Metal sealed radio frequency carbon dioxide laser dryer

A carbon dioxide and metal sealing technology, used in dryers, drying, heating devices, etc., can solve the problem of huge cost of dust removal devices, and achieve the effects of thorough surface drying, reducing processing time and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

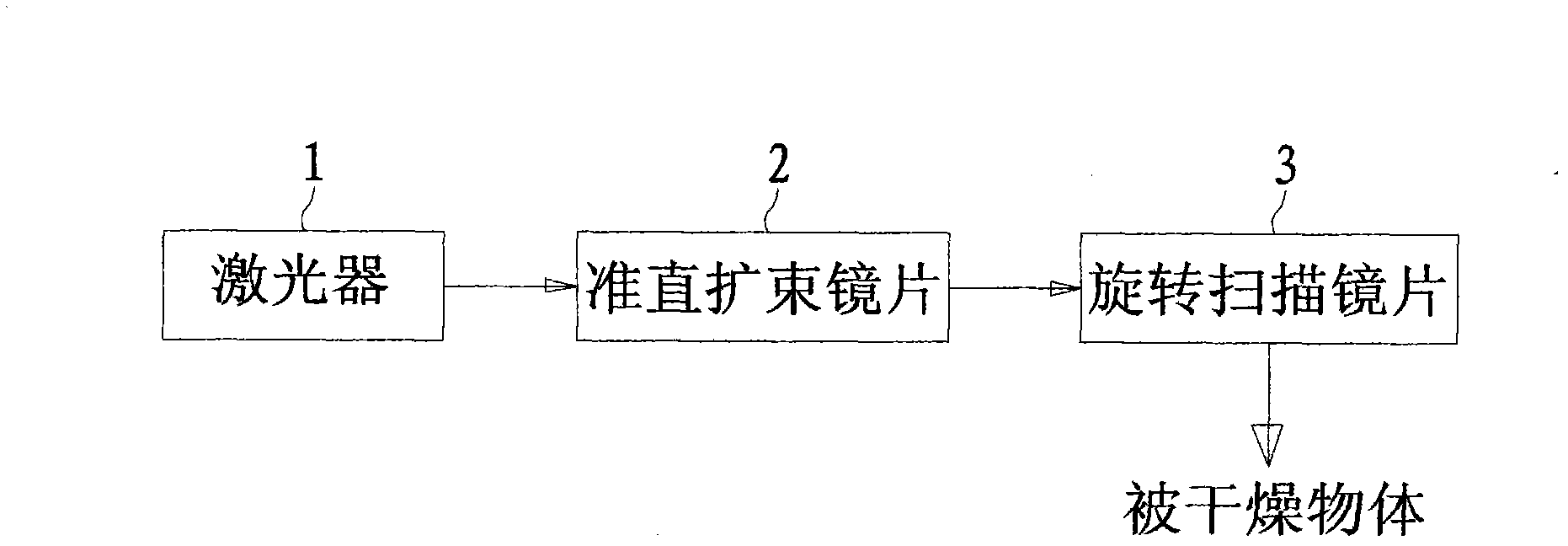

[0028] Such as figure 1 As shown, this embodiment discloses a metal-sealed radio-frequency carbon dioxide laser dryer, including a metal carbon dioxide radio-frequency laser 1, a collimating beam expander 2 connected to the outlet of the metal carbon dioxide radio-frequency laser 1, and a collimator mounted on the collimator The rotating scanning mirror 3 at the exit end of the beam expander 2, the laser wavelength generated by the metal carbon dioxide radio frequency laser 1 is 10.6 microns; of course, it also includes some other auxiliary equipment, such as simplified control system, power supply system, optical protection device, and various parts The mechanical support and the guide fan for removing water vapor, etc., are all common devices in this field.

[0029] The main components of the invention include a laser, a collimating beam expander and a rotating scanning lens. The laser mainly produces a 10.6um laser beam, which is the core part of the entire system, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com