A method for controlling smoke when CDQ is loaded

A technology of coke CDQ and red coke, applied in coke cooling, coke oven, petroleum industry, etc., can solve the problems of pre-storage chamber pressure deviation, pre-storage chamber pressure rise, unorganized discharge, etc., to avoid environmental pollution incidents, Maintain pressure balance and stability, and eliminate the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

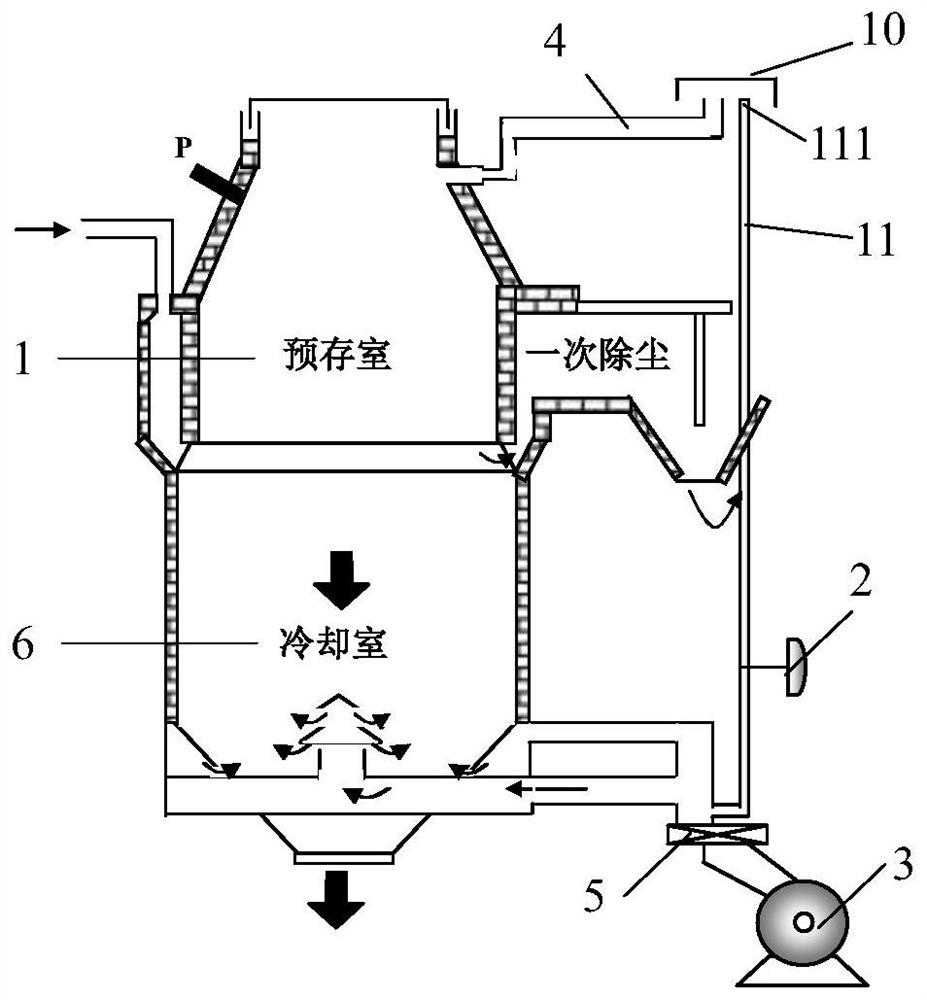

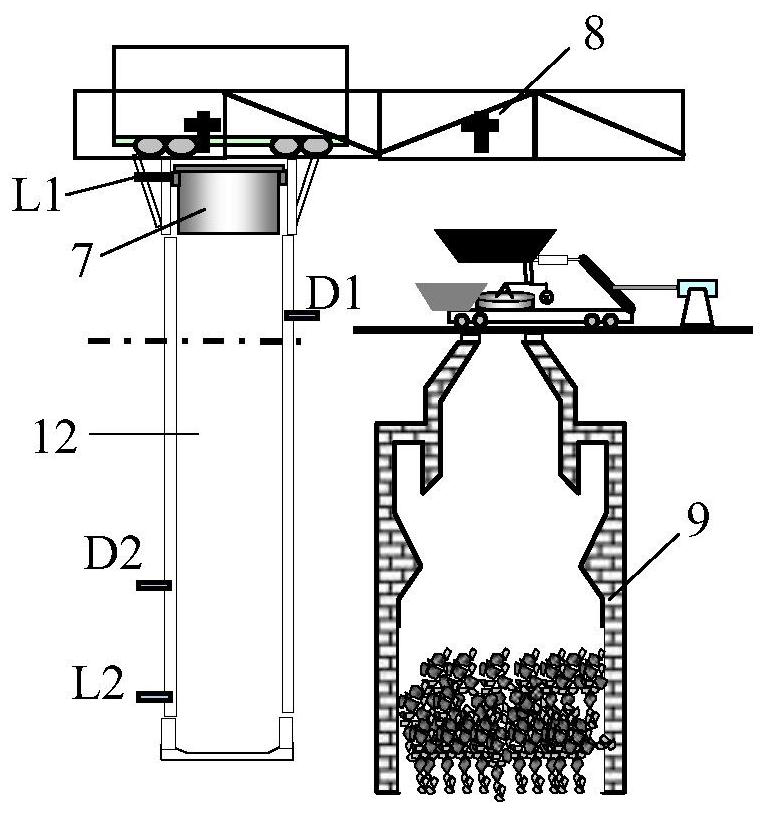

[0037] see figure 1 , figure 2 , a method for controlling smoke when CDQ is loaded into the present invention, comprising:

[0038] 1)Prestorage chamber pressure setting

[0039] Optimize the pre-storage chamber 1 pressure P set value, adjust from 0 to 0 ~ -30Pa; make the pre-storage chamber pressure P in the controlled negative pressure range;

[0040] 2) Corresponding to the adjustment of the pressure setting value, the opening of the pre-storage chamber pressure regulating valve 2 is increased by 15-35% on the basis of the original opening and locked to ensure that the pressure of the pre-storage chamber meets the preset prerequisites for coke loading. After the coking is completed, the "close" signal of the furnace cover is sent out, the pressure regulating valve of the pre-storage chamber is automatically unlocked, and the increased opening amount is automatically deducted;

[0041] 3) Establish interlocking relationship between pre-storage chamber pressure detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com