Rake type vacuum drying system

A vacuum drying and raking technology, which is applied in the direction of non-progressive dryers, drying solid materials, drying, etc., can solve the problem of poor fluidity of lithium iron phosphate suspension, unsuitable drying of lithium iron phosphate material, and uneven product fineness and other problems, to achieve the effect of improving drying efficiency, occupying a small area, and uniform fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

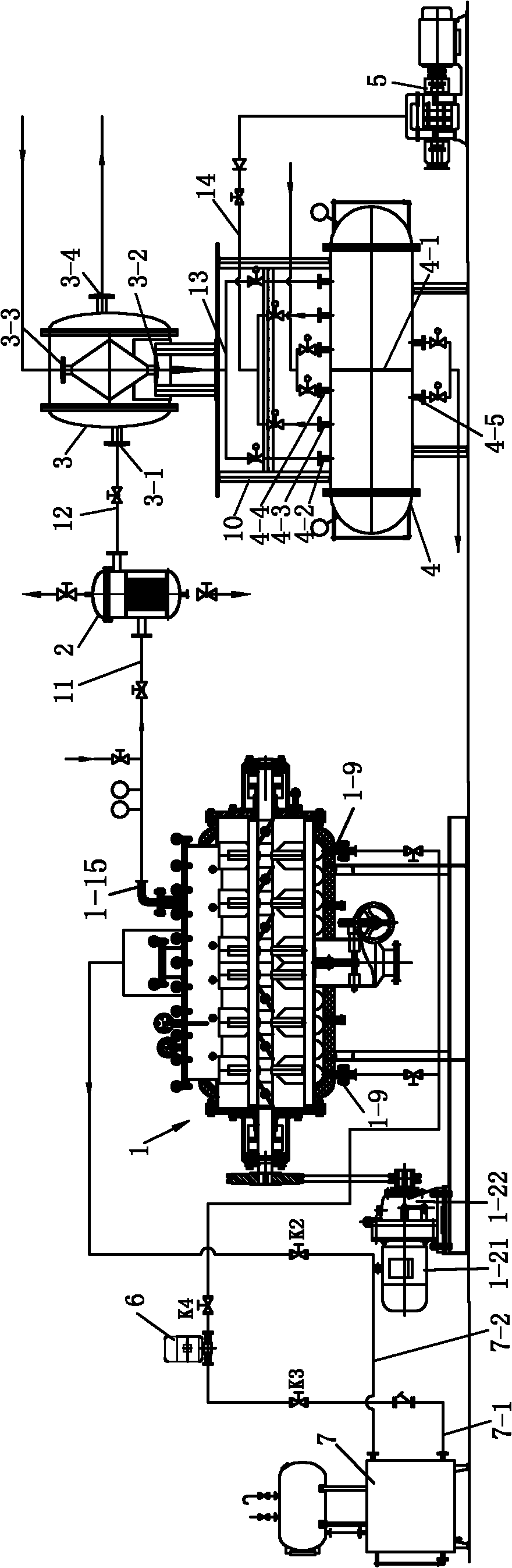

[0026] See Figure 1 to Figure 8 , a rake-type vacuum drying system, has a rake-type vacuum drying host 1, a bag filter 2, a condenser 3, a gas-liquid separator 4, a vacuum pump 5, an oil pump 6 and a thermal oil tank 7, and the thermal oil tank 7 is provided with Hot oil tank oil delivery pipe 7-1 and hot oil tank return oil pipe 7-2.

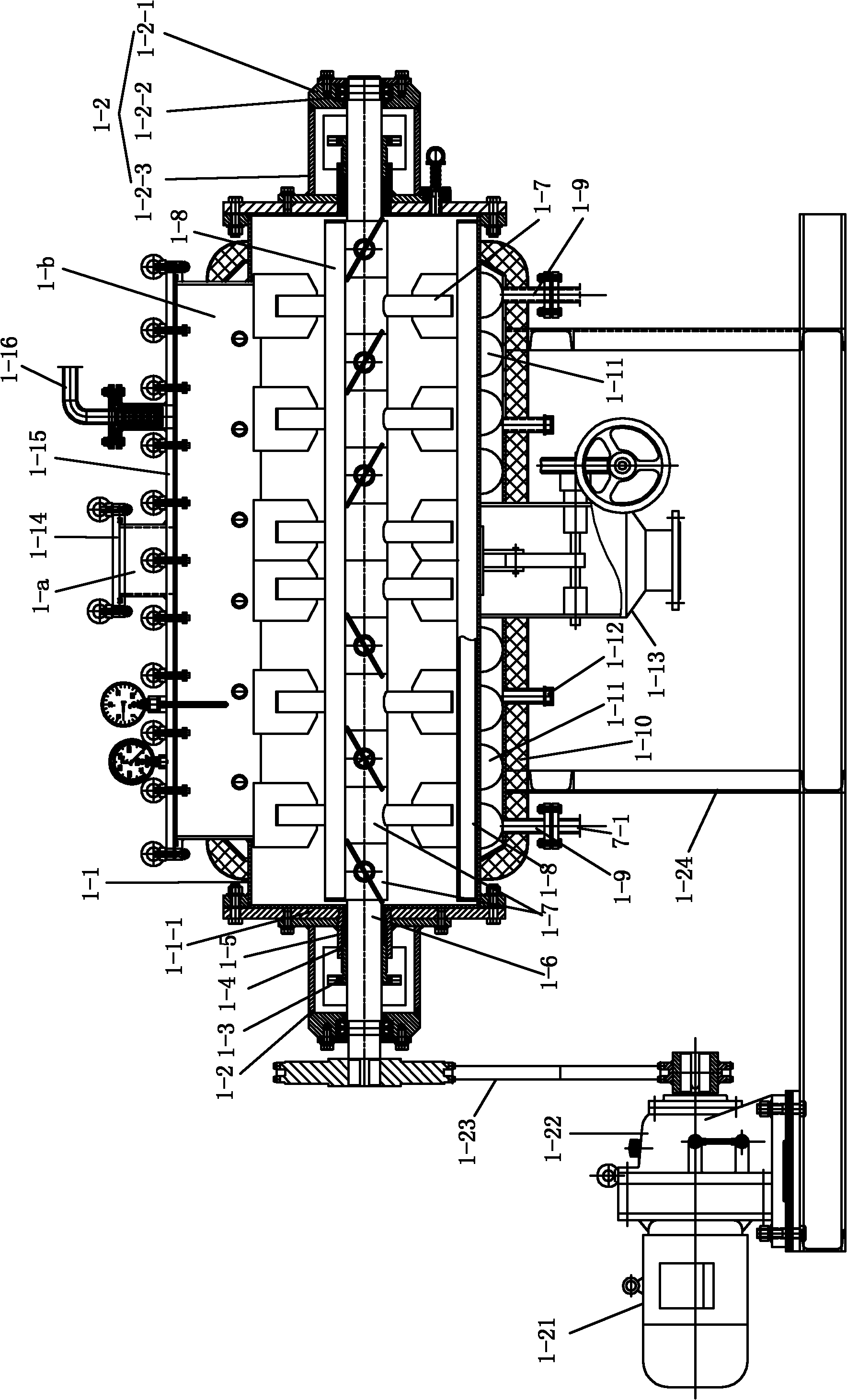

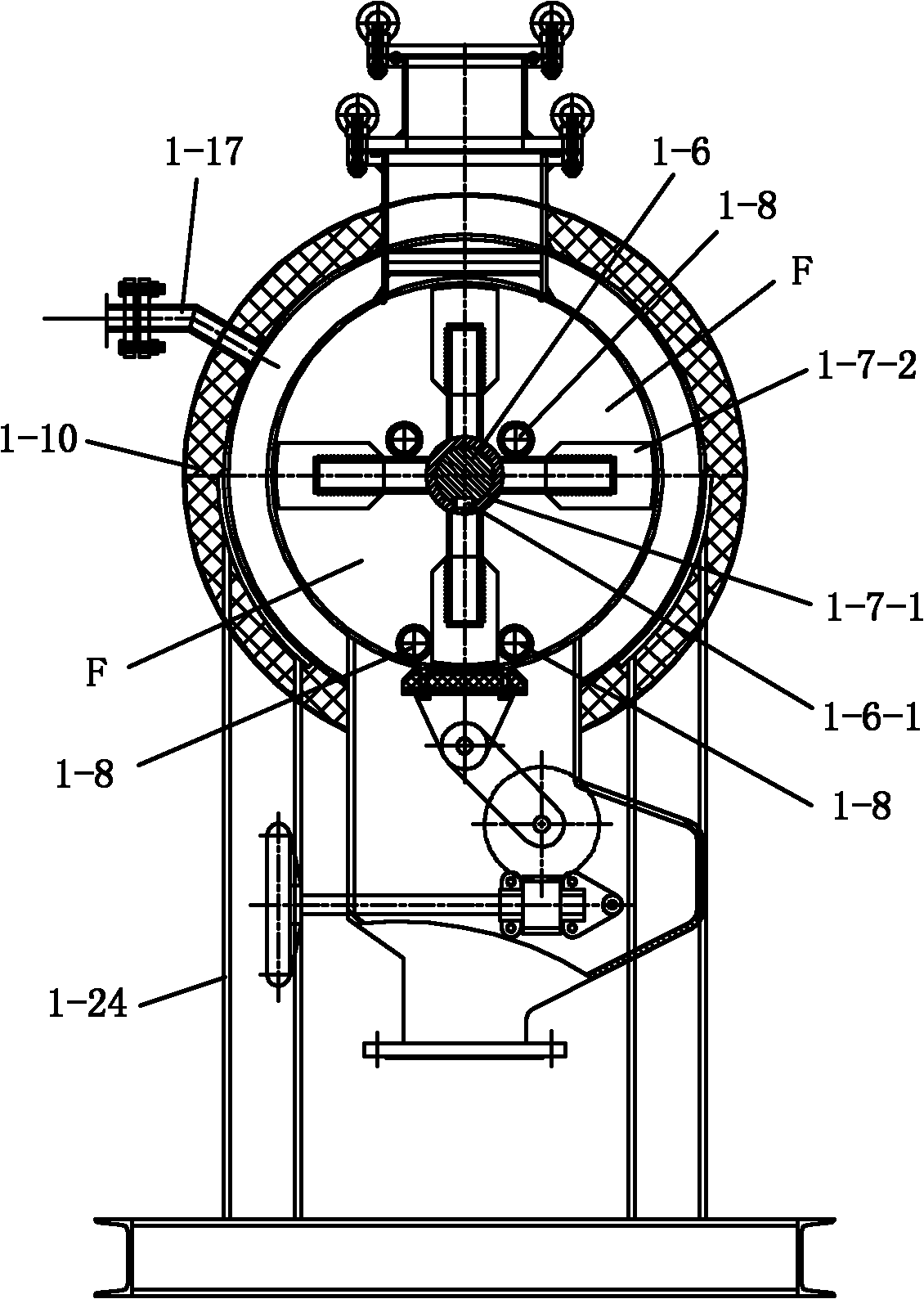

[0027] The rake type vacuum drying host 1 includes a motor 1-21, a reduction box 1-22, a saddle base 1-24, a jacketed tank 1-1 arranged on the saddle base 1-24 and a tank 1 Spindle 1-6 within -1. The output shaft of the reduction box 1-22 is connected with the above-mentioned main shaft 1-6 through a chain drive or a belt drive.

[0028] In order to facilitate maintenance and cleaning, the top of the tank body of the rake vacuum drying main machine 1 is provided with a manhole 1-b with a length greater than 1 / 2 of the tank body length, and a manhole 1-b that can be quickly opened and closed is provided on the manhole 1-b The cover plate 1-1...

Embodiment 2

[0037] On the basis of Embodiment 1, the present embodiment is also provided with a transfer oil tank 8 and a cold oil tank 9. The transfer oil tank 8 is an insulated oil tank. The transfer oil tank 8 is provided with a transfer oil tank oil delivery pipe 8-1 and a transfer oil tank return pipe 8-2. 9 is provided with a cold oil tank oil delivery pipe 9-1 and a cold oil tank return pipe 9-2, the transfer oil tank oil delivery pipe 8-1 is connected with the hot oil tank 7, the cold oil tank oil delivery pipe 9-1 is connected with the hot oil tank oil delivery pipe 7-1, and the transfer oil tank return oil pipe 8-2 and the oil return pipe 9-2 of the cold oil tank are connected with the oil return pipe 12. Each has a corresponding valve.

[0038] When working, the oil pump 6 is turned on, the valve K1 on the oil delivery pipe 8-1 of the transfer oil tank is normally open, the valve K2 on the return oil pipe 7-2 of the hot oil tank, the valve K 3 on the oil delivery pipe 7-1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com