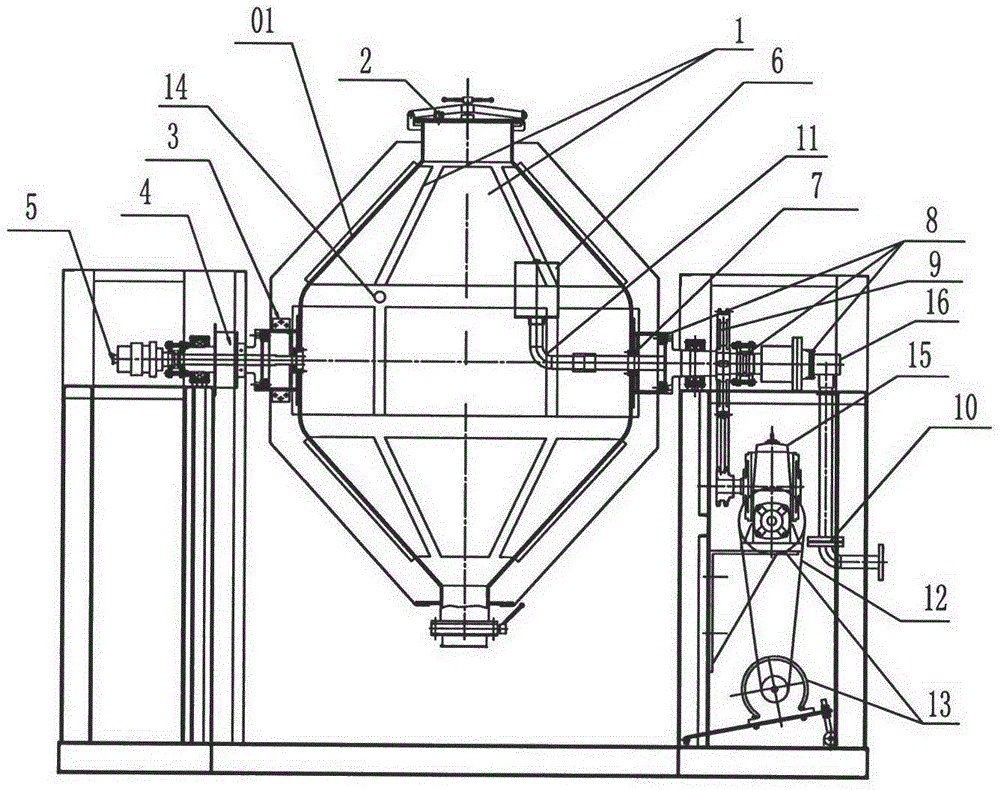

Electric heating biconical vacuum dryer

A vacuum dryer and electric heating technology, applied in the direction of non-progressive dryers, dryers, heating devices, etc., can solve the problems of poor heating effect and achieve the effects of less heat loss, avoiding blockage, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

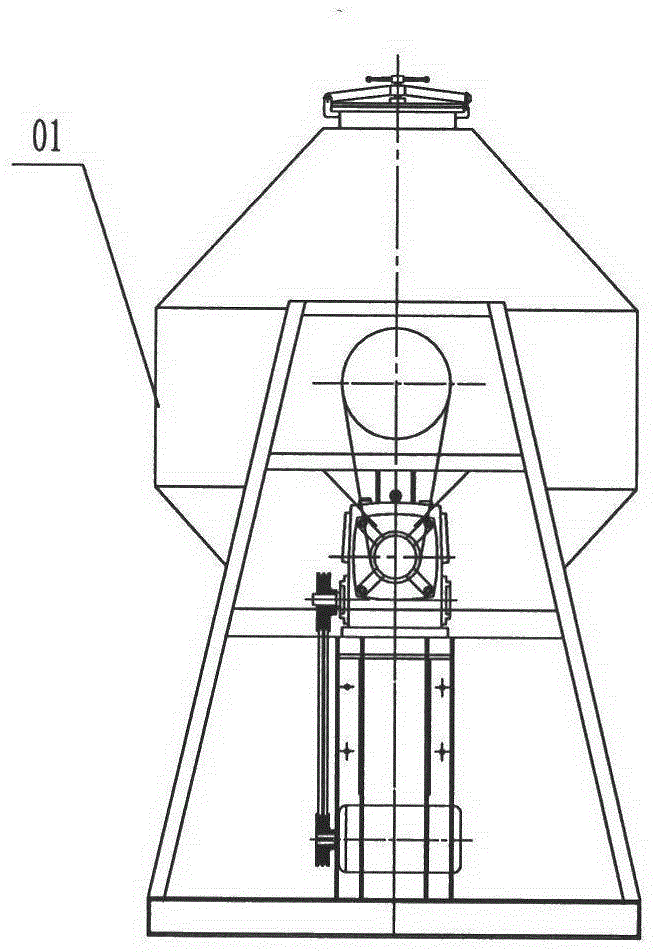

[0028] see figure 1 , an electric heating double-cone vacuum dryer, including a double-cone container 01, a double-cone container 01, an electric heating plate composite liner covering the surface of the double-cone container 01, and the electric heating plate composite liner is heated by electric heating The plate 1 is compounded with thermal insulation cotton. The electric heating plate 1 is a ceramic plate or cast aluminum plate arranged between the inner and outer shells of the double-cone container, and contains heating wires. The ceramic plate or cast aluminum plate is easy to disassemble and replace.

[0029] One side of the double-conical container 01 is provided with a terminal 3, which is used to connect three-phase 380V voltage and two signal lines. The terminal 3 is connected to the electric heating wire in the electric heating plate 1 through the line, and provides The electric current makes it heat, and then dries the material in the double cone container 01.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com