Pipe joint of superconducting pipe

A pipe joint and superconducting technology, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of heat loss, large energy consumption, energy waste, etc., and achieve stable pressure balance, high sealing performance, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

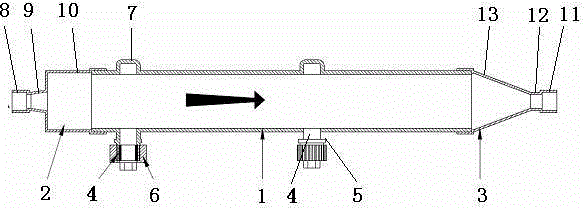

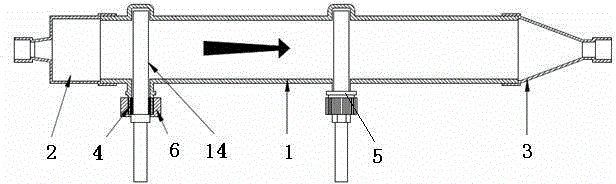

[0015] Embodiment: A superconducting pipe joint, including a fluid pipe section 1, a water inlet pipe joint 2, a return water pipe joint 3, a sealing sleeve 4, a positioning ring 5 and a silicone sealing ring 6, and the side wall of the fluid pipe section 1 is provided along the axis. There are two sealing sleeves 4, the sealing sleeves are connected with the fluid pipe section, and the inner wall of the fluid pipe section 1 is provided with a top groove 7 corresponding to the sealing sleeve 4, and the top groove 7 and the sealing sleeve 4 are on the same center line to facilitate the positioning of the superconducting tube. The sealing sleeve 4 communicates with the fluid pipe section 1, the sealing sleeve 4 is fixed with a positioning ring 5, the outer wall of the sealing sleeve 4 is provided with a threaded section, and the silicone sealing ring 6 is threaded with the sealing sleeve 4, so as to facilitate sealing and fixing the superconducting tube. To prevent water leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com