Automatic milling type wood peeling device

An automatic milling and wood technology, applied in the direction of irregular removal device, wood processing equipment, bark area/debris/dust/waste removal, etc., can solve the problems of large engineering volume, complicated processing procedures, and limited work efficiency, etc. Achieve the effects of liberating productivity, reducing costs, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

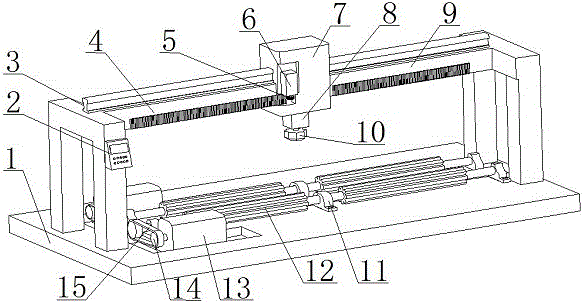

[0009] see figure 1 , the present invention comprises a kind of automatic milling type wood peeling device, is made up of controller 2, base 1, first motor 13, sprocket wheel 14, chain 15, gear pinion shaft 12, fixed bearing 11, beam 9, mobile platform 7 , guide rail 3, driving motor 6, gear 5, rack 4, second motor 8 and milling cutter 10, characterized in that: the first motor 13 is installed on the base 1, between the first motor 13 and the pinion shaft 12 Through the transmission of the sprocket 14 and the chain 15, the pinion shaft 12 is installed on the base 1 through the fixed bearing 11, and the base 1 and the beam 9 are connected by welding. The guide rail 3 moves horizontally, and the mobile platform 7 is fixed with a drive motor 6 and a second motor 8. The drive motor 6 rotates and meshes with the rack 4 through the gear 5 so that the mobile platform 7 and the beam 9 produce relative motion, and the rack 4 is embedded in the beam 9. On the side, the second motor 8 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com