Drying device for manufacturing flour

A drying device and flour technology, which is applied in application, preservation of seeds through drying, and grain processing, etc., can solve the problems of wheat mildew, economic loss of farmers, and large occupied area, so as to increase the drying area and reduce labor Strength, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

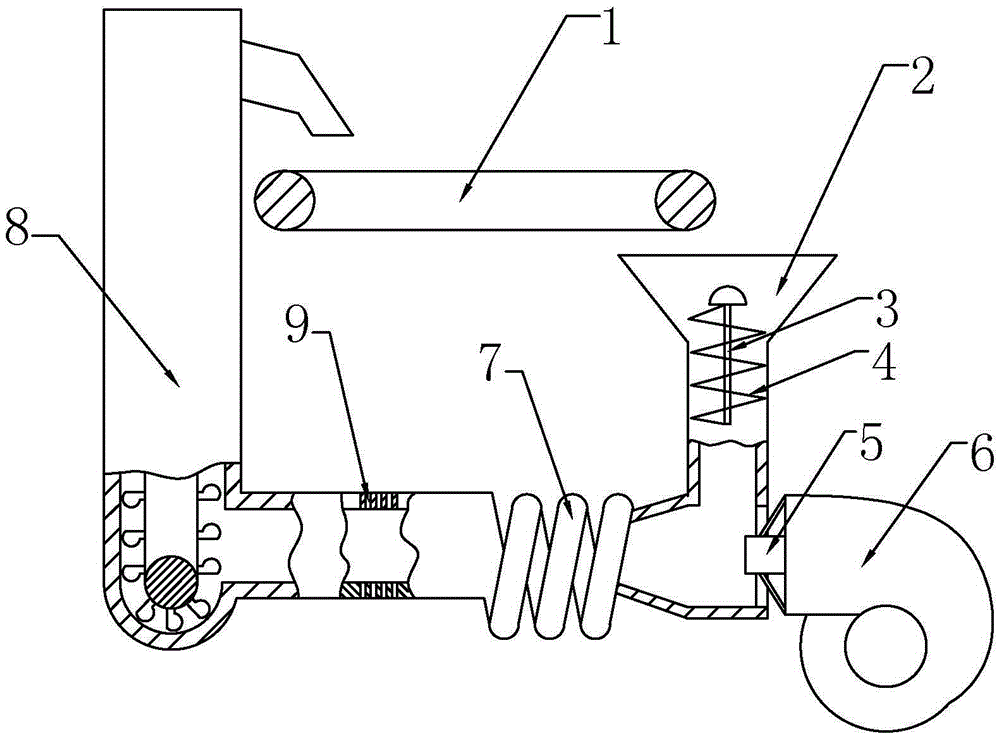

[0016] The reference signs in the drawings of the description include: belt conveyor 1, feed hopper 2, main shaft 3, helical blade 4, electric heater 5, fan 6, spiral pipe 7, bucket elevator 8, ventilation hole 9.

[0017] Example basic reference figure 1 Shown: a drying device for making flour, including a belt conveyor 1, the belt conveyor 1 is connected with a first motor, a drying belt is arranged on the belt conveyor 1, and a feeding hopper 2 is arranged under the belt conveyor 1 , the main shaft 3 is provided in the feeding hopper 2, and the heating wire is arranged in the main shaft 3, the second motor is connected to the main shaft 3, the helical blade 4 is fixedly connected to the main shaft 3, and the outlet of the feeding hopper 2 is connected with a helical pipe 7, the helical The pipe wall is provided with a first heating wire, and the wall of the feeding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com