Double-cone vacuum drier with narrow-wedge internal heating plate

A vacuum dryer and internal heating technology, applied in non-progressive dryers, dryers, heating devices, etc., can solve the problems of structural pollution hidden dangers of vacuum seals, non-compliance with GMP requirements, and affecting the quality of medicines, etc. Achieve the effect of saving stainless steel material, saving manpower and material resources, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

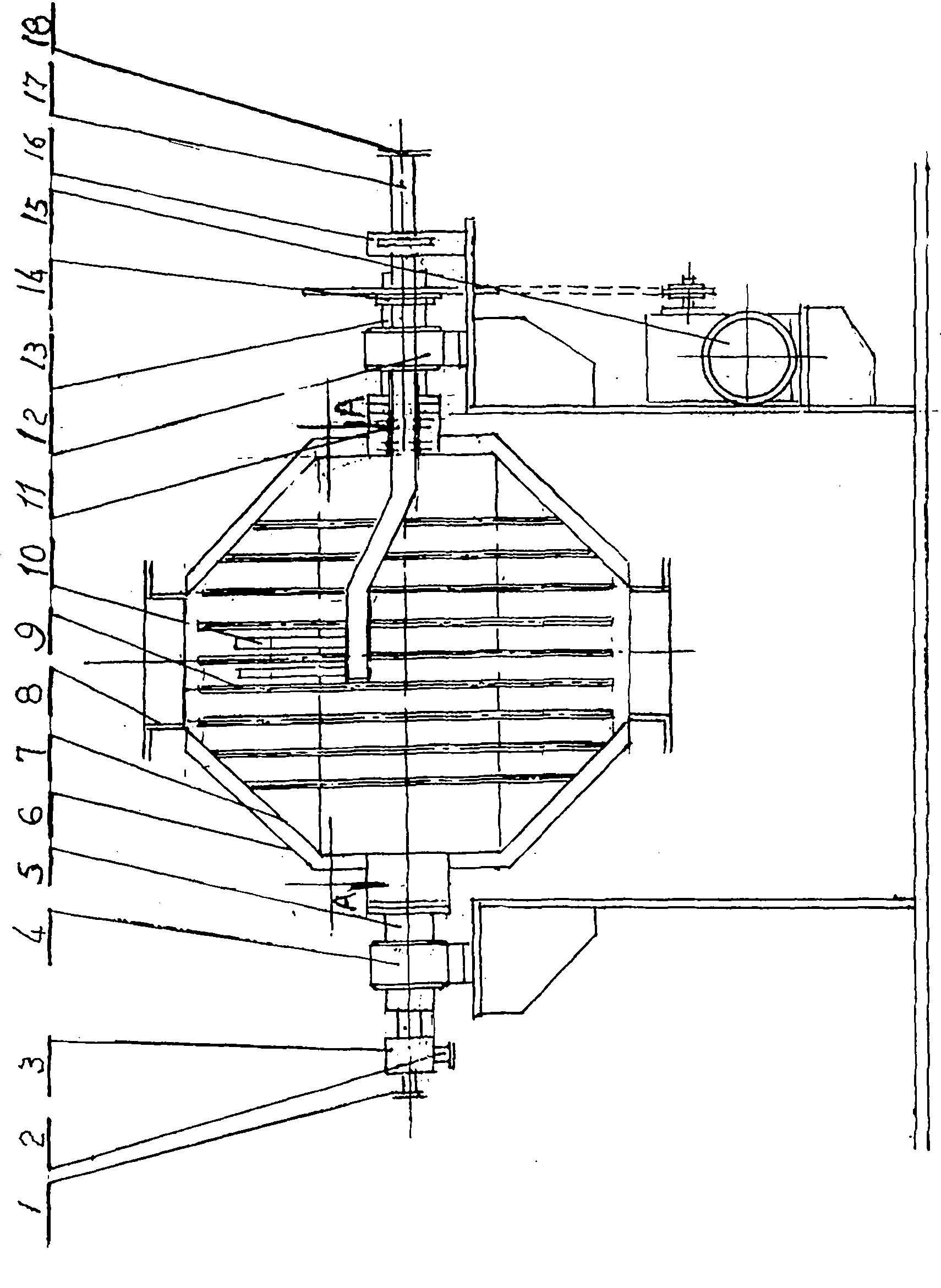

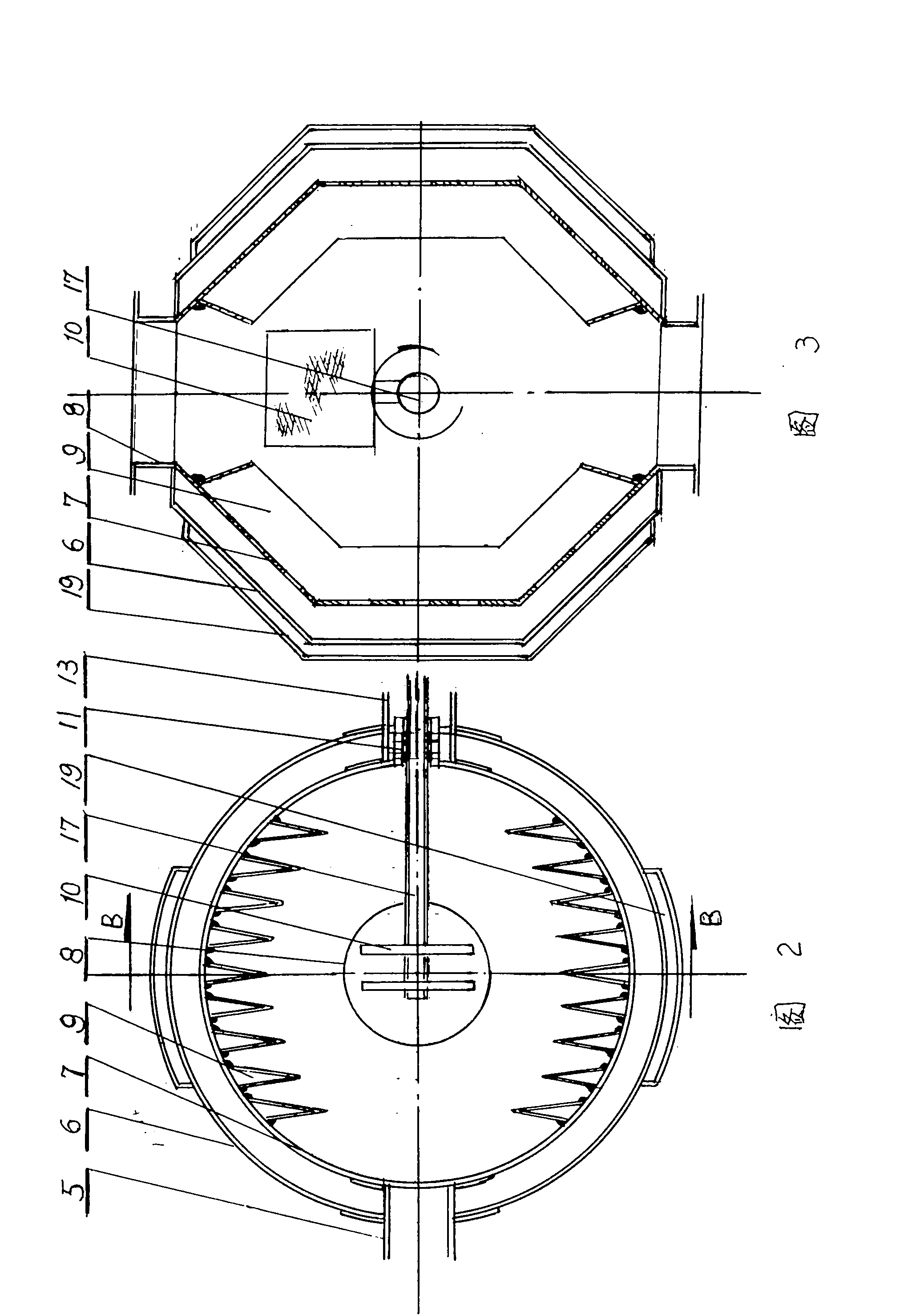

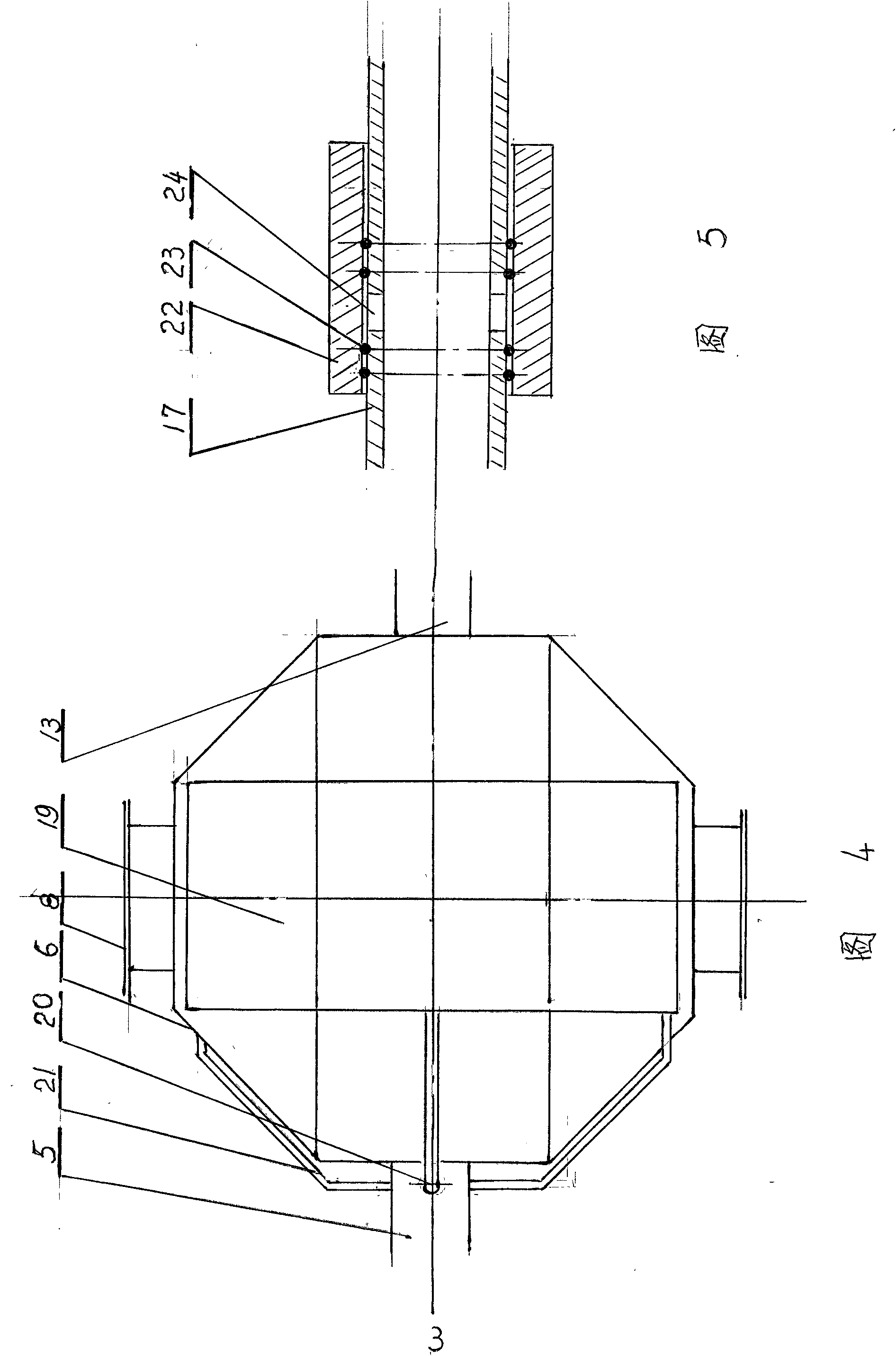

[0012] Embodiments of the present invention will be further described in conjunction with the accompanying drawings, as figure 1 , 2, 3, 4, narrow wedge-shaped inner heating plate double-cone vacuum dryer, which consists of steam inlet (1), steam condensate outlet (2), steam rotary joint (3), left (right) bearing seat (4) , 12), left (right) rotating shaft (5, 13), low-temperature saturated steam generator (6), double cone (7), manhole (8), narrow wedge-shaped inner heating plate (9), exhaust gas filter Air (10), hidden danger rotating vacuum seal (11), driving sprocket (14), driving machine (15), suction pipe fixing seat (16), suction pipe (17), suction port (18) and steam heating Jacket (19) etc. are formed. Its characteristics are: the low-temperature saturated steam generator (6) and the double cone (7) are welded to form a whole, the left (right) rotation axis (5, 13) is fixed on the rotation balance center of the double cone (7), the left ( Right) rotating shaft (5,13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com