Cloth drying device for textile processing

A drying device and textile technology, which is applied to heating devices, textiles, papermaking, drying, etc., can solve the problems of slow drying speed, inconvenient staff, and reduce the progress of textiles, so as to achieve convenient operation and increase drying. The effect of area and structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

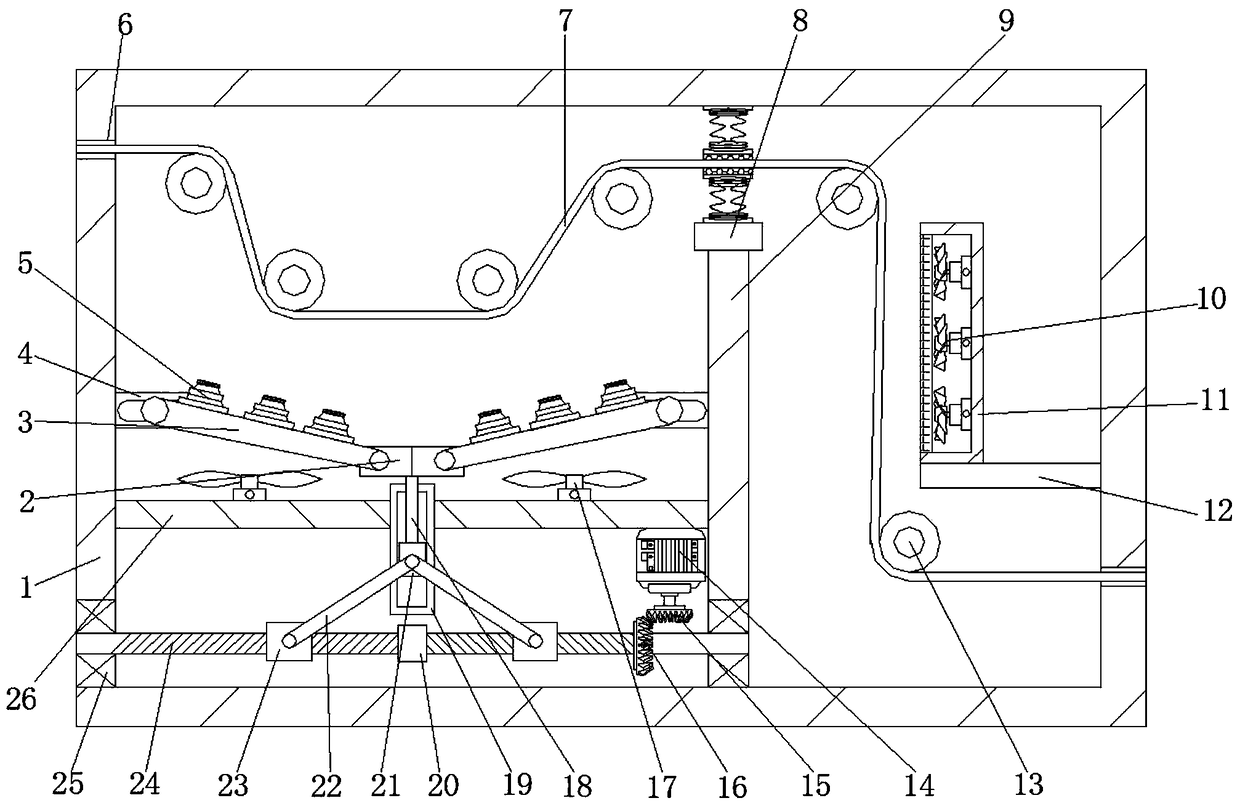

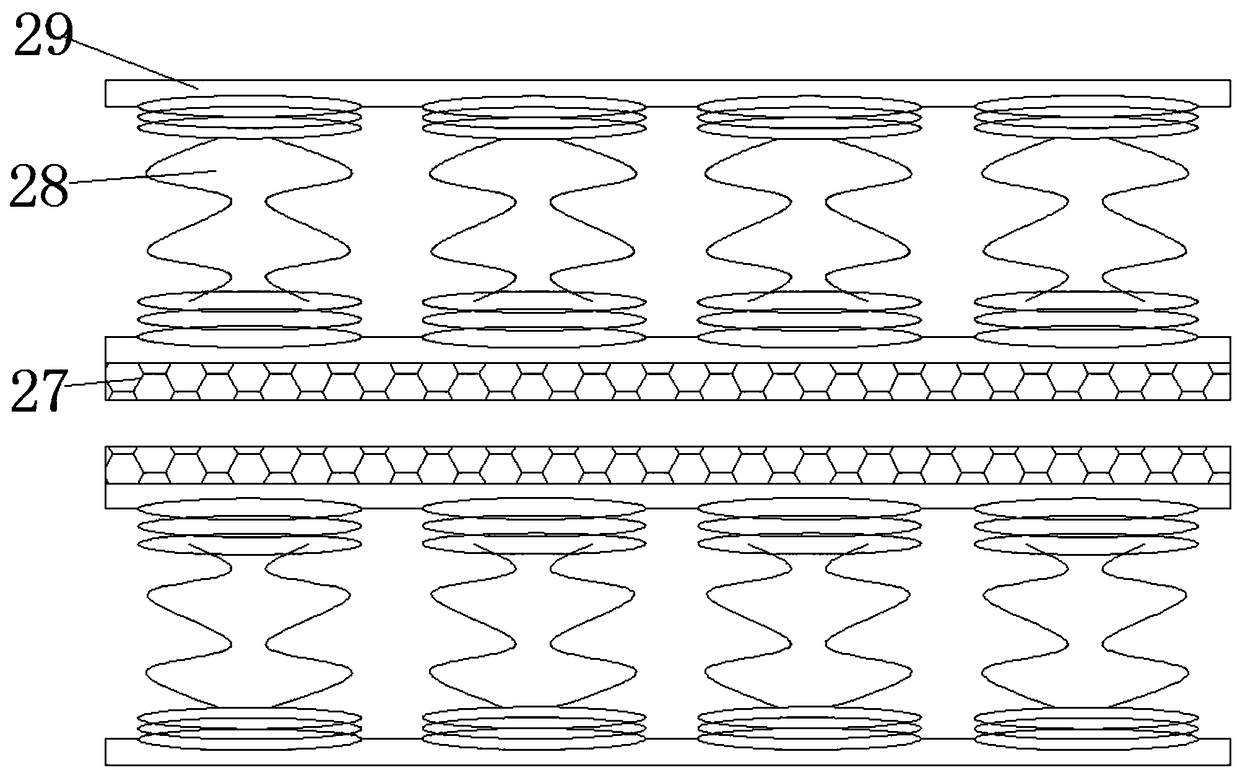

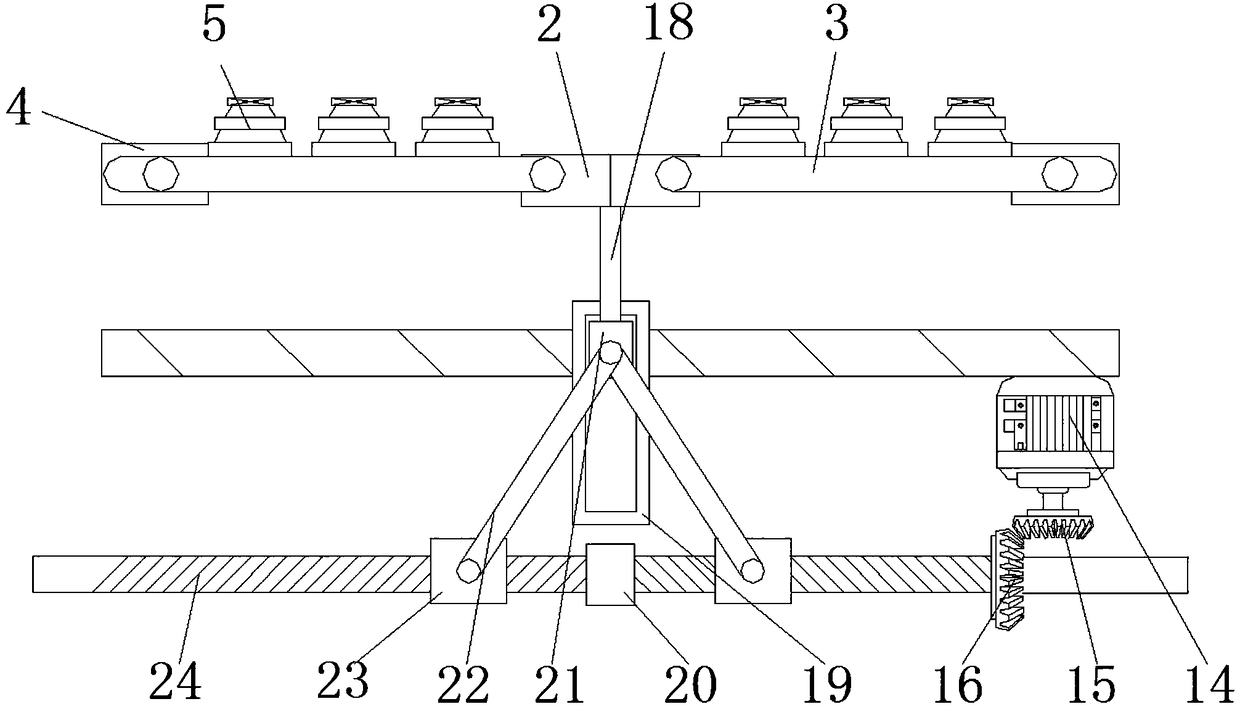

[0022] see Figure 1-4 , a cloth drying device for textile processing, comprising a drying box 1; a bearing plate 26 is welded and fixed on the lower inner wall of the drying box 1 to provide working and installation space for the drying device and lifting device inside it; The left end of the carrying plate 26 is welded and fixed on the left side inner wall of the drying box 1, and its right end is welded and fixed on the isolation plate 9 to support the weight of the connecting parts; the lower end of the isolation plate 9 is welded and fixed on the drying box The inner wall of the lower end of 1 provides installation space for the connecting parts on the left side; the right side of the lower end of the bearing plate 26 is fixedly installed with a rotating motor 14 through bolt connection; the lower end of the rotating motor 14 is fixedly sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com