Furnace bottom window structure of aluminum melting furnace with bottom agitating device

A technology of stirring device and aluminum smelting furnace, which is applied in mechanical equipment and other directions, can solve the problems of aluminum leakage in stirring window, concave deformation of steel plate, equipment damage, etc., and achieve the effect of avoiding concave deformation, slowing demagnetization and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

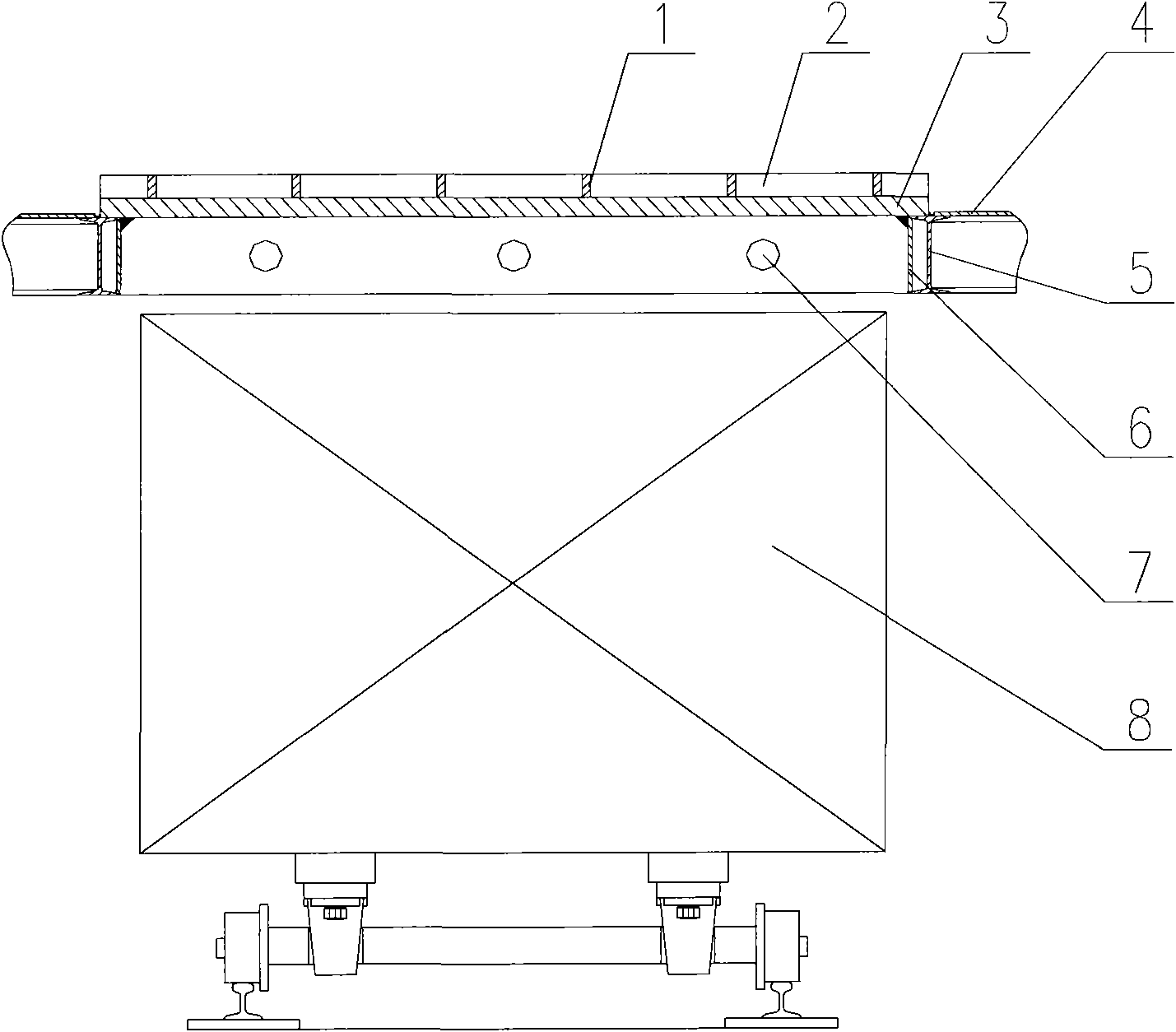

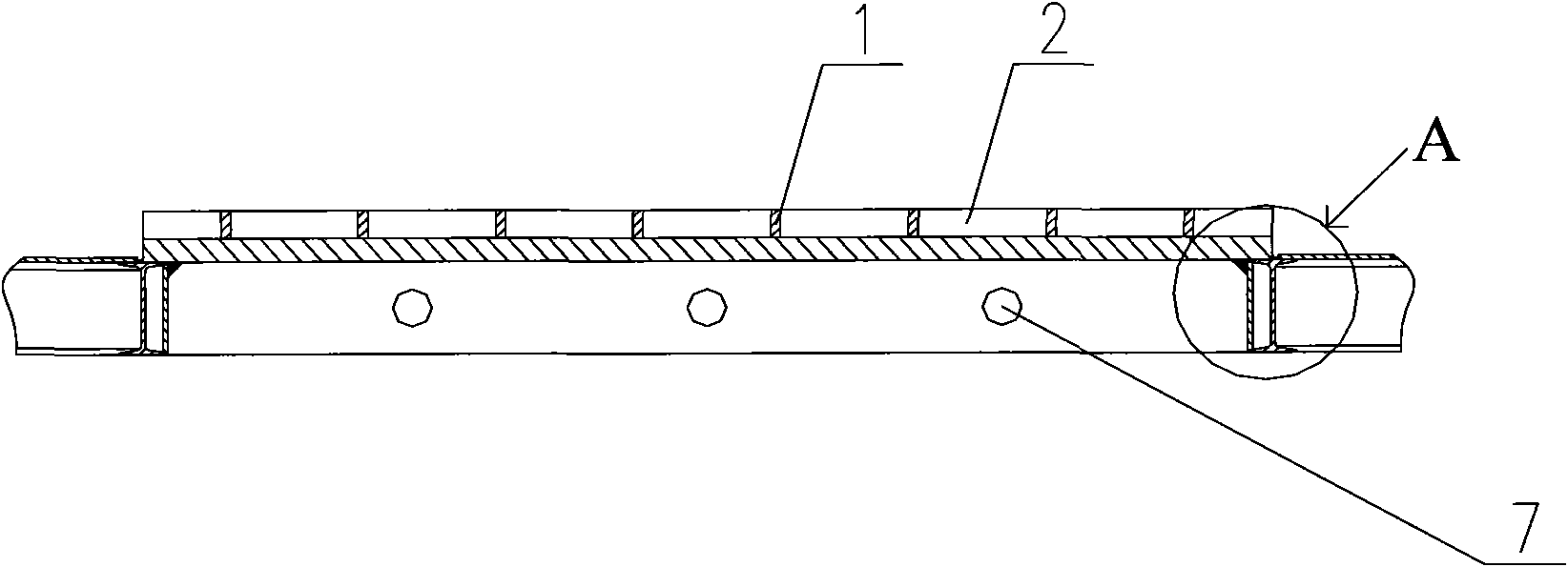

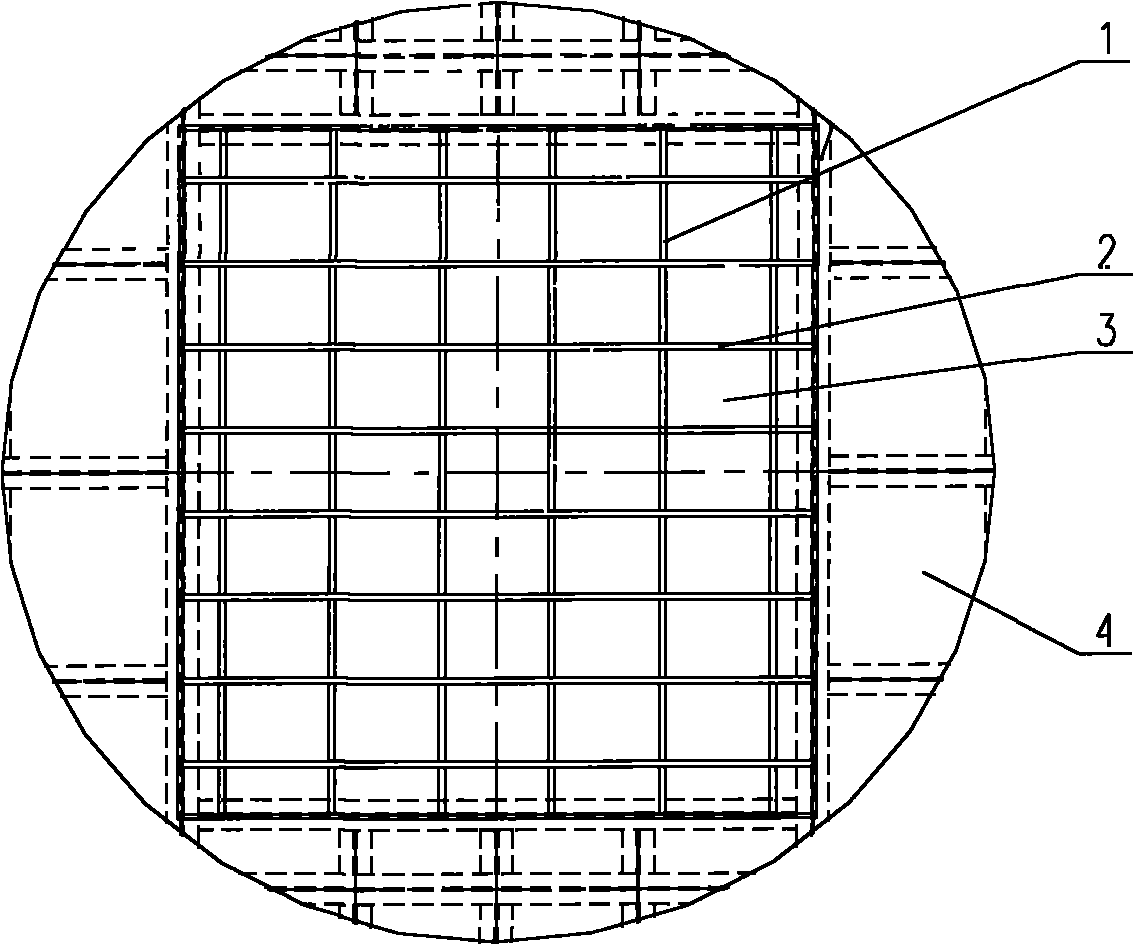

[0019] Such as Figure 1 ~ Figure 3 As shown, the bottom window structure of an aluminum smelting furnace with a bottom stirring device includes: longitudinal ribs 1, transverse ribs 2, rectangular stainless steel plates 3, furnace bottom steel plates 4, furnace bottom I-beams 5, vertical ribs 6. Ventilation holes 7, bottom-mounted permanent magnet or electromagnetic stirring device 8, four vertical ribs 6 are connected end to end to form a square frame bracket, and a rectangular stainless steel plate 3 is welded on the square frame bracket. The rectangular stainless steel plate 3 The center of the center is concentric with the square frame-type support, the area of the rectangular stainless steel plate 3 is larger than the containing surface of the square frame-type support, and the transverse rib plate 2 is welded on the rectangular stainless steel plate 3 along the transverse direction, and the longitudinal rib plate 1 is welded along the longitudinal direction, and the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com