Automatic feeding type sludge treatment equipment

A technology for sludge treatment and automatic feeding, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of insufficient sludge drying and reduced drying effect. , to achieve the effect of fast speed, sufficient drying and increasing drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

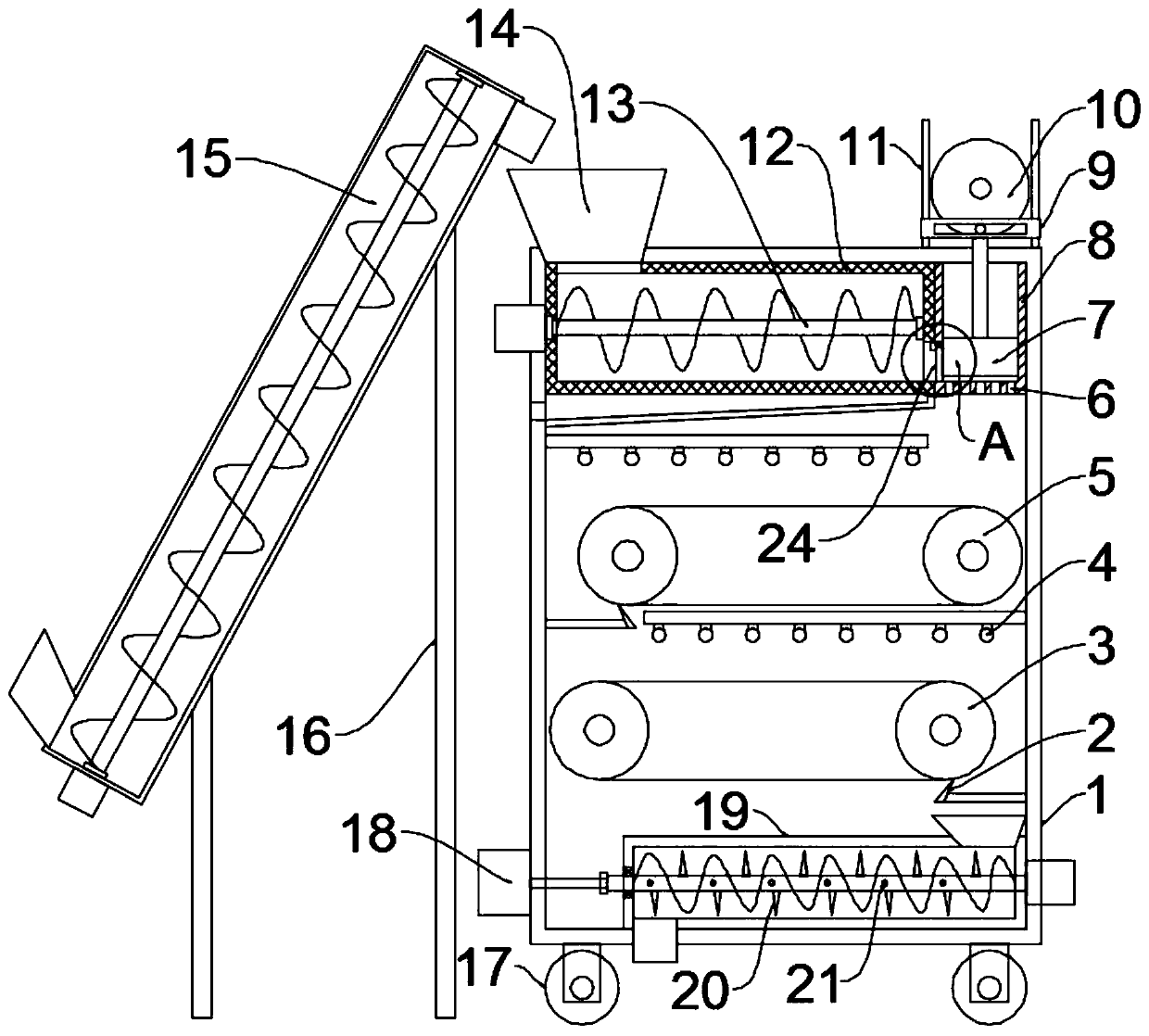

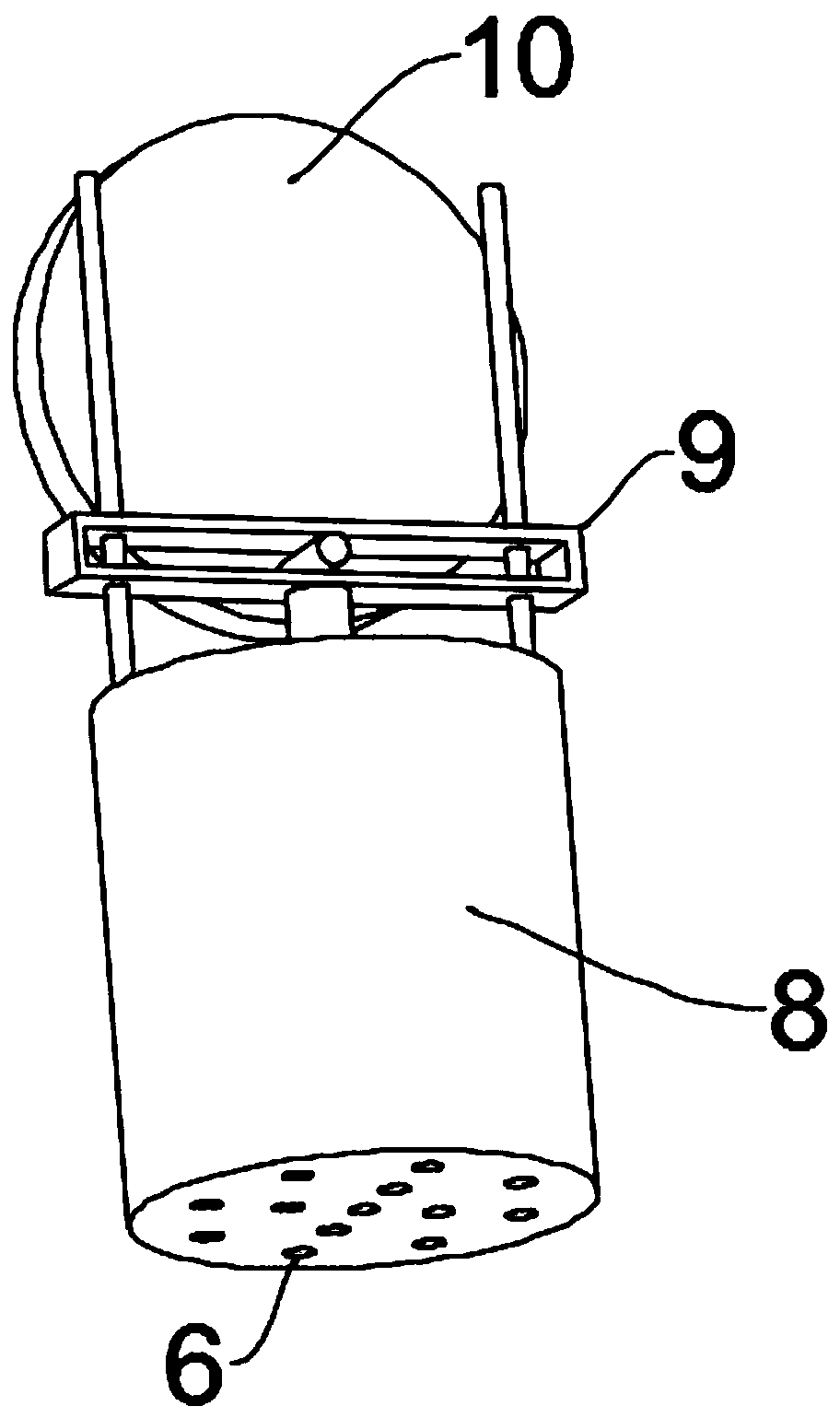

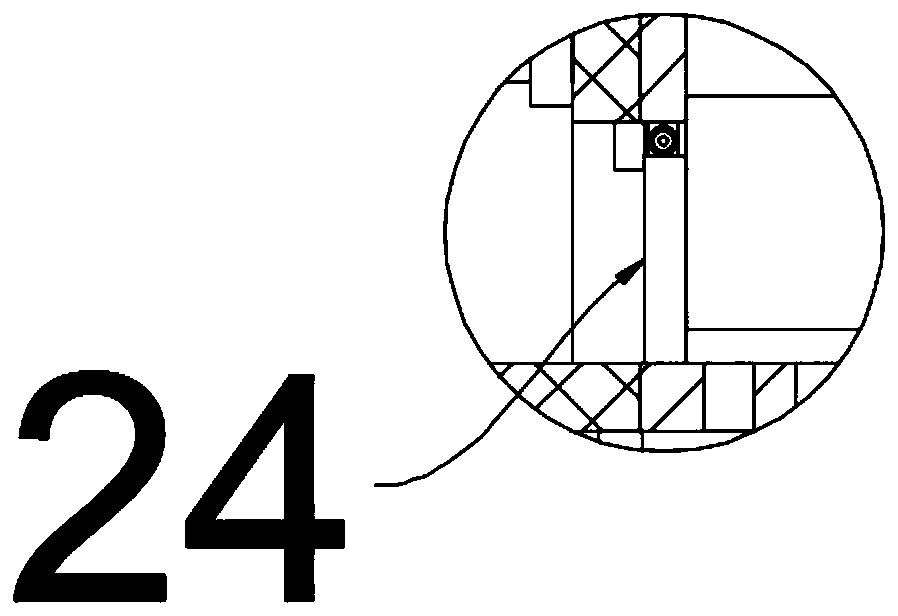

[0027] see Figure 1~3 , in the embodiment of the present invention, an automatic feeding type sludge treatment equipment includes a box body 1, a feeding unit, a drying unit and a discharging unit, and the feeding unit, the drying unit and the discharging unit are all installed in the box Inside the body 1, the drying unit is connected with the discharge unit. Rollers 17 are evenly installed on the bottom of the box 1. The rollers 17 are self-locking rollers to facilitate the movement of the device. The top left side of the box 1 is provided with a feeding Hopper 14, further, the left side of the box body 1 is equipped with a feeding auger 15 for lifting the sludge to the feeding hopper 14 through a mounting frame 16, and also includes an extrusion unit, which is located at the inlet Between the material unit and the drying unit and communicate with the two respectively, the feed unit includes a water-permeable cylinder 12 and a feed auger 13, the inner cavity on the left sid...

Embodiment 2

[0030] see Figure 4The difference between the embodiment of the present invention and embodiment 1 is that, in order to further increase the drying area of the sludge, it also includes a cutting assembly, which includes a power motor 22 and a cutting blade 23, the The power motor 22 is installed on the upper part of the side wall of the casing 1, and the output shaft of the power motor 22 is fixed with a plurality of cutting blades 23 equidistant from the ring, and the cutting blades 23 are preferably mounted on the output shaft of the power motor 22 by screws. Above, the other end of the cutting blade 23 extends to the bottom of the extrusion chamber 8, and the side wall of the box body 1 is provided with a movement groove for the rotation of the cutting blade 23. When the extrusion block 7 is extruded, the power motor 22 drives the cutting blade 23 rotates so that strip-shaped sludge can be cut into small sections, thereby further increasing the drying area, drying more f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com