Microwave multistage fluidized bed drying device and drying method thereof

A fluidized bed drying, fluidized bed technology, applied in the direction of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of high drying efficiency, overheating, uneven drying, etc., and achieve novel and reliable structure, easy manufacturing, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

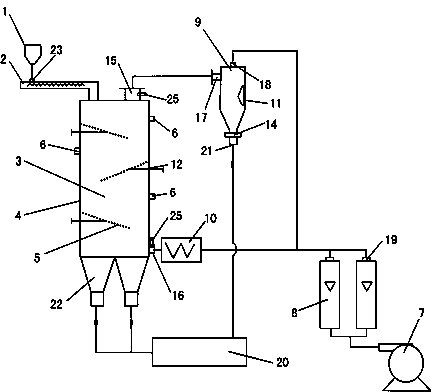

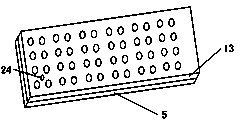

[0032] Embodiment 1, with reference to Figure 1-2 , a kind of microwave multi-stage fluidized bed drying device described in this specific embodiment, comprises silo 1, screw feeder 2 and fluidized bed drier 3, is provided with screw feeder 2 below feeder 1, and screw feeder 2 The feeder 2 communicates with the feed inlet 23 on the upper part of the fluidized bed drier 3. The fluidized bed drier 3 includes a fluidized bed body 4 and a gas distribution plate 5. On the outer wall of the fluidized bed body 4 A microwave generator 6 is provided, and three layers of gas distribution plates 5 with adjustable angles are arranged from top to bottom inside the fluidized bed body 4 .

[0033] The adjustment range of the angle between the gas distribution plate 5 and the inner wall of the fluidized bed body 4 is 0-60 degrees.

[0034] The outer wall of the fluidized bed body 4 is provided with three microwave generators 6, and the gas distribution plate 5 is located at the correspondin...

Embodiment 2

[0047] The material to be dried is lignite with an initial water content of 35%. The lignite is crushed and transported into the silo 1 with a particle size of 8mm. The raw material enters the fluidized bed dryer 3 through the screw feeder 2; the fluidized medium air passes through the gas flow The meter 8 and the gas preheater 10 enter the fluidized bed dryer 3 from the air inlet 16, and three layers of gas distribution plates 5 are laid in the fluidized bed dryer 3, and the opening rate of the gas distribution plate 5 is 4%; the microwave generator is turned on 6. The power is 2500W. The temperature of the material in the fluidized bed dryer 3 is measured by the infrared temperature measuring probe 24, and the power of the microwave generator 6 is adjusted according to the surface temperature of the raw material to keep the temperature in the fluidized bed dryer 3 at 180°C; through the gas flow meter 8 Adjust the gas velocity to about 1.6 m / s, control the residence time of th...

Embodiment 3

[0049] The material to be dried is lignite with an initial water content of 55%. The lignite is crushed and transported into the silo 1 with a particle size of 7mm. The raw material enters the fluidized bed dryer 3 through the screw feeder 2; the fluidized medium air passes through the gas flow The meter 8 and the gas preheater 10 enter the fluidized bed dryer 3 from the air inlet 16, and three layers of gas distribution plates 5 are laid in the fluidized bed dryer 3, and the opening rate of the gas distribution plate 5 is 4%; The power of the microwave generator 6 is 3000W, the temperature of the material in the fluidized bed dryer 3 is measured by the infrared temperature measuring probe 24, the power of the microwave generator 6 is adjusted according to the surface temperature of the raw material, and the temperature in the fluidized bed dryer 3 is kept at 195°C; 8. Adjust the gas velocity to about 1.8 m / s. After controlling the material residence time for 5 minutes, adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com