Temperature and humidity integration control drying room

A technology of temperature and humidity control and temperature and humidity, which is applied in drying, drying machines, drying solid materials, etc. Inhomogeneity and other problems, to achieve the effect of simple manufacturing and installation, shortened drying time, and strong material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

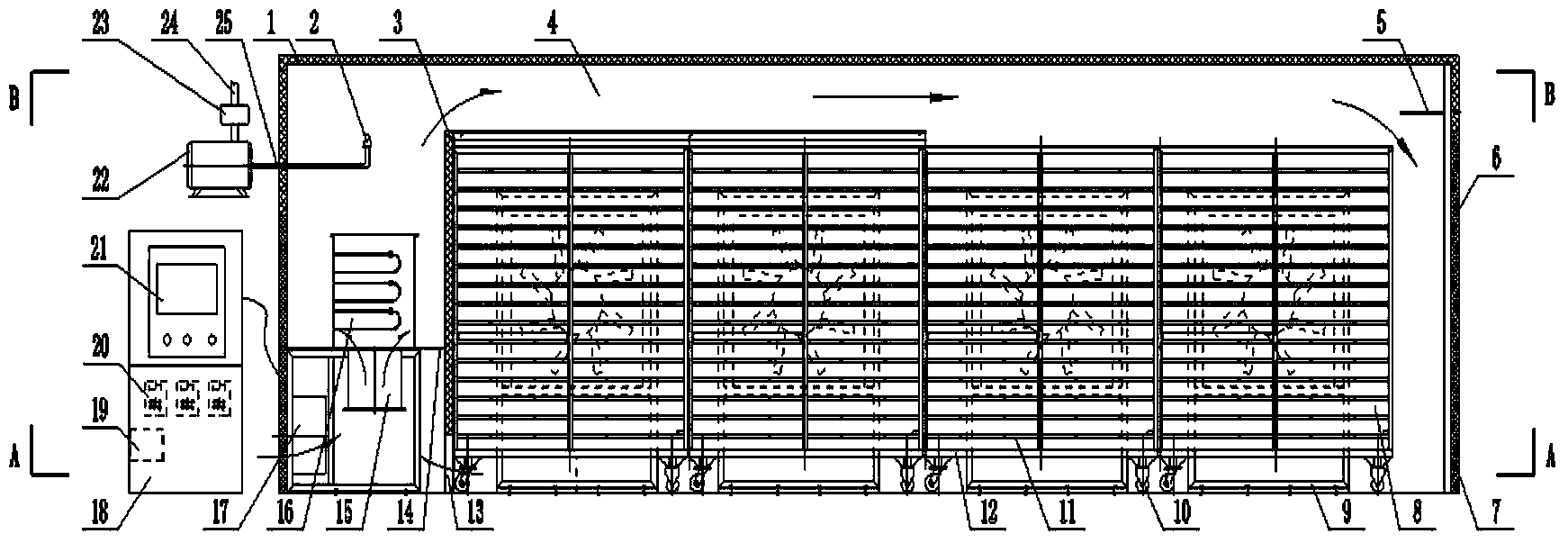

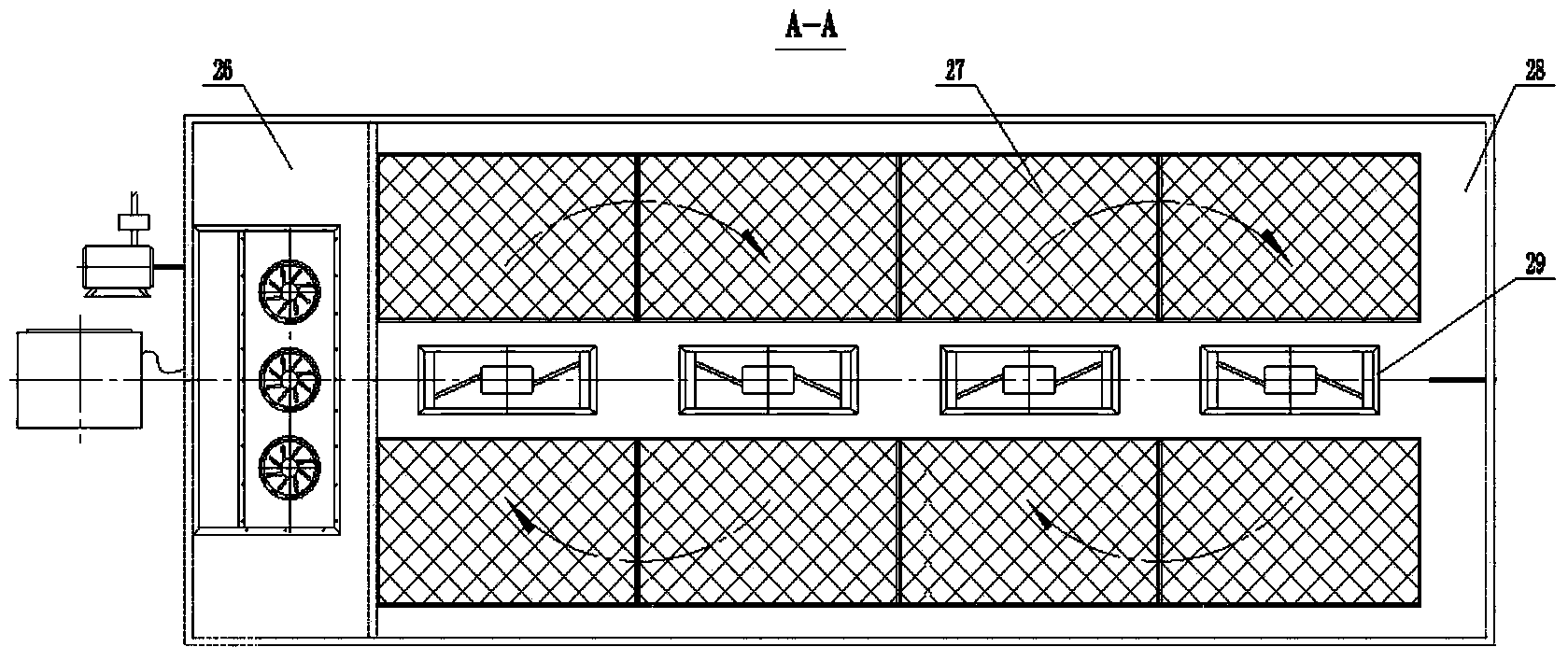

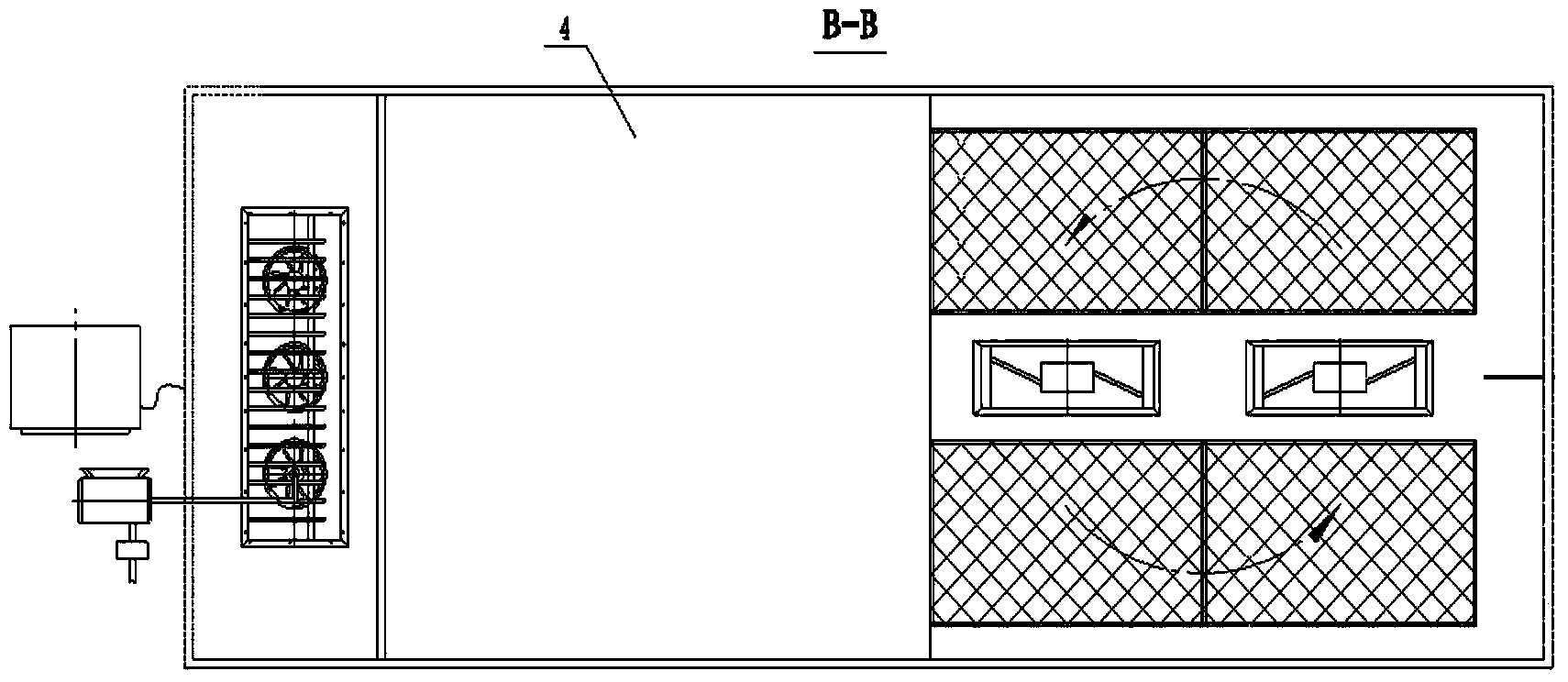

[0038] Such as figure 1 , figure 2 and image 3 As shown, a drying room with integrated temperature and humidity control includes an air circulation system, a heating and humidifying system, a material loading system, a temperature and humidity control system and a wall 1 .

[0039] A drying room with integrated temperature and humidity control can be formed by one or more parallel connections. The partition wall 3 in the wall body 1 separates the drying room with integrated temperature and humidity control into a heating room 26 on the left and a drying room 28 on the right. part space.

[0040] The air circulation system includes an air return port 13, an air outlet channel 4, a circulation fan 15 and one or more air circulation units. Wherein, the air return port 13 is located at the lower side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com