Preparation method of polyelectrolyte drug-loaded particles

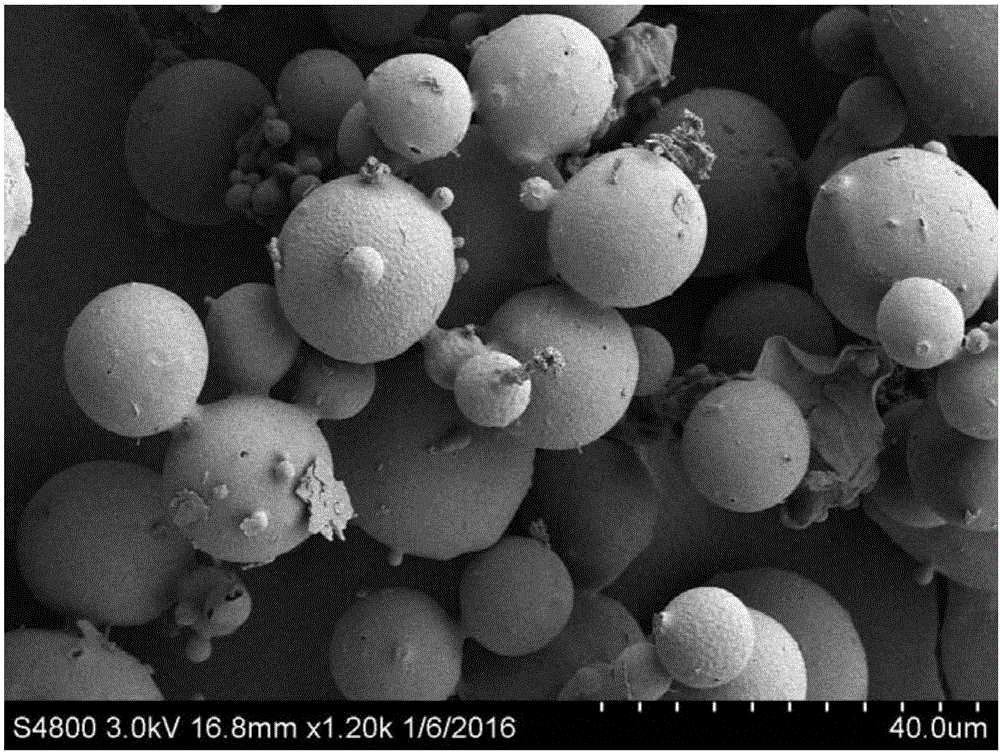

A technology of polyelectrolyte and drug-carrying particles, which is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., to achieve high drug loading and encapsulation efficiency, stable performance and smooth surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, polyelectrolyte drug-loaded particles were prepared according to the following steps:

[0034] (1) Preparation of dispersed phase

[0035] Dissolve sodium alginate in distilled water, stir evenly and remove air bubbles to obtain 10 mL of sodium alginate (NaAlg) solution with a concentration of 0.02 g / mL as the dispersed phase;

[0036] (2) Preparation of continuous phase

[0037] Mix Span 85 and Tween 85 at a volume ratio of 7:3, take 3 mL and add it to 100 mL of liquid paraffin, stir evenly, and use it as the continuous phase;

[0038] (3) homogeneous emulsification

[0039] Pour the dispersed phase prepared in step (1) into the continuous phase prepared in step (2), and homogeneously emulsify for 5 minutes at a stirring rate of 3000 rpm to obtain a homogeneous emulsion;

[0040] (4) Cross-linking curing

[0041] Add 20mL 0.06g / mL CaCl to the homogeneous emulsion 2 With a mixed solution of 0.025g / mL NaCl, solidify and react at a stirring rate of 3...

Embodiment 2

[0053] In this example, polyelectrolyte drug-loaded particles were prepared according to the following steps:

[0054] (1) Preparation of dispersed phase

[0055] Dissolve sodium alginate in distilled water, stir evenly and remove air bubbles to obtain 10 mL of sodium alginate (NaAlg) solution with a concentration of 0.02 g / mL as the dispersed phase;

[0056] (2) Preparation of continuous phase

[0057]Mix Span 85 and Tween 85 at a volume ratio of 5:5, take 3 mL and add it to 100 mL of liquid paraffin, stir evenly, and use it as the continuous phase;

[0058] (3) homogeneous emulsification

[0059] Pour the dispersed phase prepared in step (1) into the continuous phase prepared in step (2), and homogeneously emulsify at a stirring rate of 3000 rpm for 10 minutes to obtain a homogeneous emulsion;

[0060] (4) Cross-linking curing

[0061] Add 20mL 0.06g / mL CaCl to the homogeneous emulsion 2 With a mixed solution of 0.025g / mL NaCl, solidify and react at a stirring rate of 3...

Embodiment 3

[0073] In this example, polyelectrolyte drug-loaded particles were prepared according to the following steps:

[0074] (1) Preparation of dispersed phase

[0075] Dissolve sodium alginate in distilled water, stir well and remove air bubbles to obtain 10 mL of sodium alginate (NaAlg) solution with a concentration of 0.03 g / mL as the dispersed phase;

[0076] (2) Preparation of continuous phase

[0077] Mix Span 85 and Tween 85 at a volume ratio of 1:3, take 4 mL and add it to 100 mL of liquid paraffin, stir evenly, and use it as the continuous phase;

[0078] (3) homogeneous emulsification

[0079] Pour the dispersed phase prepared in step (1) into the continuous phase prepared in step (2), and homogeneously emulsify at a stirring rate of 3000 rpm for 15 minutes to obtain a homogeneous emulsion;

[0080] (4) Cross-linking curing

[0081] Add 20mL 0.06g / mL CaCl to the homogeneous emulsion 2 With a mixed solution of 0.025g / mL NaCl, solidify and react at a stirring rate of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com