Process for preparing ciltradry gas

A technology of dry gas and process method, which is applied in the direction of separation method, chemical instrument and method, dispersion particle separation, etc., can solve the problems such as inapplicability, and achieve the effect of reducing power consumption, reducing wear and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

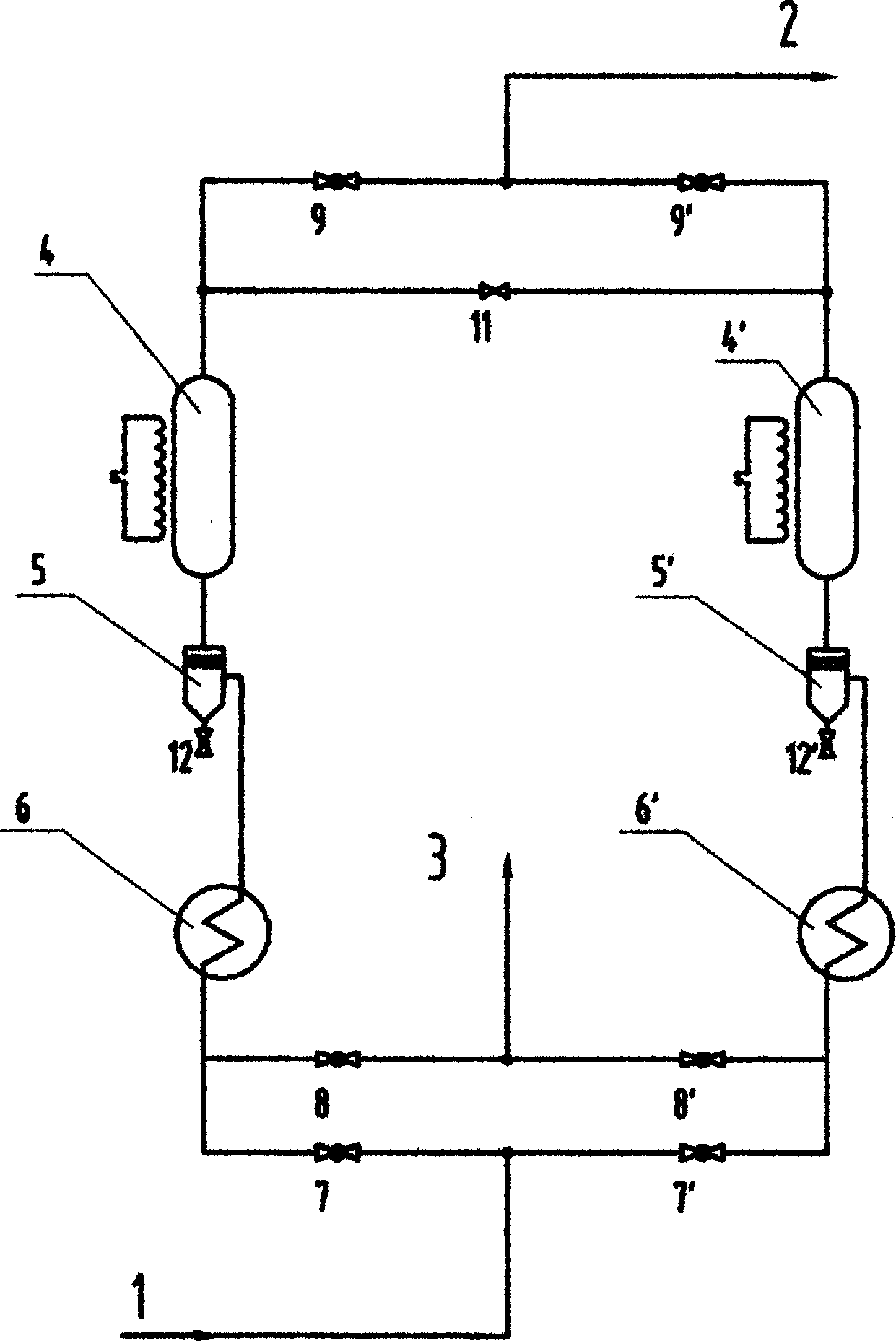

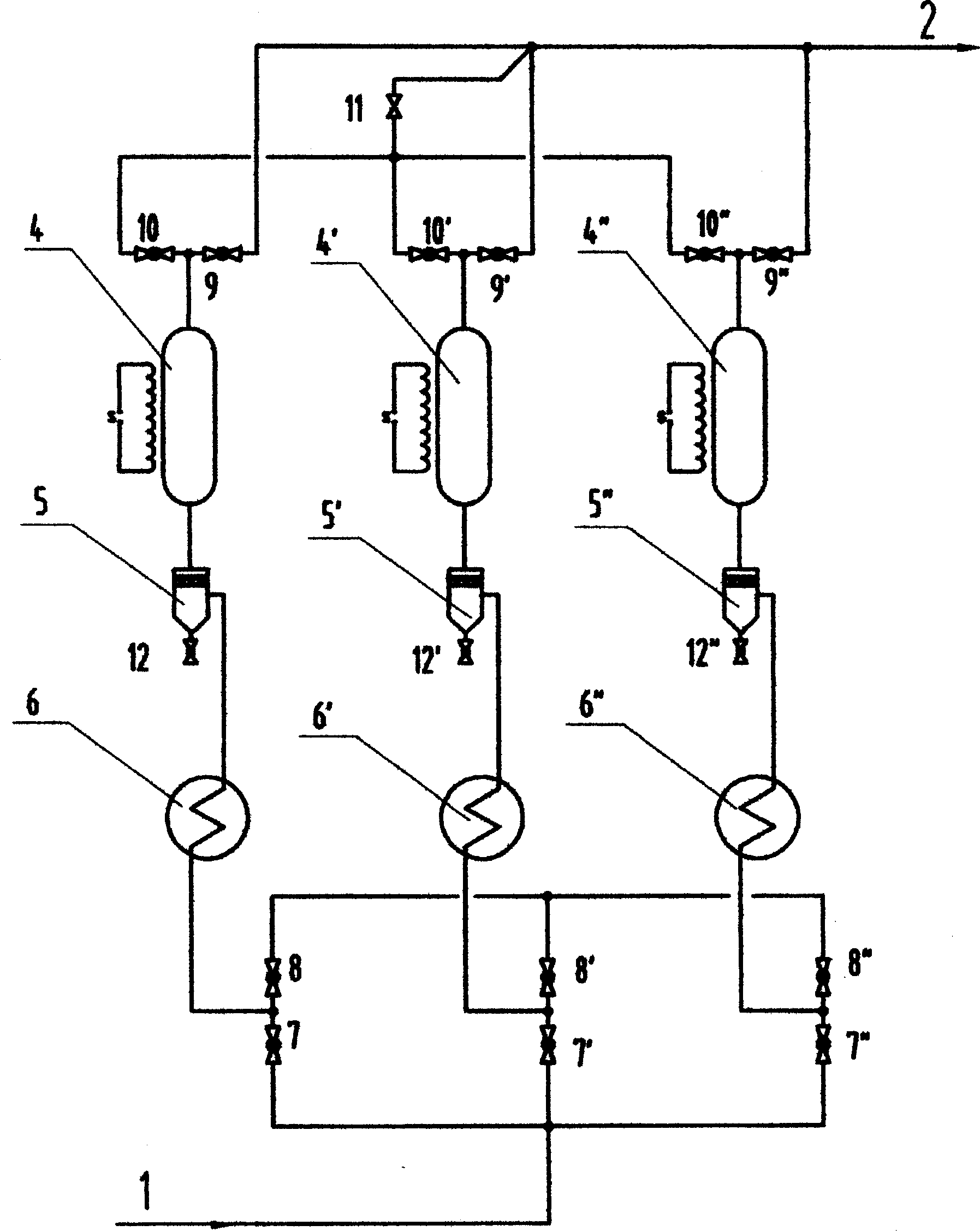

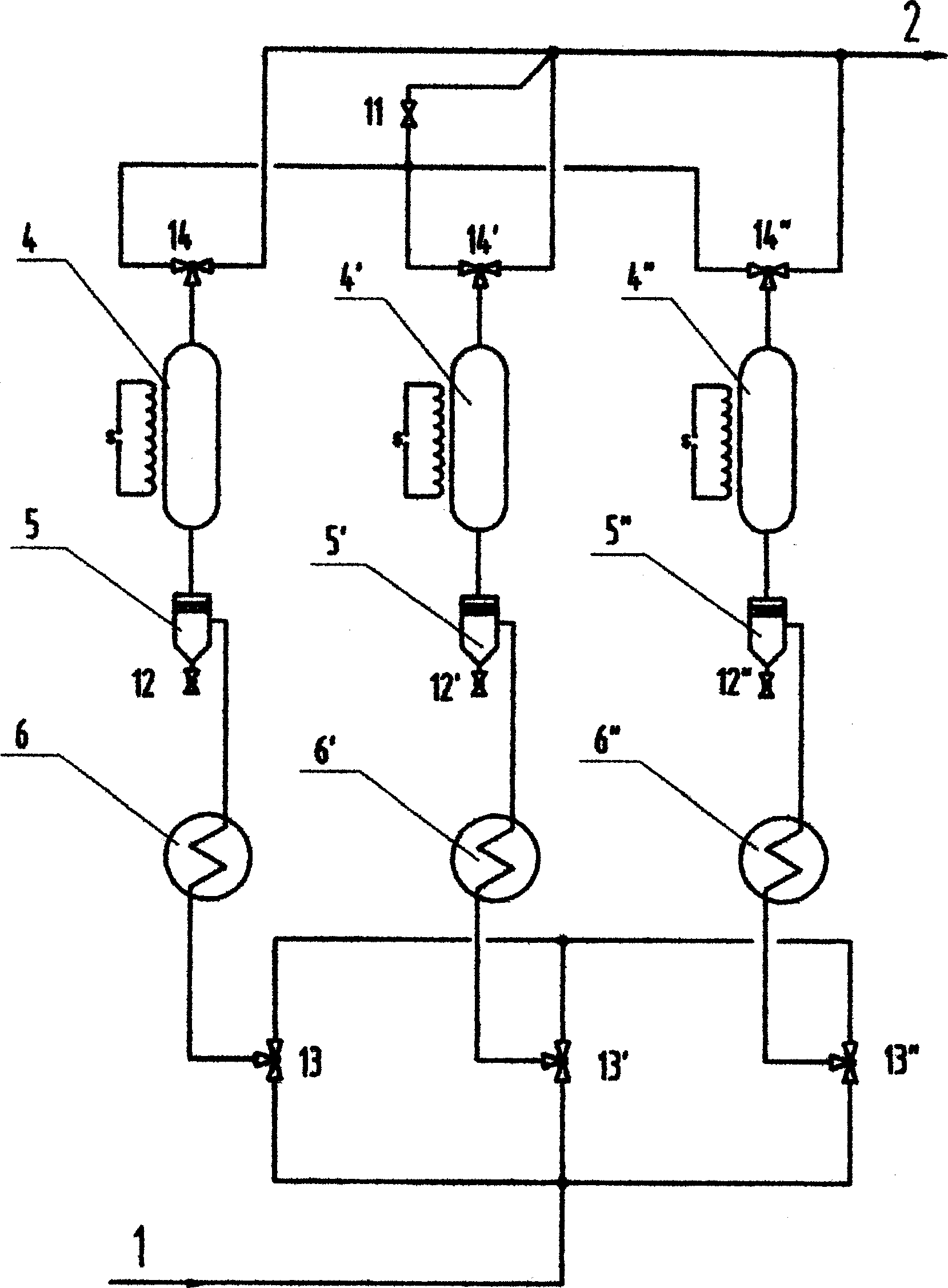

[0018] The principle of the present invention is to use the principle that molecular sieves (the types of molecular sieves are: 3A, 4A, 5A, 10x, 13x and other general types) can absorb water to absorb and eliminate the saturated or unsaturated water contained in the gas. Utilizing the characteristics of molecular sieves that can release moisture at high temperatures, heat and dehydrate it (the term is called: regeneration) and pass a certain amount of gas (called: regeneration gas) to take out the moisture, and pass through the cooler and gas-water separator , to drain the water. Whether the molecular sieve regeneration is complete determines the dew point (water content) that the product gas can reach, and the water content in the regeneration gas will seriously affect whether the molecular sieve regeneration is complete. When the product gas with a very low water content is used as the regeneration gas, the regeneration of the molecular sieve will be very thorough, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com