Drying oven for manufacturing leather products

A leather goods and oven technology, applied in drying, drying machine, local stirring dryer and other directions, can solve the problem that the equipment is not suitable for the use of leather goods, and achieve the effect of improving drying effect, reducing pollution, and being convenient to take out and store.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

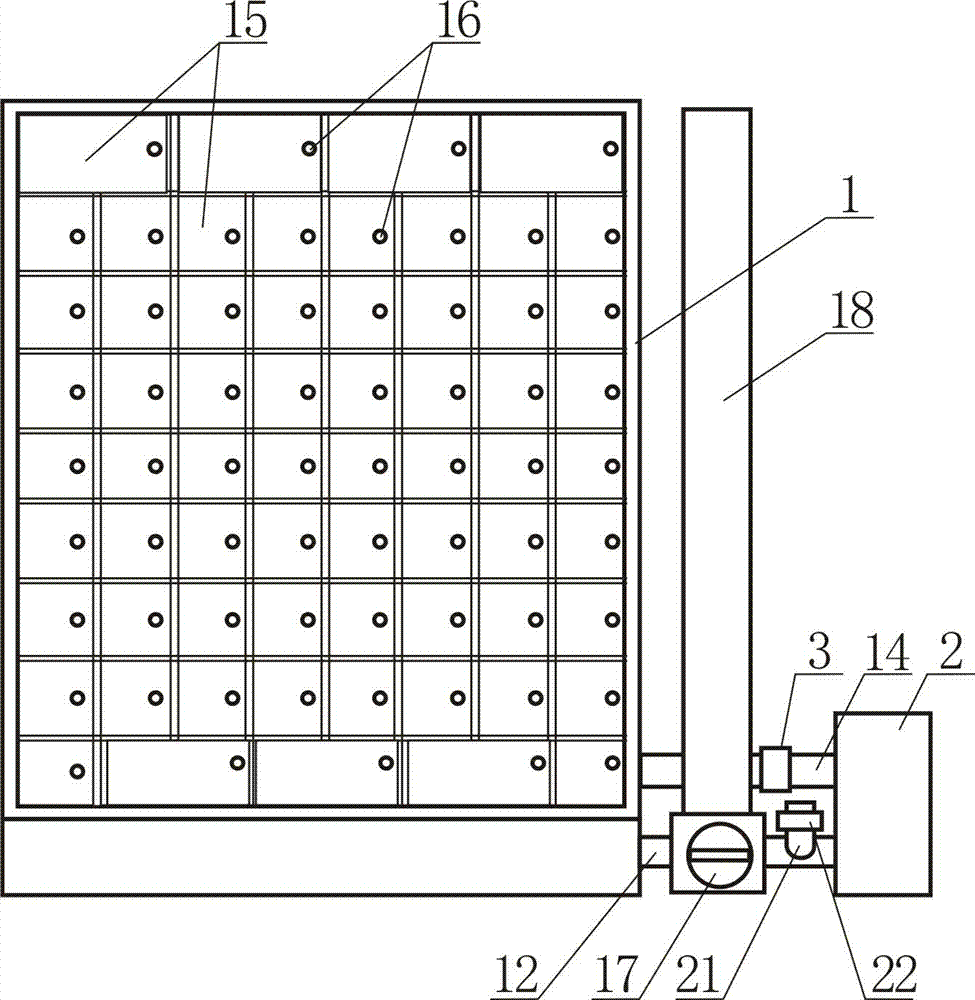

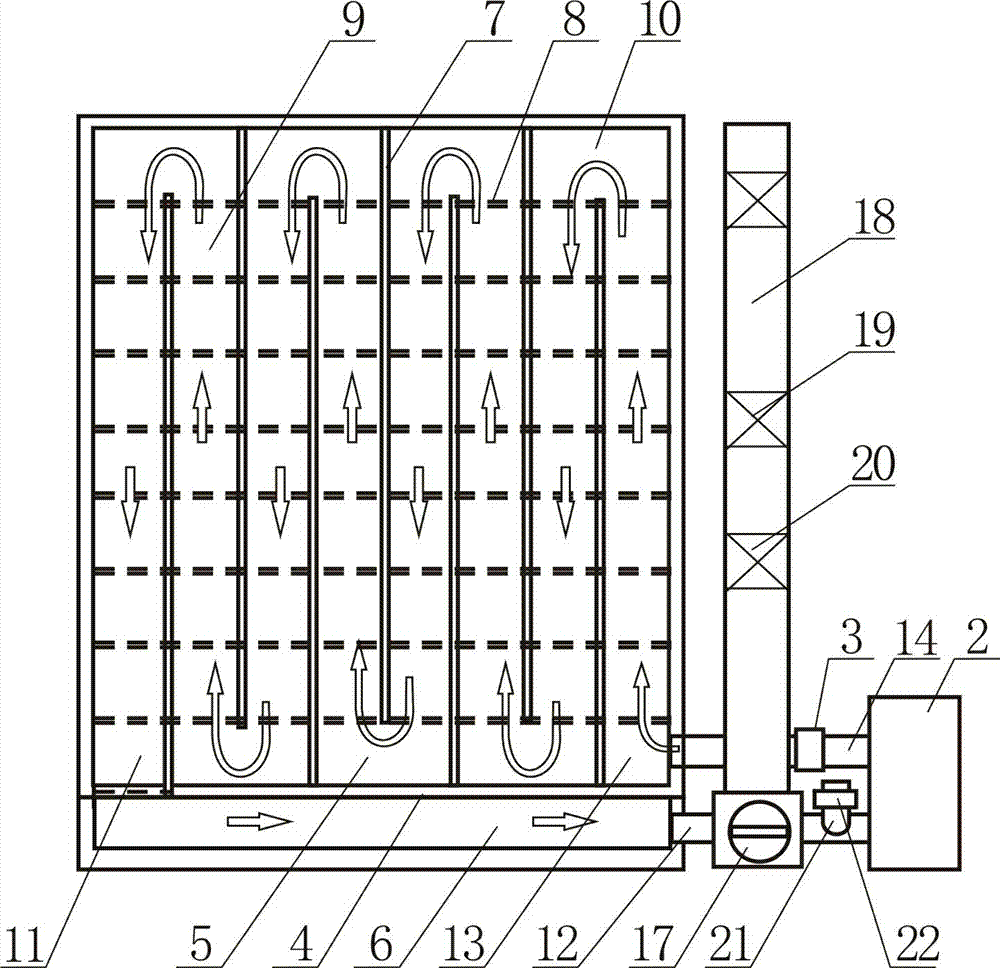

[0019] Such as figure 1 , 2 As shown, the oven for leather goods production includes a box body 1, a blower fan 2 and a heater 3. The box body 1 is divided into upper and lower cavities by a horizontal partition 4, the upper cavity is a drying chamber 5, and the lower cavity is a The exhaust passage 6, the space in the drying bin 5 is divided into multiple rows by a plurality of vertical partitions 7 distributed from left to right and a plurality of horizontal screens 8 distributed from top to bottom for placing The small grid bin 9 of the dried leather goods, the small grid bin at the top of the first row and the small grid bin at the top of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com