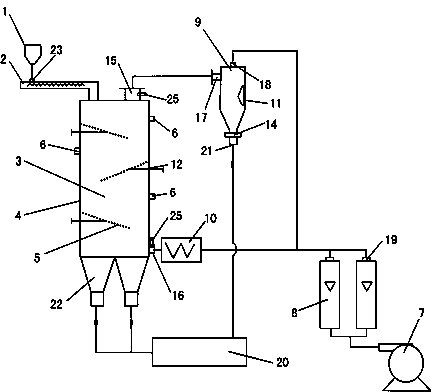

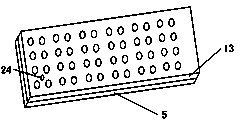

Microwave multistage fluidized bed drying device and drying method thereof

ActiveCN104006631ANovel and reliable structureSimple equipmentDrying solid materials with heatDrying gas arrangementsProcess engineeringProduct gas

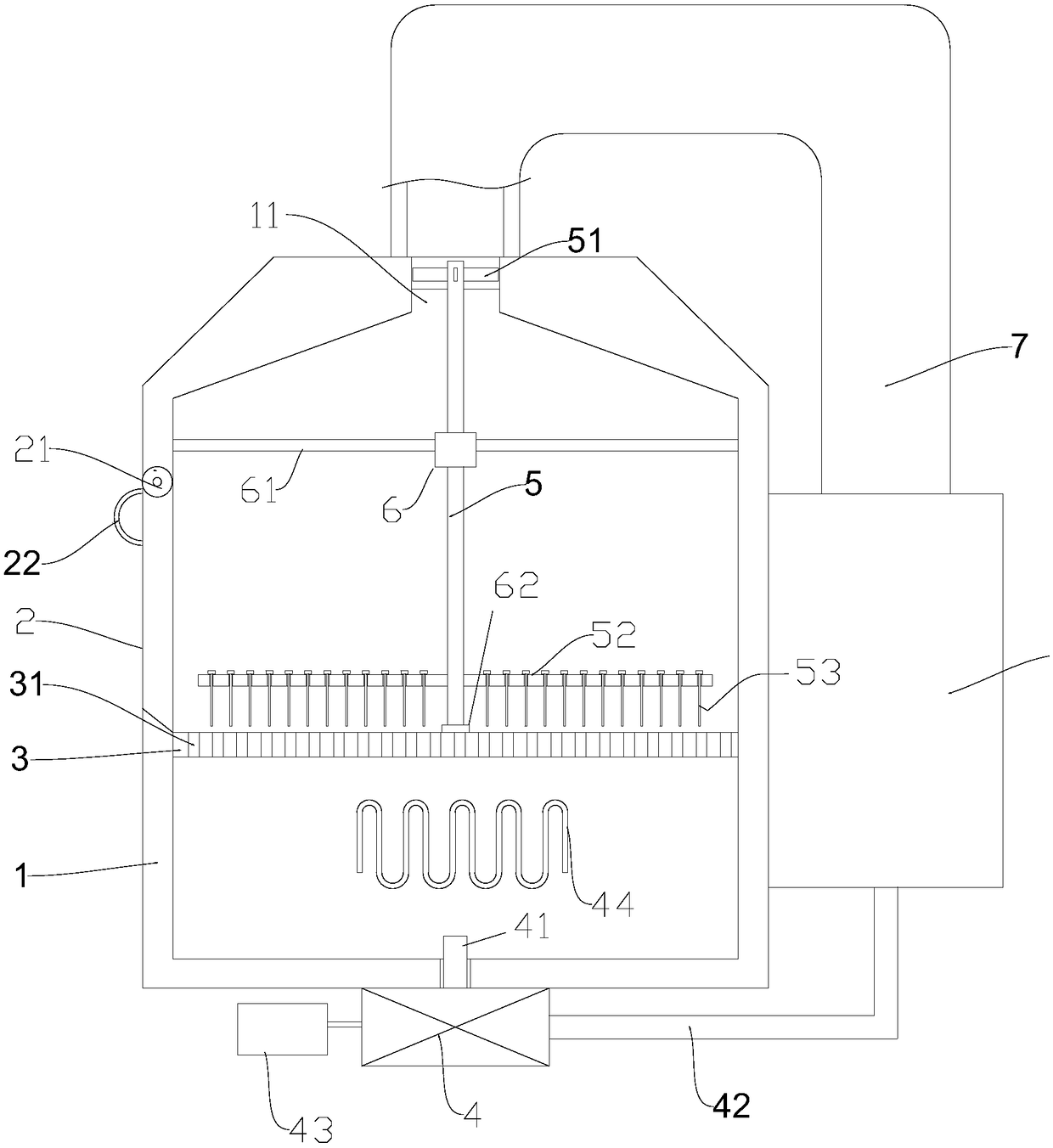

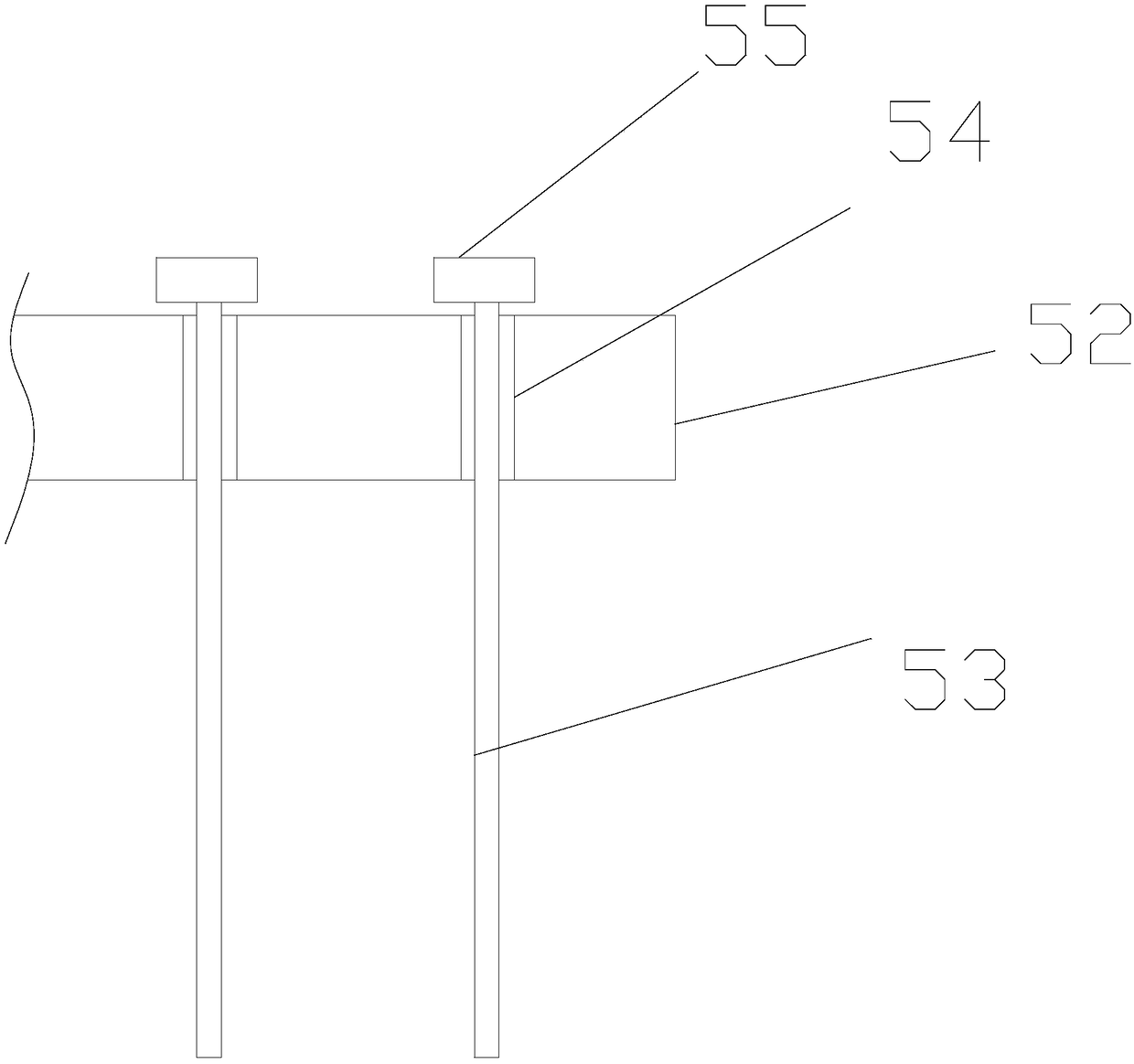

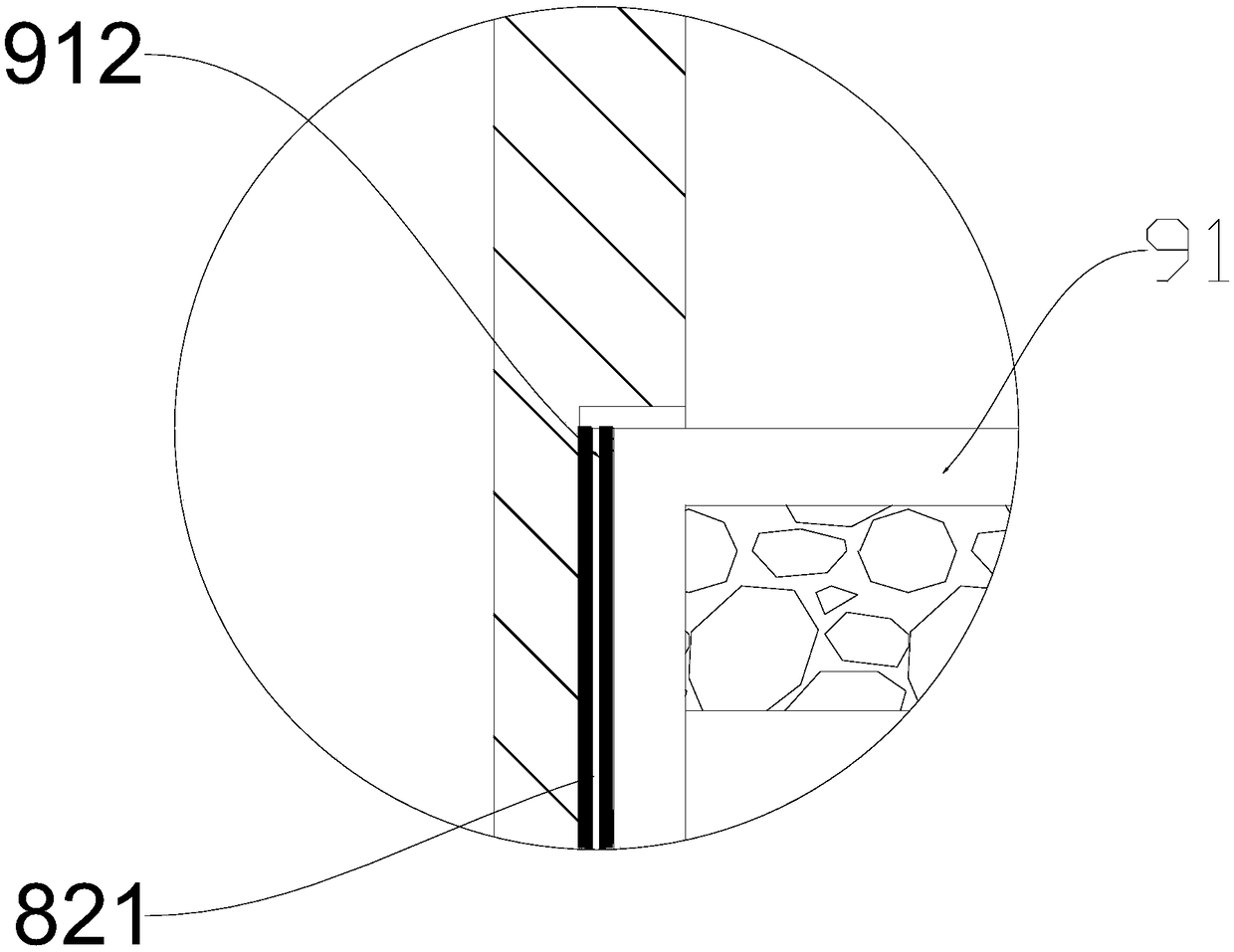

The invention relates to a microwave multistage fluidized bed drying device and a drying method of the microwave multistage fluidized bed drying device. A fluidized bed dryer comprises a fluidized bed body and gas distribution plates, a microwave generator is arranged on the outer wall of the fluidized bed body, three layers of the gas distribution plates with adjustable angles are arranged in the fluidized bed body from top to bottom, the microwave generator is started, microwaves are used as a heat source, the inclination angle and the microwave power of the gas distribution plates are adjusted according to the surface temperature of detection materials, the aperture ratio of the gas distribution plates ranges from three percent to five percent, the adjustment air speed ranges from 1 m / s to 2 m / s, the raw material standing time is controlled to be within one min to five min, the water content in raw materials is smaller than 15 percent, and the dried materials enter a product drying tank from a discharge port. The microwave multistage fluidized bed drying device and the drying method of the microwave multistage fluidized bed drying device have the advantages that the standing time of the materials in a fluidized bed drying reactor is controlled by adjusting the inclination angles of the multistage distribution plates, and the materials with different water contents can be dried; maximum utilization of microwave energy is achieved by changing the microwave drying power at feed ports of the multistage distribution plates.

Owner:JINING UNIV

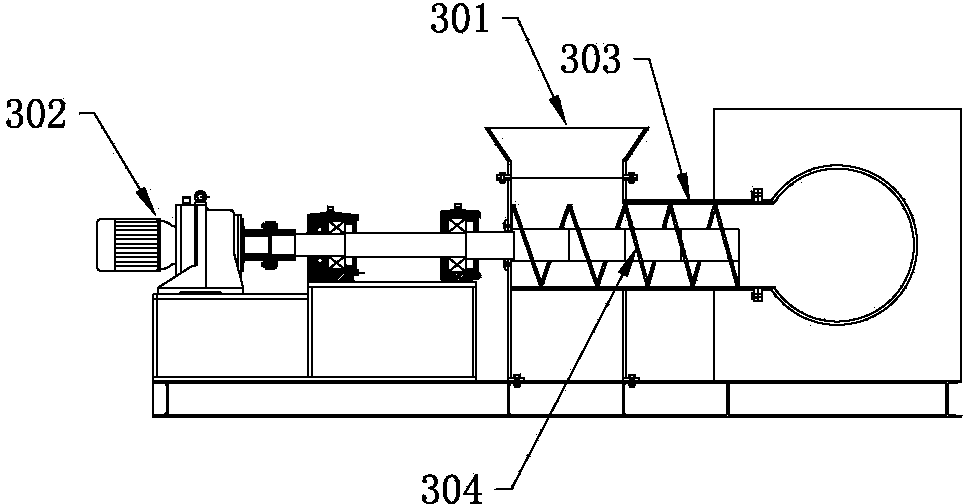

Garbage thermal cracking treatment technology

ActiveCN103464448AAchieve decompositionTo achieve the purpose of sterilizationSolid waste disposalThermodynamicsCombustible gas

The invention discloses a garbage thermal cracking treatment technology which comprises the following steps: (1) coarse crushing; (2) magnetic separation; (3) sieving; (4) fine crushing; (5) drying; (6) thermal pretreatment; (7) high temperature cracking. The garbage thermal cracking treatment technology disclosed by the invention is reasonable in design of working procedures and simple in structure, and can be used for effectively treating city household garbage and solving the problem of environmental pollution caused by the city household garbage; products, such as coke coal, tar and combustible gas, obtained from city household garbage treatment, can be collected and recycled; the garbage thermal cracking treatment technology creates new economic benefits, fully meets the requirements on reutilization, harmless treatment and reduction of garbage, and realizes zero release of garbage treatment and maximum benefit of reutilization of garbage treatment products.

Owner:GAOZHOU ZHONGLIANG MACHINERY MFG

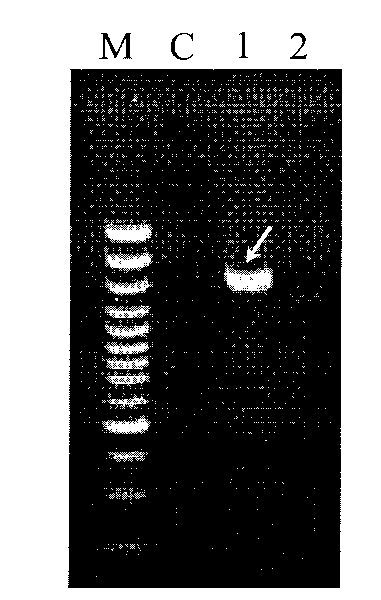

Molecular specificity mark primer for authenticating mushroom strains 241 and 241-4 and detecting method

InactiveCN101712984ADense tissueRound shapeMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceMushroom

The invention provides a molecular specificity mark primer for authenticating mushroom strains 241 and 241-4 and a detecting method for differentiating and authenticating the mushroom strains 241 and 241-4 by using same. The sequence of an upstream primer is 5'-GGTTCTGCTCCTTGTGACTG-3', and the sequence of a downstream primer is 5'-TCTGCTCTTCAGATGCAAGCT-3'. Compared with convectional morphology detection, antagonism tests and fruiting tests, the invention has the advantages of short detection time and high accuracy. The detection time in the method is only 1 to 2 days, but the time of the convectional antagonism tests is at least two weeks, and the time of the fruiting tests is at least three months.

Owner:ZHEJIANG FORESTRY ACAD

Method for preparing full-nutrient solid cane molasses

InactiveCN102321770AEasy to operateShorten drying timeSugar dryingSugar productsMoistureVacuum drying

The invention relates to a method for preparing full-nutrient solid cane molasses, namely the traditional liquid cane molasses is processed into full-nutrient solid cane molasses. The method comprises the following steps: putting liquid cane molasses without any pretreatment directly in a vacuum drying machine; removing moisture under the heating and vacuum condition; and smashing after cooling, thus powder full-nutrient solid cane molasses is obtained, wherein the drying temperature is controlled at 50-130 DEG C, and the vacuum degree is controlled within minus 0.05-minus 0.10 MPa. By adopting the method provided by the invention, the liquid cane molasses with 20-30% of water content can be converted into the full-nutrient solid cane molasses with 0.5-2.5% of water content, and the original nutrition components of the cane molasses can be preserved without influencing the using efficacy of the original cane molasses; the storage and transportation costs can be lowered; the cane molasses is convenient to use; the quality guarantee period of products is prolonged, and the application range of the products can be widened; and the method has less operation steps, has low production cost, and is easy to be industrialized.

Owner:广西轻工业科学技术研究院有限公司

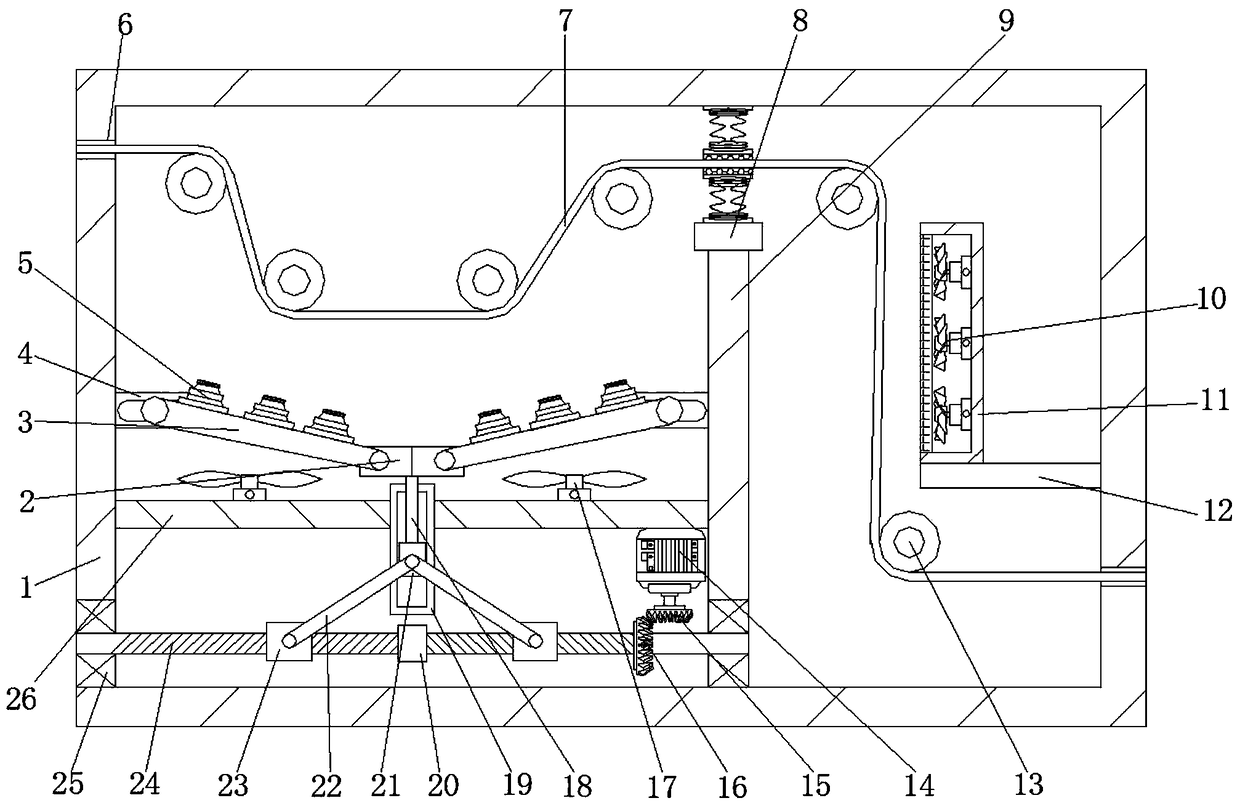

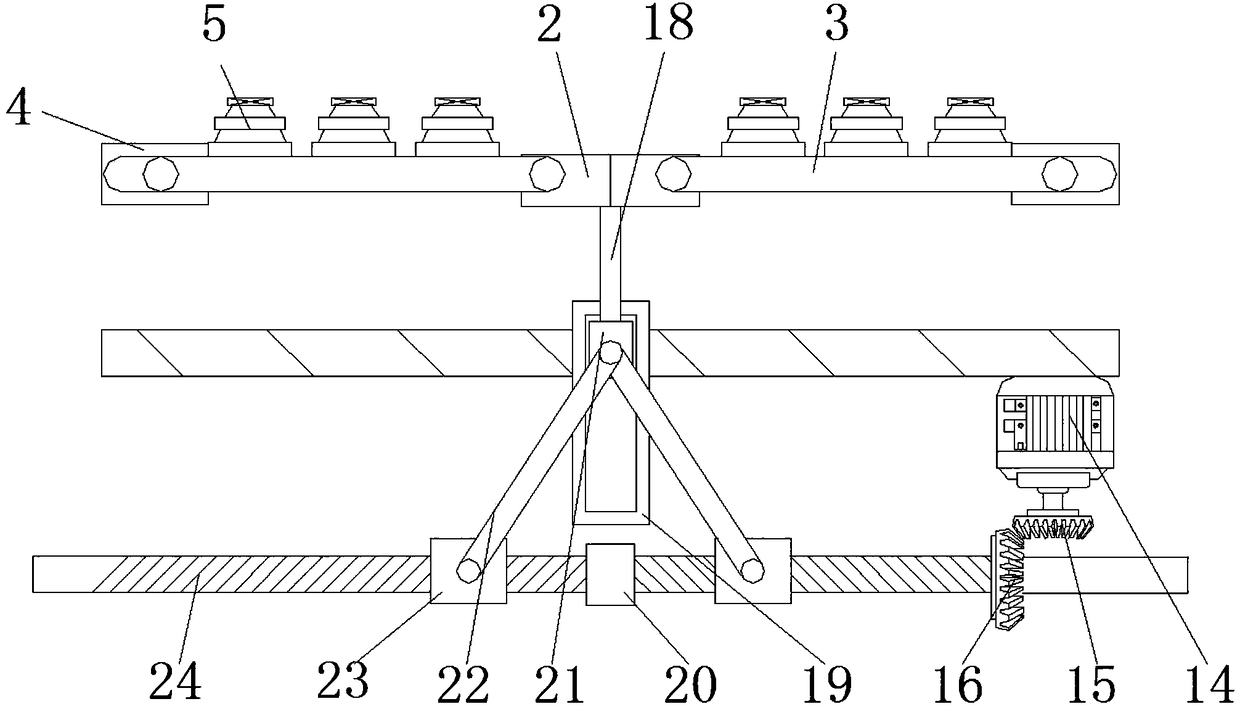

Cloth drying device for textile processing

ActiveCN109282614AIncrease the drying areaSuitable for dryingMechanical cleaningPressure cleaningFixed frameEngineering

The invention provides a cloth drying device for textile processing. The cloth drying device comprises a drying box. A bearing plate is welded and fixed to an inner wall of the lower portion of the drying box. The left end of a threaded rod is rotatably installed in an inner wall of the left side of the drying box, the right end of the threaded rod is rotatably installed in an inner wall of a partition plate, and connecting bearings are arranged at the connecting positions correspondingly. A limiting block is fixedly connected to the middle portion of the threaded rod in a sleeving mode, and threads at the left end and the right end of the limiting block have opposite screwing directions. A lifting rod penetrates upwards through a fixed frame in a connecting mode, and the upper end of thelifting rod is welded and fixed to a moving block. Cloth is placed in the upper portion of the interior of the drying box through a fixed guide roller in a bending mode, and brushes are arranged in the middle of the cloth. The upper end of a connecting plate is welded and fixed to an inner wall of the upper end of the drying box, and the lower end of the connecting plate is welded and fixed to a fixed plate. The left side of an air drying box is provided with an air dispersing hole, and a blow drying fan is arranged inside the air drying box. The cloth drying device has the advantages of beingsimple in structure, convenient to operate and high in efficiency, can complete cloth drying quickly, and is worthy of popularization and use.

Owner:安徽豹子头服饰股份有限公司

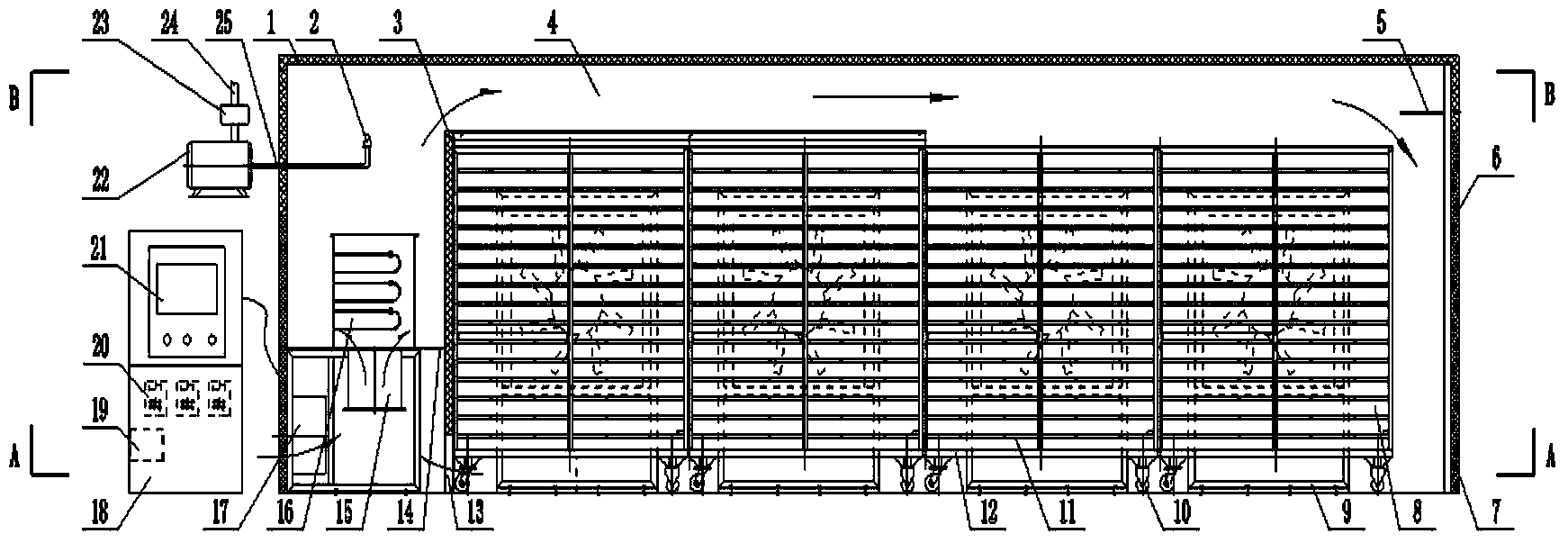

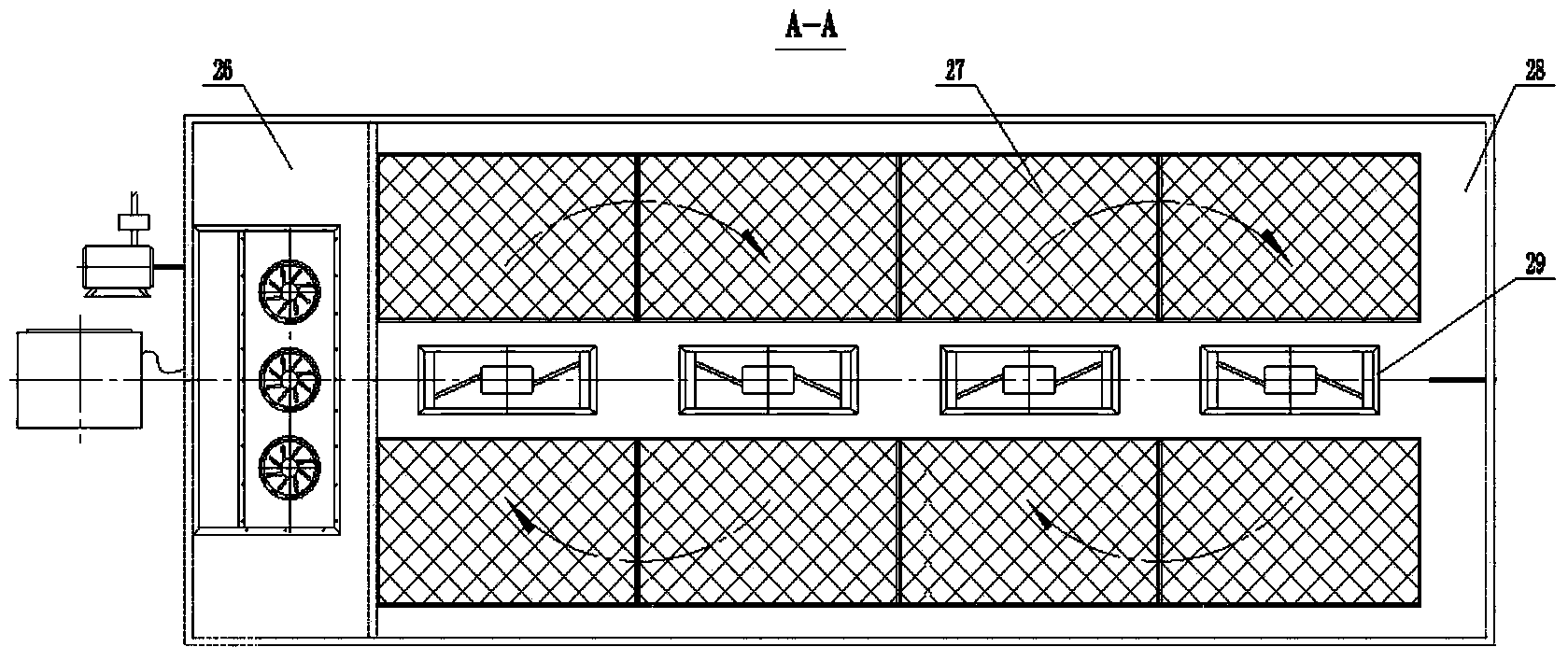

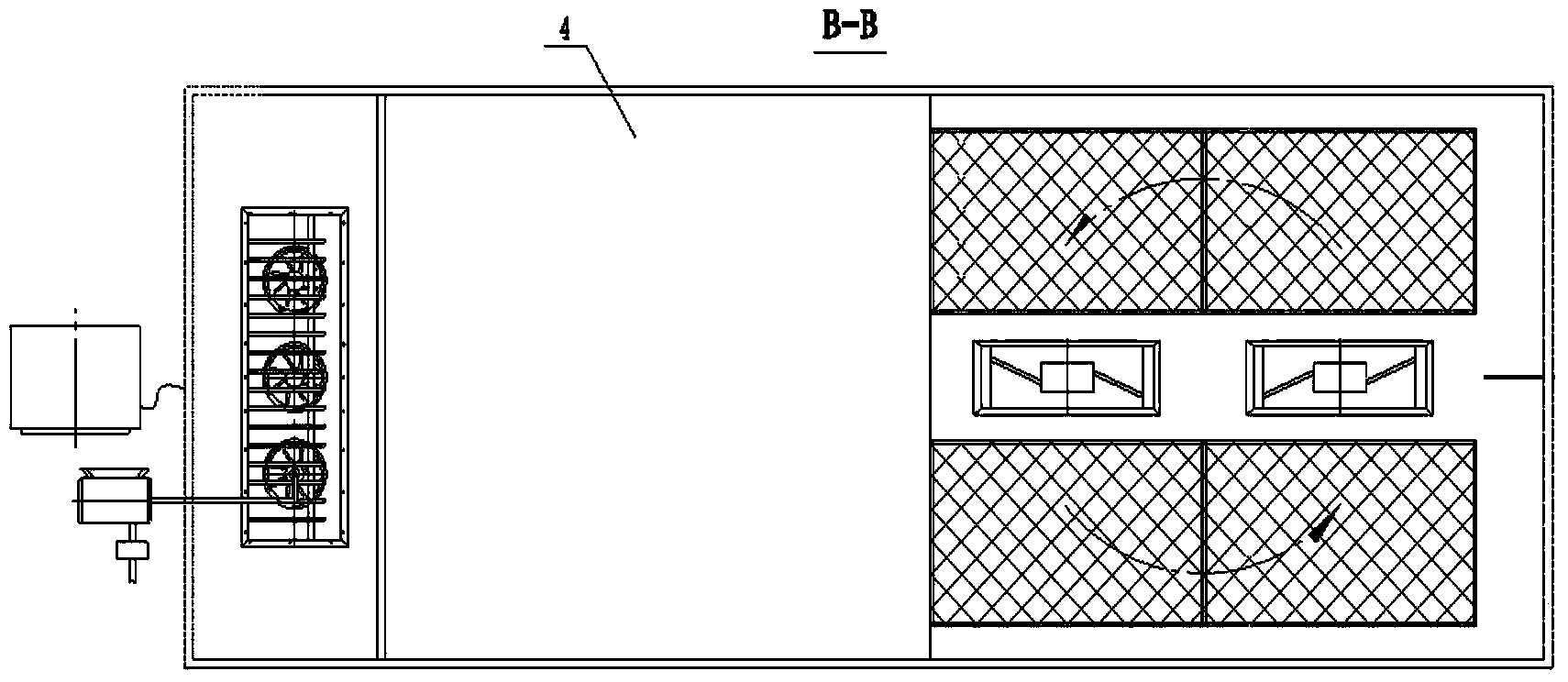

Temperature and humidity integration control drying room

InactiveCN104075546ADehydration fastIncrease enthalpyDrying solid materialsDrying machines with local agitationControl systemHeat transfer efficiency

The invention belongs to the technical field of drying and particularly relates to a temperature and humidity integration control drying room which comprises an air flow circulation system, a heating and humidification system, a material loading system, a temperature and humidity control system and a wall (1). The temperature and humidity integration control drying room can be formed by one drying room or a plurality of drying rooms in parallel connection. A partition wall (3) in the wall (1) divides the temperature and humidity integration control drying room into a heating chamber (26) on the left and a drying chamber (28) on the right. A temperature and humidity integration control drying technology is adopted in material drying, process parameters such as temperature and moisture content are regulated accurately in real time according to a material state, and fast dehydration of agricultural products is achieved at large enthalpy and high heat transfer efficiency; and compared with drying through traditional drying rooms, the temperature and humidity integration control drying room shortens drying time, reduces energy consumption and improves uniformity in the drying process.

Owner:CHINA AGRI UNIV

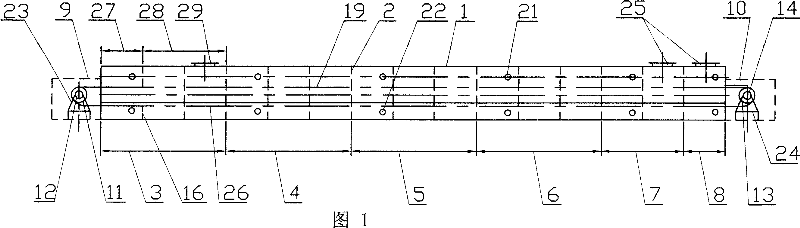

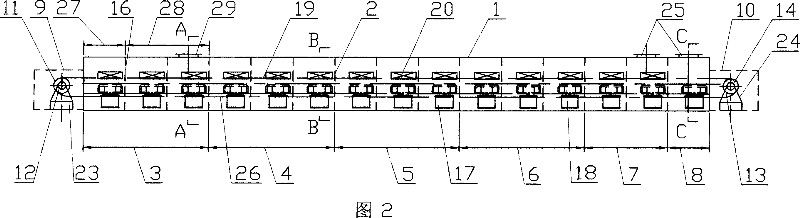

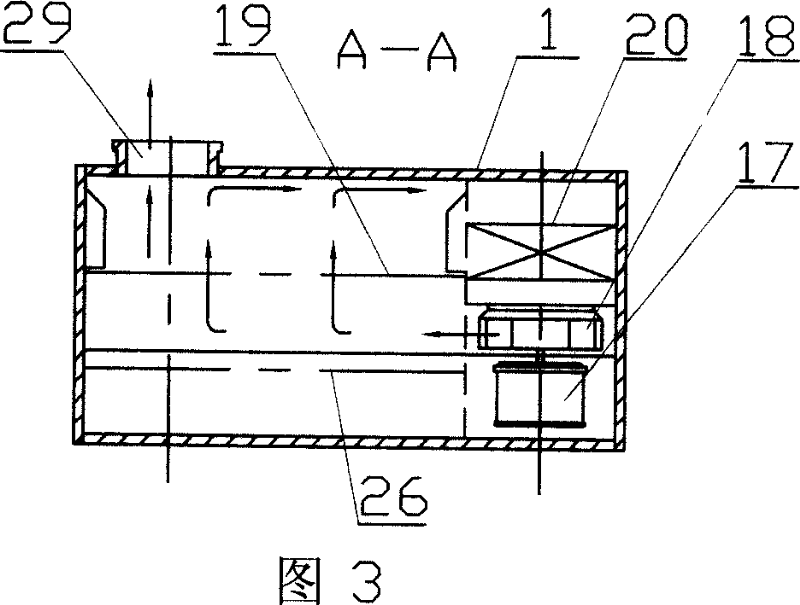

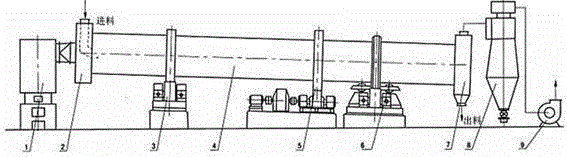

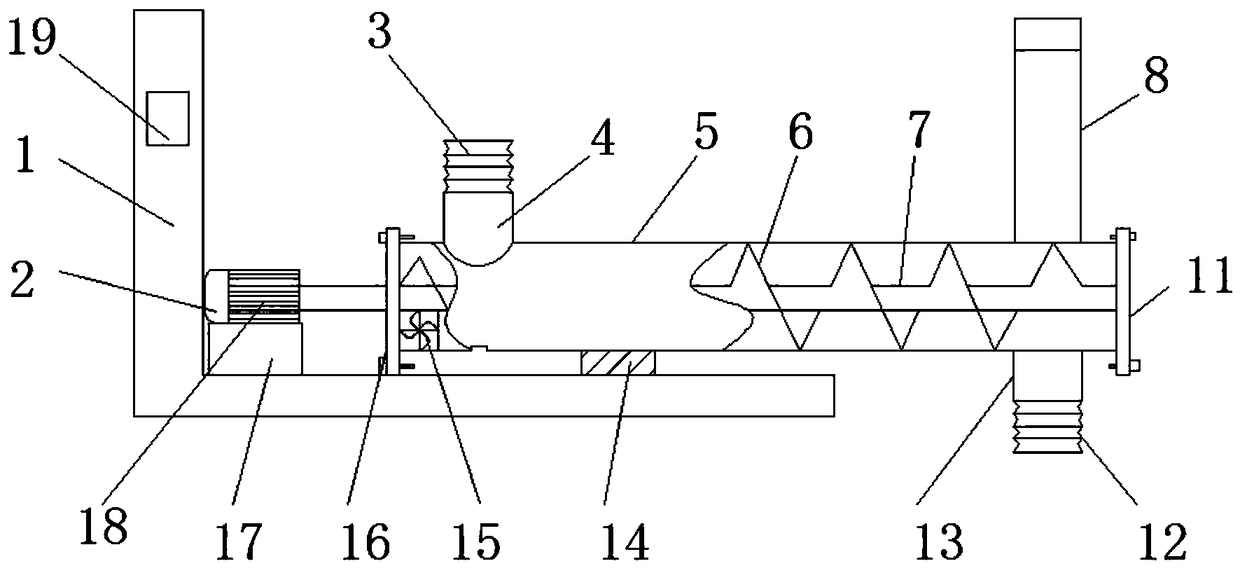

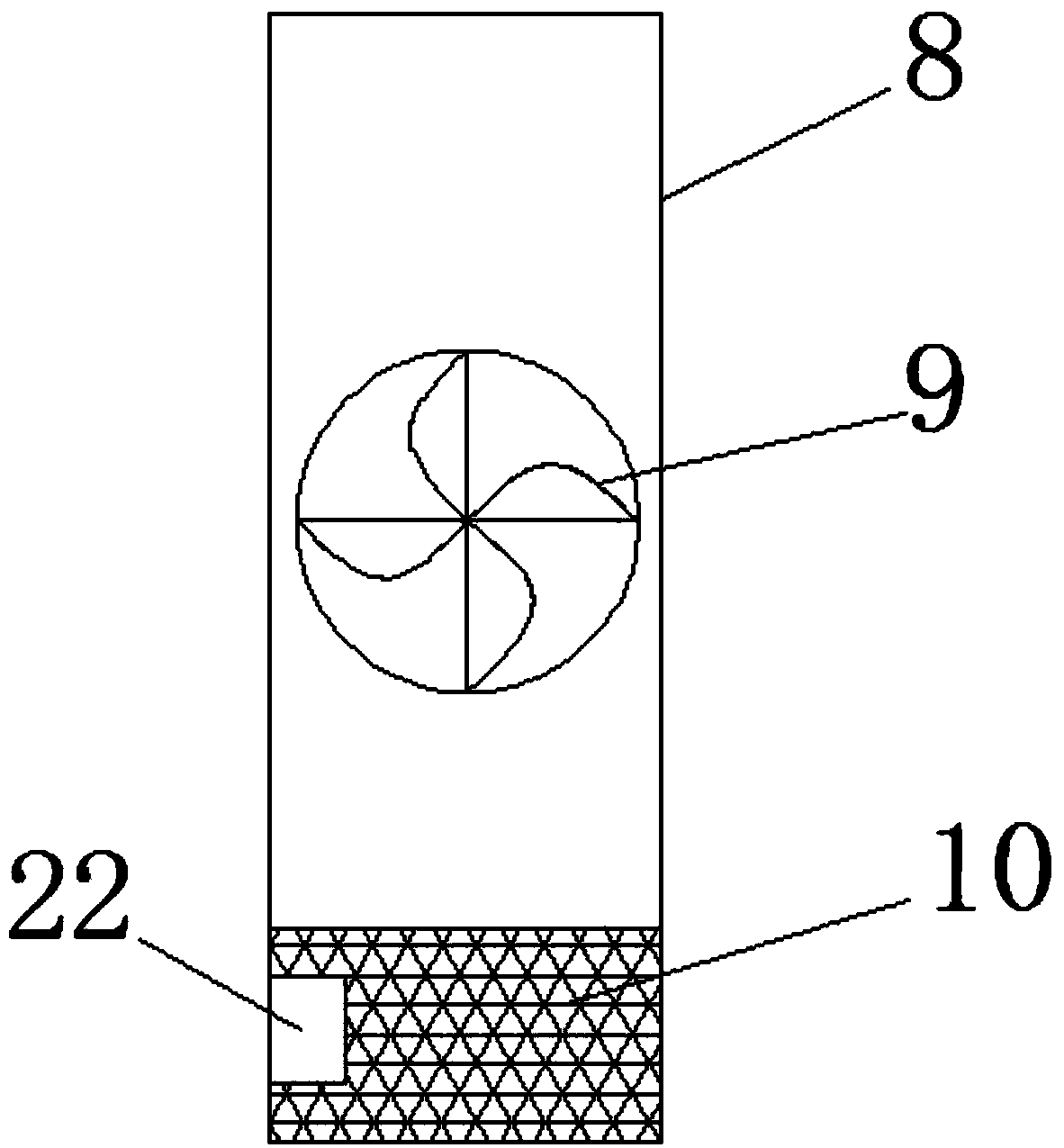

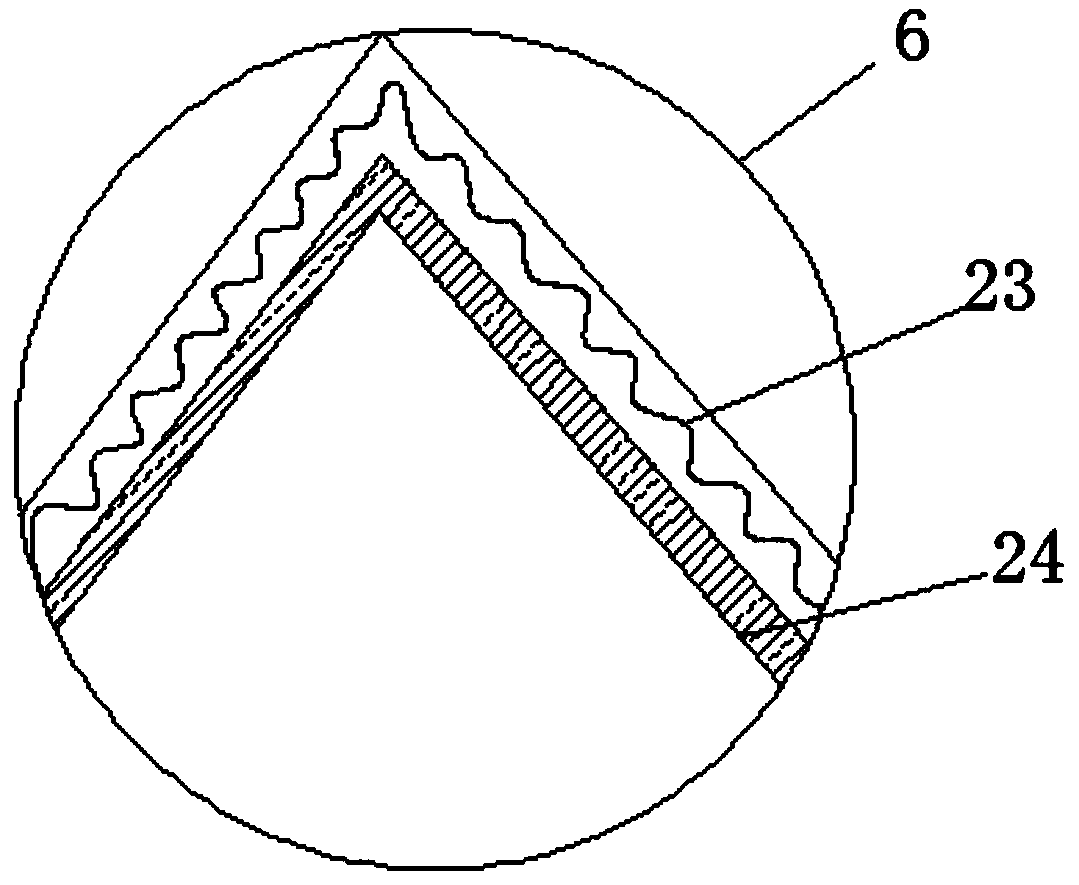

Internal recycling drying machine of rubber raw materials

InactiveCN101038127ALow costTo achieve the purpose of energy savingDrying solid materials with heatDrying machines with progressive movementsFeed driveButadiene-styrene rubber

A rubber material internal circulation drying machine relates to a rubber material drying machine. Aiming at the problem that the existing direct discharging rubber material drying machine has big heat consume and high maintain cost. The front and rear of a box (1) of the present invention are disposed with a feeding drive device (9) and a discharging drive device (10) connected by a material conveyer belt. The box (1) is divided into five drying chambers and one cooling chamber (8) by a frame (2). The fifth drying chamber (7) and the cooling chamber (8) are disposed with air inlets (25). The first drying chamber (3) is composed of a first front drying chamber (27) and a first rear drying chamber (28) which is disposed with air outlet (29). One side of the box (1) is mounted with a motor (17) and a blower (18). A heat exchanger (20) is disposed in the box (1). An upper temperature measuring device (21) and a lower temperature measuring device (22) are disposed on the upper side and lower side of the material conveyer belt. Compared with the existing technology, the present invention can save energy by 30%, and can reduce manufacturing cost by 35% compared with the same kinds of products, and is especially adapted to drying process for nitrile-butadiene rubber and styrene-butadiene rubber.

Owner:HARBIN INST OF TECH

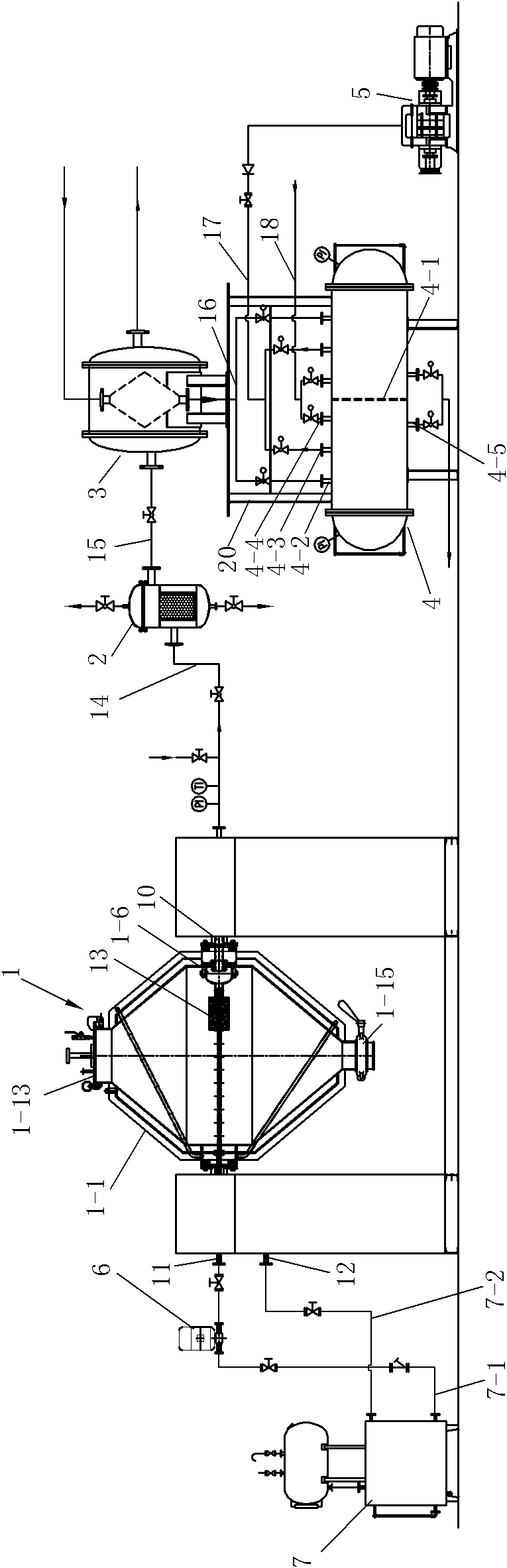

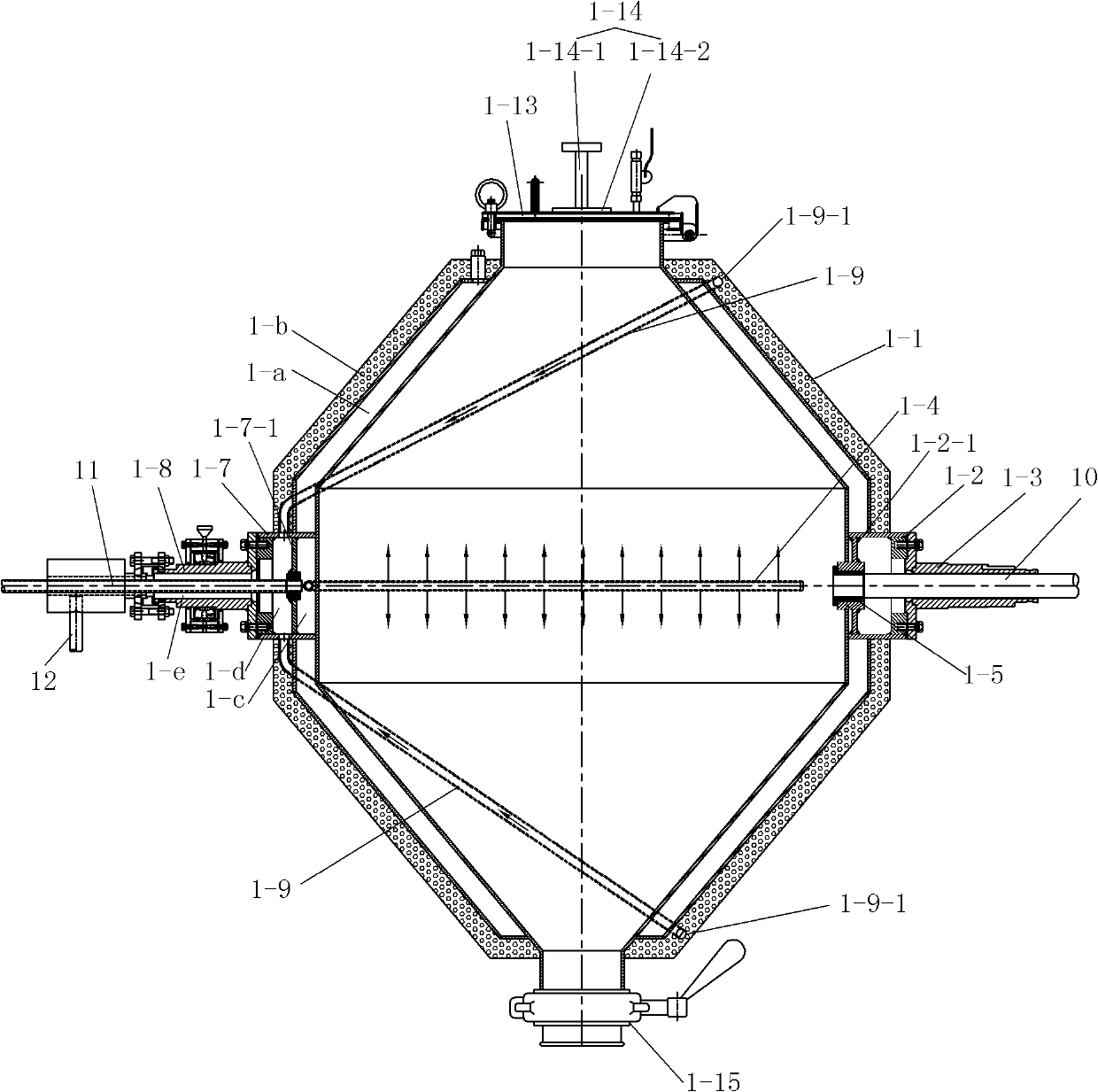

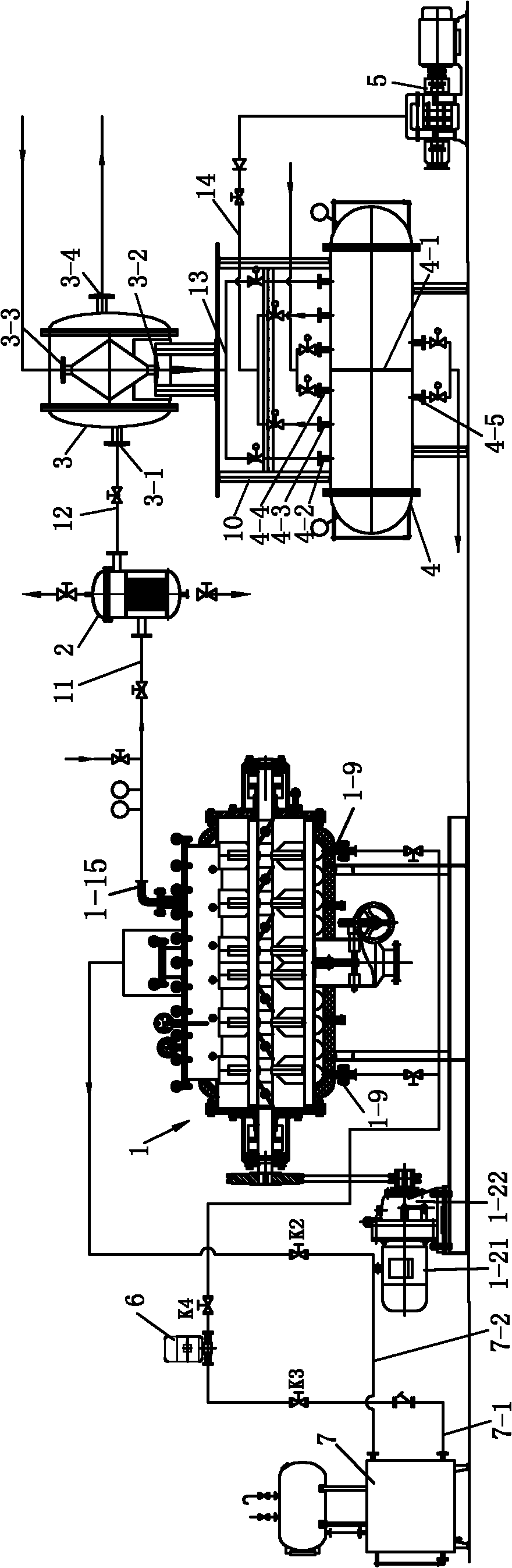

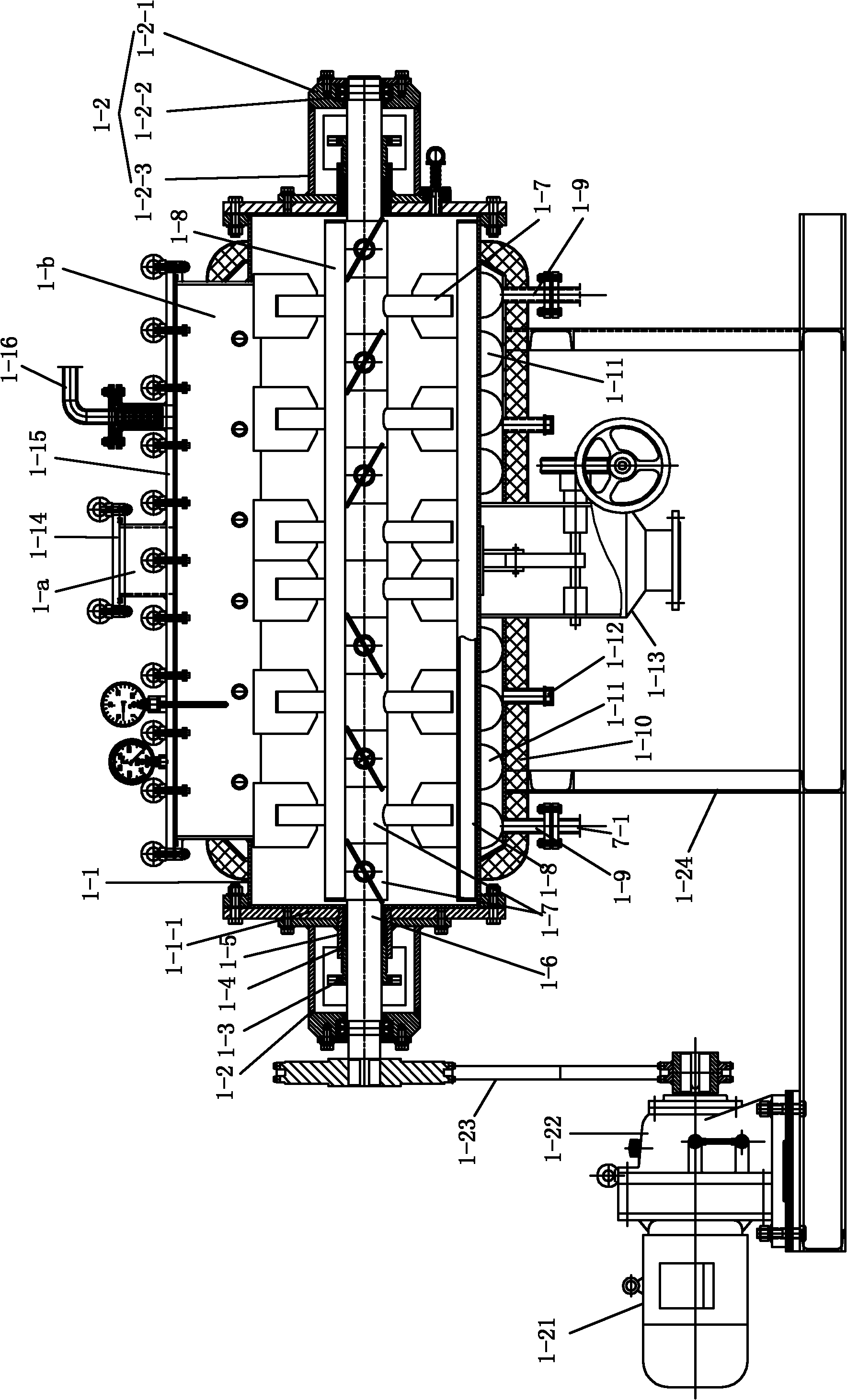

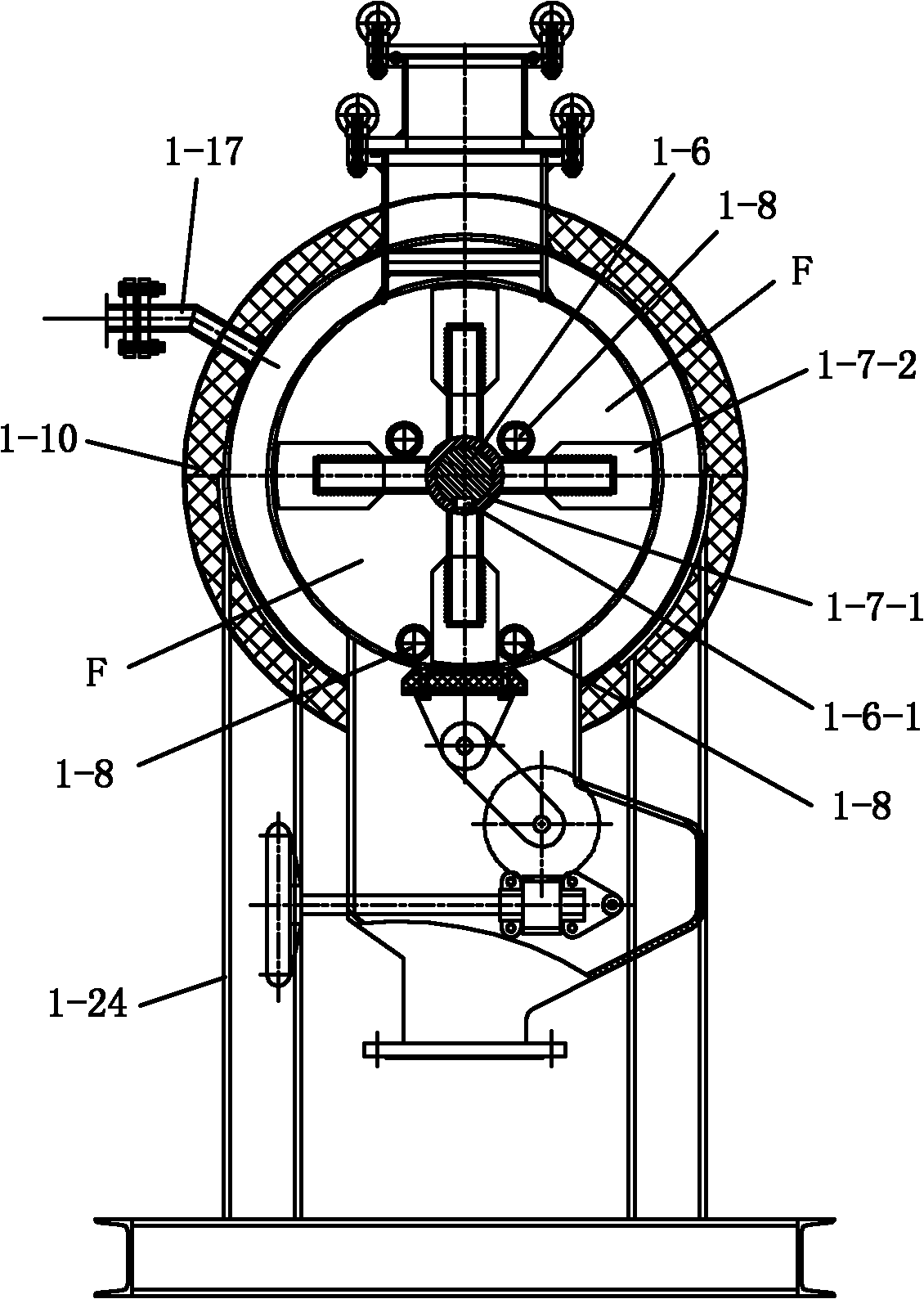

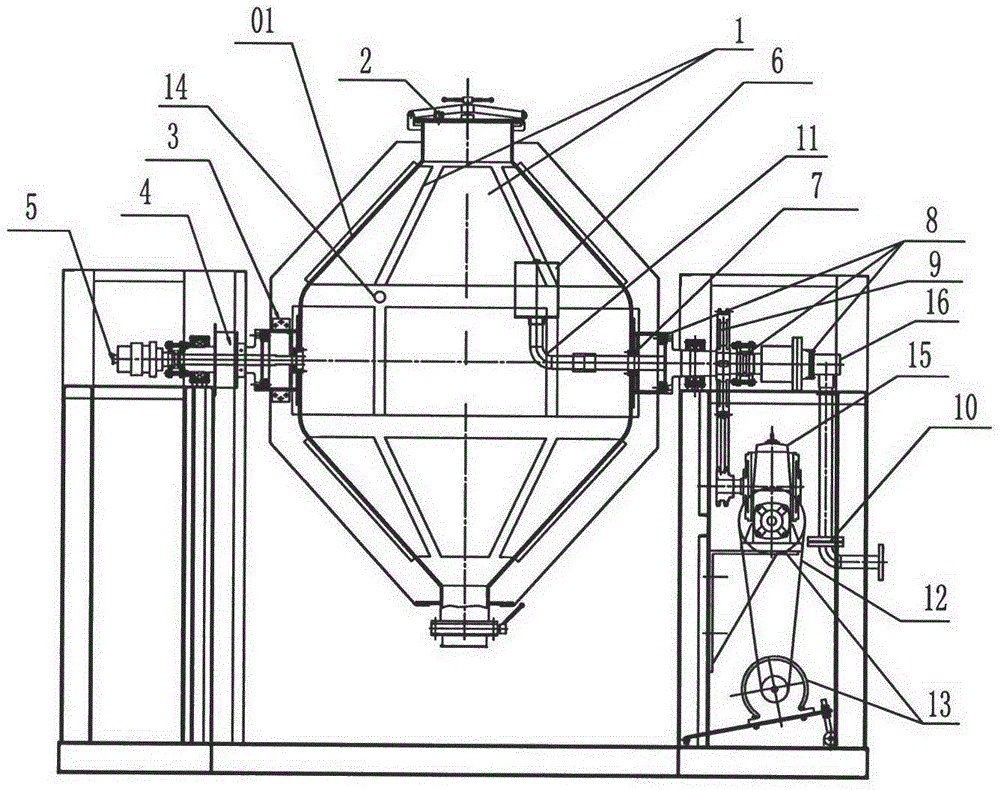

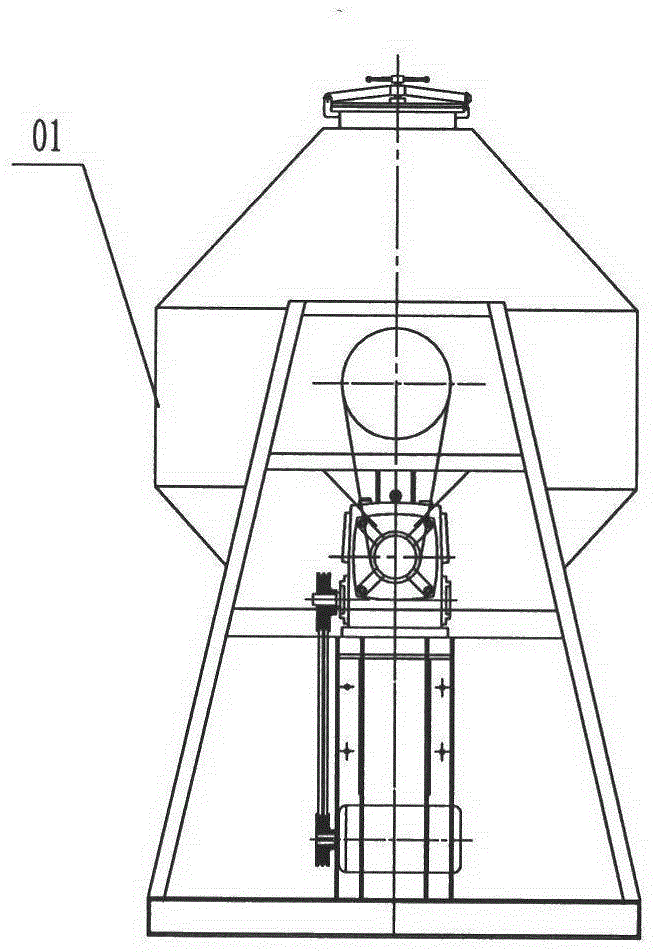

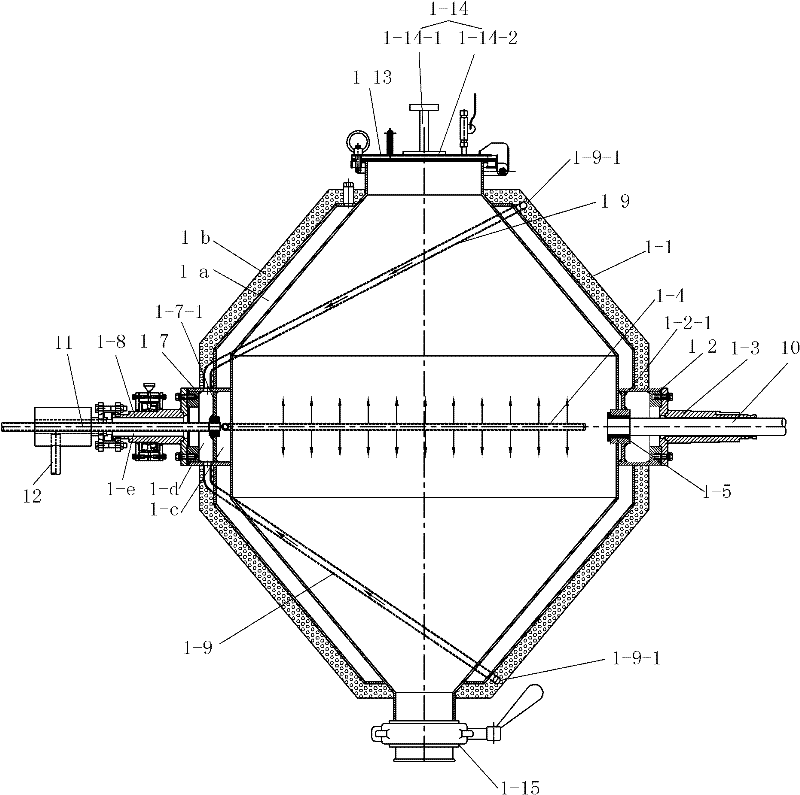

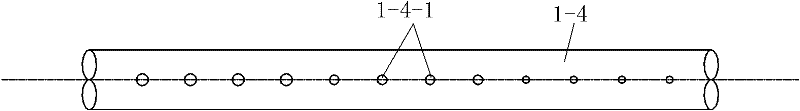

Biconical rotary vacuum drying system

ActiveCN102168909AGuaranteed uniformityUniform finenessDrying solid materials without heatDrying machines with non-progressive movementsSolventBicone

The invention relates to a biconical rotary vacuum drying system, which comprises a biconical rotary vacuum drying main machine, a condenser, a gas-liquid separator, a vacuum pump, an oil pump, a hot oil tank, a vacuumizing pipe, an oil supply pipe and an oil return pipe, wherein the vacuumizing pipe extends into a cylinder body of the biconical rotary vacuum drying main machine from the inner cavity of a driving half shaft and the pipe hole of a driving shaft base; the oil supply pipe extends into an oil inlet cavity from the inner cavity of a driven half shaft and a pipe hole on a baffle; and two built-in oil supply branch pipes which are arranged horizontally on front and back sides are arranged on the middle part of a clamp sleeve of the cylinder body and are communicated with an oil inlet cavity of a driven shaft base. By the biconical rotary vacuum drying system, heat conducting oil can be distributed to integral clamp sleeve space uniformly to ensure the uniformity of clamp sleeve heating, the problem that biconical rotary vacuum drying is 'semi-hot and semi-cold' for a long term is solved, the quality of products and the work efficiency are improved, and energy is saved. In the biconical rotary vacuum drying system, solvents are recovered by a gas condenser and a liquid separator.

Owner:JIANGSU XIANFENG DRYING ENG

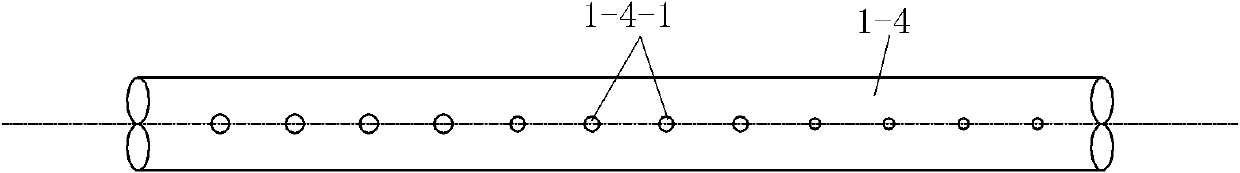

Rake type vacuum drying system

ActiveCN102183126ASpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsVapor–liquid separatorLithium iron phosphate

The invention provides a rake type vacuum drying system, which comprises a rake type vacuum drying host machine, a bag type filter, a condenser, a gas-liquid separator, a vacuum pump, an oil pump and a hot oil tank, wherein a main shaft of the rake type vacuum drying host machine is a solid main shaft; a plurality of rake tooth components are arranged on the main shaft; each rake tooth component comprises a sleeve shaft and four solid rake teeth uniformly distributed on the sleeve shaft in a fixed manner, and is connected on the main shaft through a sleeve shaft key; the rake teeth of the respective rake tooth components face towards the same direction, so that four passageways are formed in a tank body; and striking rods are respectively arranged in respective passageways or in spaced passageways. In the invention, materials inside the tank body of the drying host machine are struck continuously by using the striking rods, so that the crushing of the materials is accelerated, the materials can obtain larger specific surface areas, the drying process is accelerated, and finished products have uniform fineness and low water content; thus, the rake type vacuum drying system is suitable for drying lithium iron phosphate materials, and the product quality and drying efficiency are improved; moreover, the system is used for recovering solvents through the condenser and the gas-liquid separator, and is beneficial to reduction of the cost.

Owner:JIANGSU XIANFENG DRYING ENG

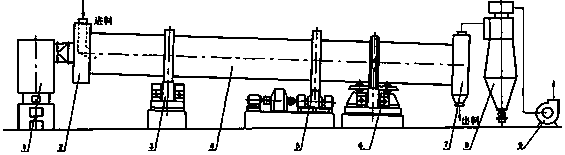

Fly ash drying machine

ActiveCN105157377AIncrease economic benefitsGuaranteed drynessDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringPollution

The invention discloses a fly ash drying machine. The fly ash drying machine comprises a drying kiln which is arranged in an inclined mode. The high end of the drying kiln is a feed end, and the low end of the drying kiln is a discharge end. A riding wheel device is arranged on the portion, close to the feed end, on the drying kiln. A riding wheel blocking device is arranged on the portion, close to the discharge end, on the drying kiln. A transmission device is arranged in the middle of the drying kiln. A heating device is connected to the feed end of the drying kiln. A discharge device is arranged at the discharge end of the drying kiln. The discharge device is connected with a cyclone separation device which is connected with an induced draught fan. Unique design is adopted for the fly ash drying machine according to the characteristics of fly ash, and the pollution and treatment problem of fly ash is solved; meanwhile, waste fly ash is turned into wealth, and economic benefits are increased.

Owner:陈宇捷

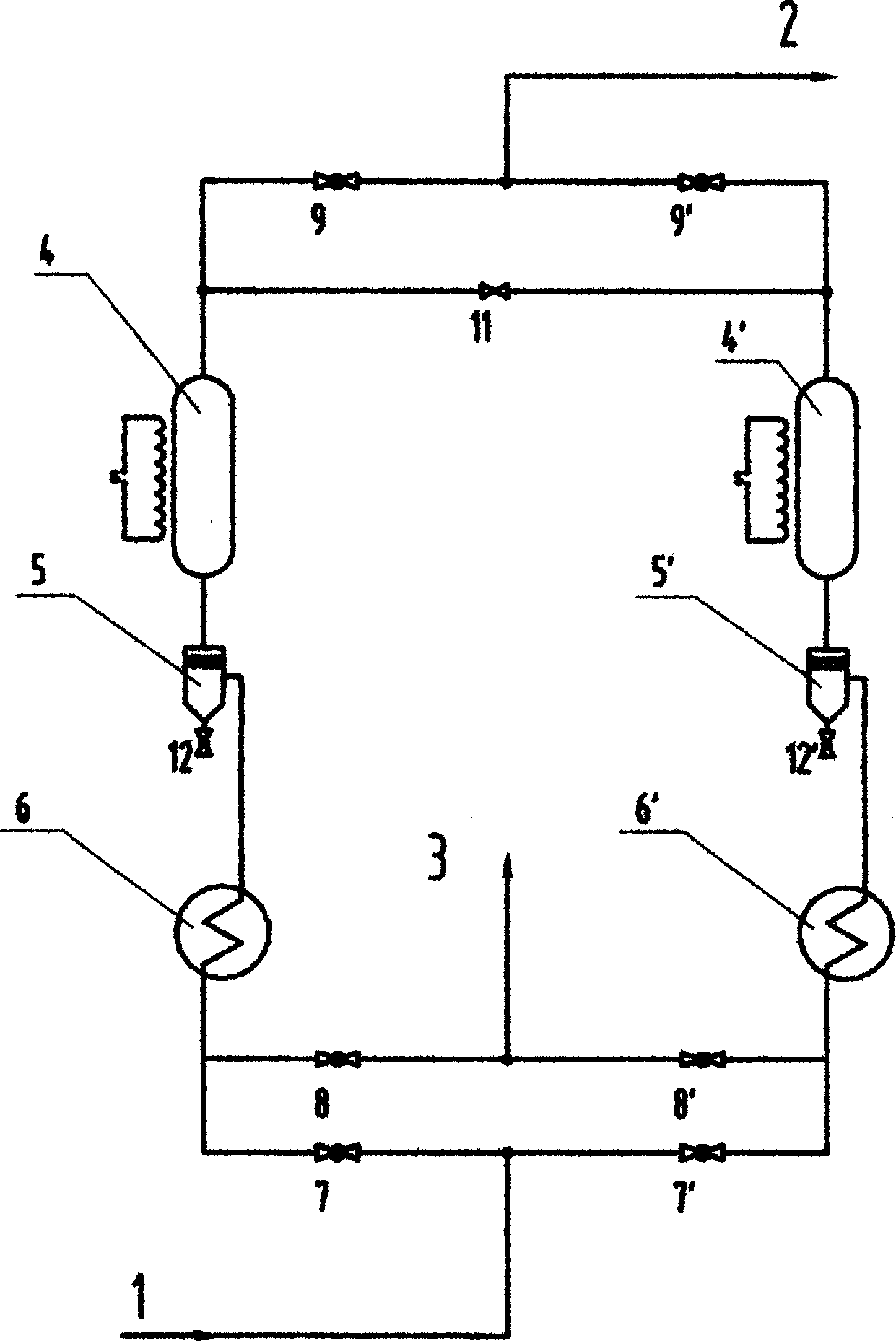

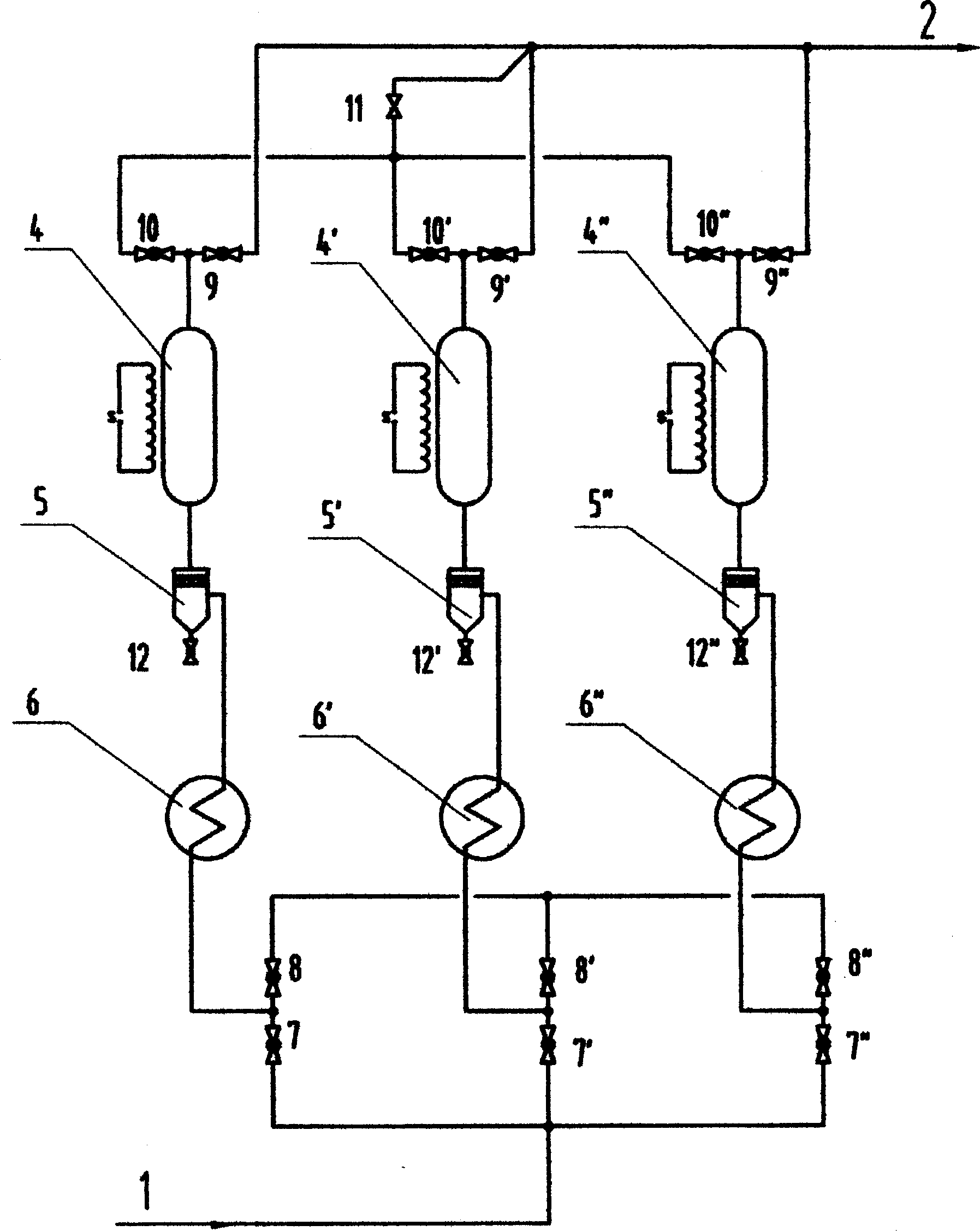

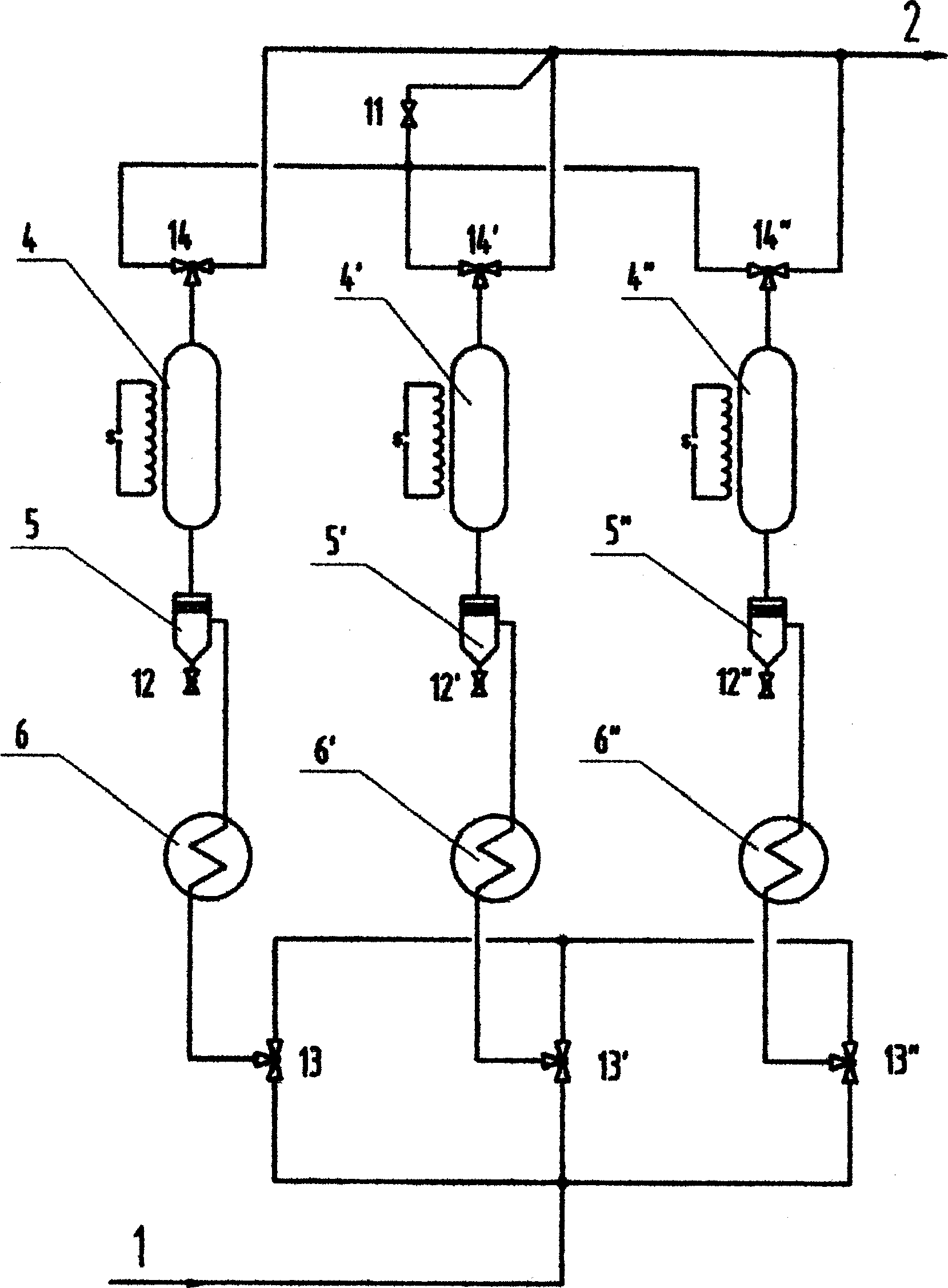

Process for preparing ciltradry gas

ActiveCN1483504AStable pressure balanceReduce wearDispersed particle separationWater contentL&D process

The technological process for preparing extra dried gas is mainly characterized by that its adopts three sets of drying column devices with identical structure, said three sets of drying column devices are arranged in the centrically symmetrical state, and its concrete structure is as follows: the top portion of the drying column is communicated with the middle point between two valves, its lower portion is communicated with gas-water separator, the lower portion of said gas-water separator is communicated with cooling device, said cooling device is communicated with middle point between other two valves, the bottom portion of the gas-water separator is equipped with discharge valve. Said invention also provides its preparation process.

Owner:中船(邯郸)派瑞氢能科技有限公司

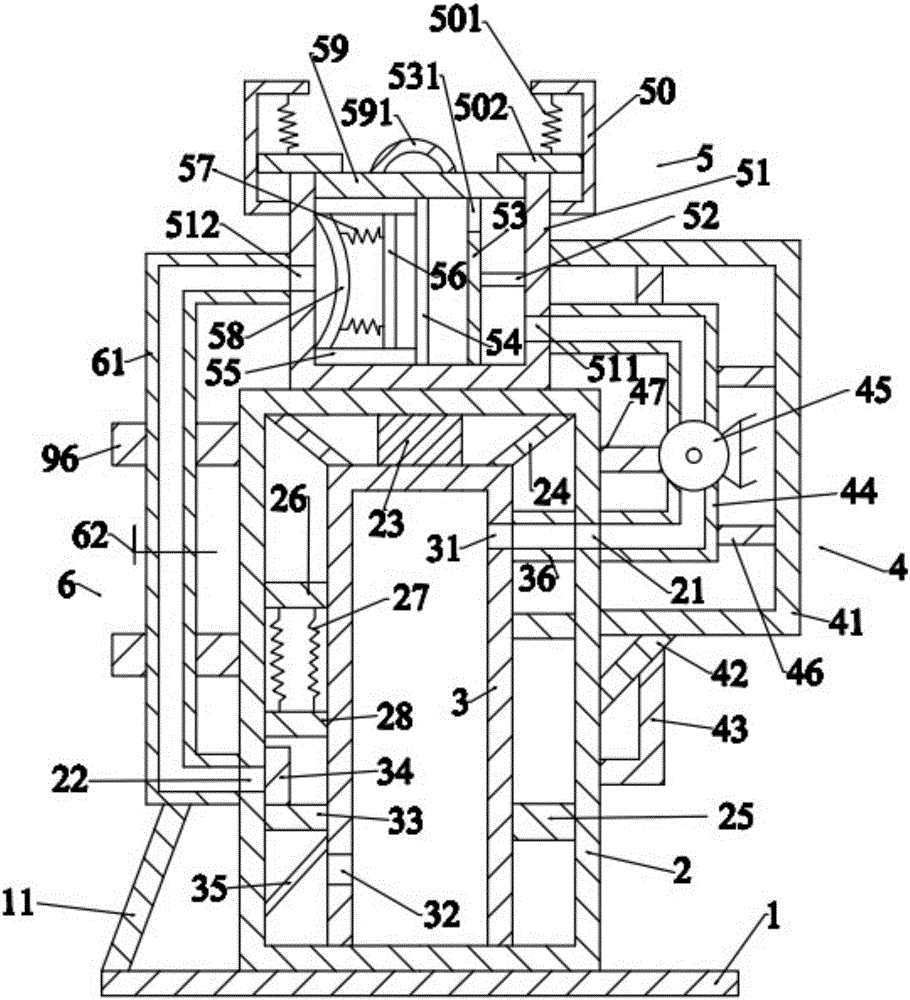

Dehumidification device of power cabinet

InactiveCN105854532ASimple dehumidifierEasy to useGas treatmentDispersed particle separationFixed frameEngineering

A dehumidification device of a power cabinet comprises a bottom plate, an isolating frame, the power cabinet, an exhaust device, a drying device and a pipeline device. A first inclined rod is arranged on the bottom plate, a first through hole, a second through hole, a first fixed block, second inclined rods, first cross rods, a second cross rod, first springs and a first baffle are arranged on the isolating frame, and a third through hole, a fourth through hole, a first sponge block, a second sponge block, a first filter screen and a first pipeline are arranged on the power cabinet. The exhaust device comprises a first support, a third inclined rod, a second support, a second pipeline, a draught fan, first connecting rods and a second connecting rod. The drying device comprises a drying box, a second filtering screen, a second baffle, a third filtering screen, third sponge blocks, a fourth filtering screen, second springs, a fifth filtering screen, a cover plate and fixed frames. The pipeline device comprises a third pipeline, a valve and fixed rods. According to the dehumidification device, the appropriate temperature in the power cabinet can be kept, and the humidity in the power cabinet can be effectively reduced.

Owner:周末

Electric heating biconical vacuum dryer

InactiveCN102564083BAchieve the purpose of dryingSuitable for dryingDrying using combination processesDrying machines with non-progressive movementsImpurityBinding post

Owner:常州市步步干燥设备有限公司

External purely-natural skincare product

ActiveCN103301050ASuitable for dryingSuitable for roughCosmetic preparationsToilet preparationsFlaxseed extractGlycerol

The invention belongs to the technical field of cosmetics, and in particular relates to an external purely-natural skincare product. The external purely-natural skincare product is prepared form the following components: 30-55 g of flaxseed extract, 1-5 g of sodium dodecyl sulphate, 1-5 g of OP emulsifier, 5-10 g of glycerine, 1-2 g of sodium citrate, 3-5 g of glycerin monostearate, 1-5 g of liquid paraffin, 3-5 g of albolene, 5-8 g of octadecanol, 1-3 g of wool fat, and 1-2 g of paraffin. A preparation method comprises the following steps of: a, mixing flaxseed extract, sodium dodecyl sulphate, an OP emulsifier, glycerine and sodium citrate, heating to 80-85 DEG C in water bath, uniformly stirring, and keeping for 20 minutes to obtain a water-phase mixed solution; b, mixing glycerin monostearate, liquid paraffin, albolene, octadecanol, wool fat and paraffin, heating to 80-85 DEG C in water bath, uniformly stirring, and keeping for 20 minutes to obtain an oil-phase mixed solution; and c, adding the water phase in the oil phase, and stirring to condense. The external purely-natural skincare product takes the flaxseed extract prepared from the purely-natural raw material of flaxseeds as a main material, and has the effects of maintaining and moistening the skin.

Owner:LANZHOU UNIVERSITY

Vacuum drying method for processing wood plate raw materials

InactiveCN102538408AReduce the temperatureAvoid lossDrying using combination processesDegree CelsiusPulp and paper industry

The invention discloses a vacuum drying method for processing wood plate raw materials, which belongs to a drying method for wood plate raw materials. Drying process includes a step A, placing the wood plate raw materials into a drying tank, sealing an opening of the drying tank, and forming a vacuum environment in the drying tank by the aid of vacuumizing equipment; and a step B, heating the drying tank from the outside of the drying tank at the temperature ranging from 30 Celsius degrees to 165 Celsius degrees for 72 hours to 360 hours, and obtaining a dried wood plate raw material finished product. By means of drying in a vacuum condition, temperature required for evaporating moisture is lowered, accordingly, the wood plate raw material is dried at relatively low temperature, loss of the raw materials due to over high temperature is avoided, and the drying tank placed transversely is favorable for being heated from the outside thereof. In addition, the steps of the vacuum drying method for processing the wood plate raw materials are simple, and the method is suitable for drying various wood materials, is particularly suitable for drying wood of fast-growing forests, and is wide in application range.

Owner:成都市双虎实业有限公司

Sterile, drop-forming, multi-phase, emulsifier-free ophthalmic product

InactiveCN101227891AImprove applicabilityComfort compatibilitySenses disorderAerosol deliveryLiquid statePhosphate

The invention relates to a sterile, drop-forming, multi-phase, emulsifier-free ophthalmic product, in particular a gel product, comprising at least one liquid aqueous phase and at least one liquid hydrophobic phase, the product comprising at least one phosphate salt and having a viscosity in the range from > 200 mPa<.>s to < 2000 MPA<.>s.

Owner:BAUSCH & LOMB INC

Improved air flow penetration type agricultural drying device

InactiveCN109028806AAvoid uneven heatingGuaranteed drying effectDrying gas arrangementsDrying solid materialsElectricityAgricultural engineering

The invention discloses an improved air flow penetration type agricultural drying device which comprises a shell, a carrying plate and a fan. An air outlet hole is formed in the top of the shell, andmicro pores are distributed in the carrying plate. A rotating shaft is further arranged in the shell, and the upper end of the rotating shaft goes deep into the air outlet hole. A plurality of axial flow blades are arranged outside the shaft body, in the air outlet hole, of the rotating shaft, and material turning rods are fixed to the two sides of the lower shaft body of the rotating shaft. The outer wall of the top of the shell is connected with a flow guide tube, and the other end of the flow guide tube is connected to a ventilation box. An electric heating tube is arranged on the lower portion in the shell, and is located below the carrying plate. A plurality of liftable elastic turning rods are arranged on the material turning rods at intervals. According to the improved air flow penetration type agricultural drying device, hot air flow penetrates through the carrying plate and crops through the characteristics that hot air flow flows upwards, so that the crops and a heat source are in complete contact, and uneven heating is avoided; the material turning rod is driven by the hot air flow to enable farm crop products to be turned, and the hot air flow is made to make all-dimensional contact with the crops; and meanwhile, circulating dehumidification can further be conducted, and the drying effect is guaranteed.

Owner:来宝根

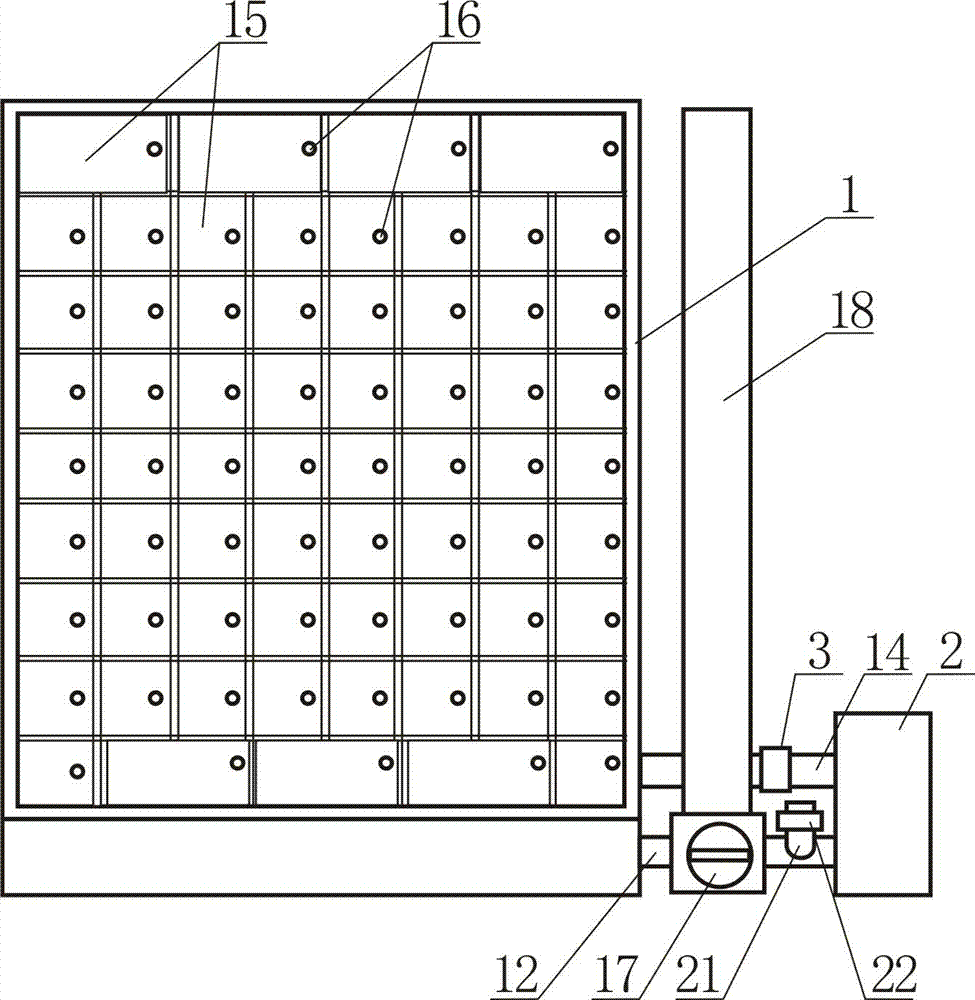

Drying oven for manufacturing leather products

ActiveCN104501546ASuitable for dryingEasy to take outDrying gas arrangementsDrying chambers/containersActivated carbon filtrationFresh air

The invention discloses a drying oven for manufacturing leather products. The drying oven comprises an oven body, a fan and a heater. The oven body is divided into an upper cavity and a lower cavity by a horizontal partition plate, the upper cavity serves as a drying bin, and the lower cavity serves as an exhaust channel, a space in the drying bin is divided into a plurality of rows of small grid bins by a plurality of vertical partition plates and a plurality of horizontal screen plates, the small grid bins are used for accommodating the to-be-dried leather products, the vertical partition plates are distributed from left to right at intervals, the horizontal screen plates are distributed from top to bottom at intervals, the exhaust channel is connected with the fan by an air return pipe, the small grid bin at the right lower corner of the oven body is connected with the fan by an air inlet pipe, the fan, the upper cavity and the lower cavity form an air circulating channel, and the heater is arranged in the air circulating channel. Bin doors are arranged on the small grid bins. A three-way valve is serially connected onto the air return pipe, an exhaust pipe is further connected onto the three-way valve, activated carbon filter layers are arranged in the exhaust pipe, a fresh air inlet is formed in the air return pipe, and an electromagnetic valve is arranged at the fresh air inlet. The drying oven has the advantages of energy conservation, environmental protection, good drying effects and convenience in accessing to-be-dried materials.

Owner:GUANGDONG FION LEATHER CO LTD

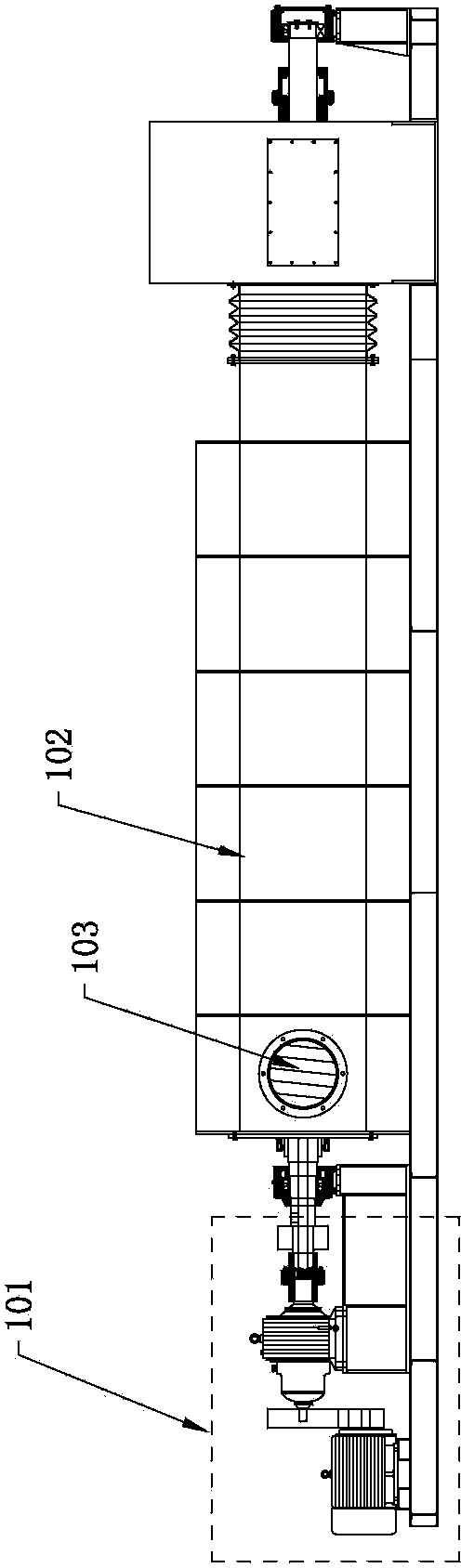

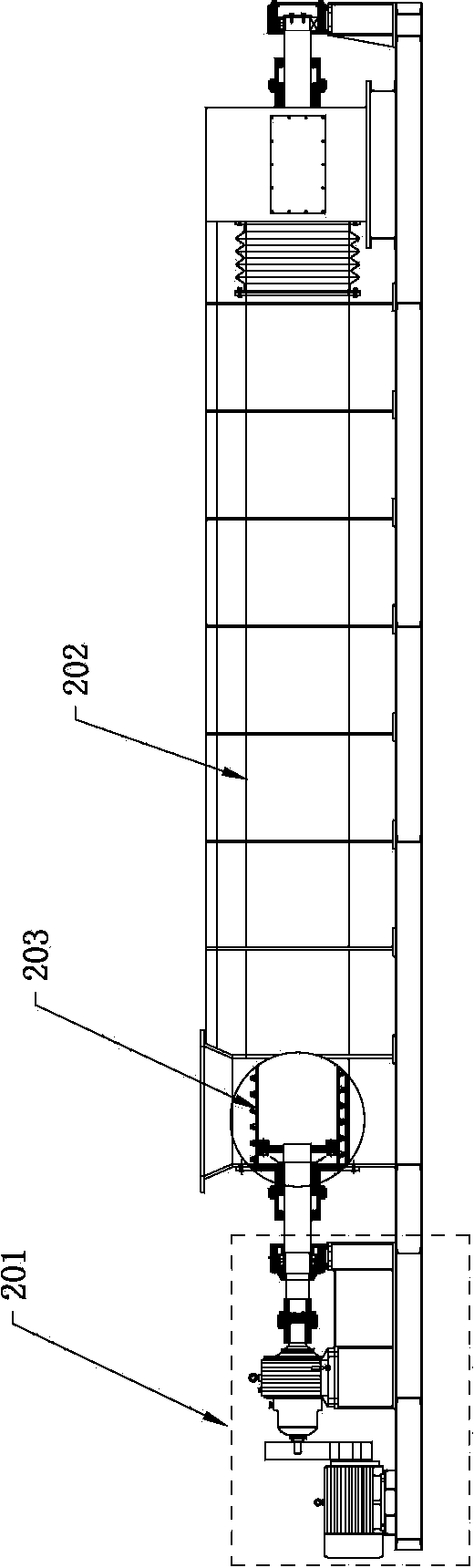

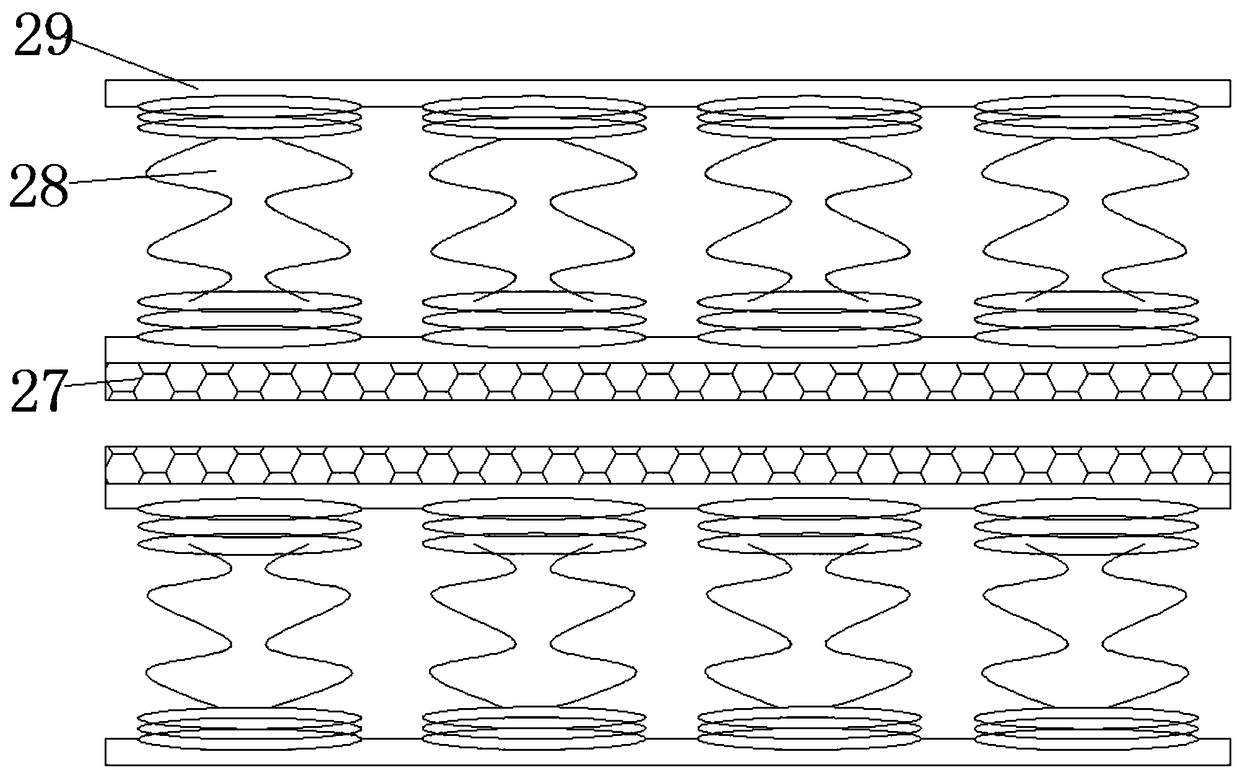

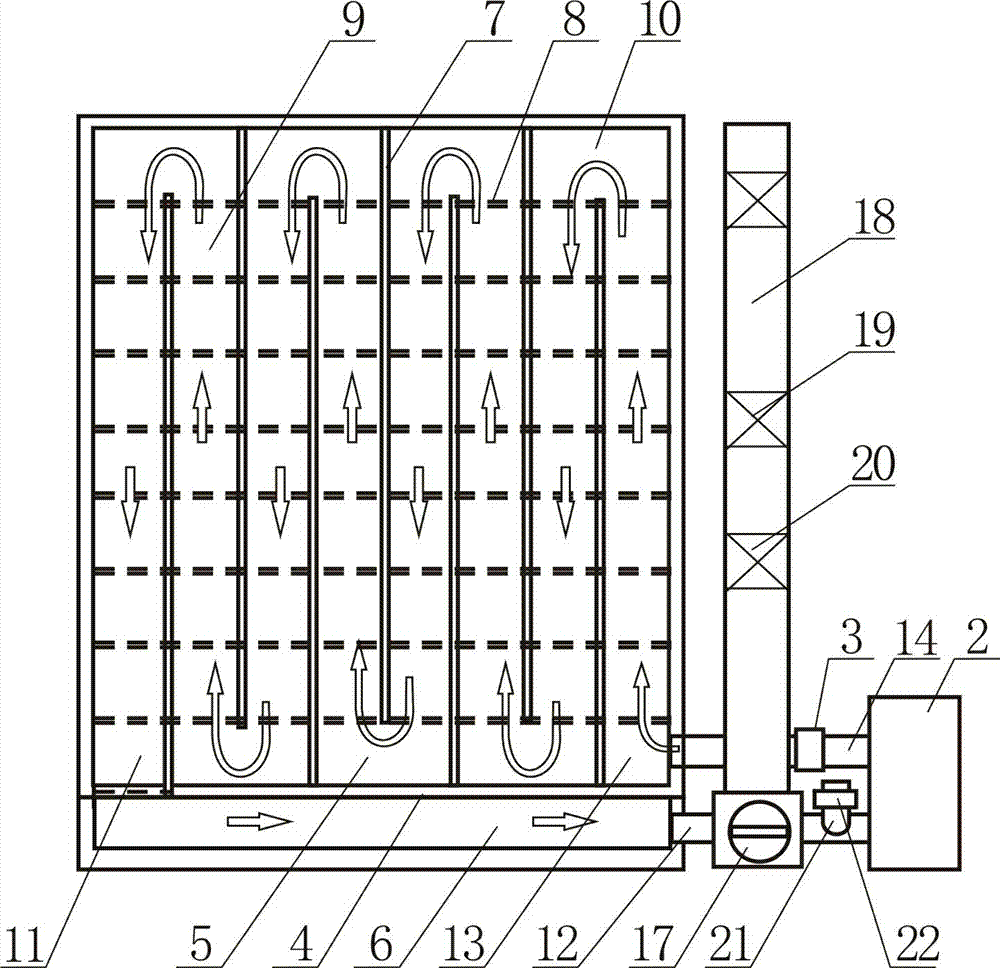

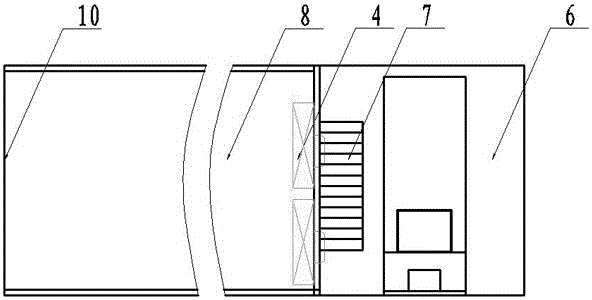

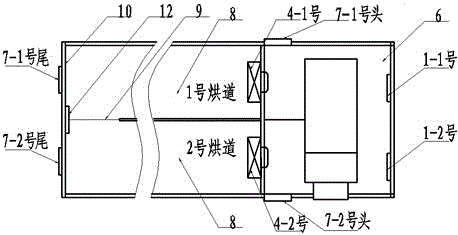

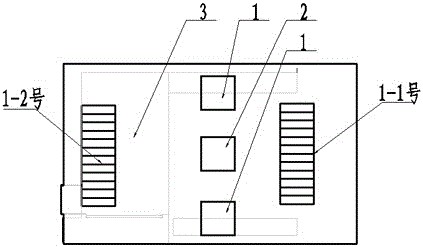

Double-drying-tunnel double-cycle drying machine and drying method thereof

ActiveCN106839664ADry evenlyImprove protectionDrying gas arrangementsDrying machines with local agitationFresh airPulp and paper industry

The invention discloses a double-drying-tunnel double-cycle drying machine and a drying method of the double-drying-tunnel double-cycle drying machine. The double-drying-tunnel double-cycle drying machine is mainly composed of a machine head part and a machine body part. A fresh air inlet, an electric air door, a heat source, a fan, a computer control cabinet, an air mixing space and a natural moisture exhaust opening are arranged on the machine head part. The machine body part comprises a main drying region, an air duct, a feeding / discharging door and a moisture exhaust device. The double-drying-tunnel double-cycle drying machine and the drying method have the beneficial effects that the original colors of agricultural products, such as rose corollas, green grapes and bright red wolfberries, can be maintained after the agricultural products are dried, the drying is uniform, the drying time is short, the energy consumption is low, natural air inlet and natural moisture exhaust are achieved, and the color and luster of the products are guaranteed.

Owner:WEIFANG SHUNTIAN ELECTROMECHANICAL APPLIANCE

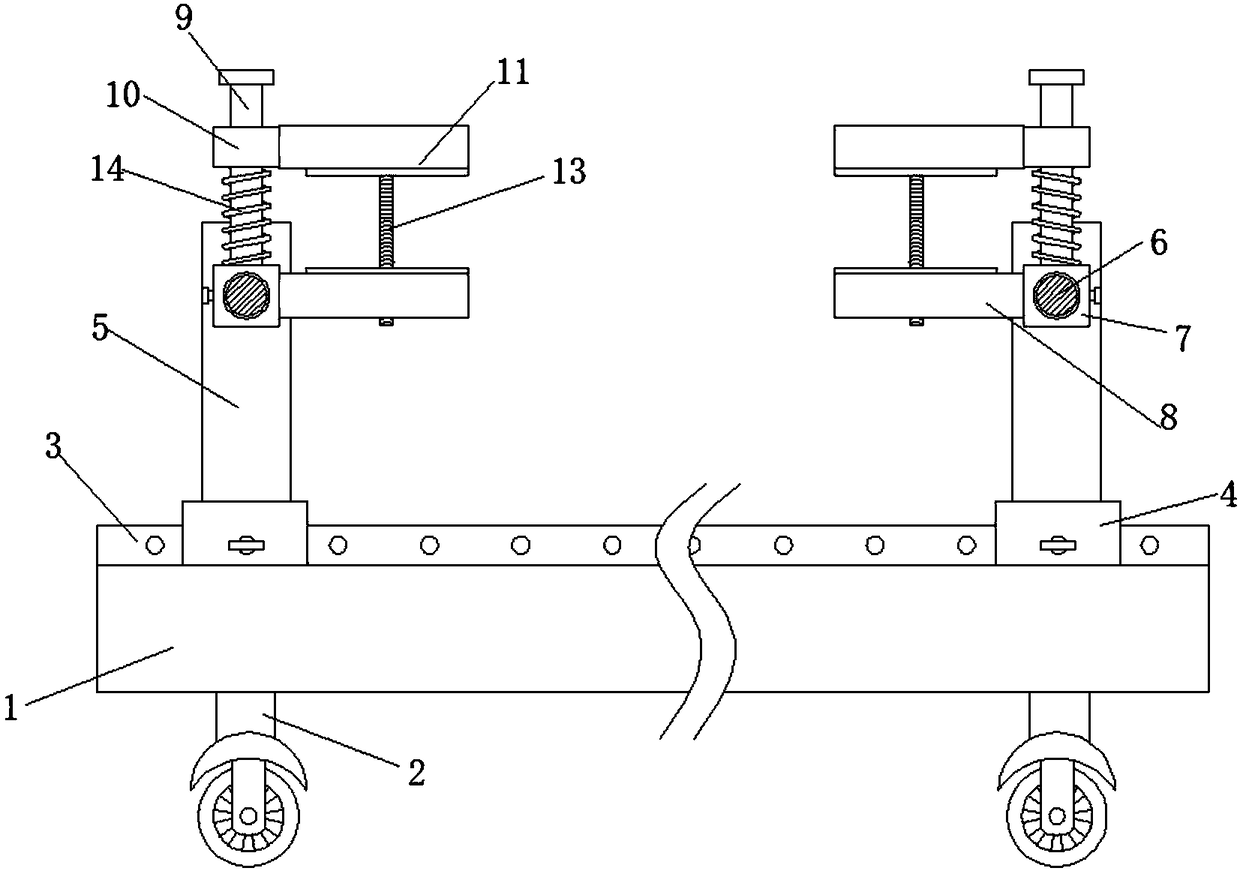

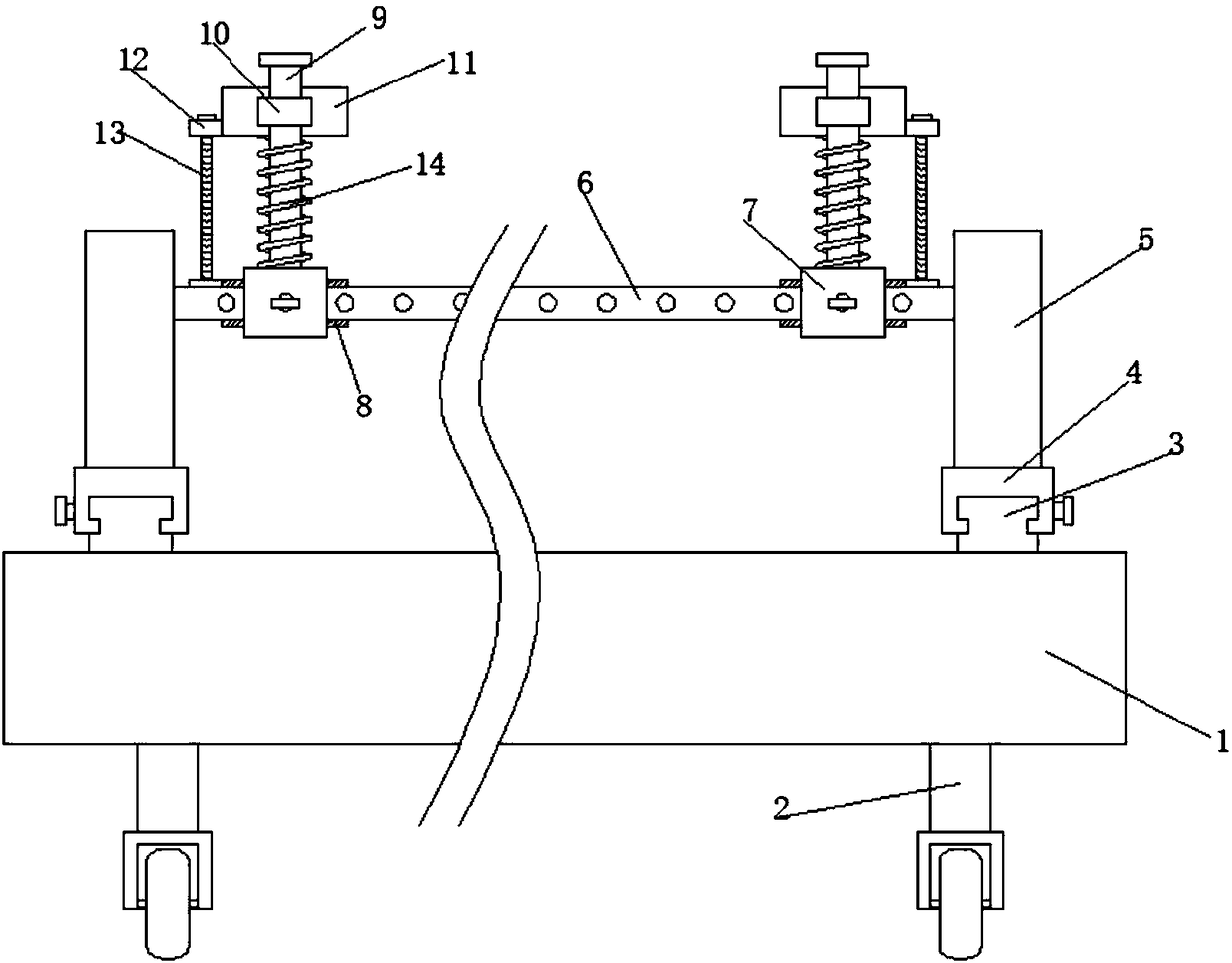

Drying rack used for bamboo panel processing

InactiveCN108180720AAvoid curling upSuitable for dryingDrying gas arrangementsDrying solid materialsEngineering

The invention discloses a drying rack used for bamboo panel processing. The drying rack used for bamboo panel processing comprises a fixed bottom frame, wherein the fixed bottom frame is of a rectangular frame structure, four supporting sill pillars are arranged at the bottom of the fixed bottom frame, a first movement guide rod is arranged on the two groups of side walls of the fixed bottom framealong length direction respectively, the two groups of first movement guide rods are the same in structure, each first movement guide rod is clamped and connected with two groups of first sliding blocks, upright posts are respectively and vertically arranged above the four groups of first sliding blocks, two groups of second movement guide rods are connected among the four groups of upright posts, the two groups of second movement guide rods are the same in structure, the two groups of second movement guide rods and the two groups of first movement guide rods are orthogonal in space, and a second sliding block sheathes on each of the second movement guide rods. The drying rack disclosed by the invention has the advantages that four corners of a bamboo panel are clamped and fixed, and thenthe bamboo panel is dried, so that the phenomenon that the four corners of the bamboo panel are rolled up is effectively avoided in a bamboo panel drying process, and the drying rack device is applicable to drying of bamboo panels of different sizes.

Owner:ZHEJIANG LIANGYUE BOARD IND CO LTD

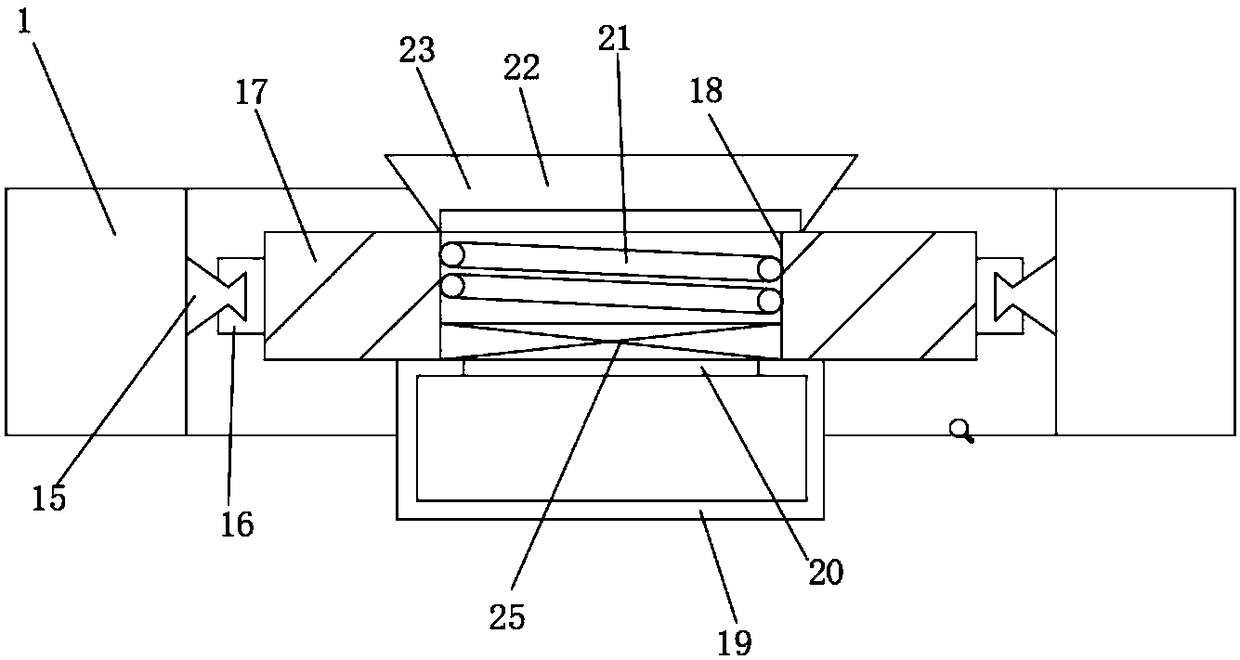

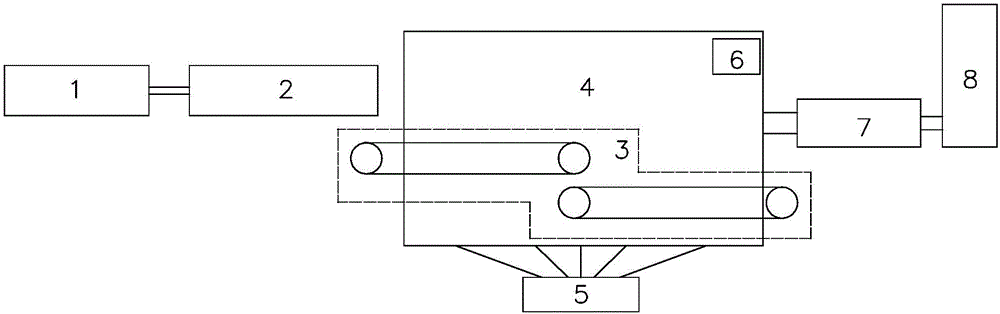

Belt-type sludge drying device

PendingCN106007338AFully dryIncrease drynessSludge treatment by de-watering/drying/thickeningConveyorsElectric machineryProcess engineering

The invention provides a belt-type sludge drying device. The belt-type sludge drying device comprises a banded extruder, a spiral distributing device, a conveyer, a drying bin and a drying machine; an input end of the banded extruder is used for introducing the sludge, an output terminal of the banded extruder is connected with the input terminal of the spiral distributing device, the conveyer comprises an upper layer conveying unit and a lower layer conveying unit, the upper layer conveying unit comprises a first driving motor, a first active sprocket wheel, a first driven sprocket and a first conveyor belt, the conveyer of the belt-type sludge drying device is composed of the upper layer conveying unit and the lower layer conveying unit, the dehydrated sludge is in the drying bin, temperature in the drying bin is increased to a set value by the dried gas, the noodle-shaped sludge flows from the upper layer conveying unit to the lower layer conveying unit, moisture in the sludge is taken away by hot air, and a purpose of full drying is achieved. The belt-type sludge drying device can fully take moisture in the sludge away, and the drying degree is high.

Owner:CHANGZHOU JINLING DRYING EQUIP

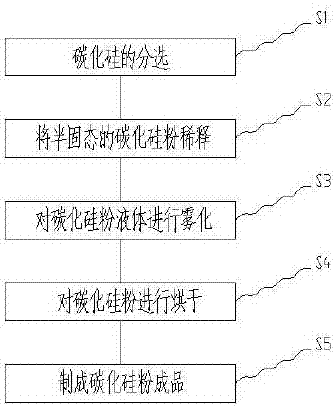

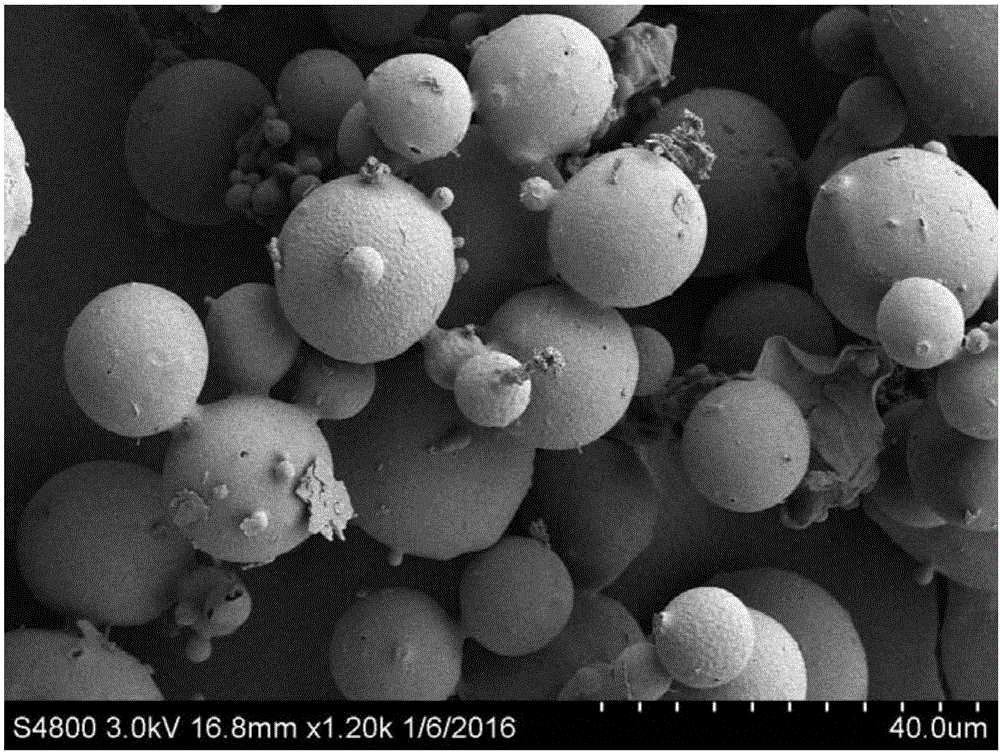

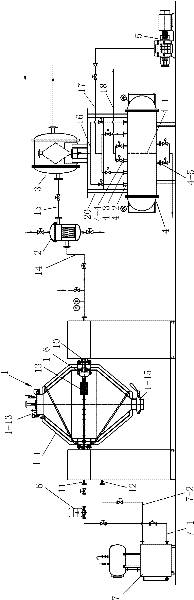

Production process of silicon carbide micropowder

InactiveCN106890724AEasy to separateImprove drying efficiencyWet separationUltrasonic vibrationDrying time

The invention discloses a production process of silicon carbide micropowder, comprising the following steps: S1 sorting silicon carbide, S2 diluting semi-solid silicon carbide powder, S3 atomizing silicon carbide powder liquid, and S4 silicon carbide powder Drying, S5 to make finished silicon carbide powder, the vibration frequency of the ultrasonic vibrating screen is 50HZ, and the collector is a glass container. The silicon carbide is sorted by a hydraulic grading conical cylinder, which has a fast screening speed and can quickly separate the ultrafine silicon carbide. The atomization duration of the silicon carbide micropowder production process is 5 seconds, and the drying The time is 10 seconds. Since the silicon carbide is atomized, the contact area between the silicon carbide and the hot air increases to enhance the drying efficiency of the silicon carbide. The invention is suitable for batch screening and drying of silicon carbide, has good practicability and is suitable for further popularization.

Owner:郑州睿科生化科技有限公司

Black garlic oligopeptide extraction method

The invention discloses a black garlic oligopeptide extraction method. The method includes steps: taking fermented black garlic as a main material, performing mincing, water distribution, addition of enzymes for enzymolysis, enzyme deactivation, centrifuging, microfiltration, nanofiltration membrane separation, concentration and compounding, and subjecting obtained filtrate to spray drying to obtain a black garlic oligopeptide product. The black garlic oligopeptide extraction method is short in production cycle, low in cost and free of environment pollution, and the obtained product is high in safety and purity and can be widely applied to fields of healthcare products, food, medicines and the like.

Owner:DELISI GROUP

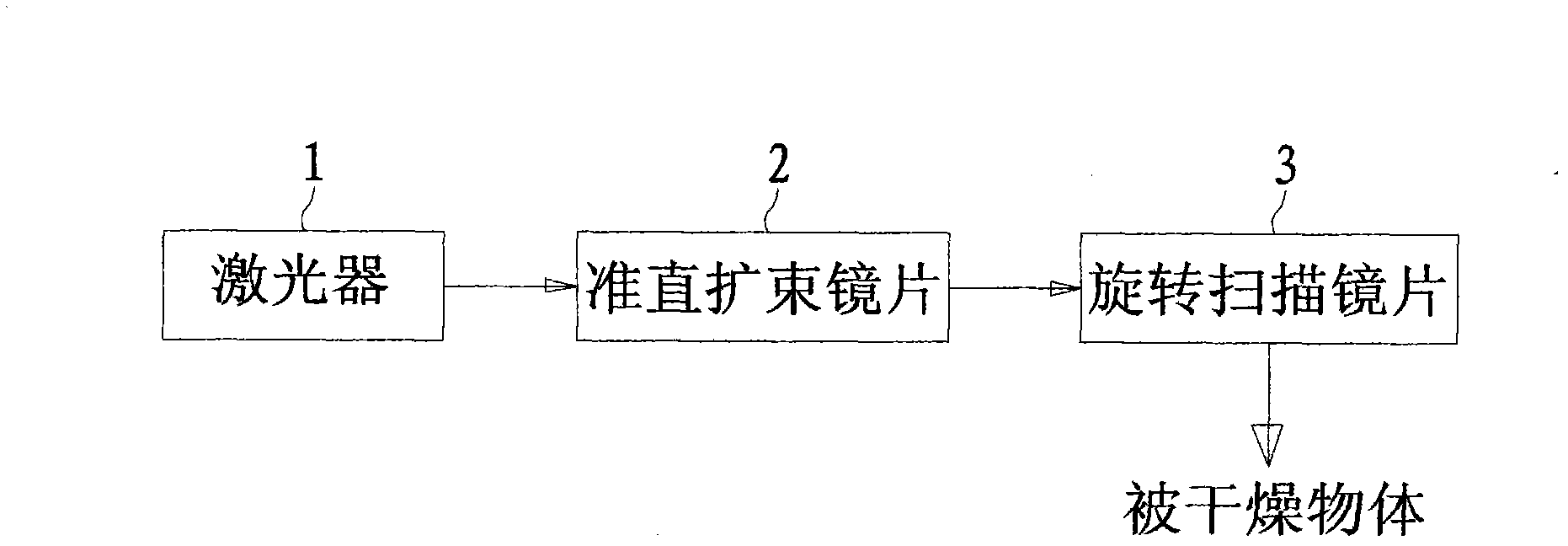

Metal sealed radio frequency carbon dioxide laser dryer

InactiveCN102759267AReduce processing timeSurface dry thoroughlyHeating arrangementRadio frequencyPhysics

The invention relates to a dryer, in particular to a metal sealed radio frequency carbon dioxide laser dryer. The dryer comprises a metal carbon dioxide radio frequency laser, a collimating beam expander and a rotary scanning lens, wherein the collimating beam expander is connected to an outlet end of the metal carbon dioxide radio frequency laser; the rotary scanning lens is arranged at an outlet end of the collimating beam expander; the wavelength of laser produced by the metal carbon dioxide radio frequency laser is 10.6 microns. The metal sealed radio frequency carbon dioxide laser dryer is particularly suitable for drying treatment of a surface; and since high energy of the laser is used, the treatment time can be shortened, the surface drying is also complete, the accuracy of the equipment can be improved in some high-accuracy vacuum systems, and dehumidification treatment is not required to be performed in advance.

Owner:武汉晶石光电技术有限公司

Preparation method of polyelectrolyte drug-loaded particles

InactiveCN106214662ASimple preparation processPreparation process scale-upOrganic active ingredientsPharmaceutical non-active ingredientsPolyelectrolyteElectrostatic coating

The invention discloses a preparation method of polyelectrolyte drug-loaded particles. The method is characterized by comprising the following steps: by using a sodium alginate solution as a disperse phase, Span 85 and Tween 85 as mixed emulsifiers and liquid paraffin as a continuous phase, carrying out homogenizing emulsifying, crosslinking curing, drug loading and electrostatic coating to obtain the polyelectrolyte drug-loaded particles. The preparation method has the advantages of simple preparation technique, low cost and low facility requests, and is suitable for mass preparation. The drug-loaded particles have the advantages of uniform size, smooth surface, high drug loading amount, high coating rate and stable performance, and are suitable for drying and vacuum packaging preservation.

Owner:ANHUI UNIVERSITY

Biconical rotary vacuum drying system

ActiveCN102168909BEvenly distributedGuaranteed uniformityDrying solid materials without heatDrying machines with non-progressive movementsVapor–liquid separatorHeat conducting

The invention relates to a biconical rotary vacuum drying system, which comprises a biconical rotary vacuum drying main machine, a condenser, a gas-liquid separator, a vacuum pump, an oil pump, a hot oil tank, a vacuumizing pipe, an oil supply pipe and an oil return pipe, wherein the vacuumizing pipe extends into a cylinder body of the biconical rotary vacuum drying main machine from the inner cavity of a driving half shaft and the pipe hole of a driving shaft base; the oil supply pipe extends into an oil inlet cavity from the inner cavity of a driven half shaft and a pipe hole on a baffle; and two built-in oil supply branch pipes which are arranged horizontally on front and back sides are arranged on the middle part of a clamp sleeve of the cylinder body and are communicated with an oil inlet cavity of a driven shaft base. By the biconical rotary vacuum drying system, heat conducting oil can be distributed to integral clamp sleeve space uniformly to ensure the uniformity of clamp sleeve heating, the problem that biconical rotary vacuum drying is 'semi-hot and semi-cold' for a long term is solved, the quality of products and the work efficiency are improved, and energy is saved. In the biconical rotary vacuum drying system, solvents are recovered by a gas condenser and a liquid separator.

Owner:JIANGSU XIANFENG DRYING ENG

Thermoplastic polyurethane elastomer drying and conveying integrated device

InactiveCN108972983AKeep dryEasy transferCoatingsElectrical resistance and conductanceHeat conducting

The invention discloses a thermoplastic polyurethane elastomer drying and conveying integrated device which comprises a bracket and a spiral conveyor, wherein the vertical surface of the bracket is provided with a control panel; the interior of the control panel is fixedly connected with a circuit mainboard; the middle of the circuit mainboard is provided with a controller; one side of the horizontal surface of the bracket is fixedly connected with a motor base, and the motor base is in bolt connection with a motor; one end of the motor is connected with a revolution speed transducer. The thermoplastic polyurethane elastomer drying and conveying integrated device is reasonable in design and is quite applicable to drying and conveying thermoplastic polyurethane elastomers; by virtue of arranging a first blower and a heat conducting net, and in combination with a heater, materials from a discharge hopper can be further effectively dried; by virtue of arranging a second blower, air flow in the spiral conveyor can be increased so as to dry products; by virtue of arranging helical blades and a rotating shaft, and in combination with resistance wires, the product drying area can be increased, the drying degree can be effectively improved, and the thermoplastic polyurethane elastomer drying and conveying integrated deiced is suitable for extensive promotion.

Owner:江苏绿艳高分子材料有限公司

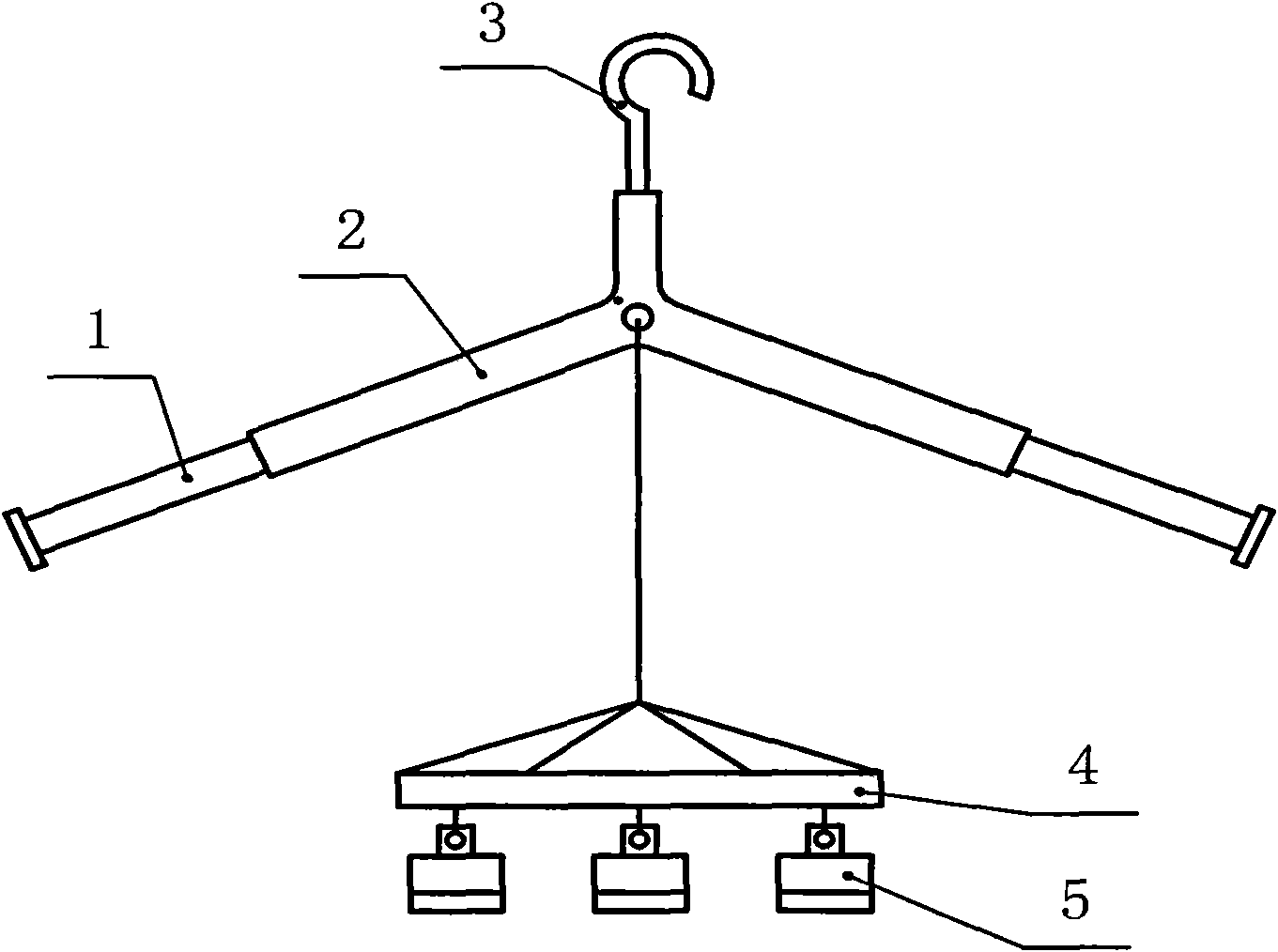

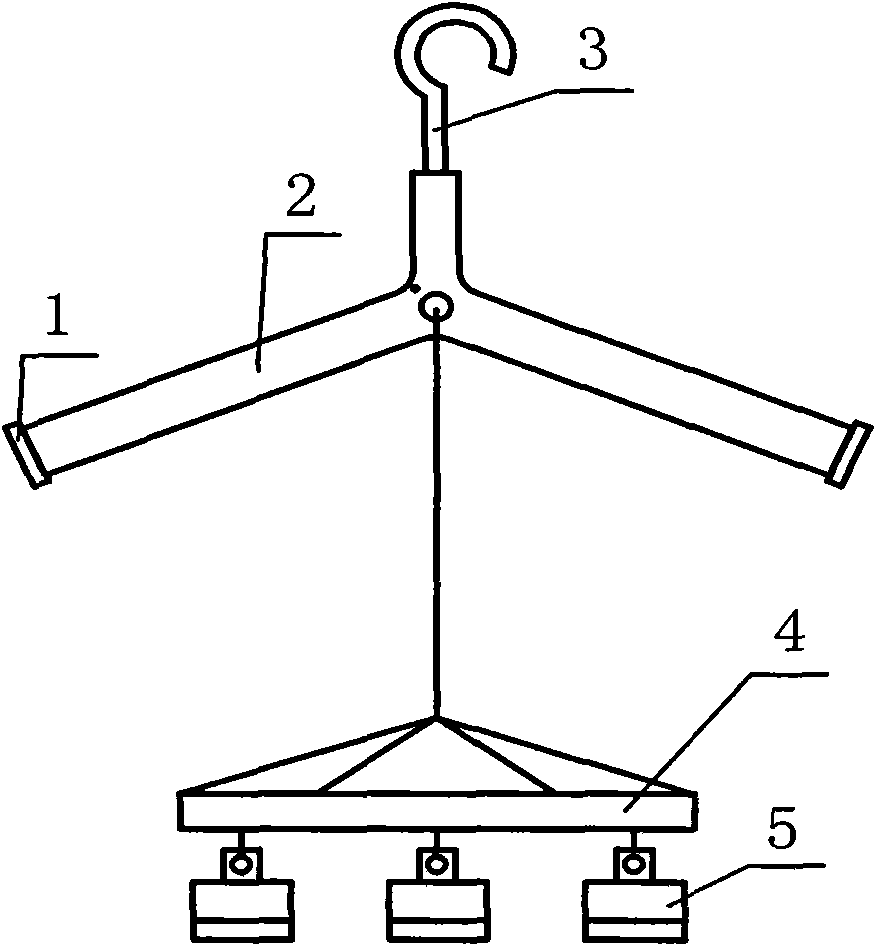

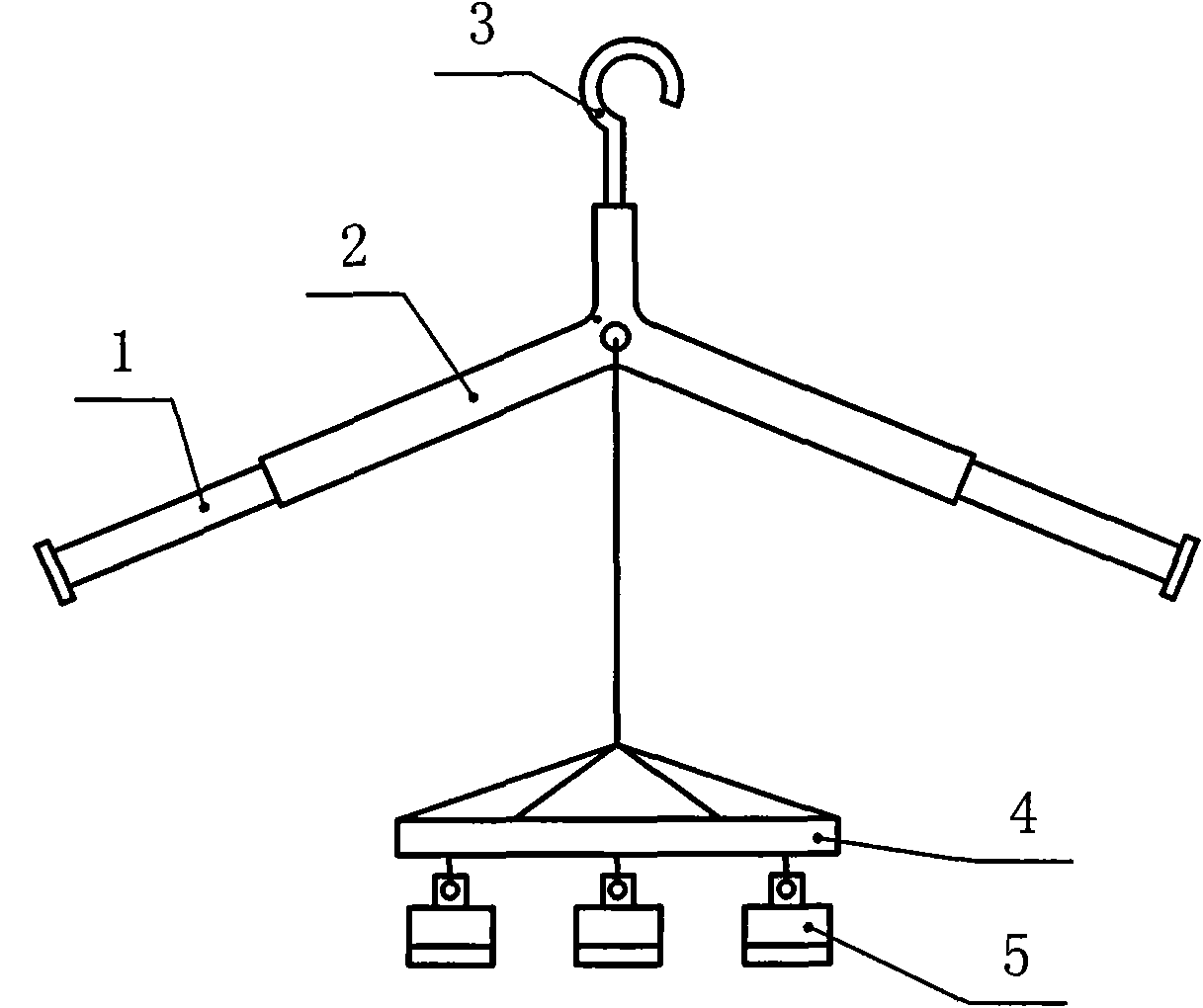

Multifunctional drawing antenna type clotheshorse

InactiveCN101991340ASuitable for dryingReduce volumeApparel holdersEconomic benefitsMechanical engineering

Owner:刘海松

Fly Ash Dryer

ActiveCN105157377BSolve pollutionSolving Disposal ProblemsDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringEconomic benefits

The invention discloses a fly ash drying machine. The fly ash drying machine comprises a drying kiln which is arranged in an inclined mode. The high end of the drying kiln is a feed end, and the low end of the drying kiln is a discharge end. A riding wheel device is arranged on the portion, close to the feed end, on the drying kiln. A riding wheel blocking device is arranged on the portion, close to the discharge end, on the drying kiln. A transmission device is arranged in the middle of the drying kiln. A heating device is connected to the feed end of the drying kiln. A discharge device is arranged at the discharge end of the drying kiln. The discharge device is connected with a cyclone separation device which is connected with an induced draught fan. Unique design is adopted for the fly ash drying machine according to the characteristics of fly ash, and the pollution and treatment problem of fly ash is solved; meanwhile, waste fly ash is turned into wealth, and economic benefits are increased.

Owner:陈宇捷

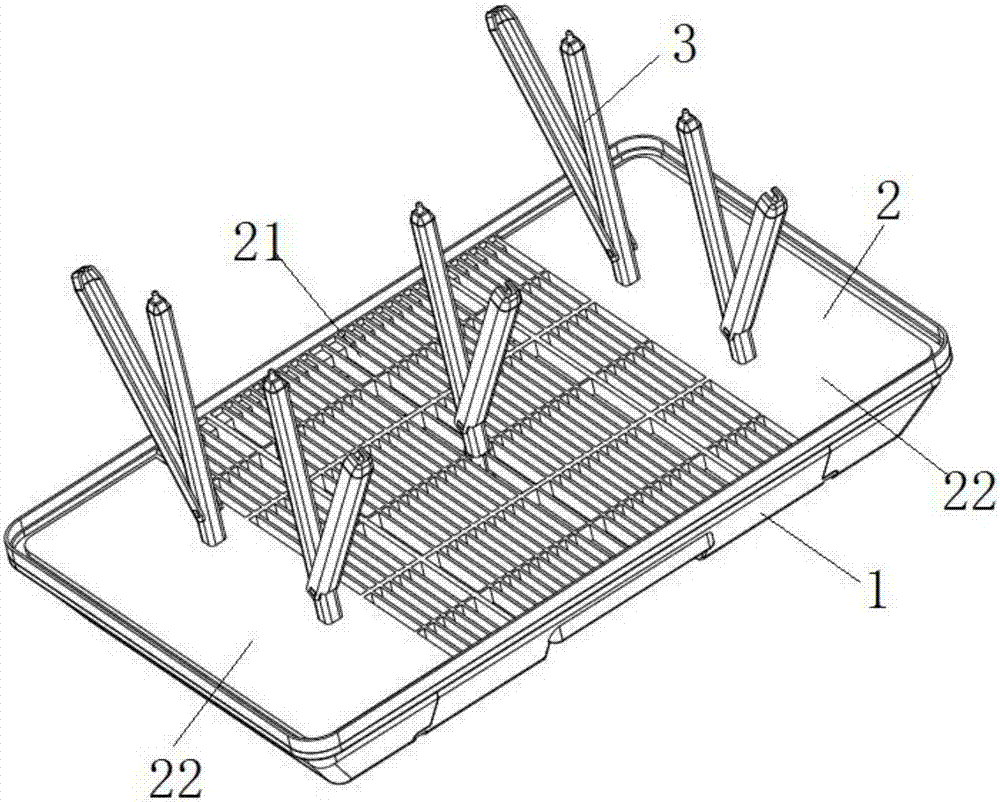

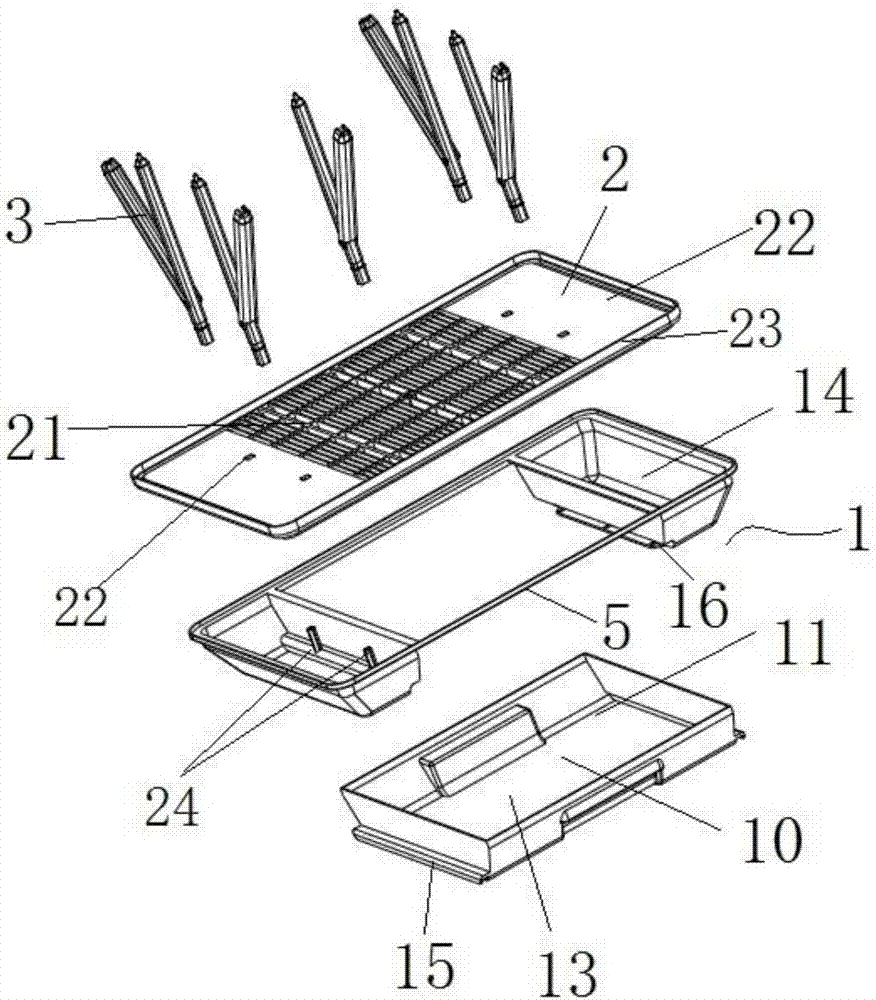

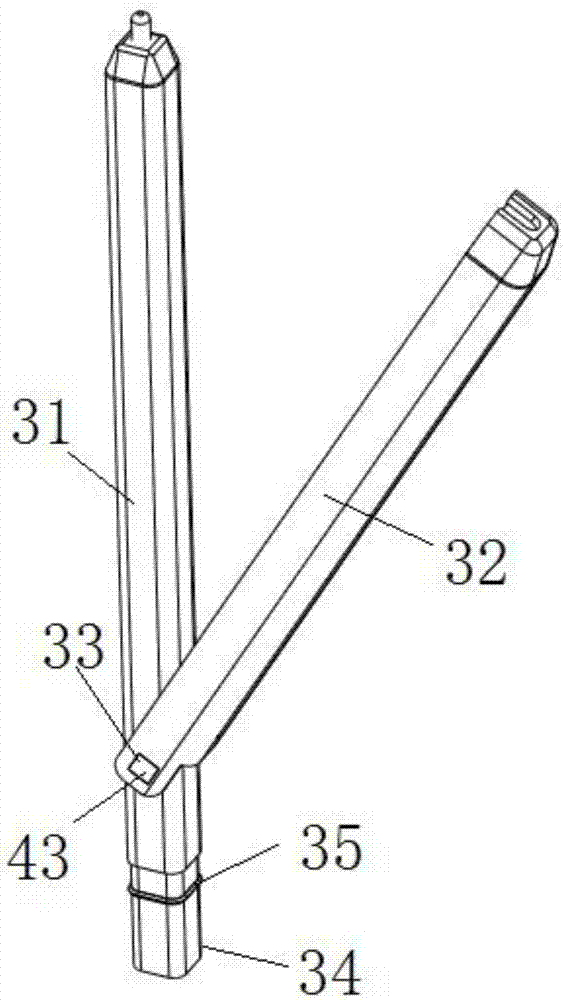

Drying rack for bag articles

InactiveCN106918207AEasy to useEasy to dryDrying chambers/containersDrying solid materialsEngineeringWater leakage

The invention provides a drying rack for bag articles. The drying rack comprises a chassis, a drain cap and at least one bracket, wherein the chassis is provided with a water containing space and an upper opening communicated with the water containing space; the drain cap is installed at the upper part of the upper opening and is provided with a plurality of water leakage holes; one end of each bracket is installed on the drain cap by an installation structure, and the other end of the bracket extends outwards and is used for supporting the article to be dried. When the drying rack for the bag articles is used for drying the bag articles, a cleaned bag can directly sleeve the bracket in a way of enabling an opening of the bag to be arranged downwards, the bracket extends into the interior of the bag so as to be used for supporting the bag, and the water in the bag can directly flow down into the drain cap and further flows into the chassis; when being used for drying the bag articles, the drying rack for the bag articles is simple to easy and convenient for drying.

Owner:崔琬婧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com