Patents

Literature

67results about How to "No whitening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide resin composition

ActiveUS20090239013A1Less amountStably subjectedEnvelopes/bags making machineryBottlesPolymer scienceActive agent

A polyamide resin composition contains a resin component containing at least a polyamide (X) and a fatty acid metallic salt having from 10 to 50 carbon atoms, and contains arbitrarily an additive (A) and / or an additive (B). The polyamide (X) is obtained through melt polycondensation of a diamine component containing 70% by mol or more of m-xylylenediamine and a dicarboxylic acid component containing 70% by mol or more of an α,ω-linear aliphatic dicarboxylic acid. The additive (A) is at least one compound selected from the group consisting of a diamide compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diamine having from 2 to 10 carbon atoms, a diester compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diol having from 2 to 10 carbon atoms, and a surfactant, and the additive (B) is at least one compound selected from the group consisting of a metallic hydroxide, a metallic acetate salt, a metallic alkoxide, a metallic carbonate salt and a fatty acid.

Owner:MITSUBISHI GAS CHEM CO INC

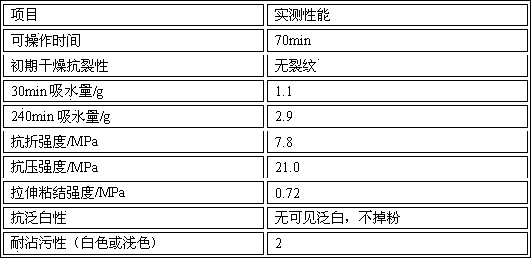

Surface-decorative mortar and preparation method thereof

The invention discloses a surface-decorative mortar for solving the problems that an existing surface-decorative mortar is easily whitened and solving the problems of crisis plant growth. The surface-decorative mortar consists of the following raw materials in parts by weight: 40-80 parts of aluminate cement, 1-30 parts of Portland cement, 20-30 parts of semi-hydrated gypsum, 350-400 parts of quartz sand, 4-12 parts of latex powder, 0.1-0.5 parts of cellulose ether, 0.01-0.5 parts of a retarder, 1-9 parts of a pigment and 75-90 parts of water, wherein the sum of the aluminate cement, the Portland cement and the semi-hydrated gypsum is 100 parts. The surface-decorative mortar disclosed by the invention does not have whitening phenomenon, is good in stain resistance, low in water absorbing capacity, high in bonding strength, good in long-term application performance, durable in color and luster and good in water-proof and air-permeable performance.

Owner:SICHUAN INSITITUTE OF BUILDING RES

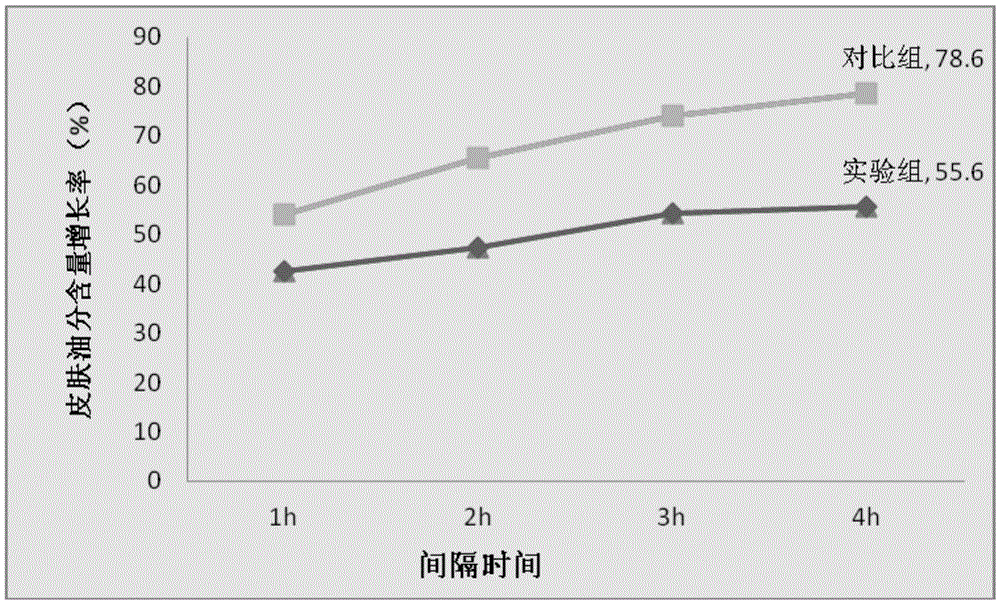

Fresh and cool sun-resistant composition with grease controlling function

InactiveCN105534737AUniform textureGood application effectCosmetic preparationsToilet preparationsSunscreen agentsHydroxystearic Acid

The invention belongs to the technical field of cosmetics, and relates to a fresh and cool sun-resistant composition with a grease controlling function. The sun-resistant composition contains starch aluminum octenylsuccinate and polyhydroxystearic acid. Starch aluminum octenylsuccinate is used for improving greasy feeling when people use the sun-resistant cosmetic, controlling and absorbing grease and relieving the shiny skin problem; polyhydroxystearic acid is used for improving a whitening phenomenon in the using process of the sun-resistant cosmetic. When starch aluminum octenylsuccinate and polyhydroxystearic acid are added into the cosmetic by an appropriate ratio, even if the content of an grease soluble sun-resistant agent and an inorganic sun-resistant agent in the sun-resistant cosmetic is high, a user feels fresh and cool without a greasy feeling, the sun-resistant composition has grease absorbing and controlling effects, and the whitening phenomenon after the sun-resistant composition is smeared is avoided.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +2

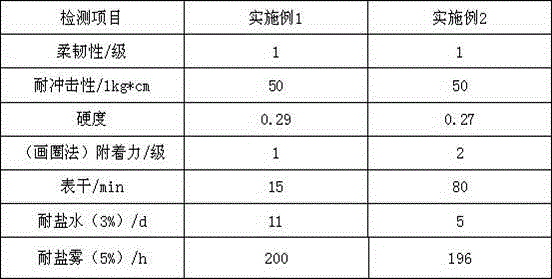

Environment-friendly single-component industrial anti-corrosion coating and preparation method thereof

The invention relates to a waste-based coating, in particular to a water-based industrial anti-corrosion coating. The invention discloses the water-based industrial anti-corrosion coating and a preparation method thereof. The anti-corrosion coating is prepared from the following components in percentage by weight: 10 to 50 percent of modified water-based acrylic resin, 5 to 20 percent of anti-rust pigments, 0.5 to 20 percent of a filler, 10 to 40 percent of a solvent, 2 to 20 percent of an auxiliary, 0.1 to 4 percent of a water-based dryer, 0.1 to 4 percent of a diluent and 0.5 to 2 percent of a water-based thickener. The water-based industrial anti-corrosion coating does not have the problems of blistering, whitening, fracturing, delaminating and the like, can be firmly attached to the surface of a metal, and is high in flexibility and bonding strength; the salt fog resistance and the corrosion resistance of the water-based industrial anti-corrosion coating can be improved, and the drying performance of the coating is improved; the water-based industrial anti-corrosion coating is excellent in corrosion resistance; furthermore, the raw materials are highly available; the production process is simple, and the construction is convenient.

Owner:广东珠江化工涂料有限公司

Water exterior wall paint and its preparing process

The invention relates to a water fluorocarbon paint for external-wall painting, comprising solvent (water), water fluorocarbon latex, filler, composite film-forming auxiliary agent, disperser, moistening agent, leveling agent, thickening agent and germicidal agent. In the paint, solvent (water) covers 5 to 15 percent, water fluorocarbon latex covers 40 to 70 percent, composite film-forming auxiliary agent covers 5 to 14 percent, rutile titanium pigment covers 10 to 25 percent, talc powder covers 5 to 10 percent, disperser covers 0.1 to 0.5 percent, moistening agent covers 0.001 to 0.003 percent, leveling agent covers 0.004 to 0.01 percent, thickening agent covers 1 to 1.8 percent, and antifoaming agent covers 0.01 to 0.05 percent. The invention provides an efficient novel water fluorocarbon paint for external-wall painting by changing fillers and increasing the dose of composite film-forming auxiliary agent. The preparation process is simple, the paint is free of dehiscence, spurging and whitening; the painted wall-surface is smooth, and the light and color are well reserved; the paint has sound flexibility, weathering resistance, corrosion resistance, heat / cold resistance, acid / alkali resistance and better film-forming performance; the paint is environment-friendly, low-cost and construction friendly; and the prospect of development is very bright.

Owner:JIANGSU UNIV OF SCI & TECH

Bright and injection-molding wood plastic composite and method for preparing the same

The invention discloses a bright and injection-molding wood plastic composite and method for preparing the same and belongs to a wood plastic composite and a method for preparing the same. The wood plastic composite comprises the following components in percentage by mass: 50 to 70 percent of renewable PP or HDPE, 30 to 50 percent of wood powder, 5.0 to 10.0 percent of nanometer absorbent, 5.0 to 10.0 percent of surfactant, 1.0 to 2.0 percent of super lubricant, 1.0 to 2.0 percent of titanate coupling agent, 0.5 to 5.0 percent of polyethylene wax, 2.0 to 5.0 percent of stearic acid or stearate, and 5.0 to 15 percent of maleic anhydride-grafted PE or PP grafted with a molecular weight of between 5,000 and 30,000. The wood powder and the nanometer absorbent are mixed at a high rotation speed of 1,500 to 2,500 r / m for 10 to 15 minutes, then the titanate coupling agent is added and mixed at a high rotation speed of 1,500 to 2,500 r / m for 5 to 6 minutes, and finally other components are added to be mixed at a rotation speed of 1,500 to 2,500 r / m for 20 to 30 minutes and then mixed at a rotation speed of 300 to 600 r / m for 5 to 10 minutes so as to obtain the premix. The premix is extruded and pelletized by an extruder to obtain the bright and plastic injection wood plastic composite. The wood plastic composite has the advantages of high surface glossiness, excellent high-temperature flow performance, high strength and toughness, low cost and the like, can widely substitute plastics and is used for production of products with complex shapes.

Owner:JIANGSU HENGFAMU PLASTIC SCI & TECH

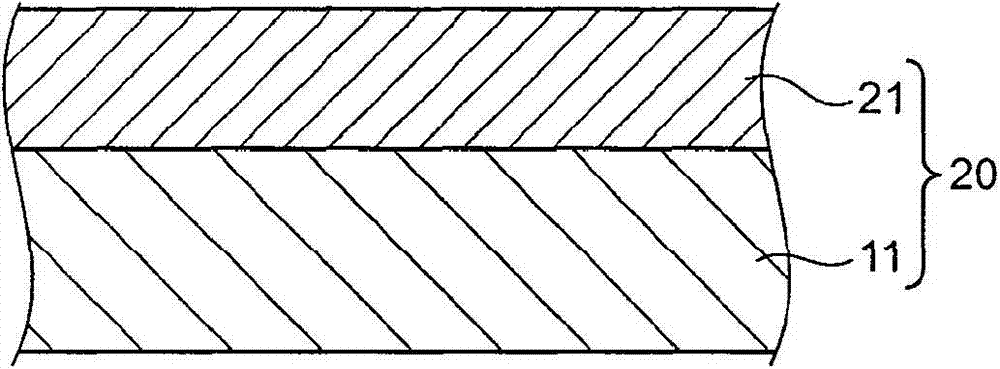

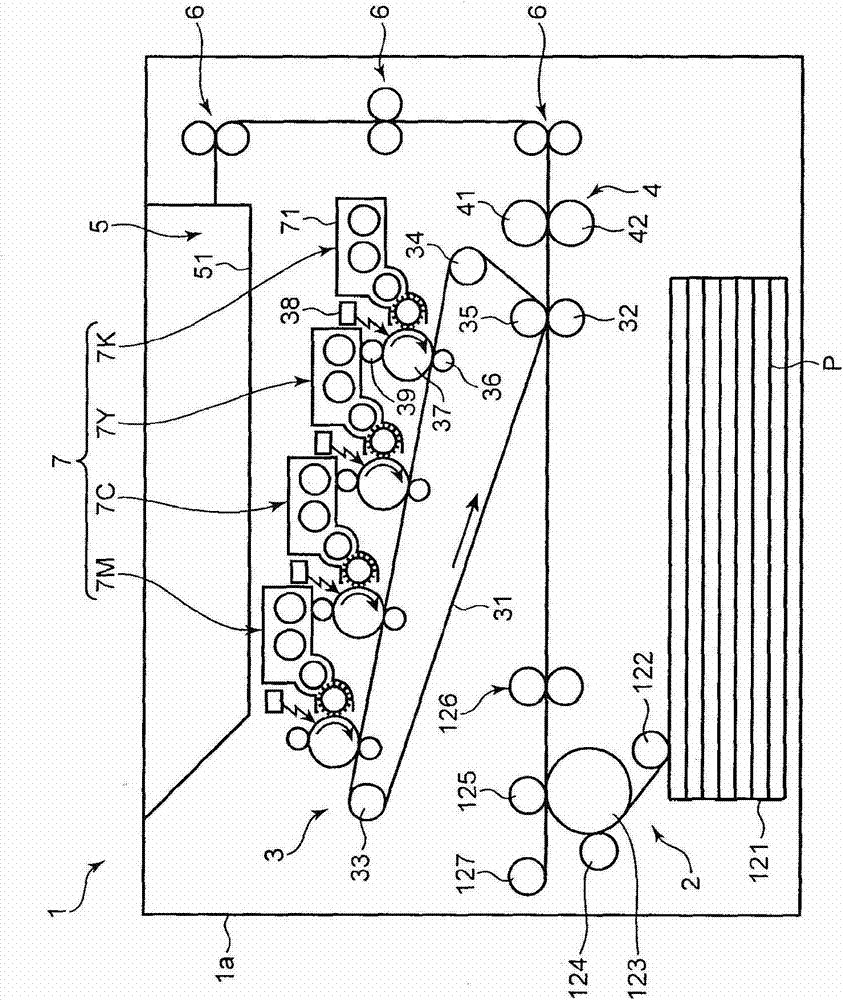

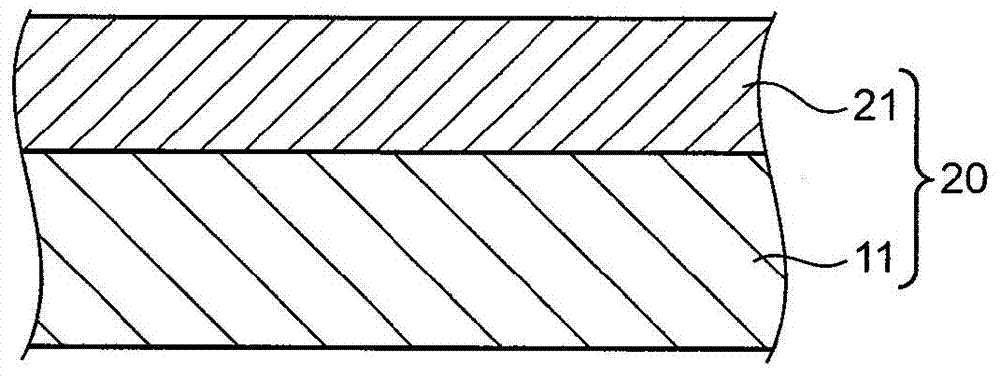

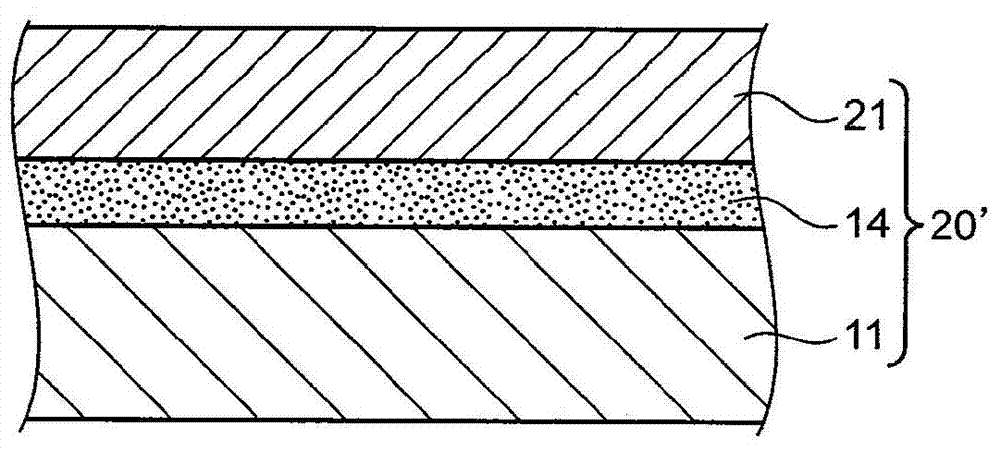

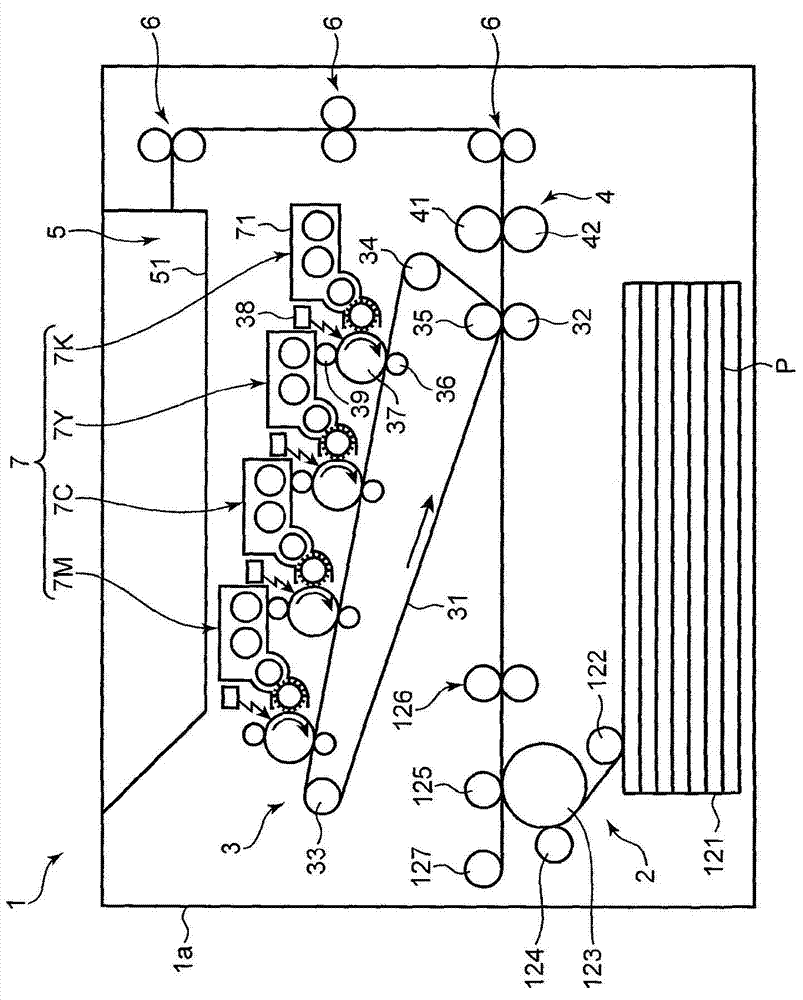

Positively-charged single-layer electrophotographic photoreceptor and image forming apparatus

The invention relates to a positively-charged single-layer electrophotographic photoreceptor and an image forming apparatus. A photosensitive layer containing at least a binding resin and a charge transporting material is provided on a photosensitive layer support base with a wall thickness of 0.7 mm or less, wherein when the charge transporting material is solely constituted by a hole transporting material, a content of the hole transporting material is 110 parts by mass or less with respect to 100 parts by mass of the binding resin, and when the charge transporting material is constituted by a hole transporting material and an electron transporting material, a content of the hole transporting material is 130 parts by mass or less and a content of the electron transporting material is 5 parts by mass or more with respect to 100 parts by mass of the binding resin, and a sum total of the hole transporting material and the electron transporting material is 140 parts by mass or less. Therefore, a support with thin wall is provided with a photosensitive layer without blushing.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

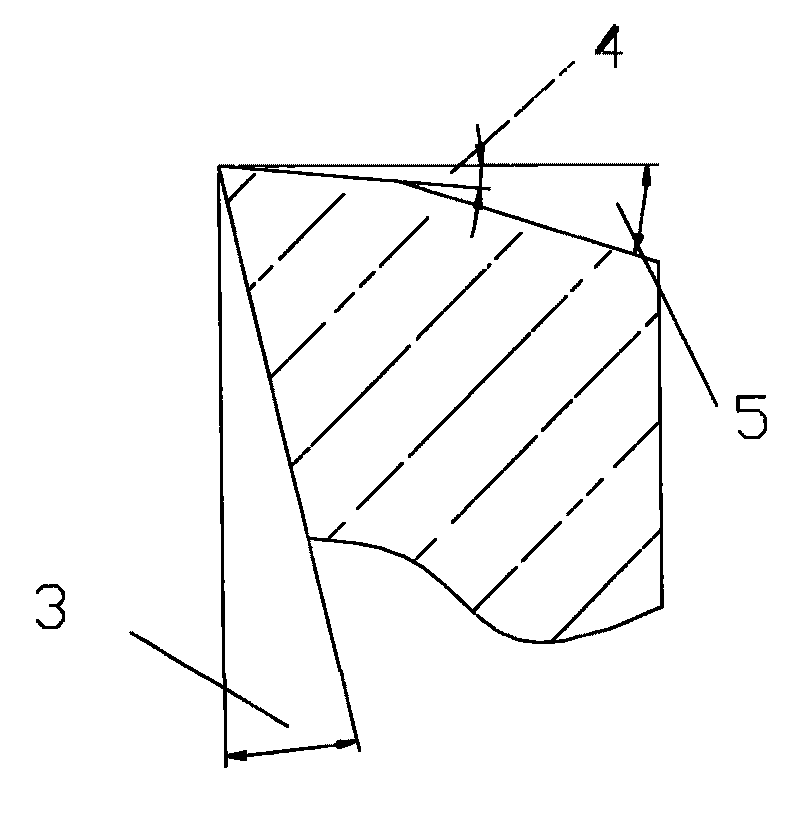

Method for processing nylon internal polygon and special cutter thereof

InactiveCN101745682ANo whiteningNo debris sticking to the knifePlaning/slotting toolsPlaning/slotting machinesMechanical engineeringIndexing head

The present invention relates to a method for processing a nylon internal polygon. All surfaces of an internal polygonal hole are orderly cut by common machine processing equipment and a special cutter. The cutting output of a part is from 0.02mm to 0.05mm during the cutting. After one face is cut, an indexing head is rotated for 360 degrees per Newton, the next face of the part is cut, and the other faces of the polygon are processed in the mode. The cutter is a straight handle type or a conic handle type, the width of a cutting edge is equal to the side length of the internal polygon, and a chip removal angle is arranged between the front cutter face and the rear cutter face of the cutter. A front cutter angle (3) is from 8 degrees to 12 degrees. The front angle (4) of a rear cutter angle is from 6 degrees to 10 degrees, and the rear angle (5) is from 9 degrees to 15 degrees. When a part of the internal polygon processed by the method is cut to the internal square root part, the phenomena of whitening part, chip adherence to the cutter, fracture failure, etc due to large cutting quantity and heated materials are avoided. The surfaces of internal square hole are smooth. The present invention has the advantages of high operability, high practicability, low manufacture cost and good product quality.

Owner:XIAN AIRCRAFT IND GROUP

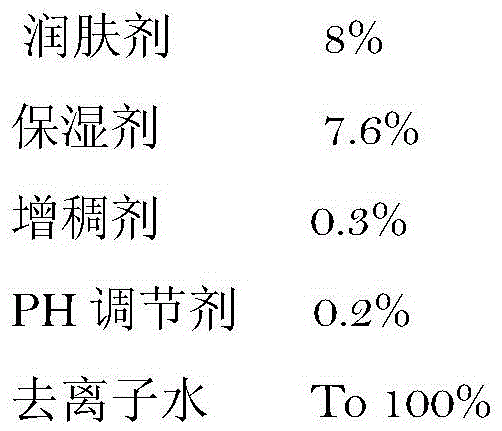

Cement waterproofing coating, and preparation method and application thereof

ActiveCN111117314AGood compactnessReduce free precipitationCement coatingsDefoaming AgentsPolymer chemistry

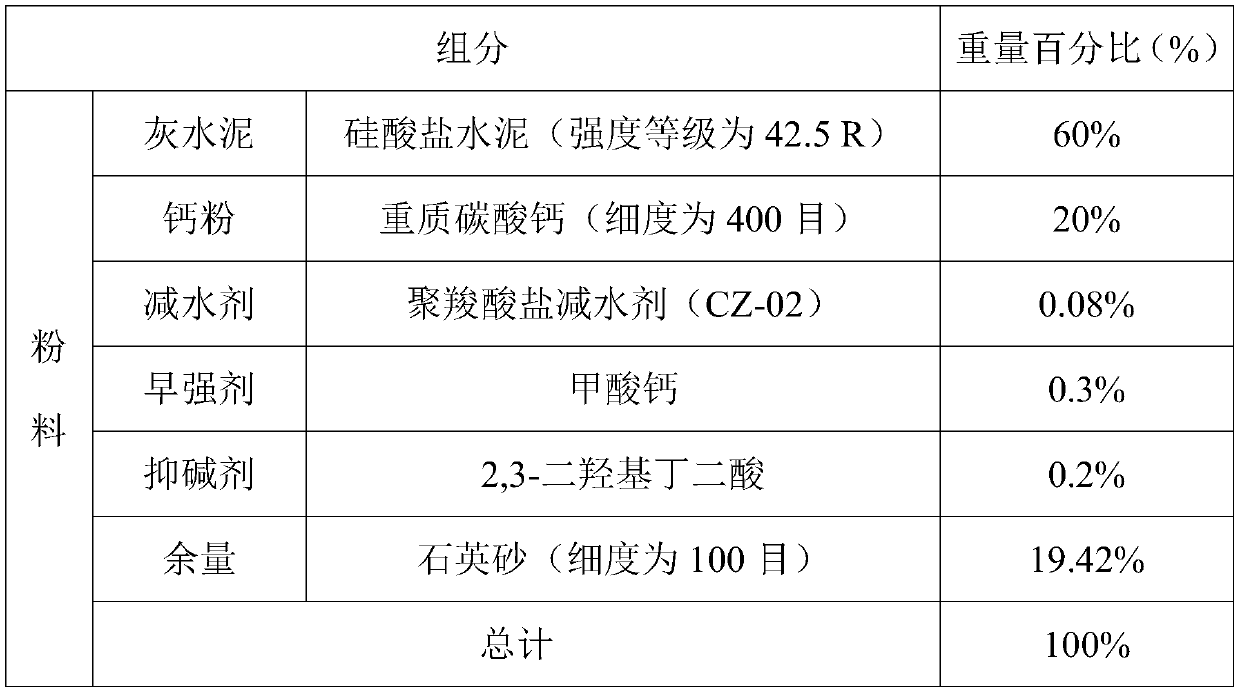

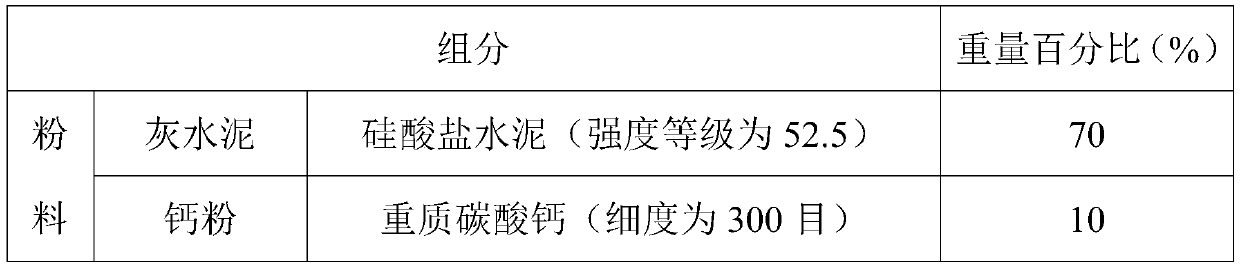

The invention provides a cement waterproofing coating, and a preparation method and an application thereof. The cement waterproofing coating is composed of a powder material and a liquid material, 100wt% of the powder material comprises 50-70 wt% of ash cement, 10-30 wt% of calcium powder, 0.02-0.1 wt% of a water reducing agent, 0.1-0.4 wt% of an early strength agent, 0.1-0.3 wt% of an alkali inhibitor, and the balance of quartz sands; and 100 wt% of the liquid material comprises 75-80 wt% of an emulsion, 0.2-0.4 wt% of a defoaming agent, 0.5-3.0 wt% of a coalescing agent, 0.3-0.6 wt% of a thickening agent, and the balance of water. The cement waterproofing coating enables a coating film to form a compact and non-whitening coating film under low-temperature and high-humidity conditions, and meanwhile, the film formed by the coating is excellent in tensile strength, elongation at break and waterproof performance.

Owner:SHENZHEN ZHUOBAO TECH +1

Anti-dazzle liquid, and preparation method and application thereof

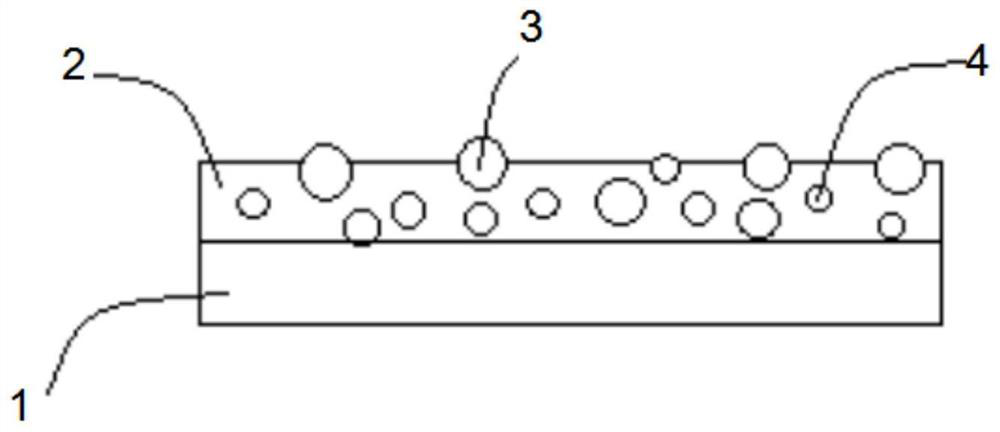

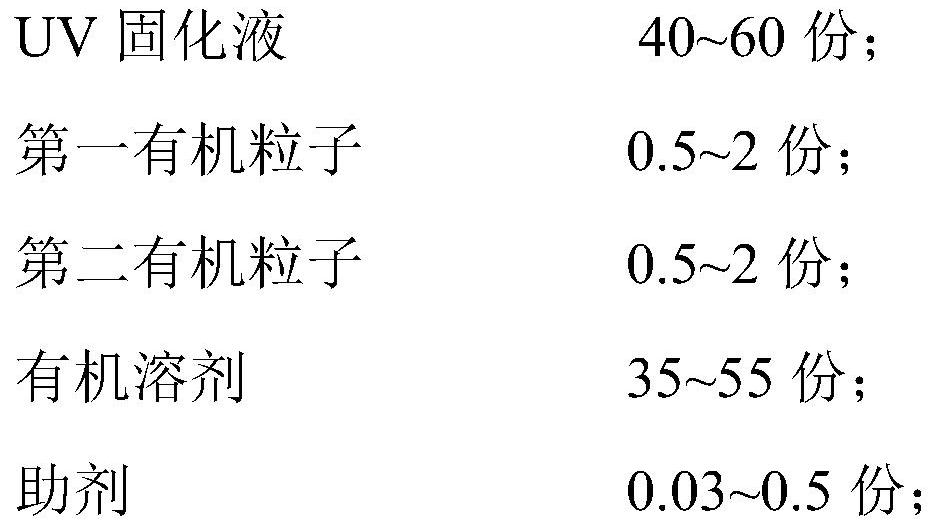

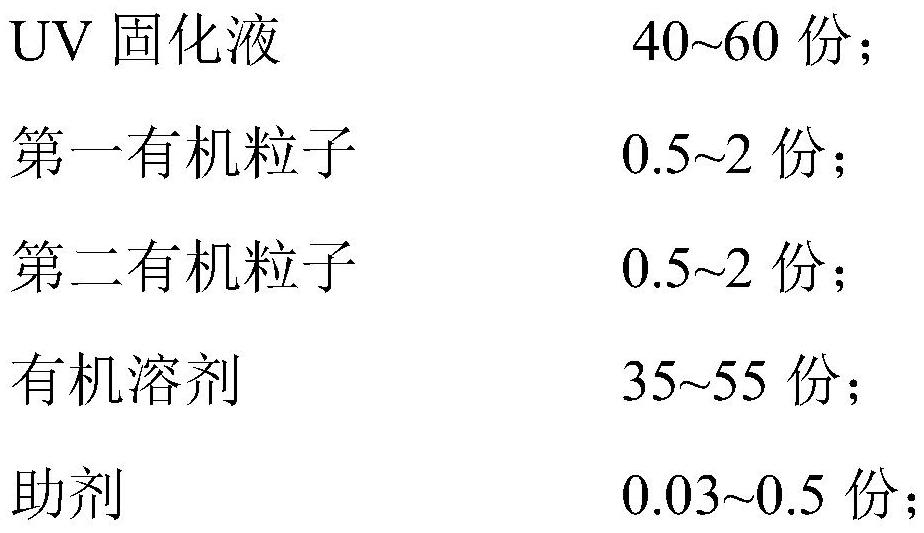

The invention relates to the technical field of display, and provides an anti-dazzle liquid, and a preparation method and application thereof. The anti-dazzle liquid comprises, by weight, 40-60 parts of a UV curing liquid; 0.5-2 parts of first organic particles; 0.5-2 parts of second organic particles; 35-55 parts of an organic solvent; and 0.03-0.5 part of an auxiliary agent. The particle size of the first organic particles is 3-5 microns, and the particle size of the second organic particles is 0.5-2.5 microns. By controlling the particle sizes of the two organic particles, on one hand, particle dispersion is facilitated, the whole coating forms a small uneven plane, and it is guaranteed that the obtained anti-dazzle film can obtain larger haze and the anti-dazzle layer does not have the whitening condition; and on the other hand, the thickness of the anti-dazzle layer can be properly increased without reducing the light transmittance of the film, and high hardness and excellent wear resistance are ensured.

Owner:SHENZHEN SUNNYPOL OPTOELECTRONICS

High-temperature-resistant low-voltage switchgear cabinet

InactiveCN105368248AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:江苏宇恒电气有限公司

Nanometer modified real stone paint base material

InactiveCN105255292AHigh boiling pointEnvironmental protection is goodAntifouling/underwater paintsPaints with biocidesStrong acidsHydroxyethyl cellulose

The invention provides a nanometer modified real stone paint base material, belonging to the technical field of constructional paint products. The nanometer modified real stone paint base material comprises the following raw materials by weight: 120 parts of water, 2 parts of hydroxyethyl cellulose ether, 2 parts of a high-efficiency thixotropic agent, 1 part of a multifunctional auxiliary agent, 3 parts of a film forming auxiliary agent, 1 part of a bactericide and 210 parts of a silicone-modified acrylate emulsion. A finished product prepared by uniformly mixing 680 parts of quartz sand with the base material composed of the above-mentioned raw materials has the following beneficial effects: excellent water resistance, no whitening, floating, falling and fading after immersion in water for 240 h, and no yellowing of a white real stone paint; high strength, good toughness, strong anti-impact force and small possibility of cracking; excellent adhesion and penetration performance, substantially prolonged service life, and co-existence of a nanometer modified real stone paint and a wall; and strong acid resistance and alkali resistance, antibacterial performance, mildew resistance, algae resistance and excellent resistance to high and low temperature.

Owner:李茂英

High-permeability skin care composition as well as nano-emulsion and preparation method thereof

InactiveCN111803425AFast absorptionPromote absorptionCosmetic preparationsToilet preparationsVegetable oilDermal exposure

The invention discloses a high-permeability skin care composition. The composition comprises a vegetable fat active component and an ester emulsifier; the weight ratio of the vegetable fat active component to the ester emulsifier is (1-15):1; and the ester emulsifier is polyglycerol fatty acid ester and / or hydrogenated lecithin. A high-permeability skin care nano-emulsion prepared from the high-permeability skin care composition has good stability, after the nano-emulsion is in contact with the skin, most of the emulsion can be rapidly absorbed by the skin, absorption of effective components is promoted, and the surface of the skin is not whitened; the skin feeling is fresh and non-irritant, the greasy filming skin feeling is avoided, and the stuffy and wet feeling is also avoided; and after long-time use, the skin is smooth and glossy, the skin texture is effectively moistened and moisturized, the skin texture is smoothened, the skin is softened, and the skin barrier is strengthened.

Owner:杨庆瑞

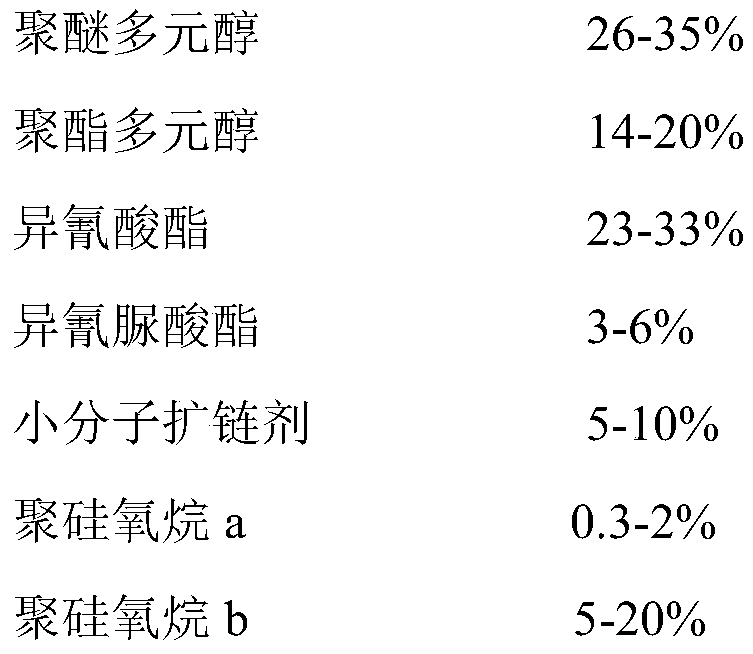

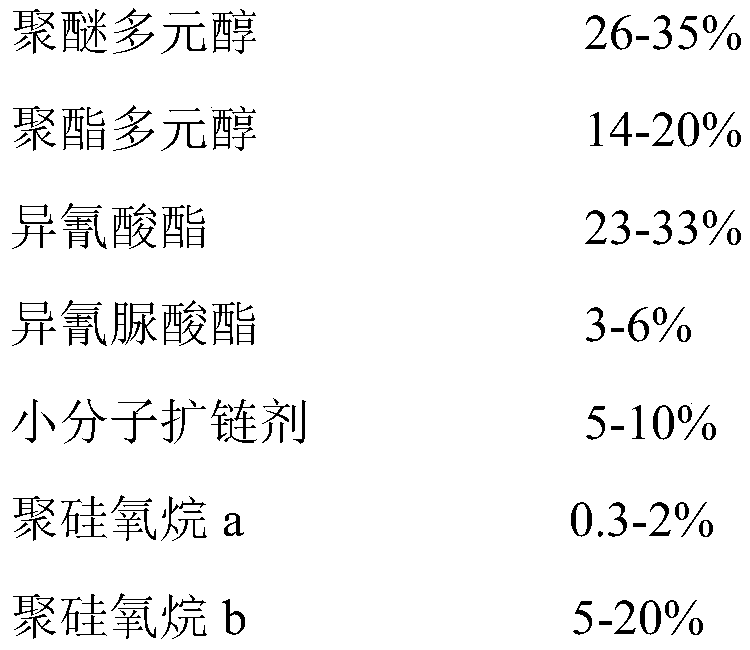

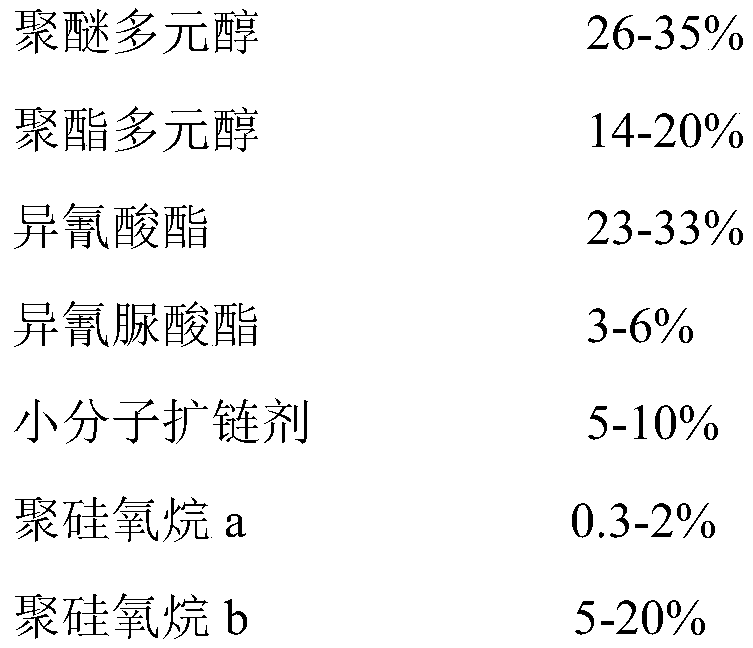

Polyurethane resin for synthetic leather surface layer, and preparation method thereof

The invention relates to a polyurethane resin for a synthetic leather surface layer, and a preparation method thereof. The preparation method of the polyurethane resin comprises the following steps: jointly adding polyether polyol, polyester polyol, polysiloxane a and a part of solvent into a reaction kettle, stirring at 40-55 DEG C until the components are completely dissolved, adding a part of isocyanate, heating to 70-80 DEG C, and carrying out a prepolymerization reaction for 0.5-1 h; continuously adding a small molecular chain extender, cooling to 50 DEG C, stirring for 15-30 min, addinga catalyst, supplementing the remaining isocyanate, heating to 70-80 DEG C, and continuously reacting for 0.5-1 h; and supplementing the remaining solvent until the viscosity reaches 100-160 cps, cooling to the temperature of 50 DEG C, continuously stirring for 1-1.5 h, and adding isocyanurate and polysiloxane b to obtain the polyurethane resin for the synthetic leather surface layer. The productprovided by the invention has outstanding wear resistance and heat resistance, does not whiten after high-temperature embossing, has a remarkable antifouling effect after being applied to synthetic leather, and is not prone to being stained with dust.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

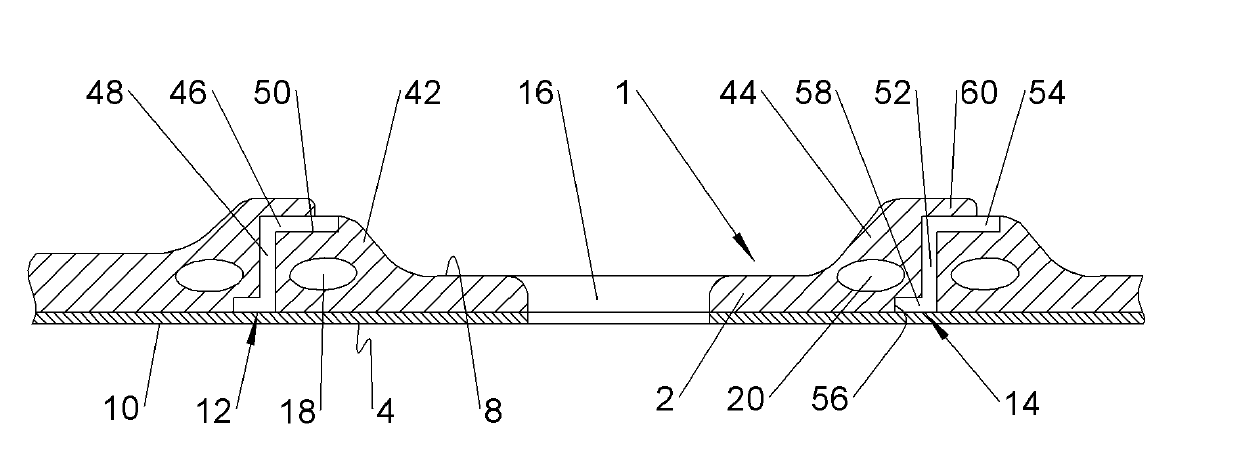

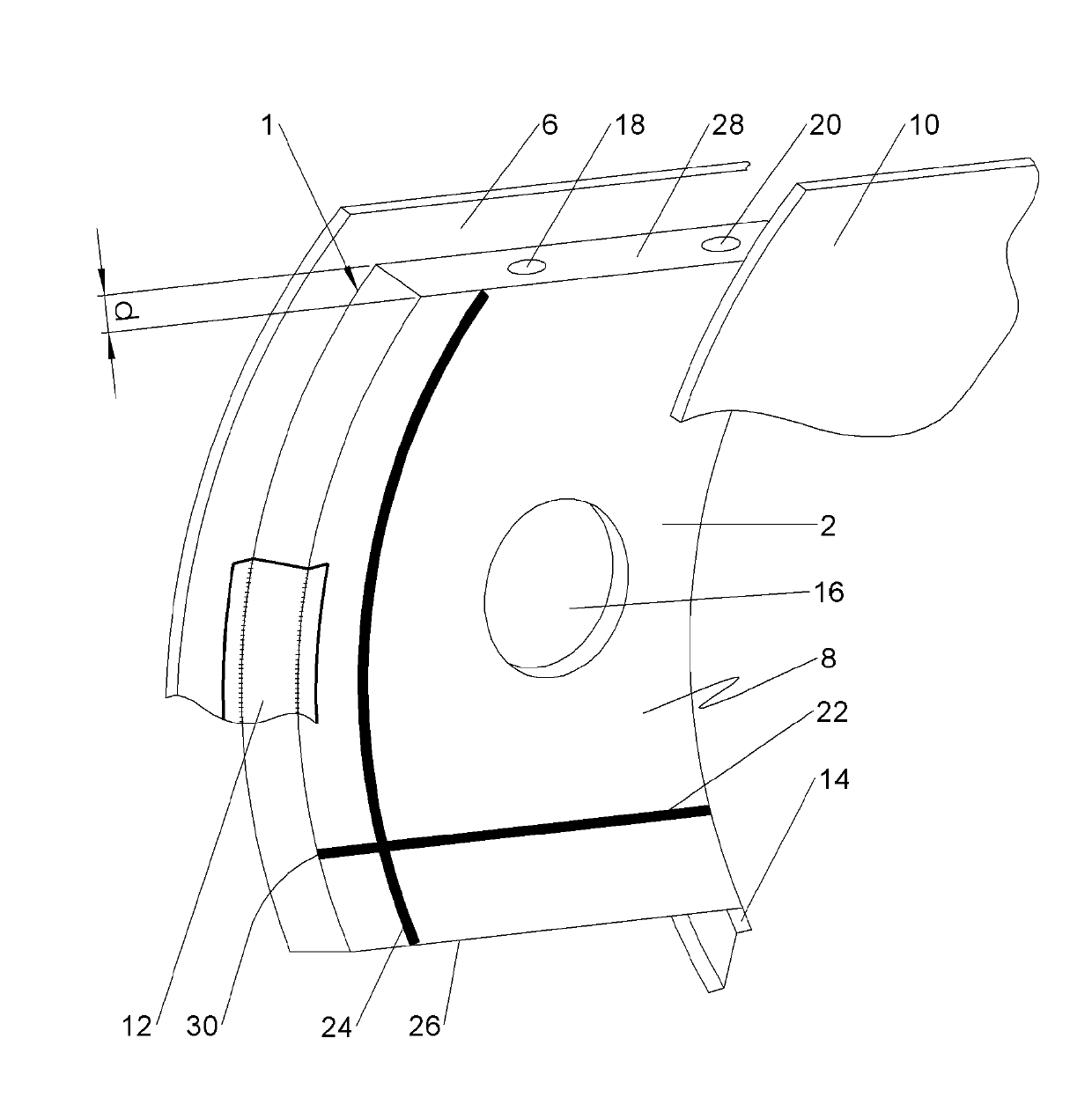

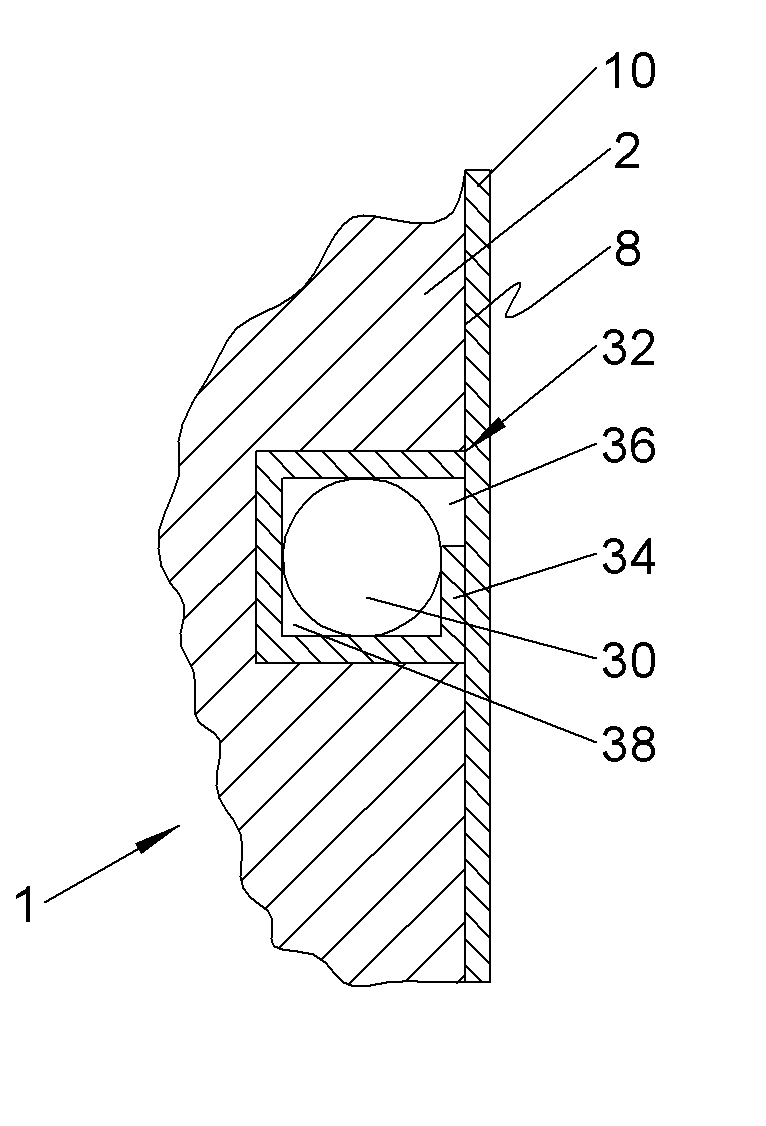

Panel, method for manufacturing a panel and aircraft

ActiveCN103502094AEasy to installReduces the risk of damaging wiring cablesFuselage framesAir-treatment apparatus arrangementsAir conditioningAerospace engineering

Owner:AIRBUS OPERATIONS GMBH

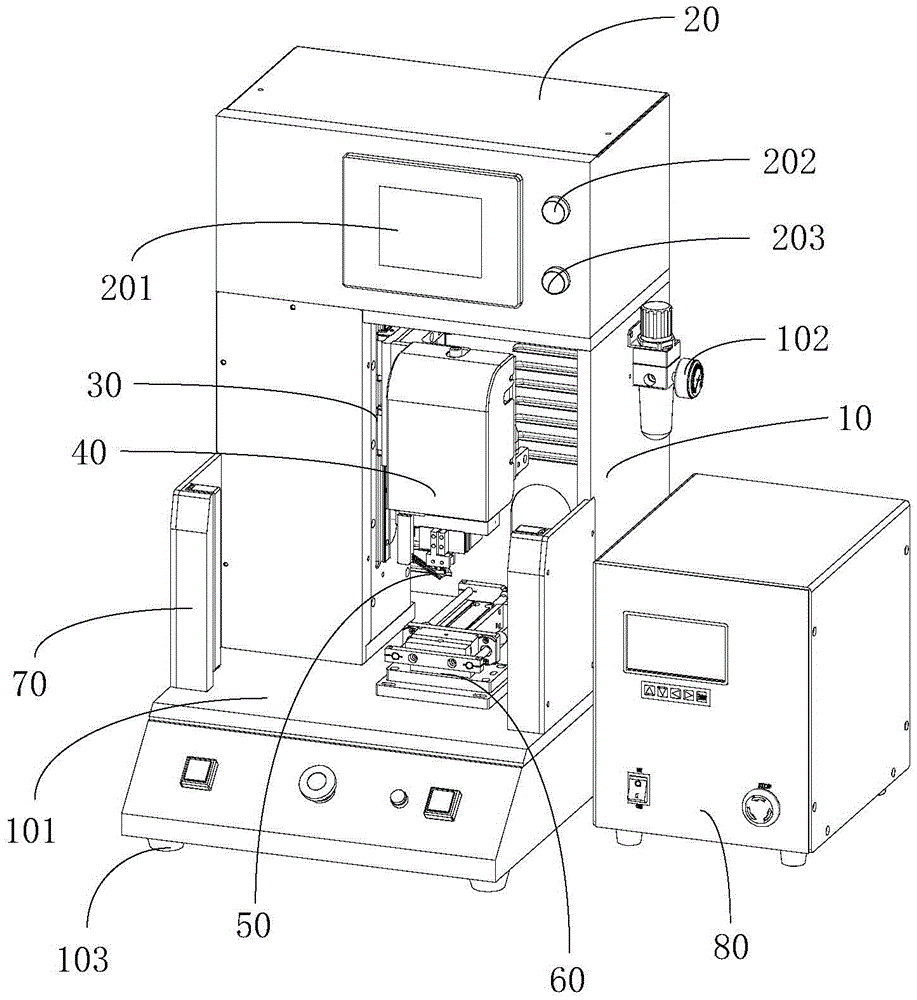

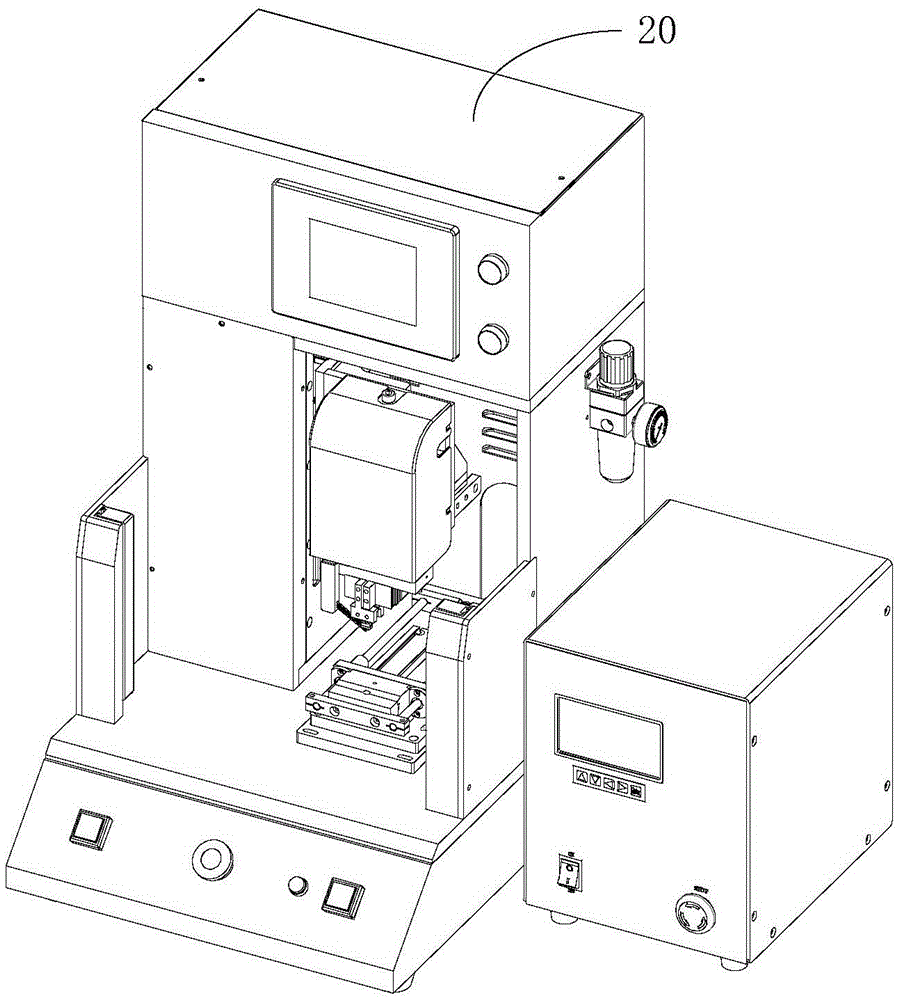

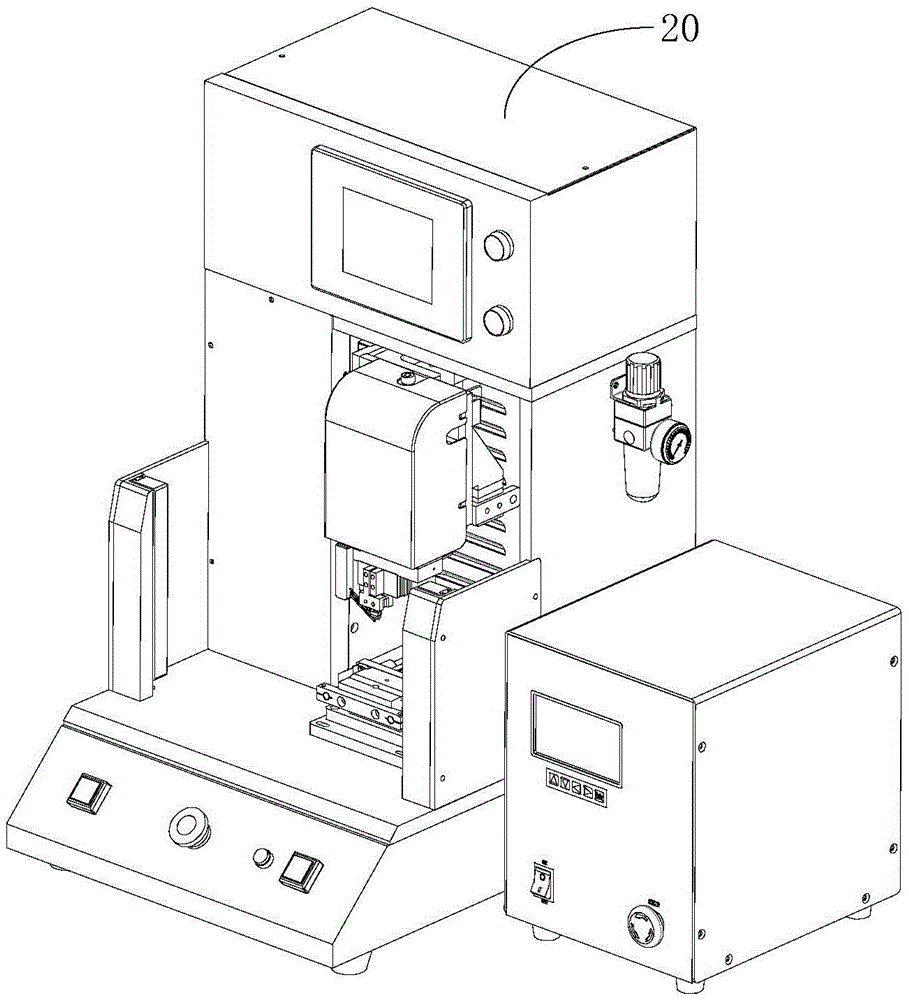

Intelligent wearable net membrane welding and splicing technique

ActiveCN105643084ANo whiteningNo cloggingMetal working apparatusNon-electric welding apparatusHot meltEngineering

The invention discloses an intelligent wearable net membrane welding and splicing technique. The intelligent wearable net membrane welding and splicing technique comprises the following steps that A, a hot-melt acoustic net membrane is cut to be of the preset size through a cutting machine, so that a membrane piece is formed; B, a waterproof test is conducted on the membrane piece obtained in the step A; C, a breathability test is conducted on the membrane piece obtained after the step B is completed; D, the sound loss degree of the membrane piece obtained after the step C is completed in the sound transmission process is tested; and E, the membrane piece obtained in the step D is fixed to the outer surface of intelligent wearable equipment or an opening communicating with the outside through hot melting by means of a servo hot melting machine, and cooling is conducted, so that a machined product is obtained. By the adoption of the technique, the rate of finished products is high, the net membrane is prevented from being blocked, the machining cost is low, and the technique is easy to apply and popularize.

Owner:DONGGUAN FUJIA MACHINERY CO LTD

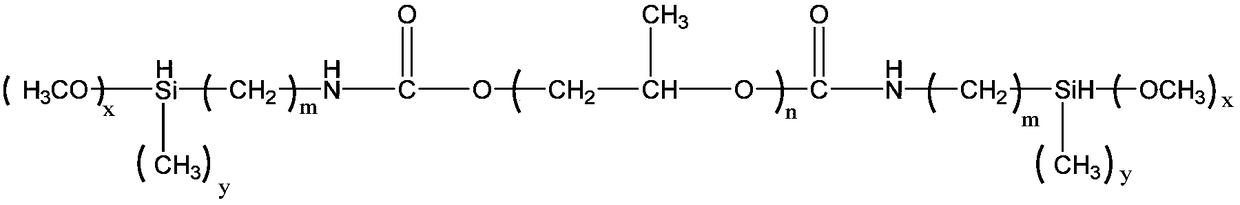

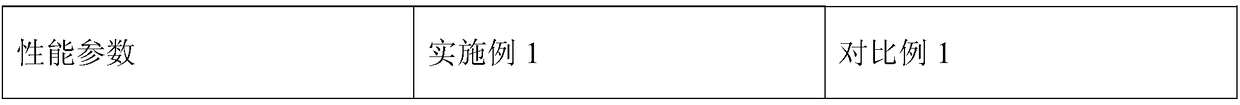

Silane-modified polyether adhesive for single-component tile seam decoration industry

InactiveCN108641667AIncrease crosslink densityGood bonding performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWeather resistanceSilicone resin

The invention discloses a silane-modified polyether adhesive for the single-component tile seam decoration industry. The silane-modified polyether adhesive comprises, by weight, 20-60 parts of silane-terminated polyether, 20-50 parts of silicone resin, 1-10 parts of polyether polyol or diisodecyl ortho-phthalate, 1-5 parts of a dehydrating agent, 0.1-1 part of an antiager, 0.1-1 part of a hinderedamine light stabilizer, 1-20 parts of a filler, 1-5 parts of a tackifier, 5-15 parts of a crosslinking agent and 5-8 parts of a thixotropic agent. The filler comprises one or more of nano-titanium dioxide, carbon black, pearl powder and glitter powder. The tackifier is gamma-(2, 3-epoxypropoxy)propyltrimethoxysilane. The cross-linking agent is gamma-aminopropyltriethoxysilane. The thixotropic agent is fumed silica. The silicone resin is methoxy functional polyphenylmethylsiloxane. The adhesive is anti-mild, anti-black, excellent in weather resistance, excellent in anti-yellowing, non-whitening, excellent in bonding performances and convenient in operation.

Owner:广州锋凌新材料科技有限公司

Anti-corrosion and anti-abrasion coating for power generator blade and preparation method thereof

InactiveCN108504244AImprove wear resistanceHigh bonding strengthFireproof paintsAnti-corrosive paintsEpoxySolvent

The invention discloses an anti-corrosion and anti-abrasion coating for a power generator blade and a preparation method thereof. The anti-corrosion and anti-abrasion coating is prepared from the following components in parts by weight: 30 to 40 parts of epoxy resin, 12 to 20 parts of organic silicon resin, 5 to 10 parts of graphite powder, 3 to 7 parts of mica powder, 4 to 8 parts of hydroxy propyl methyl cellulose, 5 to 12 parts of nanometer silicon dioxide, 7 to 16 parts of anti-abrasion filler, 1 to 5 parts of preservative, 1 to 3 parts of curing agent, 0.4 to 1.4 parts of flattening agent, 0.2 to 0.6 part of dispersant, and 20 to 30 parts of solvent. The anti-corrosion and anti-abrasion coating has the advantages that the anti-corrosion and high temperature-resistant properties are realized; the anti-abrasion property is good, the adhering strength is excellent, the dielectric property is good, the size stability of the product is good, the hardness is high, the flexibility is better, and the stability to alkaline and most of solvents is realized; the anti-corrosion, air-blocking and water-blocking properties are good, the service life is long, and the problems of foaming, cracking, whitening, delaminating and the like are solved.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Non-benzene harmless diluent and production method thereof

InactiveCN104946001AHas a fruity scentIncrease relative volatilityCoatingsNitrocelluloseKetone solvents

The invention discloses a non-benzene harmless diluent which comprises, by mass percent, 55-70% of acetal-type or ethanol mixtures, 23-30% of aliphatic carboxylic acid derivatives, 5-7% of aliphatic alcohol, 2-5% of ketone solvents and 0-3% of solvents with multifunctional groups. According to the non-benzene harmless diluent, the preparation is easy, the cost is low, the dissolving capacity is strong, the evaporation speed is high, and the film-forming time is short, so that paint films are shining, blushing of the paint films does not occur, and the anti-humidity property and the heat-resistant property are improved; the non-benzene harmless diluent can dissolve and dilute materials of cellulose acetate, nitrated cellulose, resin and rubber, cellulose ether, chlorinated rubber, synthetic resin, coatings and paint.

Owner:汪青

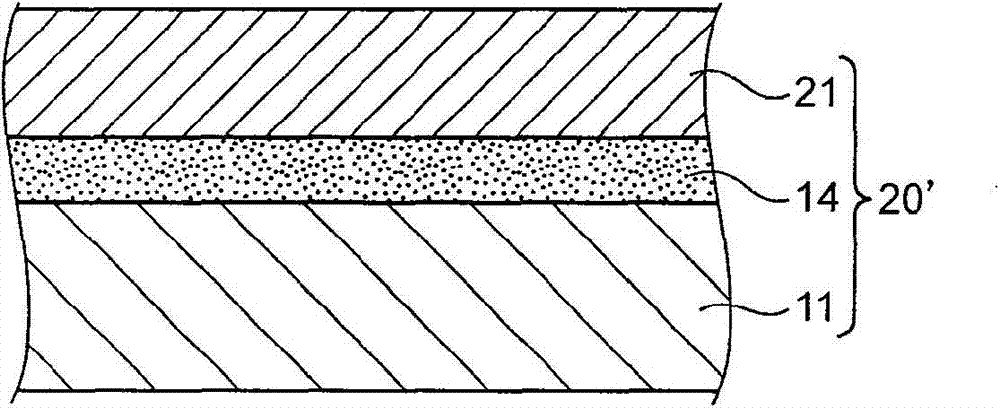

Electrophotographic photoreceptor, method of manufacturing electrophotographic photoreceptor, and image forming apparatus

The invention relates to a positively-charged single-layer electrophotographic photoreceptor, a method of manufacturing electrophotographic photoreceptor, and an image forming apparatus. The method of manufacturing a positively-charged single-layer electrophotographic photoreceptor including the steps of: producing a photosensitive layer application liquid containing a good solvent with respect to a binding resin and at least one organic solvent having a boiling point of 70 DEG C. or higher; and forming a photosensitive layer by coating a photosensitive layer support base having a wall thickness of 0.7 mm or less, with the photosensitive layer application liquid and then drying the photosensitive layer application liquid. Therefore, even when a thin-walled support base is used, blushing can be prevented.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Fresh-keeping fruit wax for fruits and preparation method of fresh-keeping fruit wax

InactiveCN107027879ANo whiteningWith breathable water controlFruits/vegetable preservation by coatingFood ingredient for microbe protectionWaxAmmonium hydroxide

The invention discloses fresh-keeping fruit wax for fruits and a preparation method of the fresh-keeping fruit wax. The fresh-keeping fruit wax consists of the following formula ingredients in parts by mass: 18-28 parts of vegetable wax, 6-8 parts of an ammonia solution, 1-2 parts of a glossy agent, 4-6 parts of aleuritic acid, 5-7 parts of myristic acid, 7-9 parts of citric acid, 14-16 parts of abietic acid resin, 1-2 parts of a food preservative, 10-14 parts of calcium chloride, 14-16 parts of morpholine, 3-5 parts of ethanol and 50-60 parts of water. The fresh-keeping fruit wax disclosed by the invention not only has comprehensive excellent efficacy of being shiny and bright after wax film formation, free from whitening, ventilated, capable of retaining water, lasting and stable, capable of keeping fresh, capable of guaranteeing quality and the like, and is environmental-friendly and hygienic.

Owner:钦州阜康农副食品有限公司

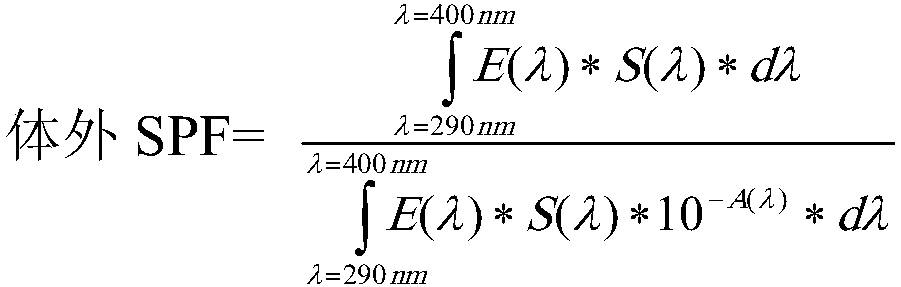

Photoprotective system

InactiveCN108464951AFlawless application formNon stickyOrganic active ingredientsCosmetic preparationsBenzoic acidEthyl group

The present invention concerns a topical, cosmetic or pharmaceutical preparation containing a combination of 3 or 4 solar filters comprising: -one or two UVA filters to obtain a critical wavelength >370 nm, chosen from among: ( i) - 5, 6, 5, 6-tetraphenyl-3, 3'-(1,4-phenylene)-bis[1, 2, 4]triazine; (ii) 1,1'-(1,4-piperazinediyl)bis[1-[2-[4-(diethylamino)-2-hydroxybenzoyl]phenyl]-methanone; (iii)- Butyl Methoxydibenzoylmethane (BMDBM), in a quantity less than 2% by weight with regard to the total weight of said composition; (iv) - Hexyl -[4-(diethylamino)-2- hydroxybenzoyl]benzoate, -2,4-Bis[4-(2-ethylhexyloxy)-2-hydroxyphenyl]-6- (4-methoxyphenyl)-1, 3, 5-triazine = (BEMT), - one or two selected from the group consisting of diethylhexyl butamido triazone, ethylhexyl triazone, and filtersof tris-biphenyl triazine, ethylhexyl salicylate, phenylbenzimidazole sulfonic acid and TiO2 in an amount of from 3% by weight to 7% by weight relative to the total weight of the composition.

Owner:PIERRE FABRE DERMO COSMETIQUE CORP

Thermo-cycling and non-blushing PE varnish

The invention provides a thermo-cycling and non-blushing PE varnish and belongs to the field of chemical coatings. The thermo-cycling and non-blushing PE varnish is prepared from the following four components of A, B, C and D, wherein the component A is prepared from air-dried unsaturated polyester resin, a leveling agent, 0 to 0.2 percent of a defoaming agent, 0 to 5 percent of an anti-settling agent, styrene, 0 to 0.5 percent of a dispersing agent, a polymerization inhibitor and 0 to 50 percent of a filler; the component B is prepared from the styrene, xylene, ethyl ester, the polymerizationinhibitor and dimethyl carbonate; the component C is cobalt iso-octoate containing 6 percent of cobalt by mass fraction; the component D is methyl ethyl ketone peroxide. As the air-dried unsaturatedpolyester resin and various aids which have good compatibility with a resin system are selected, the obtained thermo-cycling and non-blushing PE varnish disclosed by the invention has the advantages of high gloss of a formed film, good transparency of the varnish film, thermo-cycling resistance and no blushing phenomenon after being stored for several months.

Owner:CARPOLY CHEM GRP

Process for manufacturing polycrystalline glass

The invention relates to a technology for manufacturing polycrystalline glass. Multicolored powder mixed with a glass brightening agent is sprayed and coated on the glass surface and glass polycrystalline glaze is sprayed and coated to be baked to prepare the polycrystalline glass. The glass brightening agent is prepared from 52 weight percentages of brightening agent, 27 weight percentages of diluting agent and 21 weight percentages of solidifying agent which are mixed. The glass polycrystalline glaze is prepared from 30.8 weight percentages of glass paint, 36.5 weight percentages of turpentine oil and 32.7 weight percentages of solidifying agent which are mixed. The technology adopts a baking temperature of 80 DEG C to 100 DEG C, and the baking time of 454 minutes. Because the invention uses a special proportion of the glass brightening agent and the polycrystalline glaze and a special technical method, the structure of the polycrystalline glaze and the glass is more compact, the polycrystalline layer can not easily fall off, the polycrystalline surface high brightness, abundant and vivid colors, and can not fade after long-time storage.

Owner:ZHANGJIAJIE YONGXING GLASS

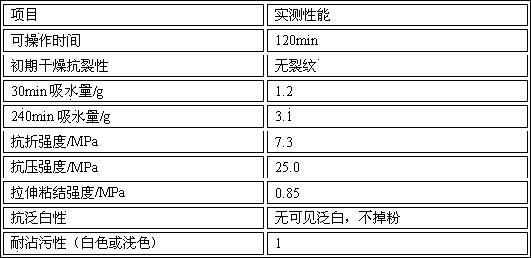

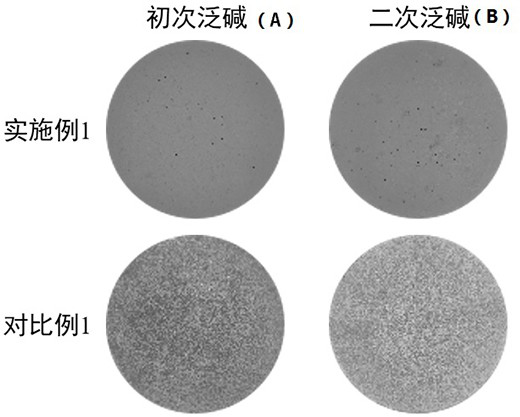

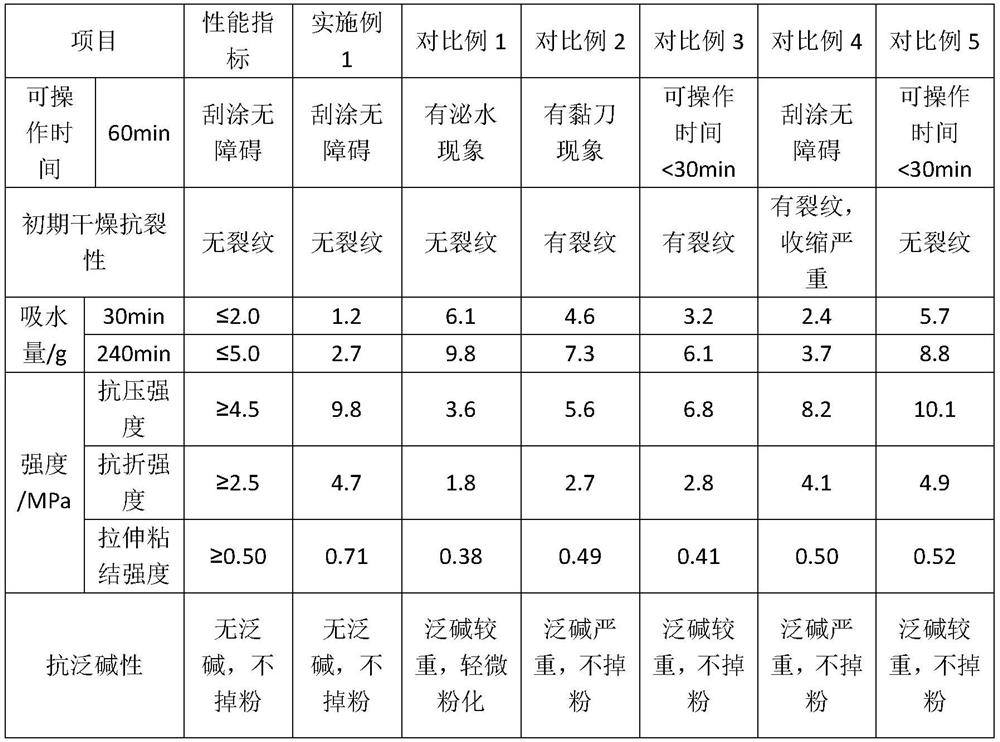

Gypsum-based colored facing mortar and preparation method thereof

The invention discloses gypsum-based colored facing mortar and a preparation method thereof. The gypsum-based colored facing mortar comprises 20-25 parts of gypsum, 5-10 parts of aluminate cement, 0-5 parts of Portland cement, 1-5 parts of fly ash, 70-80 parts of quartz sand, 3-6 parts of an additive and 0.5-1.0 part of a pigment, wherein the addition amount of water is 60-70% of the total mass of the gypsum, the aluminate cement and the Portland cement. According to the gypsum-based colored facing mortar disclosed by the invention, the saltpetering of wall facing mortar is controlled, various properties are excellent, and the prepared saltpetering-resistant colored facing mortar has the characteristics of no whitening, no cracking, high strength, light weight, water resistance, air permeability, good durability, rich colors and shapes and the like in the use process; the paint is suitable for indoor or outdoor wall decoration of buildings. The gypsum-based colored facing mortar is simple to prepare and rich in raw material source, and can be industrially produced and used in a large scale.

Owner:YANCHENG INST OF TECH

Engineering oil cylinder coating method

ActiveCN103071610AFlat and smooth appearanceNo whiteningPretreated surfacesCoatingsEpoxyWrinkle skin

The invention discloses an engineering oil cylinder coating method which is characterized by consisting of the following steps of polishing, oil pre-removal, oil removal, four-in-one phosphorization, phosphating film drying, the spraying of red iron oxide epoxy primer TNE-HD001, the preparation of working lacquer liquid, the adoption of the red iron oxide epoxy primer, the spraying of the primer, napping, sootblowing and the spraying of finish; a product paint film has level and smooth appearance, and has no such quality defects as particles, bottom exposure, bubbles, needle holes, heat rash particles, wrinkled skin, flood and flying paint misty edges; and the paint film is fine, full and the color consists with that on a standard color disk. According to the engineering oil cylinder coating method, the total adhesive force of the paint film is less than or equal to Level 1 (GB / T9286-88); and no whitening, bubbles or rust spots occur 720 hours after a neutral salt spray resistance test of the paint film is taken.

Owner:CNHTC CHENGDU WANGPAI COMML VEHICLE

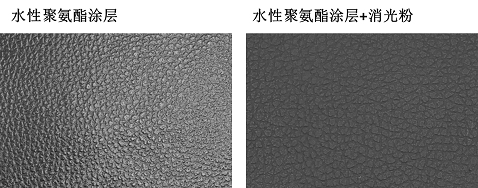

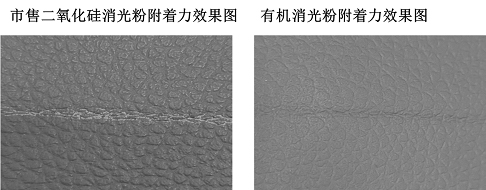

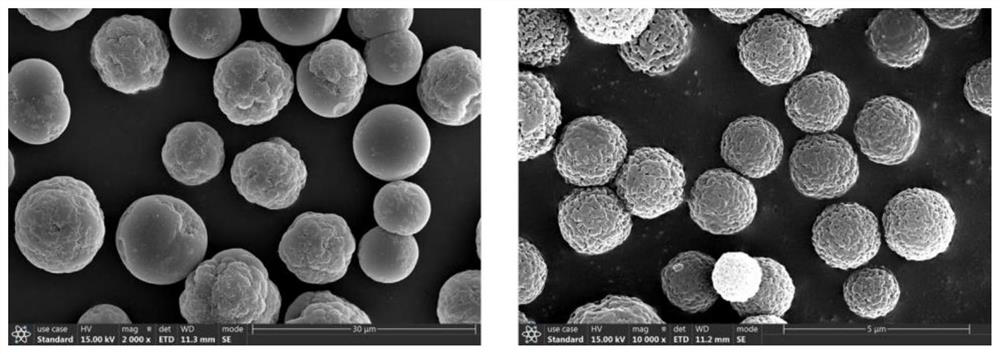

Preparation and application of polyurea extinction microspheres with light scattering characteristic

ActiveCN113845642AHas light scattering propertiesGood matting effectPolyurea/polyurethane coatingsHydrophilic monomerCoated surface

The invention discloses preparation and application of polyurea extinction microspheres with light scattering characteristics, and the preparation of the extinction microspheres comprises the following raw material components in parts by weight: 100 parts of an acetonitrile / water mixed solvent, 1-10 parts of a monomer, 0.1-1 part of a hydrophilic monomer and 0.1-4 parts of a surface roughening agent, the polyurea microspheres with different particle sizes and surface roughness are prepared in a water / acetonitrile system through a precipitation polymerization method, the polyurea microspheres are used as a water-based coating matting auxiliary agent, the particle sizes and the surface roughness of the polyurea microspheres are controlled by adjusting the dosage of MPDSA-Na, the dosage of IPDI, the dosage of SiO2 and the like, and then the glossiness of the coating is adjusted. The polyurea microspheres and waterborne polyurethane are compounded to be used for coating surface glossiness treatment, the glossiness of the surfaces of coatings such as synthetic leather can be remarkably reduced, the particle size distribution ranges from 1 micrometer to 2 micrometers, and the polyurea microspheres high in surface roughness have a better matting effect. Therefore, the polyurea extinction microsphere with the light scattering characteristic has a wide application prospect in coatings of automotive trim leather and furniture decorative leather.

Owner:SICHUAN UNIV

Polyamide resin composition

ActiveUS8273431B2Less amountStably subjectedEnvelopes/bags making machineryBottlesPolyamideCarboxylic acid

A polyamide resin composition contains a resin component containing at least a polyamide (X) and a fatty acid metallic salt having from 10 to 50 carbon atoms, and contains arbitrarily an additive (A) and / or an additive (B). The polyamide (X) is obtained through melt polycondensation of a diamine component containing 70% by mol or more of m-xylylenediamine and a dicarboxylic acid component containing 70% by mol or more of an α,ω-linear aliphatic dicarboxylic acid. The additive (A) is at least one compound selected from the group consisting of a diamide compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diamine having from 2 to 10 carbon atoms, a diester compound obtained from a fatty acid having from 8 to 30 carbon atoms and a diol having from 2 to 10 carbon atoms, and a surfactant, and the additive (B) is at least one compound selected from the group consisting of a metallic hydroxide, a metallic acetate salt, a metallic alkoxide, a metallic carbonate salt and a fatty acid.

Owner:MITSUBISHI GAS CHEM CO INC

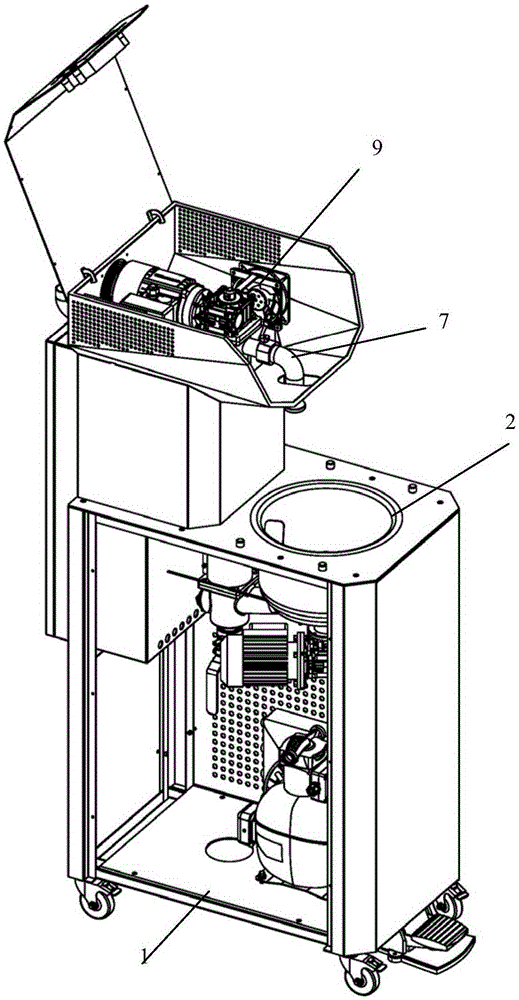

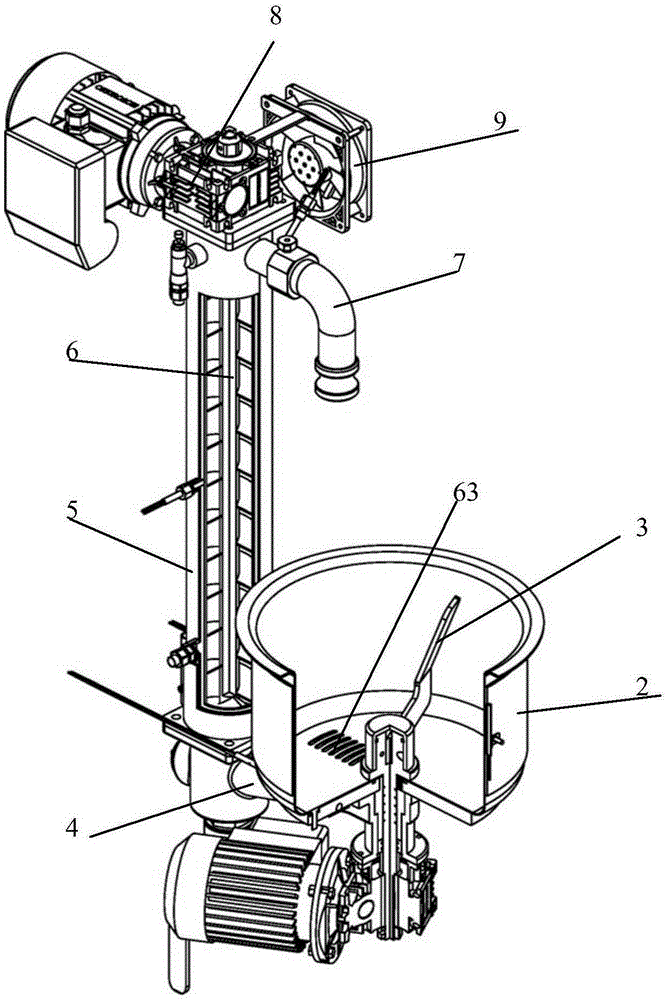

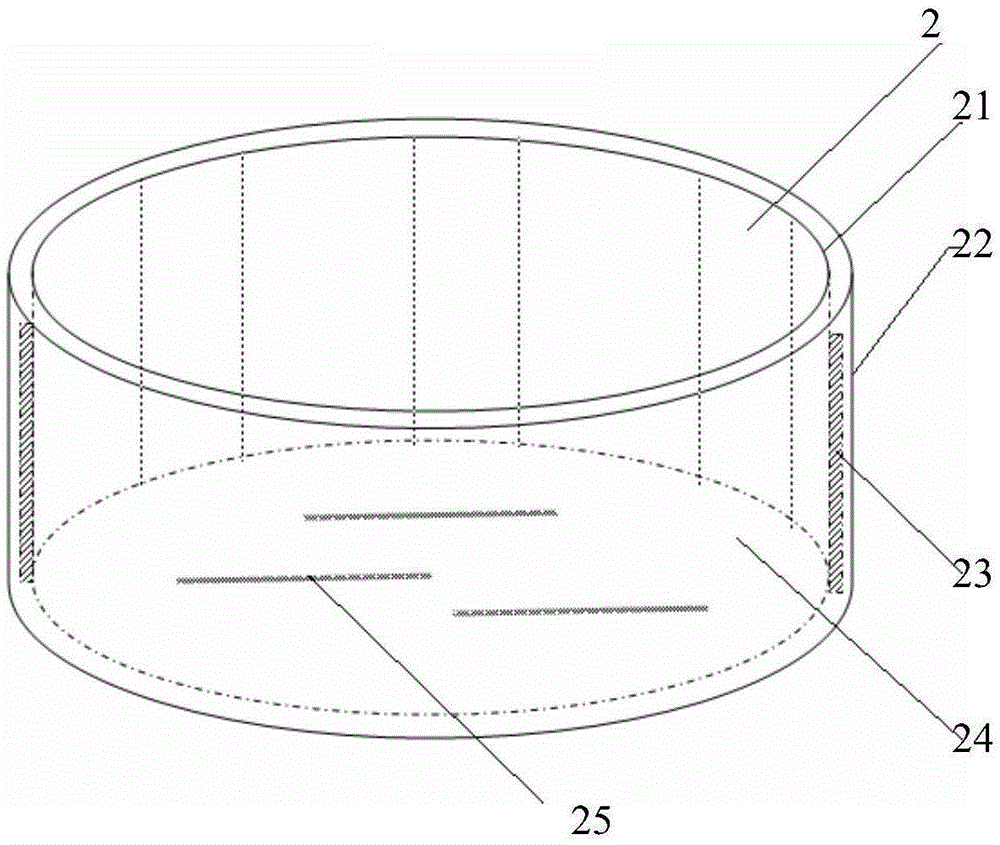

Chocolate temperature-control homogenizer

The present invention discloses a chocolate temperature-control homogenizer which includes a heating and stirring part and a cooling and conveying part. The heating and stirring part comprises a heating container and a stirring rake driven for rotary stirring arranged inside the heating container. The cooling and conveying part includes a jacketed barrel body connected with the bottom of the heating container through a connecting tube, a packing auger arranged inside the jacketed barrel body, and a discharging tube connected with a discharging end of the jacketed barrel body. The chocolate temperature-control homogenizer set heating and stirring and cooling and conveying in one to reduce the complexity of the equipment, and to improve the processing efficiency, at the same time, the use of the heating function of the heating container plays a role in uniformly and efficiently heating and stirring chocolate in the chocolate production process; and in the conveying process, the use of jacketed cooling is simple and ingenious in structure, condensed water is inlet using a interlayer design, and the liquid chocolate in the water jacket is subjected to cooling in the conveying process driven by the rotation of the screw.

Owner:丽汀豪(天津)科技发展有限公司

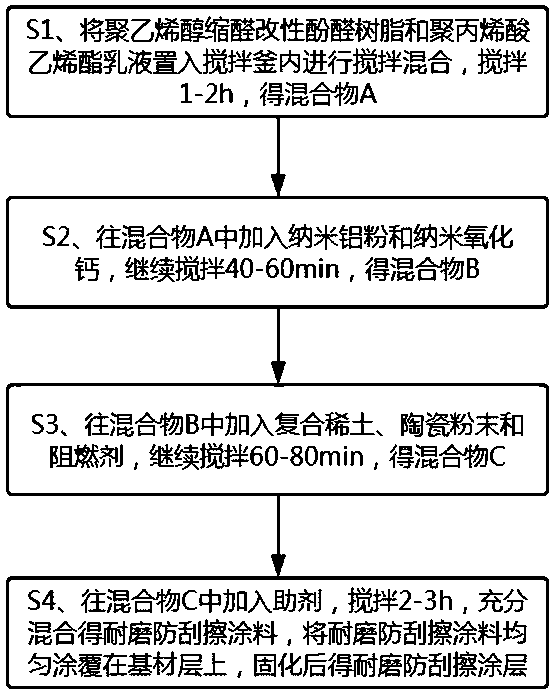

Wear-resistant and scratch-resistant coating and preparation method thereof

InactiveCN111087880AReasonable control of the amount addedImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsPolyvinyl alcoholFire retardant

The invention discloses a wear-resistant and scratch-resistant coating and a preparation method thereof, and belongs to the technical field of wear-resistant coatings. According to the wear-resistantand scratch-resistant coating and the preparation method thereof, the wear-resistant and scratch-resistant coating is formed by uniformly coating a wear-resistant and scratch-resistant coating on a composite film and curing the wear-resistant and scratch-resistant coating, the wear-resistant and scratch-resistant coating is prepared from the following components: polyvinyl acetal modified phenolicresin, polyacrylic acid vinyl ester emulsion, composite rare earth, nano aluminum powder, nano calcium oxide, ceramic powder, a flame retardant and the like. The wear-resistant and scratch-resistantcoating disclosed by the invention has excellent bonding strength; the wear-resistant and scratch-resistant coating has the advantages of favorable dielectric properties, favorable product dimensionalstability, high hardness, favorable flexibility, high stability for alkali and most solvents, favorable corrosion resistance, favorable gas resistance, favorable water resistance, favorable flame retardancy and the like, and has long service life, and the wear-resistant and scratch-resistant coating obtained by coating the wear-resistant and scratch-resistant coating can not have the problems ofblistering, cracking, whitening, delaminating and the like. The preparation method is simple, and large-batch and large-scale production is easy to carry out.

Owner:YIXING YULONG PLASTIC PACKAGE PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com