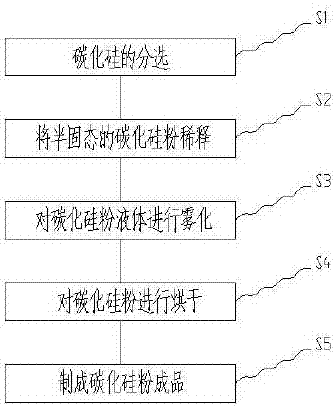

Production process of silicon carbide micropowder

A silicon carbide micropowder and production process technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of silicon carbide screening and drying troubles, batch production limitations, etc., to achieve manpower saving, good practicality Sexuality and the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] 1. Sorting of silicon carbide

[0043] Take the silicon carbide solid, grind the silicon carbide solid into powder with a grinder, set the speed of the grinder to 650r / min when pulverizing, and then use the hydraulic classification conical cylinder to sort the silicon carbide powder, because Under the effect of hydraulic power, ultra-fine silicon carbide will float on the upper layer of water, collect the floating silicon carbide liquid on the upper layer, and then use a 100-mesh filter to filter the silicon carbide powder to obtain semi-solid silicon carbide powder. At the same time, continue to sort the filtered liquid according to the S1 step;

[0044] 2. Dilute the semi-solid silicon carbide powder

[0045] Add distilled water diluent to the semi-solid silicon carbide powder in the mother liquor tank, the concentration of dilution is 10%, put the semi-solid silicon carbide powder into the mother liquor tank with agitator, start the agitator, the speed of the agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com