Biconical rotary vacuum drying system

A vacuum drying and vacuum pump technology, which is applied in the direction of drying solid materials, non-progressive dryers, and drying solid materials without heating, can solve problems such as inappropriate drying of lithium iron phosphate materials, affecting product purity, and affecting dryness. To achieve the effect of convenient replacement, guaranteed purity and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

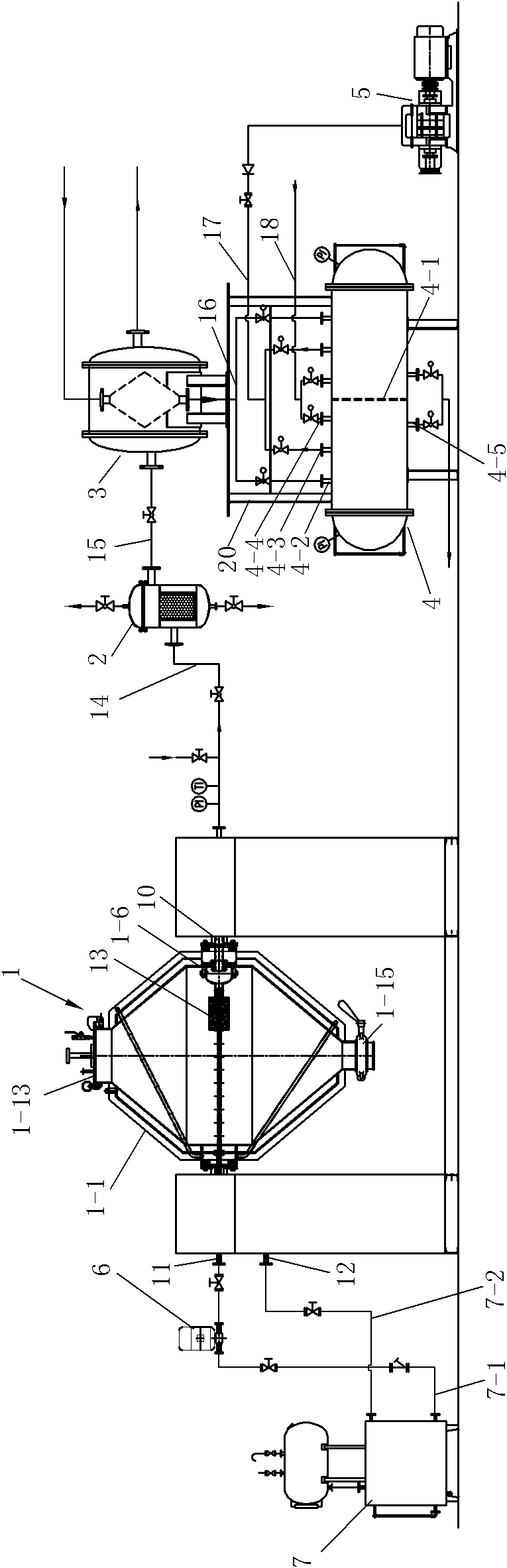

[0025] See Figure 1 to Figure 4 , this embodiment includes a double-cone rotary vacuum drying host 1, a bag filter 2, a condenser 3, a gas-liquid separator 4, a vacuum pump 5, an oil pump 6, a hot oil tank 7, a vacuum pipe 10, an oil supply pipe 11 and an oil return pipe 12.

[0026] The hot oil tank 7 is provided with a hot oil tank oil delivery pipe 7-1 and a hot oil tank oil return pipe 7-2, the hot oil tank oil delivery pipe 7-1 is connected with the oil pump 6, the oil pump 6 is connected with the oil supply pipe 11, and the hot oil tank Oil return pipe 7-2 is connected with oil return pipe 12. The hot oil tank oil delivery pipe 7-1 and the hot oil tank oil return pipe 7-2 are all provided with corresponding valves.

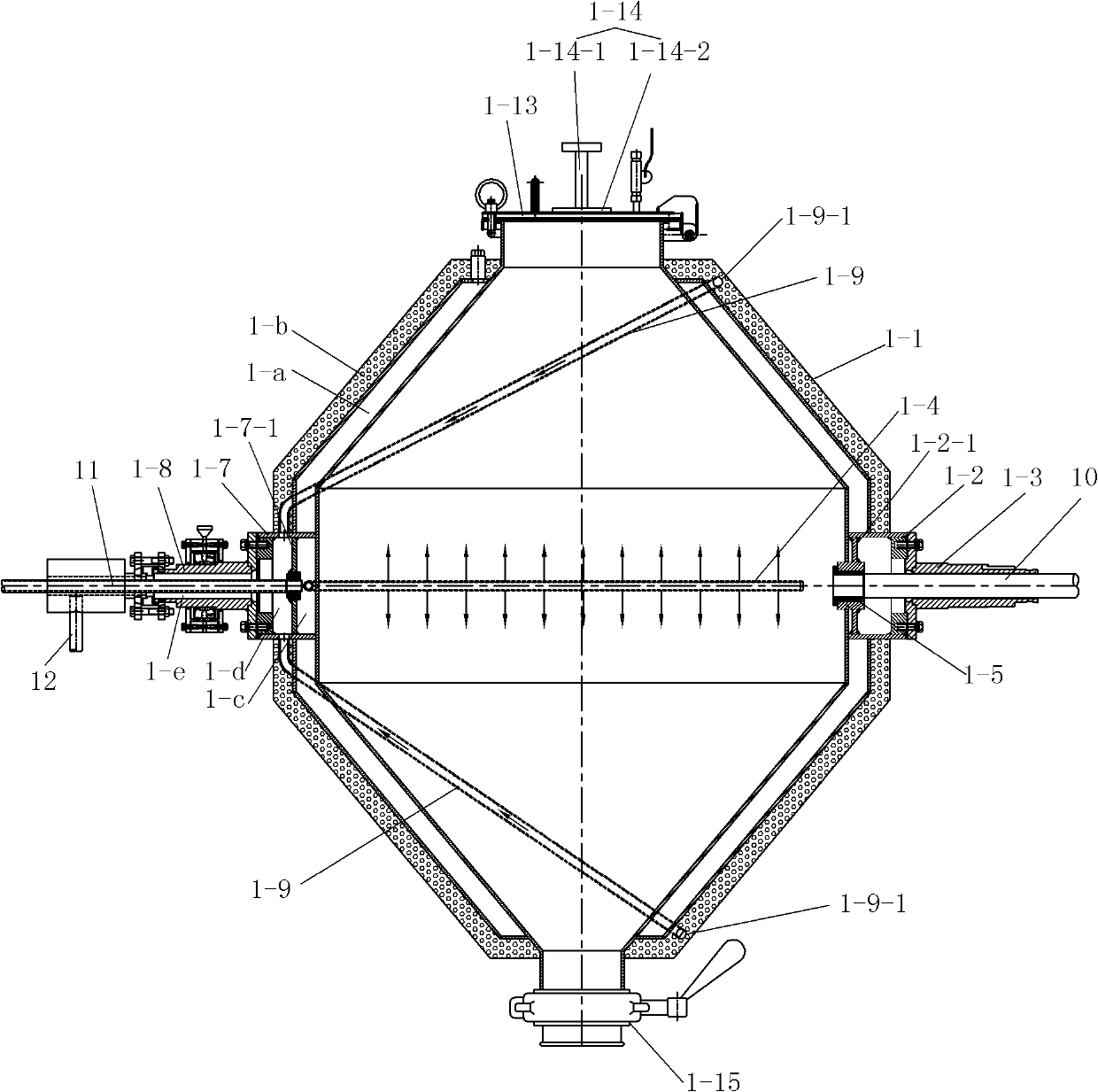

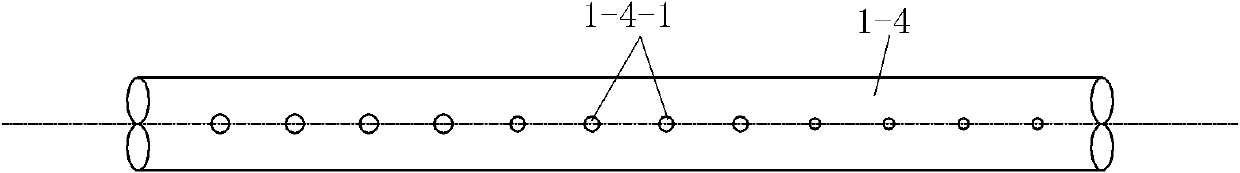

[0027] The jacketed cylinder body 1-1 of the double-cone rotary vacuum drying main engine 1 is provided with a feed pipe, a discharge pipe, a driving shaft seat installation hole and a driven shaft seat installation hole, and a feed pipe is provided with ...

Embodiment 2

[0036] On the basis of Embodiment 1, the present embodiment is also provided with a transfer oil tank 8 and a cold oil tank 9. The transfer oil tank 8 is an insulated oil tank. The transfer oil tank 8 is provided with a transfer oil tank oil delivery pipe 8-1 and a transfer oil tank return pipe 8-2. 9 is provided with a cold oil tank oil delivery pipe 9-1 and a cold oil tank return pipe 9-2, the transfer oil tank oil delivery pipe 8-1 is connected with the hot oil tank 7, the cold oil tank oil delivery pipe 9-1 is connected with the hot oil tank oil delivery pipe 7-1, and the transfer oil tank return oil pipe 8-2 and the oil return pipe 9-2 of the cold oil tank are connected with the oil return pipe 12. Each has a corresponding valve.

[0037] When working, the oil pump 6 is turned on, the valve K1 on the oil delivery pipe 8-1 of the transfer oil tank is normally open, the valve K2 on the return oil pipe 7-2 of the hot oil tank, the valve K 3 on the oil delivery pipe 7-1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com