Bentonite grouting method for construction of shield tunnel

A technology of shield tunneling and bentonite slurry, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of destroying the stability of interlayer soil, increasing the operation risk of existing lines, and increasing the settlement of existing operating lines, etc., to achieve Strong economy and operability, good economy and applicability, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

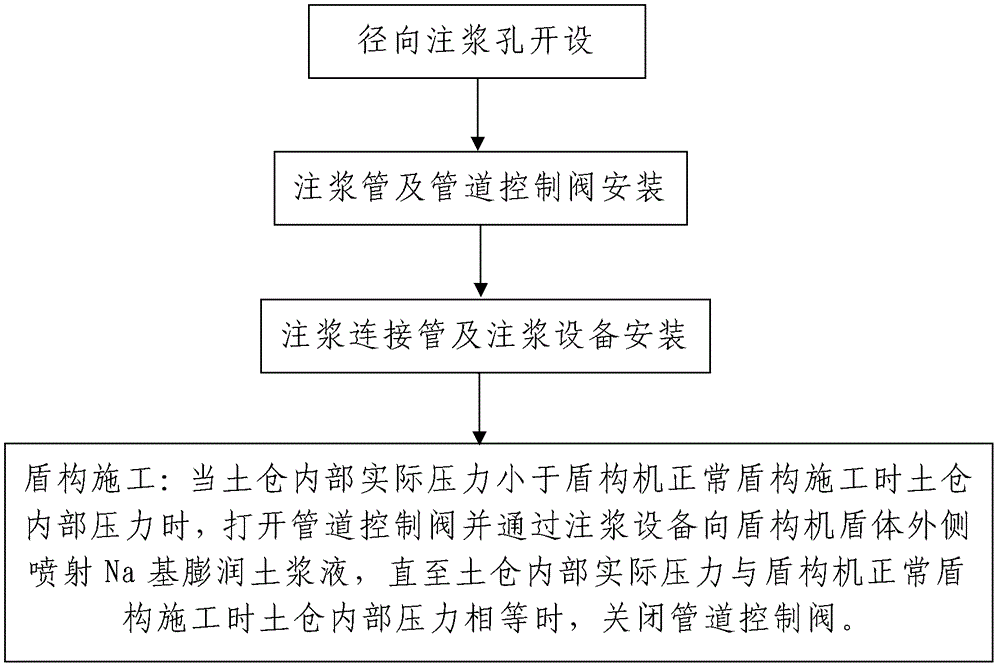

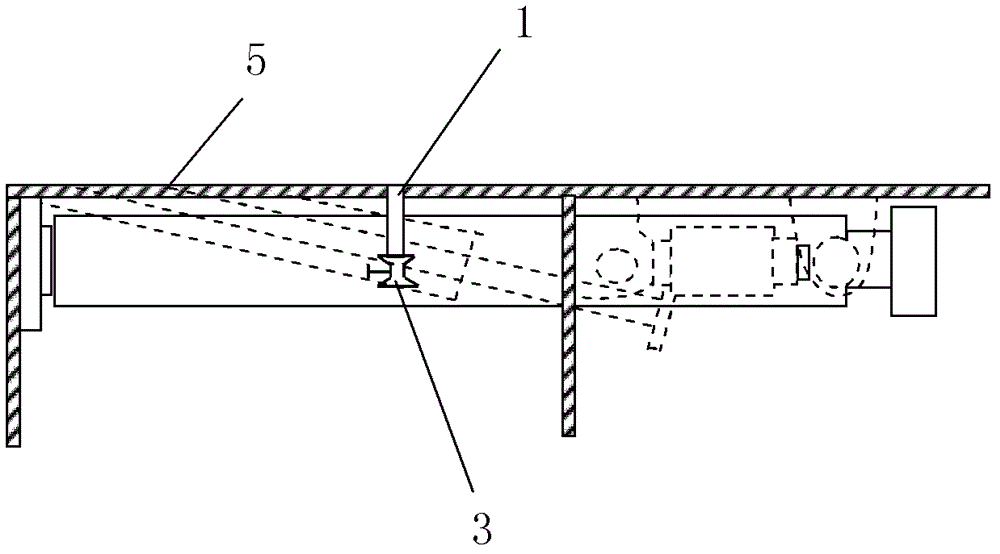

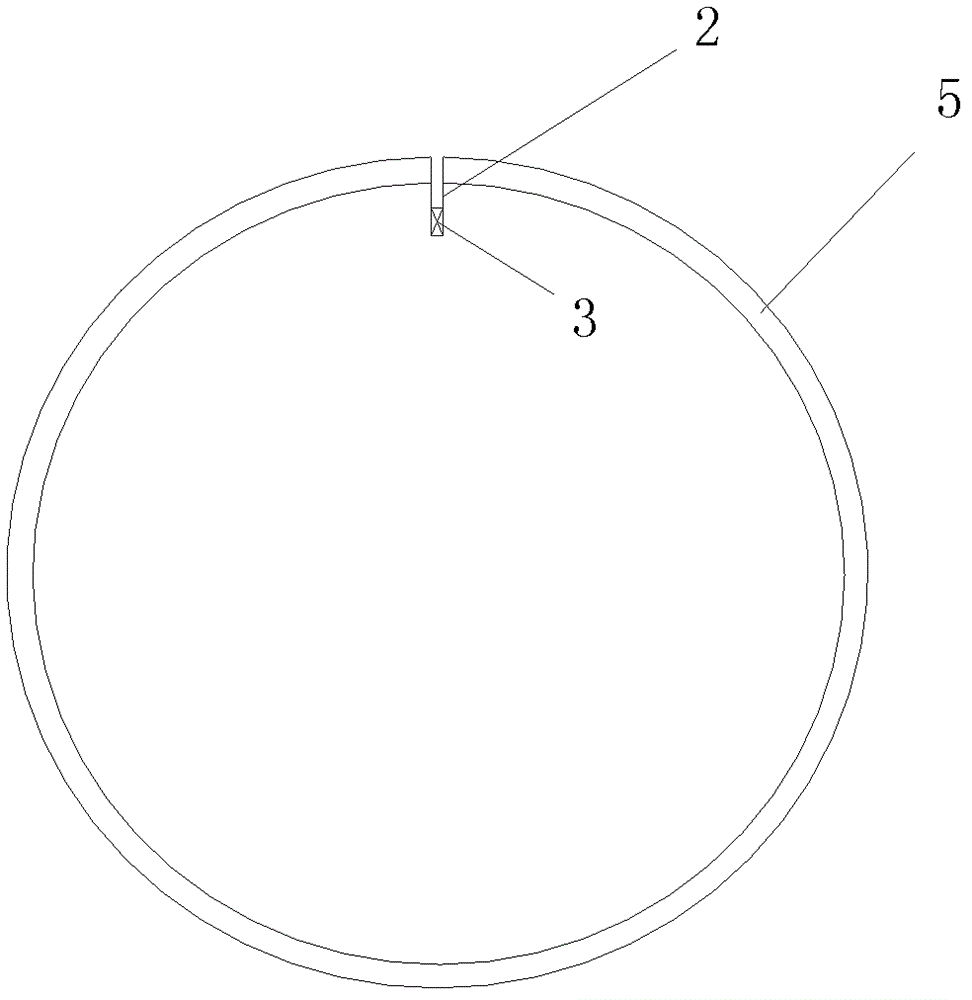

[0035] like figure 1 A bentonite grouting method for shield tunnel construction is shown, and the shield tunnel to be constructed is a tunnel section passing through existing tunnels, buildings or structures. In this embodiment, the shield tunnel section to be constructed (i.e., the newly-built tunnel) is a tunnel section that passes through the existing subway tunnel under the shield section and intersects with the existing subway tunnel. The net distance between the subway tunnels is 1.46m, and the net distance between the left tunnel of the shield tunnel to be constructed and the existing subway tunnel is 1.23m. This small distance is currently the smallest underpass distance in China. The existing subway tunnels are mainly located in the gravel clay layer and the fully weathered granite layer; the constructed shield tunnel mainly passes through the fully weathered granite layer and the strongly weathered granite layer, and the soil between the constructed shield tunnel and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com