Drying rack used for bamboo panel processing

A board processing and drying rack technology, applied in lighting and heating equipment, partial agitation dryers, dryers for static materials, etc., can solve curling and curling angles, affect the quality of bamboo boards, and affect the subsequent processing of bamboo boards and other issues to achieve the effect of avoiding roll-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

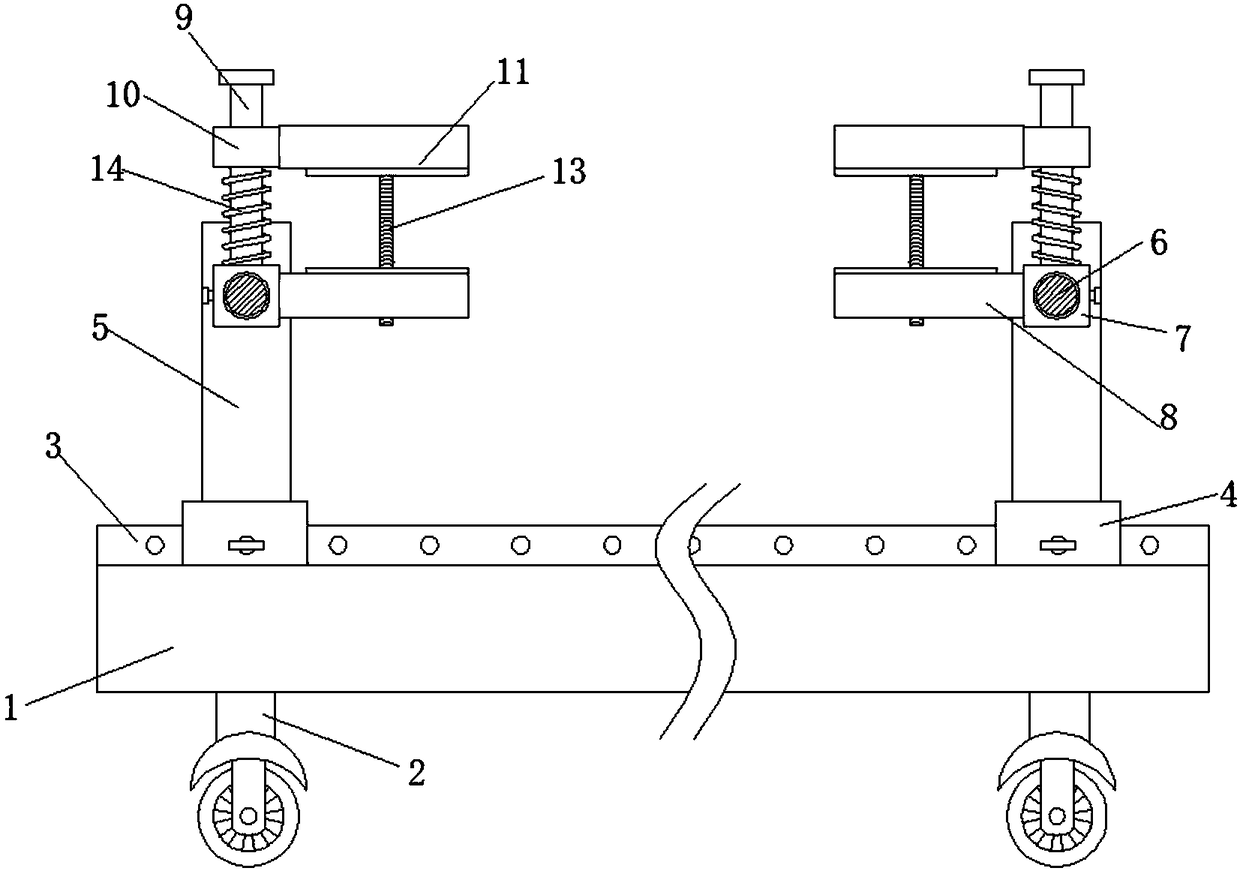

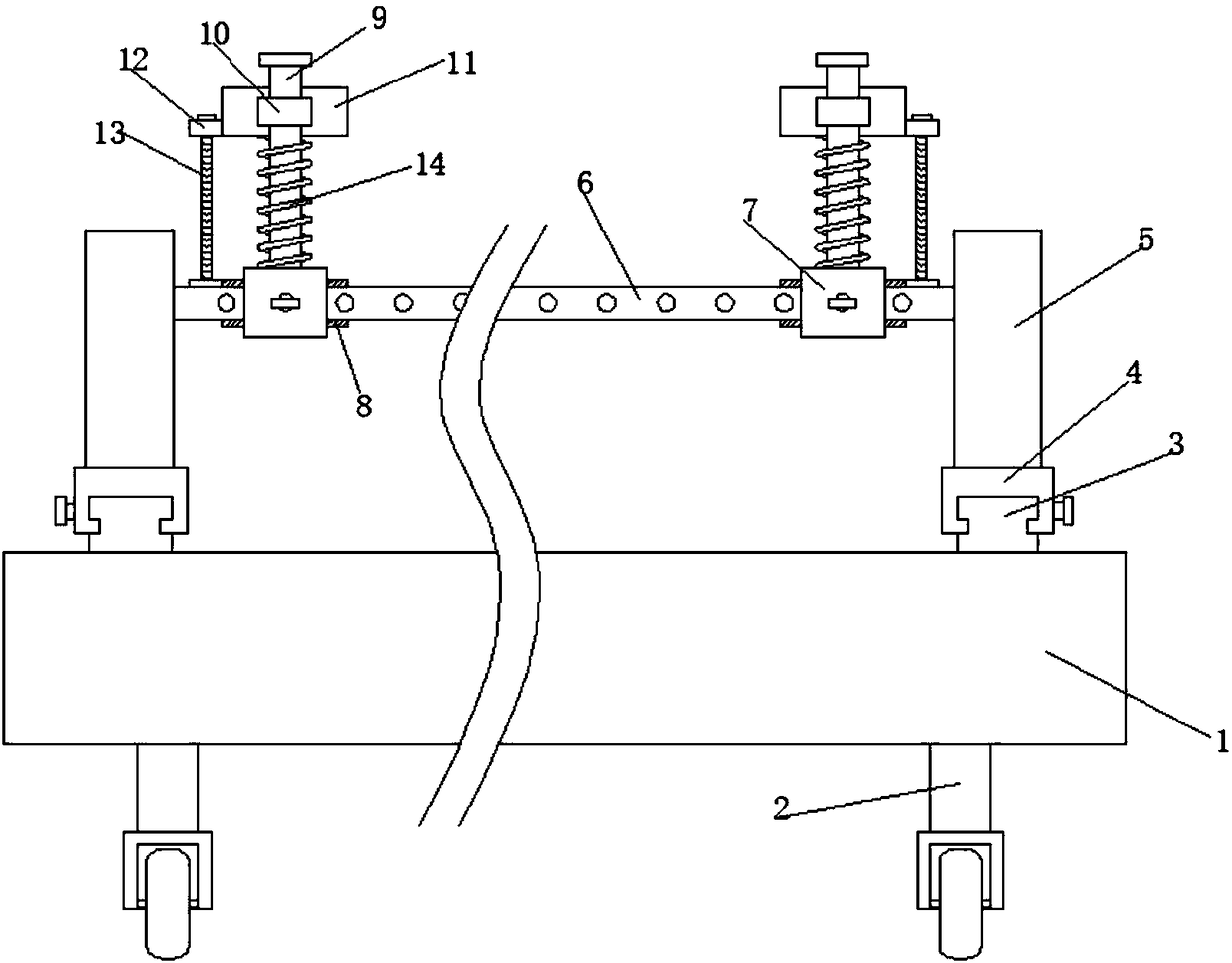

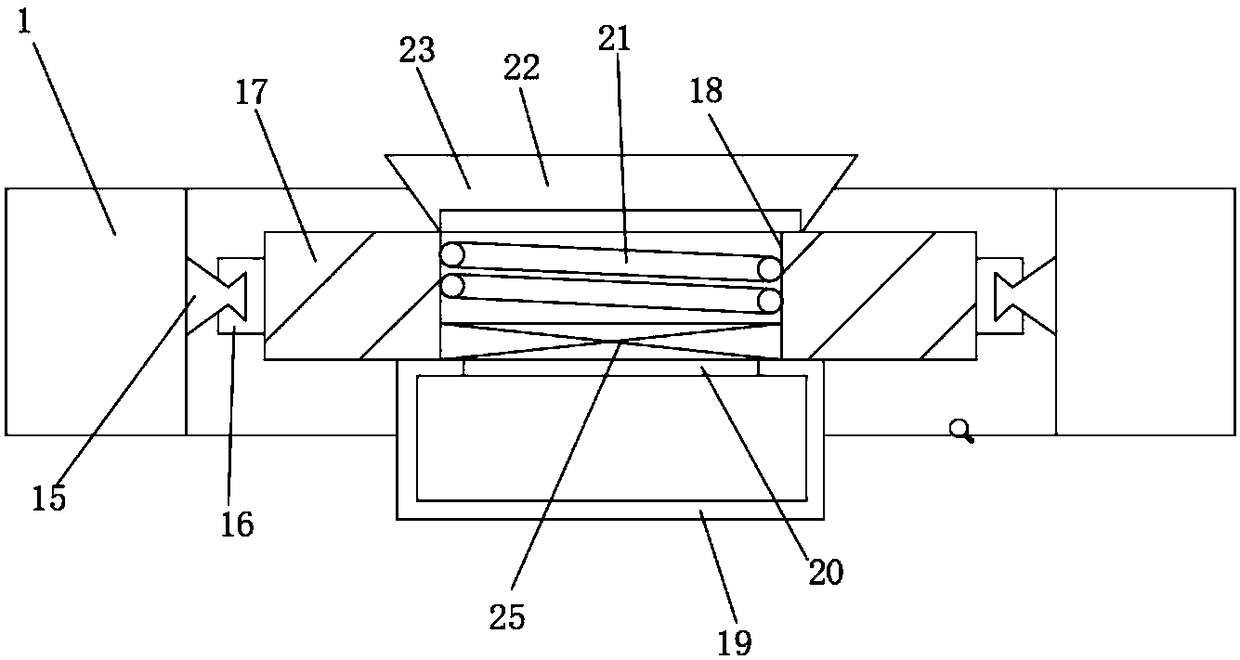

[0017] refer to Figure 1-2 , a drying rack for processing bamboo boards, comprising a fixed bottom frame 1, the fixed bottom frame 1 is a rectangular frame structure, four groups of supporting bottom columns 2 are arranged on the bottom of the fixed bottom frame 1, and the structures of the four groups of supporting bottom columns 2 are the same , vertically arranged at the four corners of the bottom of the fixed bottom frame 1, and the bottoms of the four sets of supporting bottom columns 2 are all provided with universal wheels, and the two groups of side walls of the fixed bottom frame 1 are provided with first moving guides along the length direction. Rod 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com