Double grating nanostructure composed of quadrangular double cone arrays and preparing method thereof

A nanostructure, four-corner biconical technology, applied in nanotechnology, nano-optics, nanotechnology, etc., can solve problems such as hindering the improvement of geometry and affecting the AR effect of pyramidal gratings, and achieve the effect of improving light sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

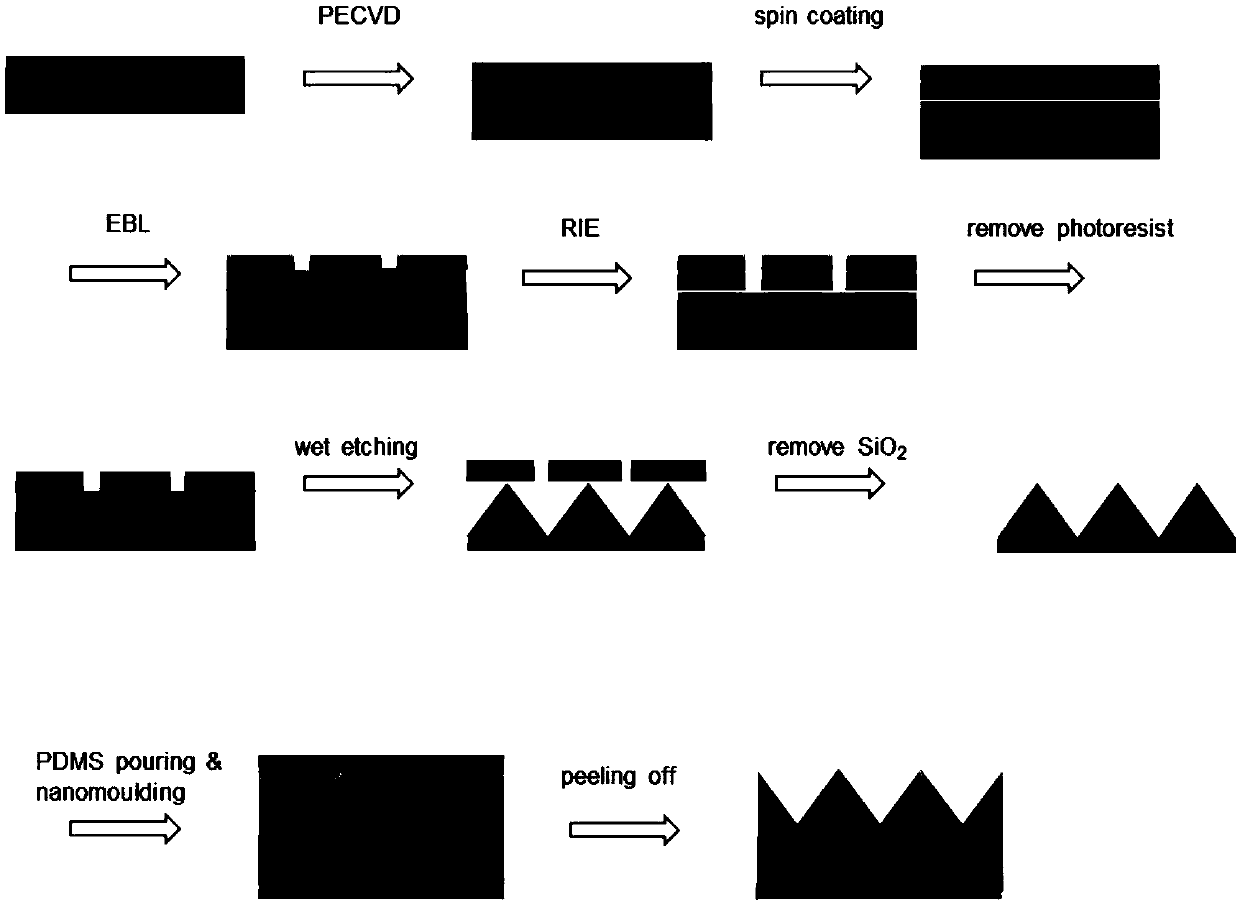

[0033] The embodiment of the present invention also provides a method for preparing a double-grating nanostructure composed of the above-mentioned quadrangular bipyramid array, which includes:

[0034] S1. abutting the installation surfaces of two porous silicon substrates that are mirror images of each other, so that the holes of the two porous silicon substrates correspond one by one to form a plurality of quadrangular biconical cavities;

[0035] S2. Fill polydimethylsiloxane in multiple cavities to form multiple grating nanostructure units;

[0036] S3. Peel off any one of the two porous silicon substrates to obtain a double grating nanostructure.

[0037] Further, in the actual operation process, in order to facilitate the operation, the way to fill polydimethylsiloxane in multiple cavities is to first drop polydimethylsiloxane on the mounting surface of one of the porous silicon substrates , and then covered with another porous silicon substrate, in the process of align...

Embodiment

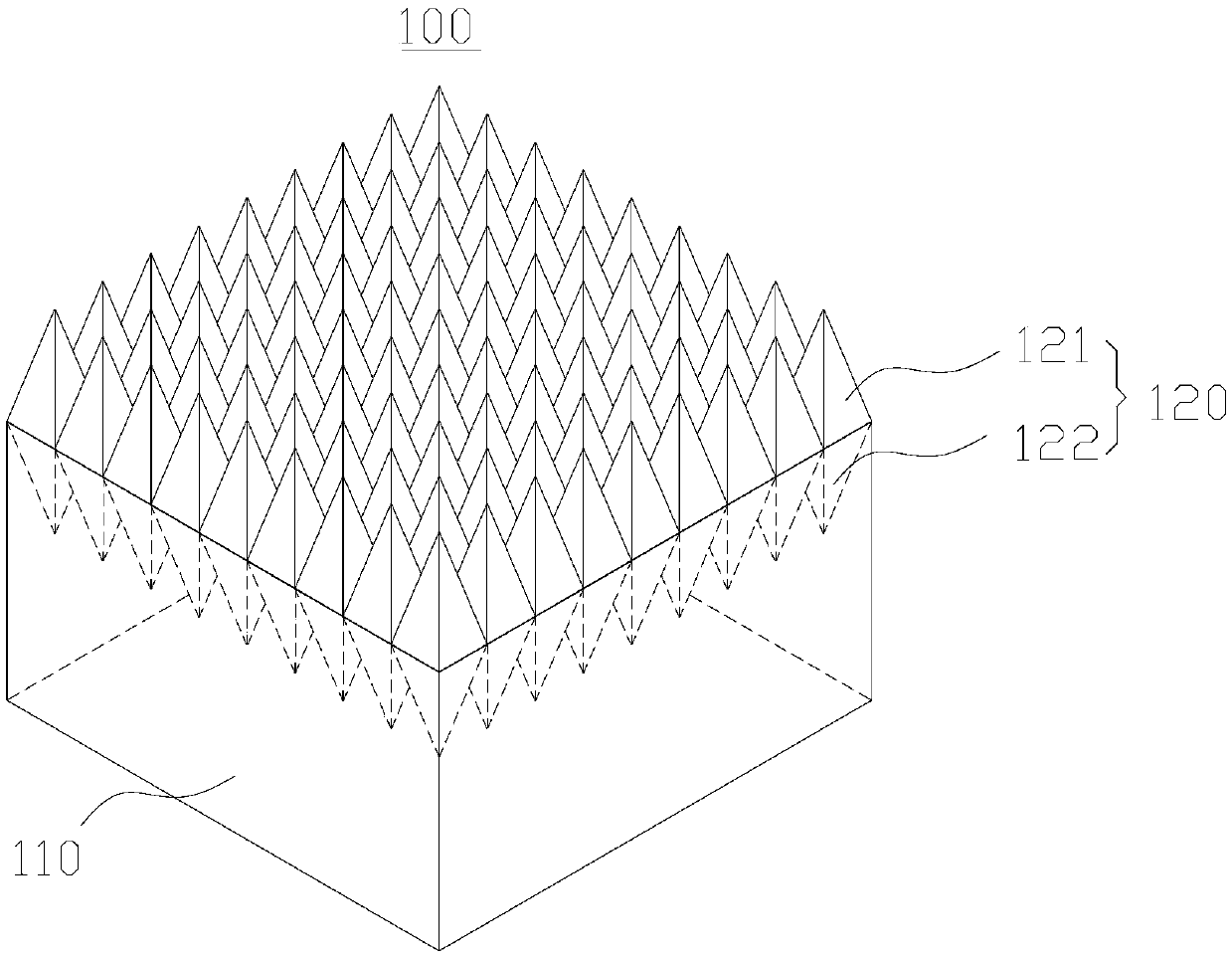

[0055] This embodiment provides a double grating nanostructure 100 composed of a quadrangular bipyramid array, the structure of which is as follows figure 1 As shown, it includes a porous silicon substrate 110 and a plurality of grating nanostructure units 120 .

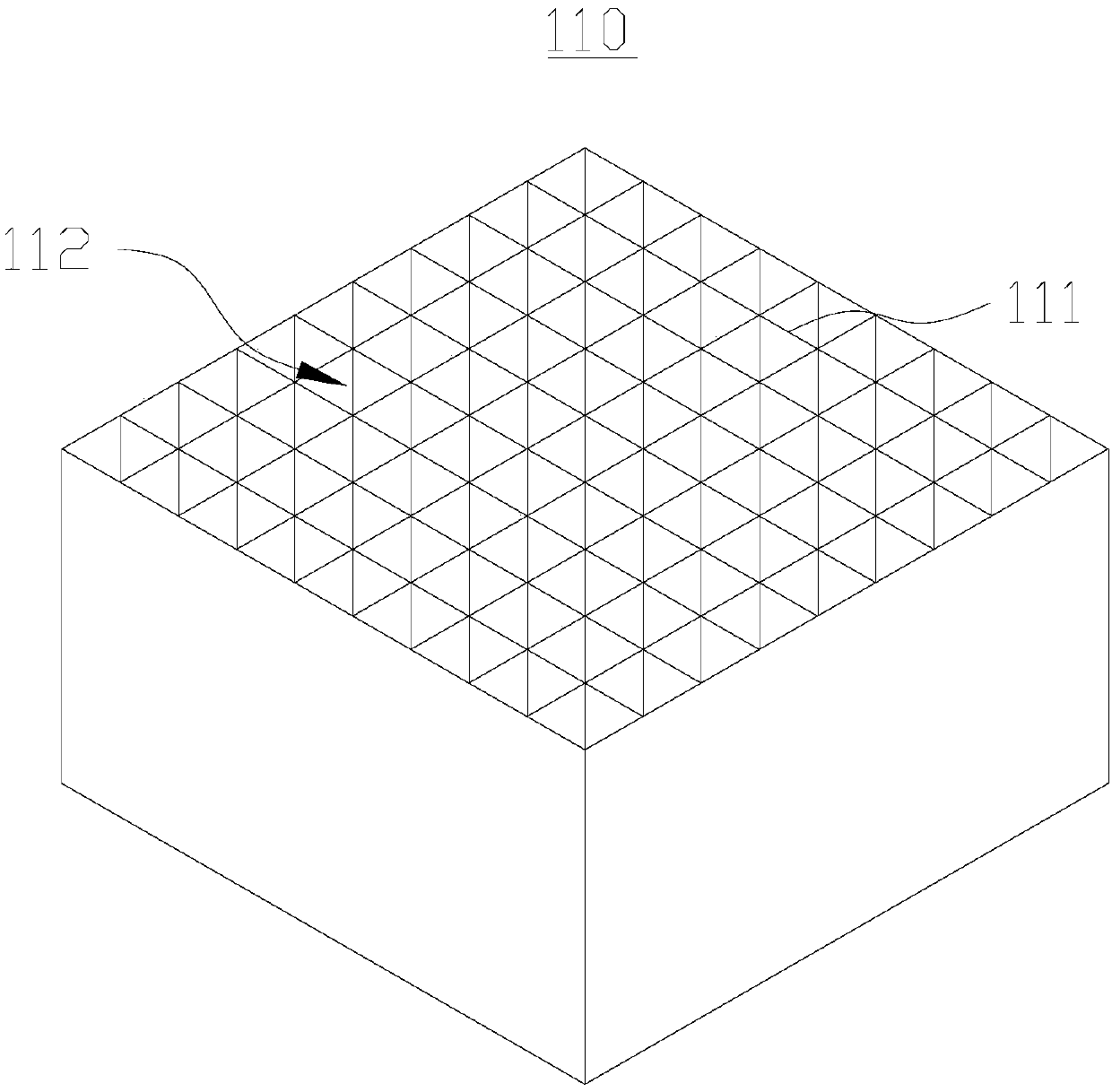

[0056] Wherein, the porous silicon substrate 110 includes a mounting surface 111, and a plurality of holes 112 for installing the grating nanostructure unit 120 are arrayed on the mounting surface 111. The shape of the holes 112 is an inverted quadrangular pyramid, and the apex of the quadrangular pyramid faces the porous silicon substrate. Inside, the bottom surface is located on the mounting surface 111 . The quadrangular pyramid-shaped hole 112 has a depth of 700 nm and a bottom surface of a square with a side length of 200 nm.

[0057] The material of the grating nanostructure unit 120 is polydimethylsiloxane. A plurality of grating nanostructure units 120 correspond to a plurality of holes 112, and each gratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com