Patents

Literature

41results about How to "No blistering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly single-component industrial anti-corrosion coating and preparation method thereof

The invention relates to a waste-based coating, in particular to a water-based industrial anti-corrosion coating. The invention discloses the water-based industrial anti-corrosion coating and a preparation method thereof. The anti-corrosion coating is prepared from the following components in percentage by weight: 10 to 50 percent of modified water-based acrylic resin, 5 to 20 percent of anti-rust pigments, 0.5 to 20 percent of a filler, 10 to 40 percent of a solvent, 2 to 20 percent of an auxiliary, 0.1 to 4 percent of a water-based dryer, 0.1 to 4 percent of a diluent and 0.5 to 2 percent of a water-based thickener. The water-based industrial anti-corrosion coating does not have the problems of blistering, whitening, fracturing, delaminating and the like, can be firmly attached to the surface of a metal, and is high in flexibility and bonding strength; the salt fog resistance and the corrosion resistance of the water-based industrial anti-corrosion coating can be improved, and the drying performance of the coating is improved; the water-based industrial anti-corrosion coating is excellent in corrosion resistance; furthermore, the raw materials are highly available; the production process is simple, and the construction is convenient.

Owner:广东珠江化工涂料有限公司

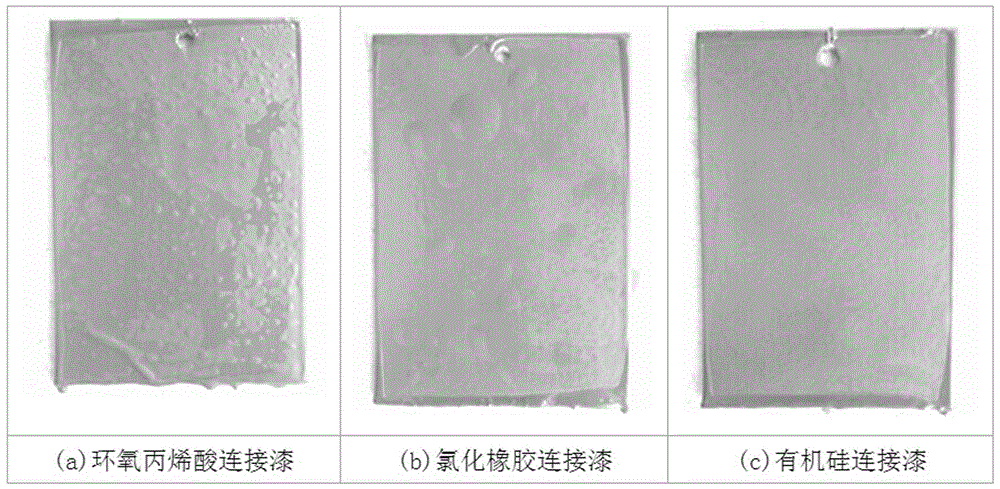

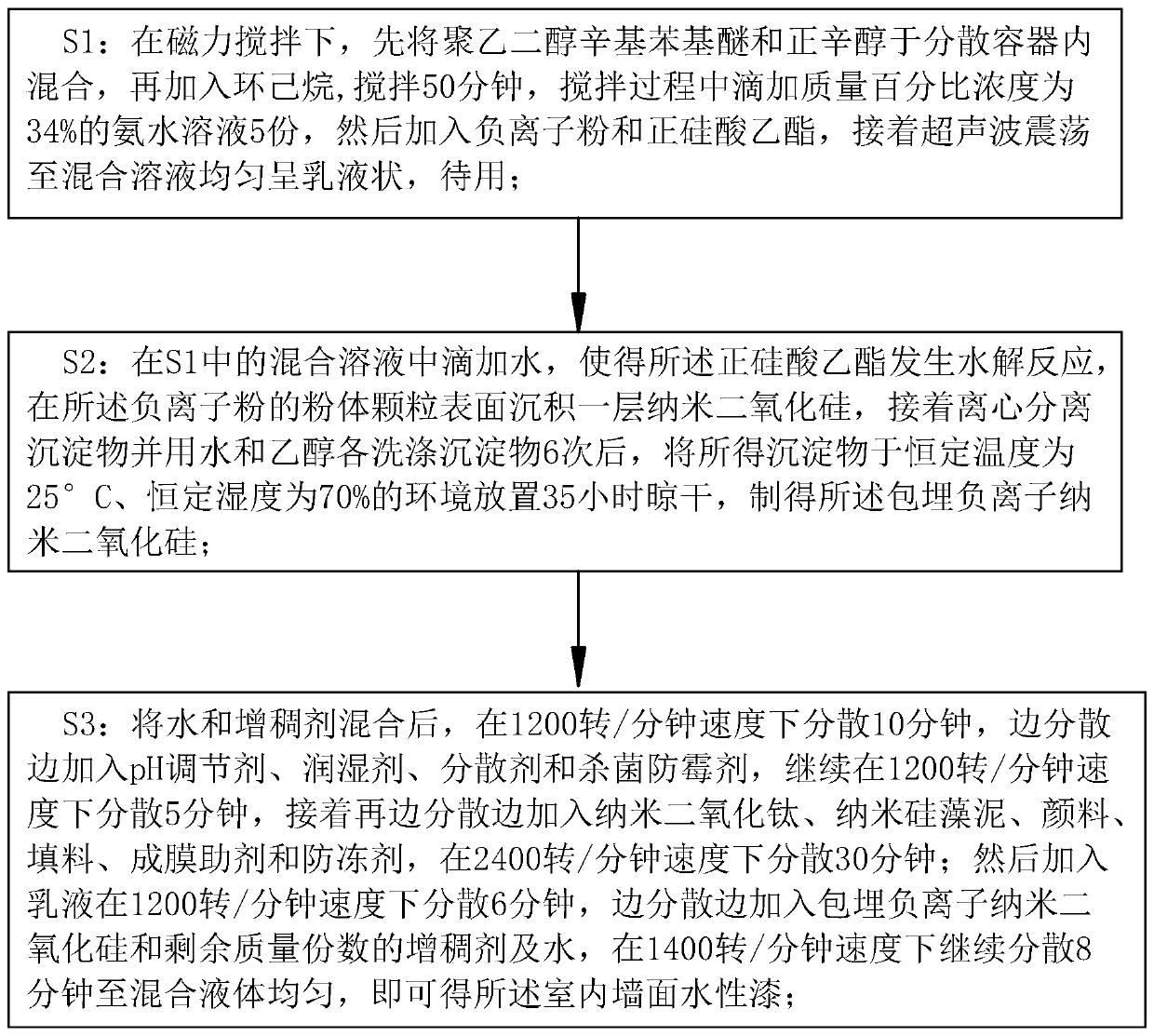

Special-effect heath indoor wall aqueous paint composition and preparation method thereof

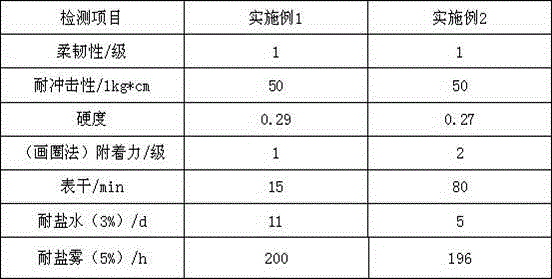

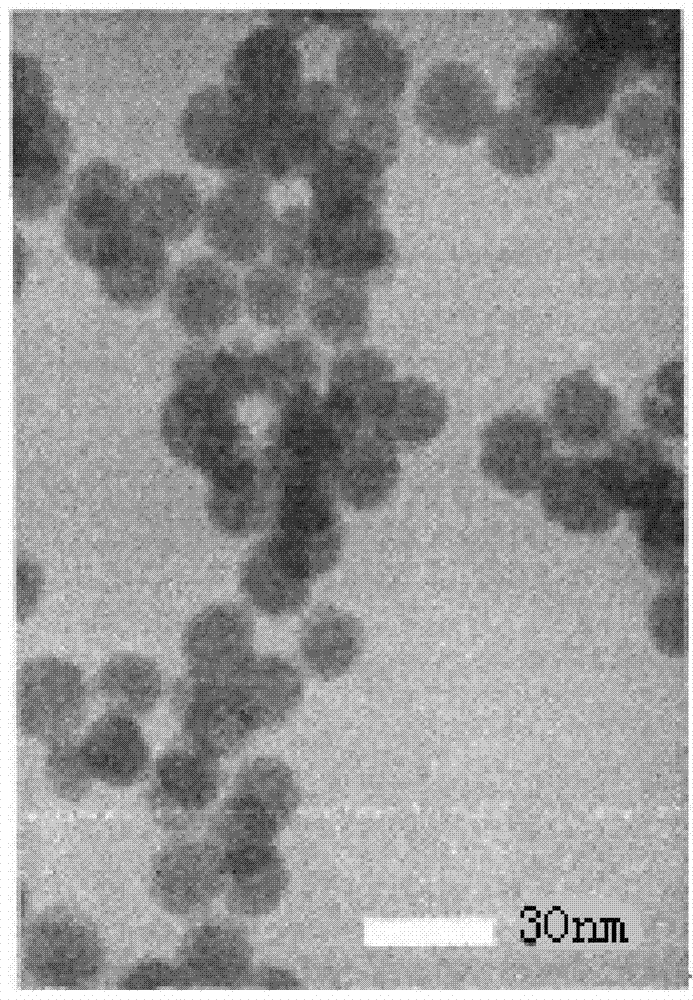

The invention relates to a special-effect health indoor wall aqueous paint composition and a preparation method thereof, and belongs to the field of aqueous paint compositions for construction decoration. The paint composition is composed of the following raw materials in parts by weight: 20 to 30 parts of water, 0.2 to 0.5 part of thickening agent, 0.05 to 0.2 part of pH adjuster, 0.1 to 0.3 part of antifoaming agent, 0.1 to 0.4 part of wetting agent, 0.2 to 0.7 part of dispersant, 10 to 25 parts of nano titanium dioxide, 1 to 10 parts of nano diatom ooze, 2 to 10 parts of embedded anionic nano silicon dioxide, 20 to 40 parts of filling material, 9 to 18 parts of emulsion, 0.2 to 0.7 part of anti-freezing agent, 0.1 to 0.5 part of film-forming auxiliary agent, and 0.2 to 0.4 part of bactericidal mildew inhibitor. The paint composition can absorb the harmful components in air, is healthy and environment-friendly, and also has the advantages of excellent color retention, scrubbing resistance, water and alkali resistance, and proper softness of paint film.

Owner:SKSHU PAINT

Chemical nickel plating solution and aluminum silicon carbide plating method

InactiveCN102732865AIncrease coverageSuitable for mass productionLiquid/solution decomposition chemical coatingSpreadabilityMaterials science

The invention discloses a chemical nickel plating solution and an aluminum silicon carbide plating method. The invention aims at the aluminum silicon carbide material with high silicon carbide content. According to the invention, the plated nickel layer has a good spreadability as a primer coat on the surface of an aluminum silicon carbide workpiece (metals such as gold, silver and tin can further be plated on the plated nickel layer), such that the method is suitable for batch productions. The plated layer can resist a temperature no less than 300 DEG C. After a high-temperature test, the plated layer has no peeling or blistering phenomenon when tested under a 10-time microscope. The method is suitable for modules and subassemblies, and can satisfy high-temperature welding of materials such as metal solders. The method is based on an aluminum alloy plating process, such that the method is advantaged in simple operation, stable process, low cost, and suitability for batch productions.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

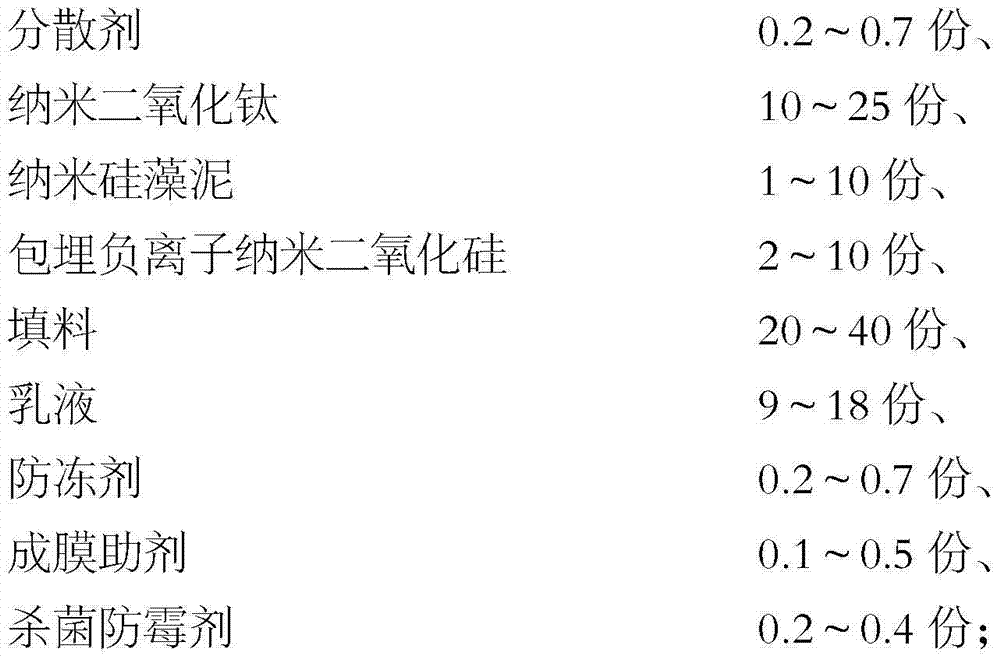

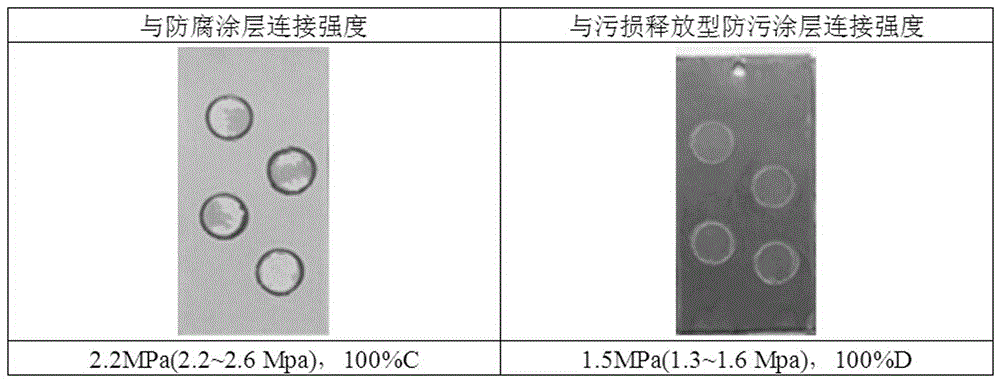

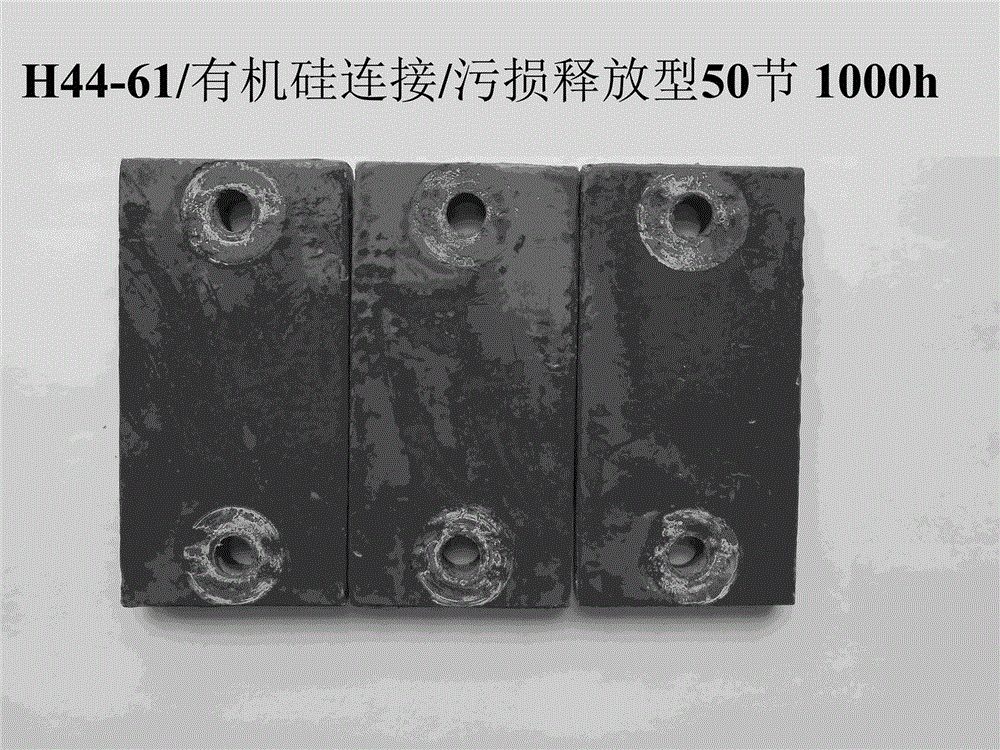

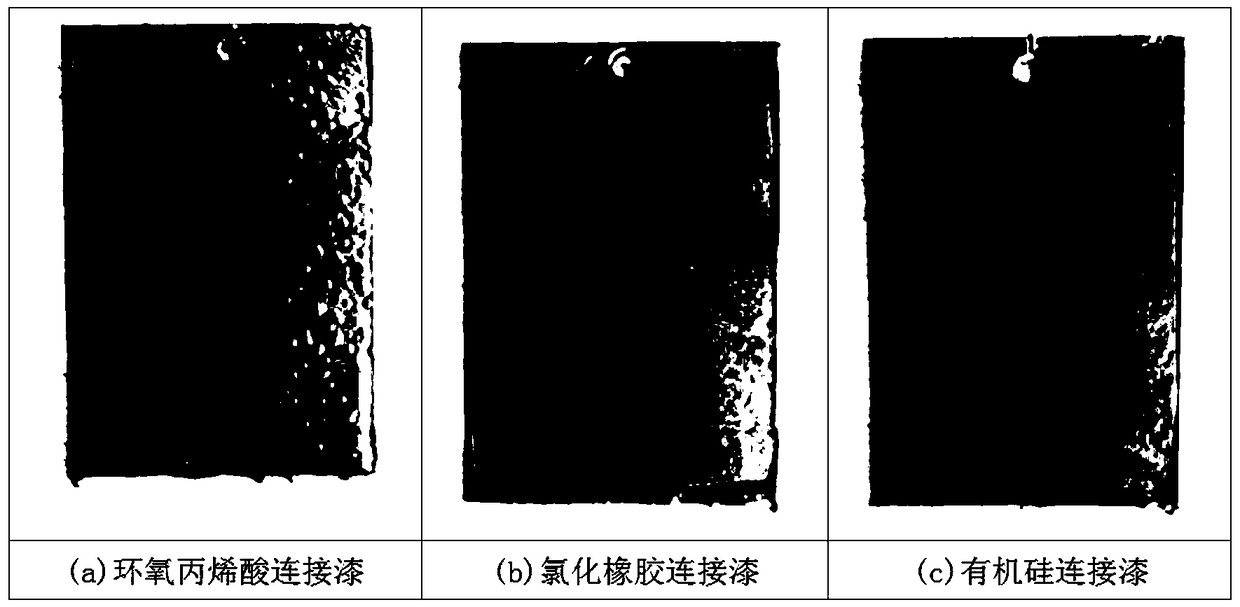

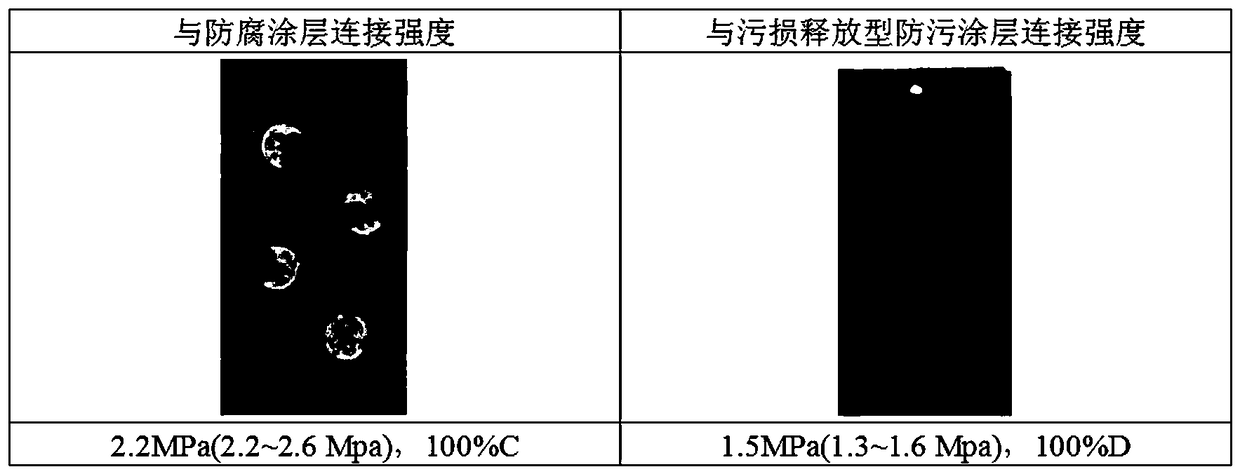

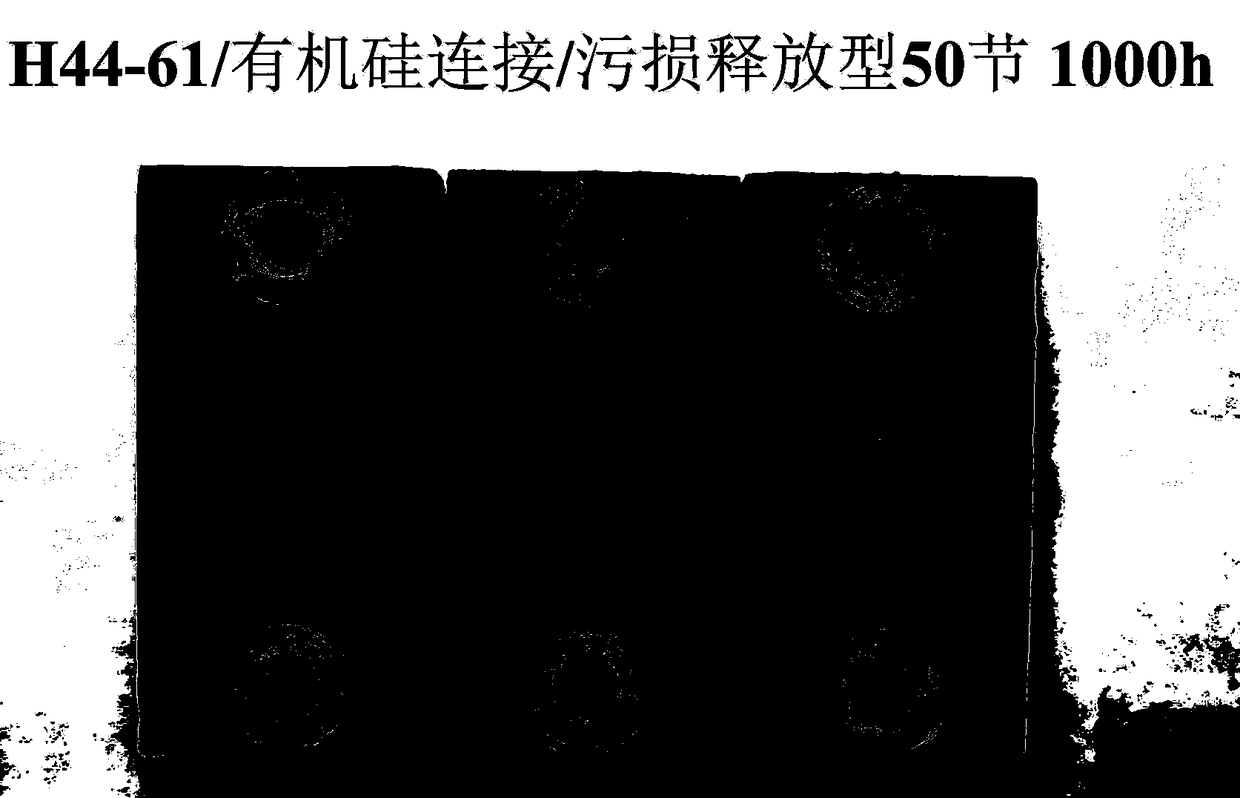

Bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint

ActiveCN106336799AImprove adhesionNo foamingAntifouling/underwater paintsPaints with biocidesCavitationSolvent

The invention discloses bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint. The bi-component interfacial bonding organosilicone connection paint is prepared from a first component and a second component according to the weight ratio of 10:1. The first component is prepared from organosilicone, pigments and filler, a solvent and a thixotropic agent. The second component is prepared from a high-toughness curing agent and a reaction promoter. The bi-component interfacial bonding organosilicone connection paint is prepared from the first component including, by weight, 35-55% of organosilicone, 20-40% of pigments and filler, 15-30% of solvent and 0-5% of thixotropic agent and the second component including, by weight, 10-20% of high-toughness curing agent and 0.01-0.03% of reaction promoter. According to the connection paint, the problem that pollution release type anti-fouling paint and anti-rusting paint are poor in adhesive force is solved, the adhesive strength to an anticorrosion coating reaches 2.2 MPa or above, the connection strength for an anti-fouling coating reaches 1.3 MPa or above, and 100% cohesive failure is shown; after being scoured by 50 sections of high-speed flow for 1,000 hours, the coatings are free of bubbling, disengaging and cavitation damage, and have good adhesive performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High-temperature-resistant paint for hydraulic cylinder and preparation method thereof

ActiveCN104789116AStrong adhesionNot easy to fall offRubber derivative coatingsAnti-corrosive paintsPhosphorous acidPolymer science

The invention discloses a high-temperature-resistant paint for a hydraulic cylinder and a preparation method thereof. The high-temperature-resistant paint for the hydraulic cylinder is prepared from the following constituents in parts by weight: 58-60 parts of modified epoxy organic silicon resin, 22-24 parts of hydrogenated acrylonitrile butadiene rubber, 27-29 parts of bisphenol A epoxy resin, 12-14 parts of mica powder, 10-13 parts of butyl rubber, 5-7 parts of polydimethylsiloxane, 12-14 parts of phenylmethylsilane resin, 3-5 parts of dioctyl phthalate, 2-4 parts of copper powder, 2-4 parts of rutile type titanium dioxide, 1-3 parts of ceramic powder, 20-25 parts of deionized water, 2-4 parts of triethylene tetramine, 5-7 parts of triphenyl phosphite, and 1-3 parts of an auxiliary.

Owner:SUZHOU TONGMING MACHINERY

High-temperature-resistant low-voltage switchgear cabinet

InactiveCN105368248AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:江苏宇恒电气有限公司

EVA (ethylene-vinyl acetate) locating adhesive tape for crystalline silicon solar cell module

InactiveCN103555217ANo blisteringThere will be no problems such as stratificationFilm/foil adhesivesPhotovoltaic energy generationSolventCrystalline silicon

The invention discloses an EVA (ethylene-vinyl acetate) locating adhesive tape for a crystalline silicon solar cell module. The EVA locating adhesive tape comprises an adhesive tape base material and a solvent adhesive layer arranged on the adhesive tape base material, wherein the adhesive tape base material comprises the following components by parts by weight: 93-97 parts of EVA resin, and 3-7 parts of performance additive. The adhesive tape base material is made of EVA resin, in the lamination and solidification process of the modules, the adhesive tape base material and the EVA adhesive film can be melted and solidified into a whole, the adhesive tape does not have bubbles and layers, so that the EVA locating adhesive tape not only can play a role in locating battery pieces, but also has good adhesive property and ageing resistance, and ensures that the solar cell module can be used for a long time.

Owner:ZHEJIANG ZHENGXIN PHOTOVOLTAIC TECH

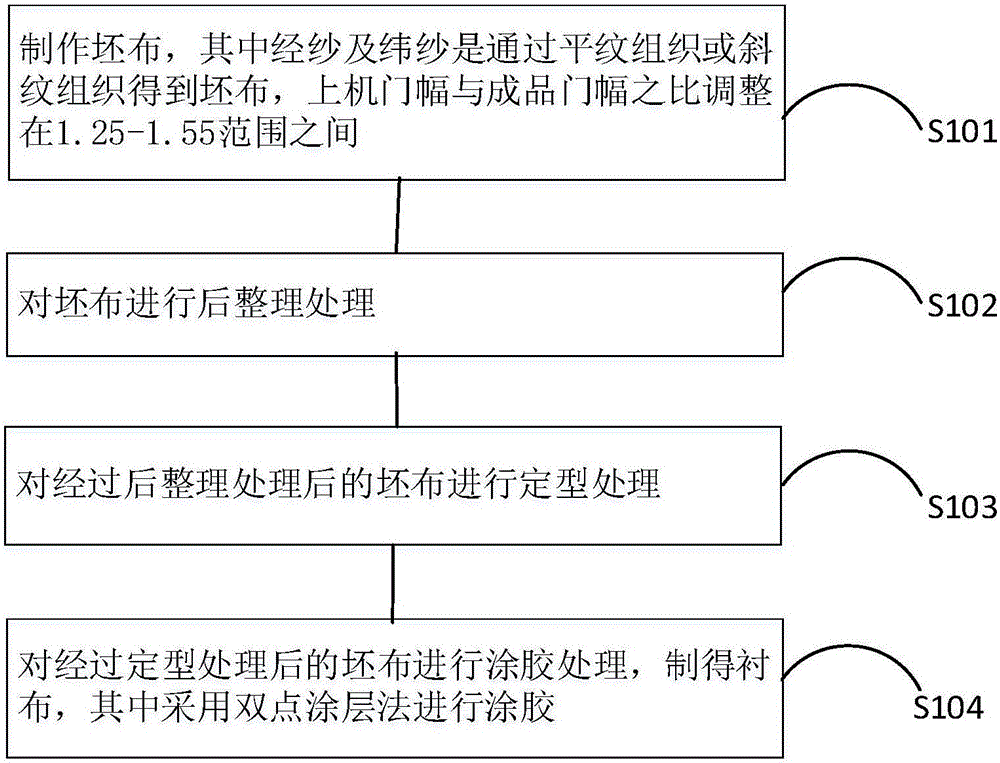

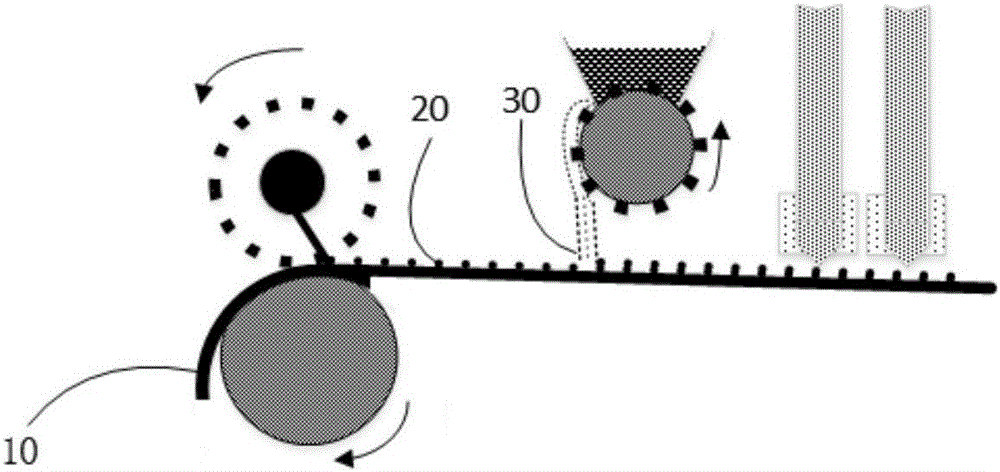

Lining cloth and making method thereof

ActiveCN106012580AIncrease elasticitySoft touchSucessive textile treatmentsFibre treatmentEngineeringWidth ratio

The invention discloses a lining cloth making method. The method comprises the steps of making a gray fabric, wherein the gray fabric is obtained through plain weaving or twill weaving of warps and wefts, and the ratio of looming width to finished product width is adjusted to be 1.25-1.55; conducting after finishing on the gray fabric; conducting shaping on the lining cloth subjected to after finishing; conducting gumming on the shaped lining cloth with the double-dot coating method. The invention further provides a lining cloth made with the method. According to the method, an appropriate looming width to finished product width ratio is adopted, and the gray fabric is obtained through plain weaving or twill weaving; the obtained gray fabric is subjected to after finishing and shaping, high elasticity and soft and fluffy hand feel are guaranteed after gumming of the lining cloth, smoothness of a finished garment after dyeing is guaranteed, degumming, blistering and the like are avoided, and soft hand feel is realized.

Owner:CPL NEW MATERIAL TECH CO LTD

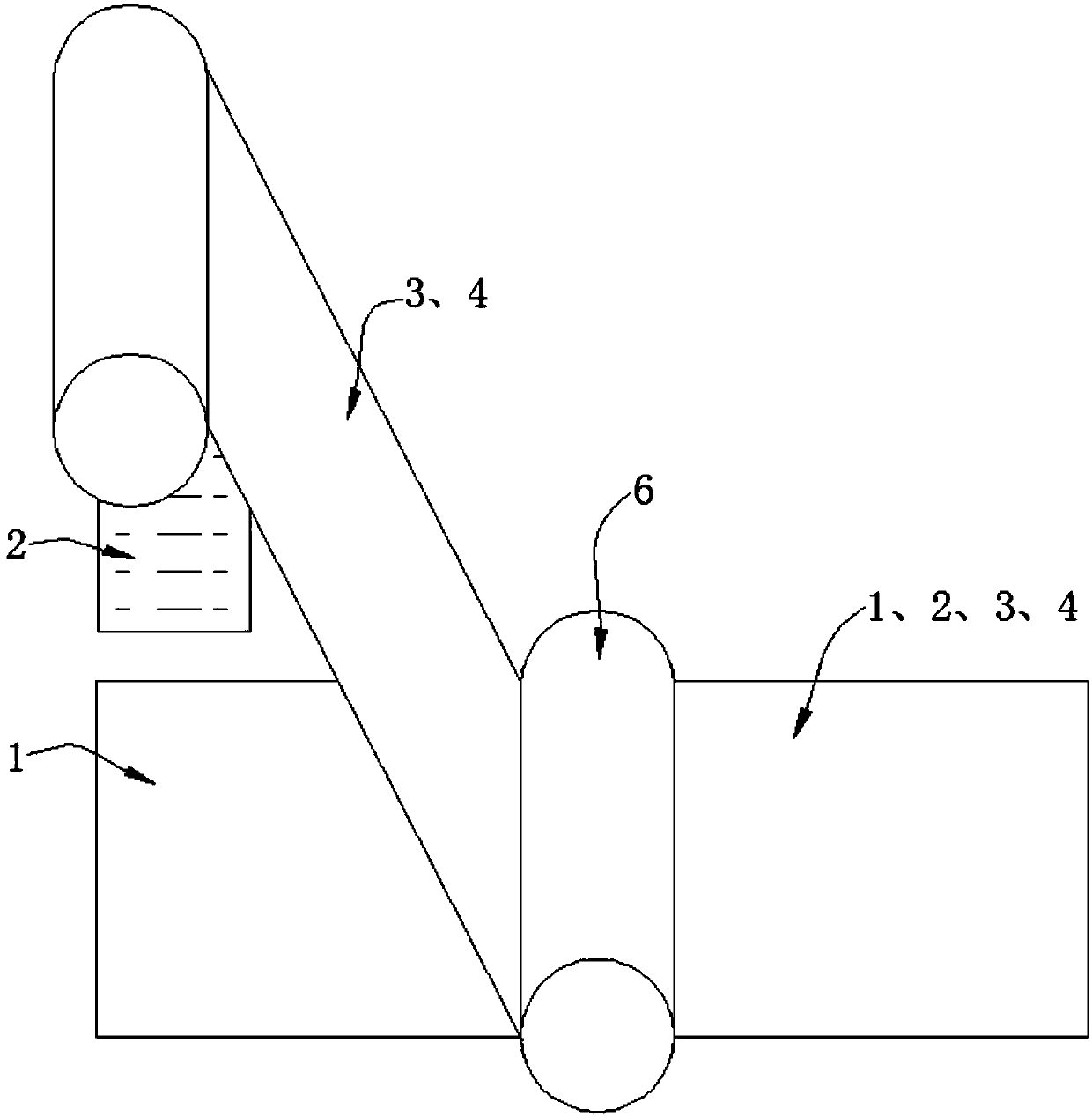

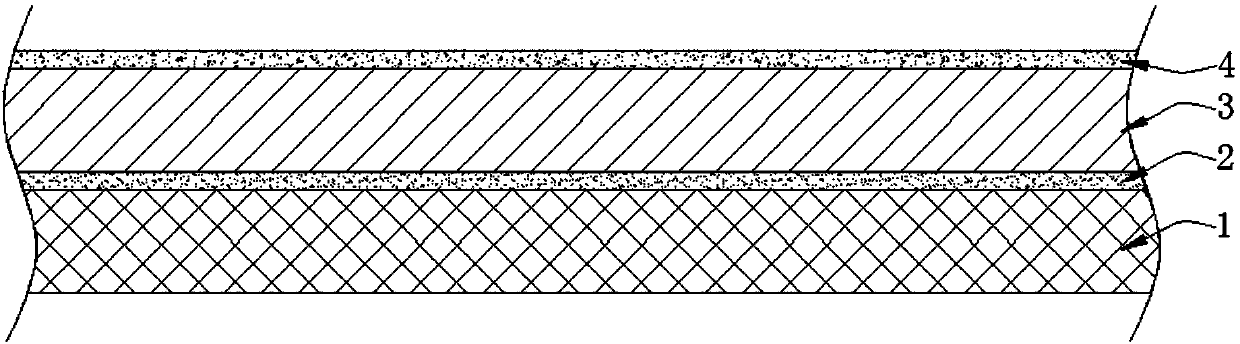

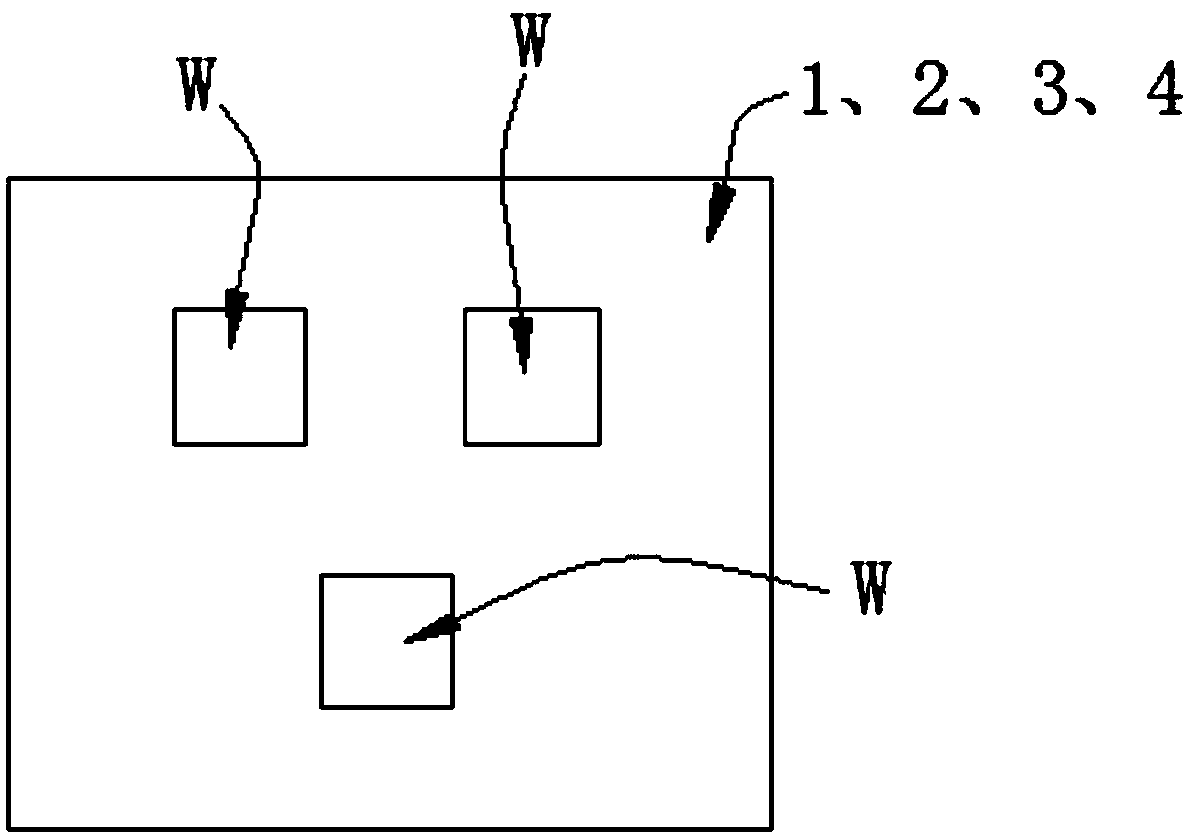

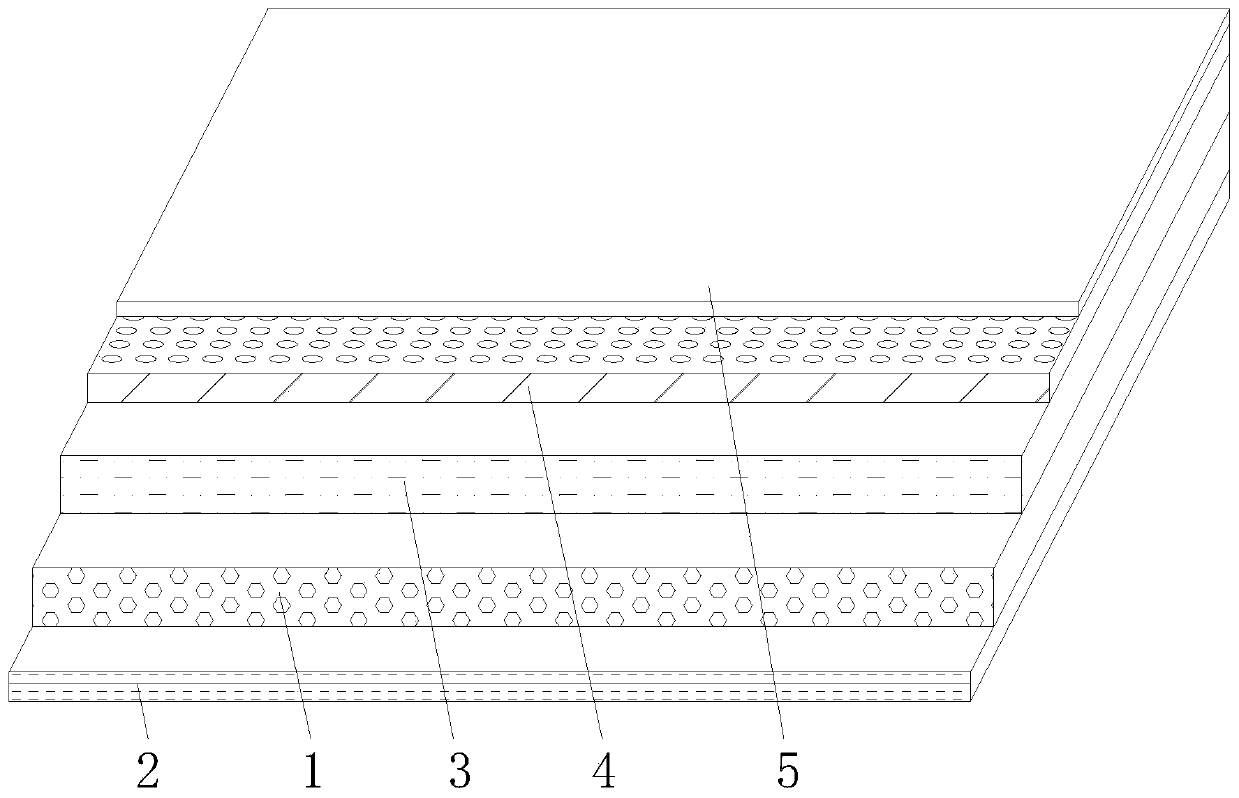

Heat-resisting conveyor belt designed according to temperature distribution and preparing method of heat-resisting conveyor belt

The invention relates to a heat-resisting conveyor belt designed according to the temperature distribution and a preparing method of the heat-resisting conveyor belt. The conveyor belt is composed of a laminated structure of a framework layer, a transition layer, upper covering glue and lower covering glue. According to the using requirement, the parameters of the conveyor belt in the running process are known before design and manufacture are carried out, the temperature distribution of a belt body of the conveyor belt in the running process is tested or worked out, a reasonable belt body structure is designed, any one of EP canvas, nylon canvas and cotton canvas which are small in shrinking amount under the high temperature condition and insensitive in strength to the temperature is selected as the framework layer, the framework layer, the transition layer, the upper covering glue and the lower covering glue are laminated to form a complete belt billet, the belt billet is vulcanized through a vulcanizing machine, and then the heat-resisting conveyor belt can be obtained through cooling and forming after vulcanizing. The heat-resisting conveyor belt is reasonable in structure, the overall using performance of the conveyor belt is greatly improved, the production cost and energy consumption are effectively reduced, and the heat-resisting conveyor belt can be widely applied to coal, mines, ports, metallurgy, electric power, casting, cement, chemical engineering and other industries and places needing materials to be conveyed at a high speed.

Owner:刘山根

Anti-corrosion and anti-abrasion coating for power generator blade and preparation method thereof

InactiveCN108504244AImprove wear resistanceHigh bonding strengthFireproof paintsAnti-corrosive paintsEpoxySolvent

The invention discloses an anti-corrosion and anti-abrasion coating for a power generator blade and a preparation method thereof. The anti-corrosion and anti-abrasion coating is prepared from the following components in parts by weight: 30 to 40 parts of epoxy resin, 12 to 20 parts of organic silicon resin, 5 to 10 parts of graphite powder, 3 to 7 parts of mica powder, 4 to 8 parts of hydroxy propyl methyl cellulose, 5 to 12 parts of nanometer silicon dioxide, 7 to 16 parts of anti-abrasion filler, 1 to 5 parts of preservative, 1 to 3 parts of curing agent, 0.4 to 1.4 parts of flattening agent, 0.2 to 0.6 part of dispersant, and 20 to 30 parts of solvent. The anti-corrosion and anti-abrasion coating has the advantages that the anti-corrosion and high temperature-resistant properties are realized; the anti-abrasion property is good, the adhering strength is excellent, the dielectric property is good, the size stability of the product is good, the hardness is high, the flexibility is better, and the stability to alkaline and most of solvents is realized; the anti-corrosion, air-blocking and water-blocking properties are good, the service life is long, and the problems of foaming, cracking, whitening, delaminating and the like are solved.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

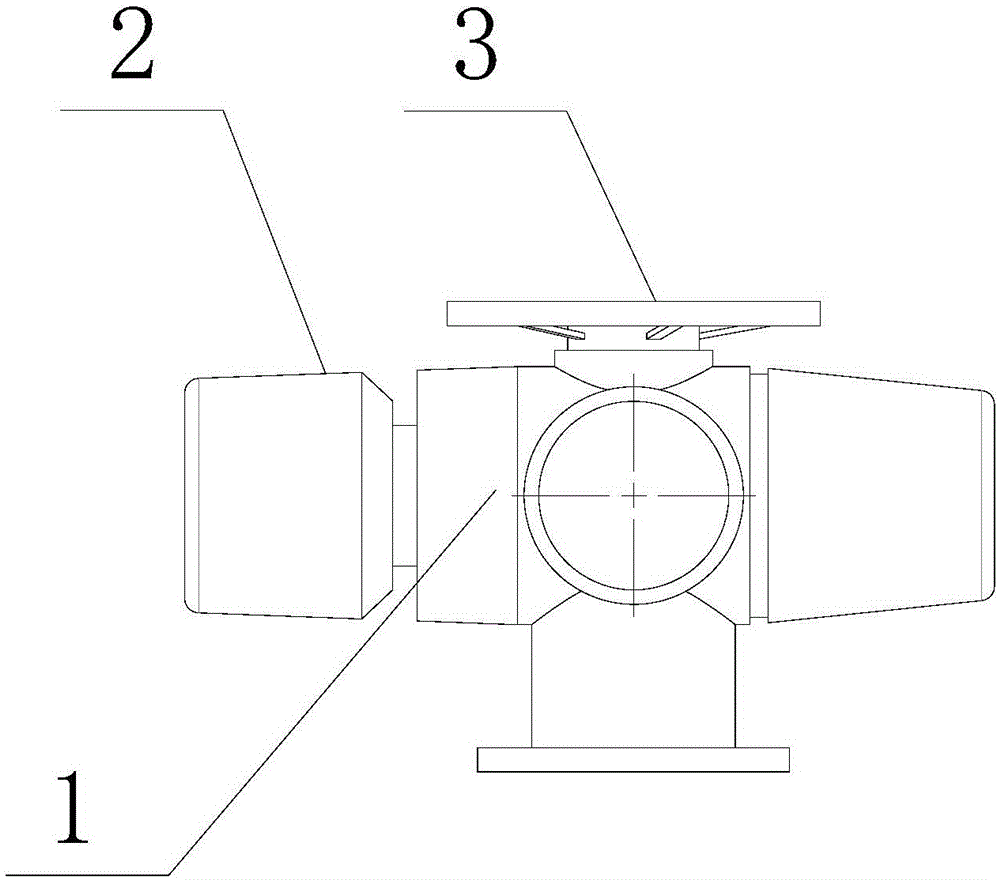

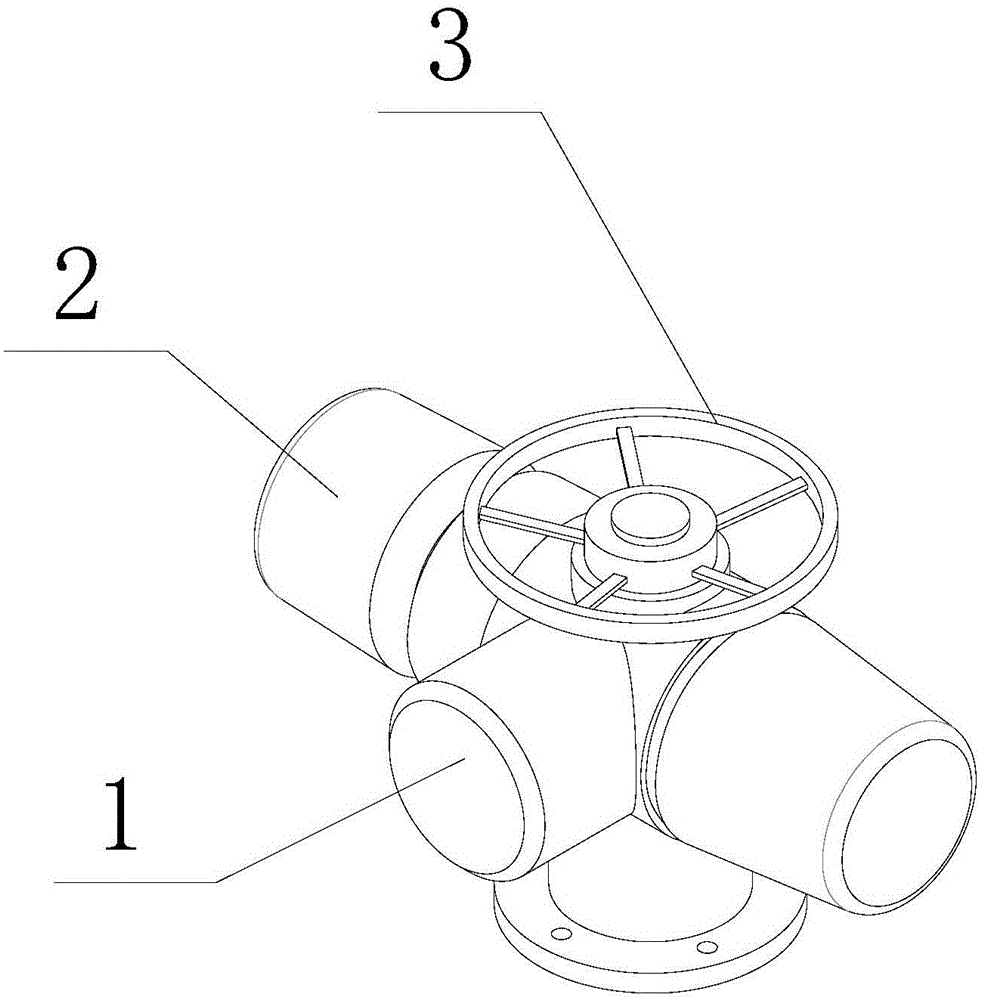

Actuator used for thermal control complete equipment and treatment technology thereof

InactiveCN105131687AImprove surface friction resistanceExtended service lifeRubber derivative coatingsAnti-corrosive paintsBenzoic acidPolyvinyl alcohol

The invention discloses an actuator used for thermal control complete equipment and a treatment technology thereof. The actuator is composed of a body, a servo motor and a hand wheel. The hand wheel is arranged at the upper end of the body, the servo motor is arranged at one end, in the length direction, of the body, and the surfaces of the body, the servo motor and the hand wheel are coated with anti-corrosion paint. The anti-corrosion paint is prepared from, by weight, 40-60 parts of epoxy-modified silicone resin, 12-14 parts of hydrogenated butadiene-arylonitrile rubber, 12-18 parts of bisphenol A epoxy resin, 5-7 parts of mica powder, 14-16 parts of talcum powder, 8-10 parts of polyvinyl butyral, 4-6 parts of benzyl silicon resin, 2-7 parts of dioctyl phthalate, 10-12 parts of copper powder, 2-4 parts of rutile titanium dioxide, 1-3 parts of ferro-phosphorus powder, 20-25 parts of deionized water, 2-4 parts of ethyl silicate, 5-7 parts of benzoic acid, 1-3 parts of rare earth and 1-3 parts of auxiliaries.

Owner:WUXI HUAHONG INFORMATION TECH

Method for oxidizing residual crystalline solids of bonded neodymium iron boron rapid-quenching permanent magnetic powder

The invention discloses a method for oxidizing residual crystalline solids of bonded neodymium iron boron rapid-quenching permanent magnetic powder. According to the technical scheme, the method includes the steps that neodymium iron boron permanent magnetic powder undergoing crystallization heat treatment is wetted through vapor, and accordingly the crystalline solids left in the neodymium iron boron permanent magnetic powder are completely oxidized. Further, the neodymium iron boron rapid-quenching permanent magnetic powder oxidization procedures include feeding, spreading, humidifying through vapor, drying, blanking, detection and packaging. Further, by means of humidifying through vapor, the neodymium iron boron permanent powder is wet but does not contain liquid water. The method has the following advantages that the method is easy to operate, the neodymium iron boron permanent magnetic powder is humidified through water vapor, the crystalline solids left in the neodymium iron boron permanent magnetic powder are completely oxidized, and manufactured magnets cannot peel or bubble.

Owner:JIANGSU JUXIN MAGNET

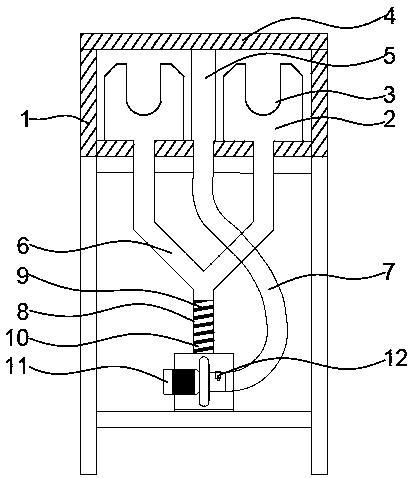

Heat cycle type energy-saving drying equipment

InactiveCN107655267AUniform and efficient dryingEasy transferDrying gas arrangementsDrying solid materialsHigh frequency powerEngineering

The invention provides heat cycle type energy-saving drying equipment and belongs to the field of drying. The heat cycle type energy-saving drying equipment comprises an outer box, a plurality of inner boxes arranged on the upper portion of the interior of the outer box and an electromagnetic heating part arranged on the lower portion of the interior of the outer box; the outer box is provided with a plurality of through holes; grooves corresponding to the through holes are formed in the inner boxes; the side surface of each groove is provided with a plurality of air outlets; air delivery pipes communicating with the air outlets are disposed in the corresponding inner boxes; the electromagnetic heating part is arranged at the other end of the air delivery pipes; the electromagnetic heatingpart comprises a heating iron pipe arranged outside the air delivery pipes in a sleeving mode and a conducting wire which is arranged outside the heating iron pipe in a surrounding mode and connectedwith a high-frequency power supply; the air delivery pipes are connected with the blowing end of a high-pressure fan; and the outer box is provided with air suction boxes used for dividing the innerboxes and sucking air in the inner boxes, and the air suction boxes are connected with the air suction end of the high-pressure fan through an air suction pipe. The heat cycle type energy-saving drying equipment can achieve fast drying of wet materials, moreover heat cycle utilization is achieved, the energy loss is reduced, a dry-wet contact interface of the equipment is coated with an anti-corrosion coating, the service life of the equipment is prolonged, and the cost is reduced.

Owner:兰溪市捷喜食品加工技术有限公司

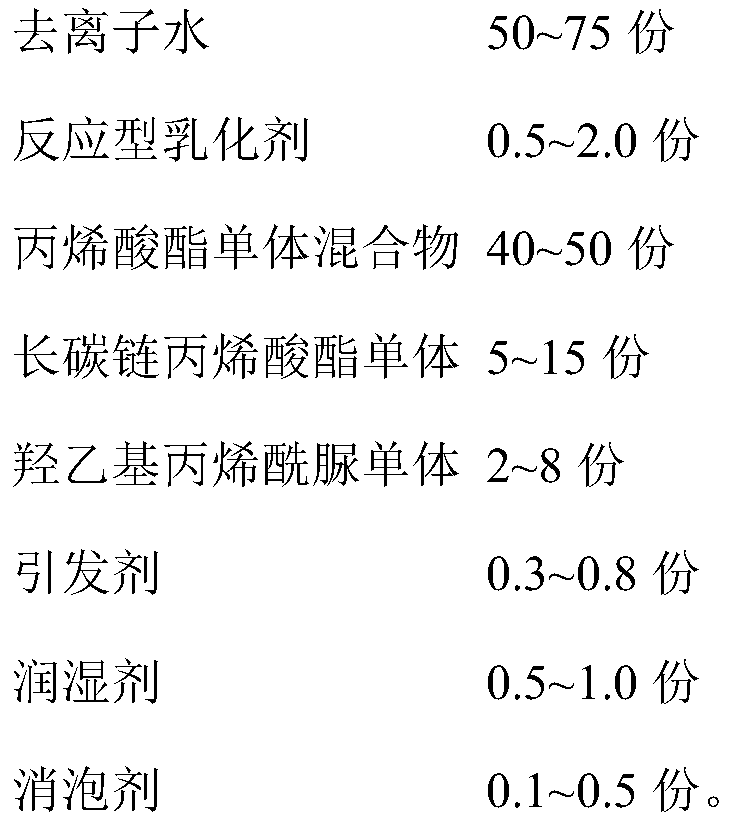

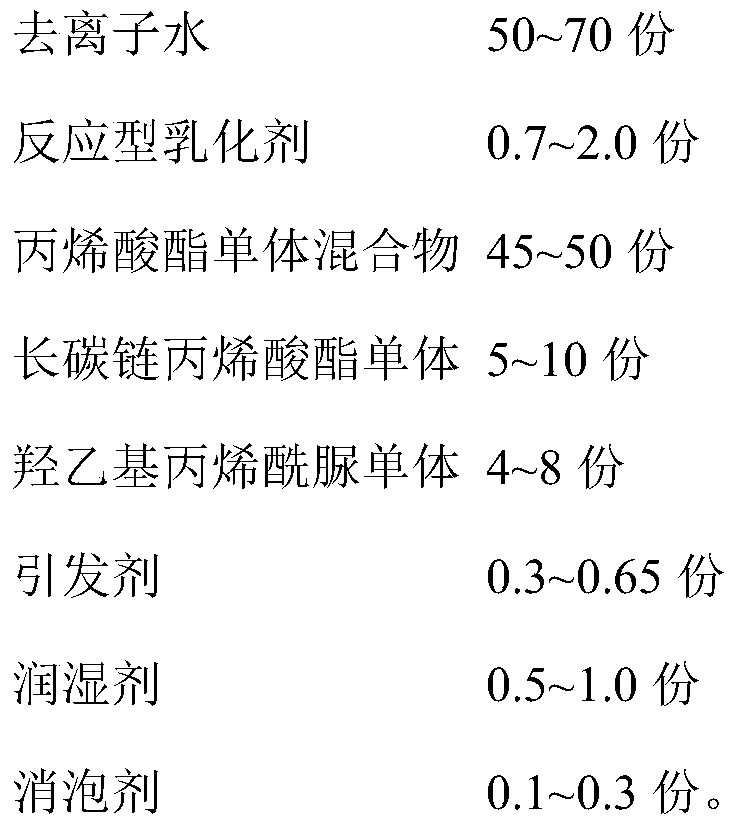

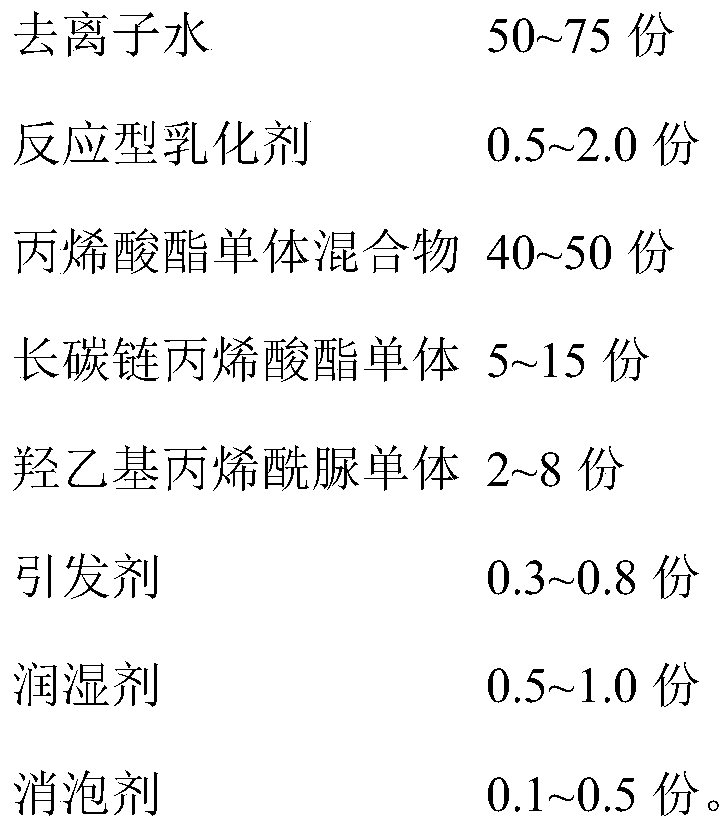

Water-based adhesive for deep embossed paper-plastic compounding, and preparation method thereof

ActiveCN109897576ALower glass transition temperatureStrong initial tackEster polymer adhesivesWater basedMolded pulp

The invention relates to the technical field of water-based adhesives, and concretely relates to a water-based adhesive for deep embossed paper-plastic compounding, and a preparation method thereof. The preparation method of the water-based adhesive comprises the following steps: preparing a monomer drop-by-drop addition solution from, by weight, 20-33 parts of deionized water, 0.4-1.5 parts of areactive emulsifier, 40-50 parts of an acrylate monomer mixture, 5-15 parts of a long carbon chain acrylate monomer, 2-8 parts of hydroxyethyl acryloyl urea and 0.2-0.6 part of an initiator; preparinga kettle bottom solution from 30-42 parts of deionized water, 0.1-0.5 part of the reactive emulsifier and 0.1-0.2 part of the initiator; and dropwise adding a part of the monomer drop-by-drop addition solution to the kettle bottom solution to prepare a seed emulsion, then dropwise adding the remaining monomer drop-by-drop addition solution, and carrying out a reaction under specific process conditions to prepare the water-based adhesive. The water-based adhesive can be stored at a high temperature of 50 DEG C and a high relative humidity of 85% for 120 h without generating white spots, foaming or degumming after being applied to paper-plastic compounding and deep embossing.

Owner:DONGGUAN STAR COSM POLYMER

Water-based paint for indoor wall surfaces

InactiveCN110746810AReduce the amount of solutionMeet brushing requirementsAntifouling/underwater paintsPaints with biocidesHazardous substanceNano titania

The invention belongs to the technical field of water-based paint for architectural decoration and particularly relates to water-based paint for indoor wall surfaces. The water-based paint comprises the following ingredients in parts by weight: 40 parts of water, 1 part of thickener, 0.5 part of pH adjuster, 0.5 part of antifoamer, 1 part of humectant, 0.9 part of dispersant, 30 parts of nano-titania, 20 parts of nano diatom ooze, 7 parts of anion embedded nano-silica, 50 parts of fillers, 15 parts of emulsion, 0.6 part of antifreezer, 0.5 part of film forming assistant and 2 parts of bactericidal mildew preventive. The water-based paint for the indoor wall surfaces, provided by the invention, can be used for effectively adsorbing formaldehyde released due to indoor fitment, organic aromatic hydrocarbon benzene solvents on sheets and substances harmful to human bodies such as amine substances; and through actions such as neutralization with harmful gases with positive charges and coating and settling of ions or particles of electrically-neutral harmful gases, the activity of the substances harmful to the human bodies is lost or lowered, and thus, a safe air quality environment fordwelling and living is provided.

Owner:高卫

Production method of filmed glass

The invention discloses a production method of filmed glass. The production method comprises the following steps of: (1) placing the glass on a conveyor; (2) conveying the glass to a cleaner for cleaning by the conveyor; (3) drying the cleaned glass; (4) coating a film-covering masking liquid with photosensitive induction to UV (ultra violet) on the surface of the dried glass; (5) adhering a film on the glass surface coated with the film-covering masking liquid and leveling the filmed surface through a pair of rotatable rollers; (6) performing the first UV photosensitive drying on the filmed glass; (7) trimming the firstly dried filmed glass, and cutting the overflowed dried masking liquid; and (8) performing the second UV photosensitive drying on the trimmed filmed glass. The film-covering efficiency of the glass is greatly improved, the filmed glass produced by the method provided by the invention is good in quality and free from bubbles, and the anti-explosion performance of the filmed glass is improved.

Owner:苏州威仕薄膜科技有限公司

Aqueous softening aid for synthetic leather

InactiveCN106939109APromote environmental protectionGood flexibilityPolyurea/polyurethane coatingsTextiles and paperPolyvinyl butyralPotato starch

The invention discloses an aqueous softening aid for synthetic leather and relates to the technical field of synthetic leather functional aids. The aqueous softening aid is prepared from 20 to 25 parts by weight of polyvinyl butyral, 3 to 5 parts by weight of aqueous alpha-pinene / diacetone acrylamide copolymer, 3 to 5 parts by weight of microcrystalline cellulose, 2 to 3 parts by weight of polyvinylpyrrolidone, 2 to 3 parts by weight of oligosaccharide, 1 to 2 parts by weight of pregelatinized potato starch, 1 to 2 parts by weight of nanometer titanium dioxide-loaded rosin glyceride, 1 to 2 parts by weight of calcium stearyl lactylate, 0.5 to 1 part by weight of hexakis(methoxymethyl)melamine, 0.5 to 1 part by weight of methylene diacrylamide, 0.1 to 0.3 parts by weight of polylysine and 100 to 150 parts by weight of water. The aqueous softening aid in the aqueous polyurethane slurry can effectively improve the softness of the synthetic leather product and make the synthetic leather product soft and smooth.

Owner:江西展邦科技有限公司

Window lamination method for paper

InactiveCN107599598ARealize window coatingBonded firmlyLamination ancillary operationsLaminationWork in processEngineering

The invention discloses a window lamination method for paper. The window lamination method comprises the following steps: step 1, a two-sided corona film with one side pre-coated with hot melt glue isadopted, the other side of the two-sided corona film is bonded with the surface of the paper to be subjected to window lamination, full lamination of the two-sided corona film on the paper is realized, and an early semi-finished product is obtained; step 2, windowing is performed on the early semi-finished product, that is, a window is die-cut in a predetermined position of the early semi-finished product, scraps produced in die cutting are removed, and an intermediate semi-finished product is obtained; step 3, a heat seal film provided with co-polypropylene on at least one side is adopted, hot melt glue of the intermediate semi-finished product is covered with the side, provided with co-polypropylene, of the heat seal film, the heat seal film and the intermediate semi-finished product are bonded together through hot pressing by a hot pressing roller, and a finished paper product subjected to window lamination is obtained. The window lamination method has the advantages that the process difficulty is low, the effect of the window lamination finished product is good and the production efficiency is high.

Owner:广州市恒远彩印有限公司

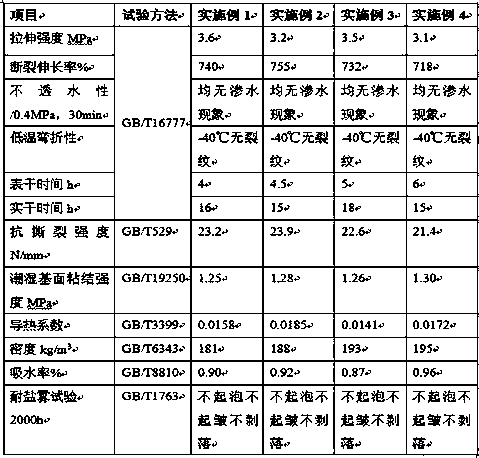

Preparation method of novel single-component water-cured polyurethane waterproof coating

ActiveCN111057461AShort curing timeGood mechanical propertiesPolyurea/polyurethane coatingsPolymer scienceTriol

The invention provides a preparation method of a novel single-component water-cured polyurethane waterproof coating. The specific preparation process comprises the steps of drying, mixing, pre-polymerizing, chain extending and film forming. During the preparation process, according to the invention, polyether glycol and polyether triol are mixed according to a specific ratio; a certain amount of benzamide is added; the addition amount, the reaction temperature and the reaction time of diphenylmethane diisocyanate in the prepolymer synthesis process are reasonably controlled; by combining the use of a chain extender and materials, the single-component water-cured polyurethane waterproof coating has the advantages of higher tensile strength, higher elongation at break, excellent heat resistance, excellent water resistance, excellent aging resistance, convenience in construction, lower cost and no environmental pollution, and is suitable for large-scale popularization and application.

Owner:ZHOUKOU NORMAL UNIV

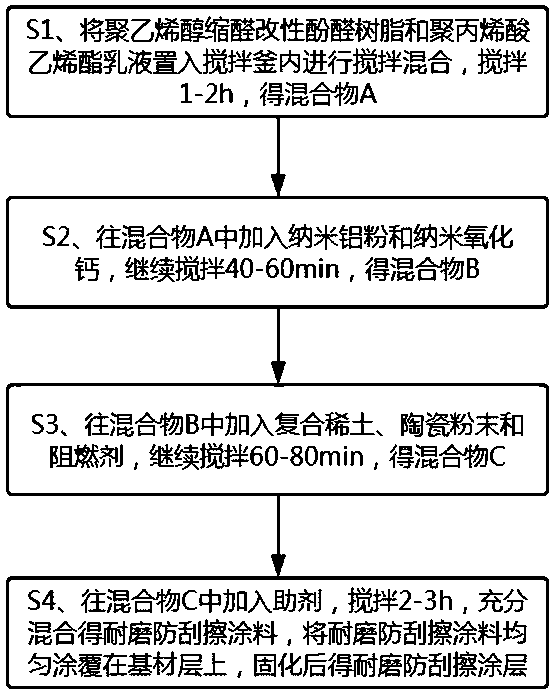

Wear-resistant and scratch-resistant coating and preparation method thereof

InactiveCN111087880AReasonable control of the amount addedImprove anti-corrosion performanceFireproof paintsAnti-corrosive paintsPolyvinyl alcoholFire retardant

The invention discloses a wear-resistant and scratch-resistant coating and a preparation method thereof, and belongs to the technical field of wear-resistant coatings. According to the wear-resistantand scratch-resistant coating and the preparation method thereof, the wear-resistant and scratch-resistant coating is formed by uniformly coating a wear-resistant and scratch-resistant coating on a composite film and curing the wear-resistant and scratch-resistant coating, the wear-resistant and scratch-resistant coating is prepared from the following components: polyvinyl acetal modified phenolicresin, polyacrylic acid vinyl ester emulsion, composite rare earth, nano aluminum powder, nano calcium oxide, ceramic powder, a flame retardant and the like. The wear-resistant and scratch-resistantcoating disclosed by the invention has excellent bonding strength; the wear-resistant and scratch-resistant coating has the advantages of favorable dielectric properties, favorable product dimensionalstability, high hardness, favorable flexibility, high stability for alkali and most solvents, favorable corrosion resistance, favorable gas resistance, favorable water resistance, favorable flame retardancy and the like, and has long service life, and the wear-resistant and scratch-resistant coating obtained by coating the wear-resistant and scratch-resistant coating can not have the problems ofblistering, cracking, whitening, delaminating and the like. The preparation method is simple, and large-batch and large-scale production is easy to carry out.

Owner:YIXING YULONG PLASTIC PACKAGE PROD

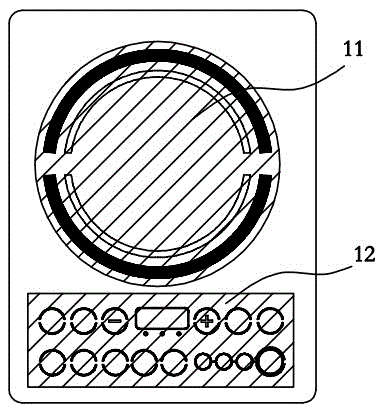

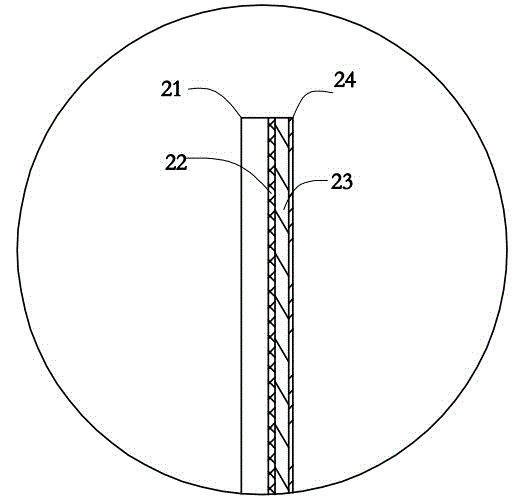

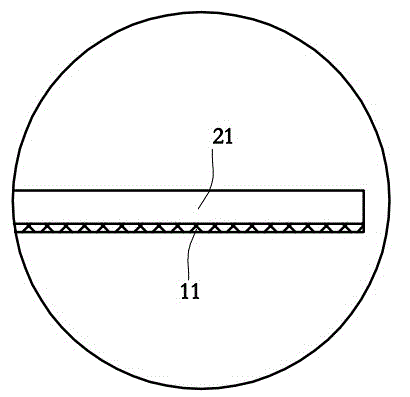

Induction cooker panel

The invention relates to an induction cooker panel which is characterized in that a first oil ink layer (11) is arranged on one side of the panel by adopting a transfer paper printing technique, wherein the thickness of the first oil ink layer (11) is 0.01-0.1mm; the overall thickness of the oil ink is only 0.01-0.10mm, and is thinner than that of an original screen printing; the induction cooker panel has the advantage that the oil ink layer is thin; the expansion coefficient is small and the oil ink layer is organically combined with a microcrystalline panel and has the scratch resistant effect and the high temperature resistant effect; during usage of the induction cooker, the imperfect problems of oil ink color change, bubbling and falling off do not occur; the service life of the induction cooker panel is prolonged and the overall appearance performance of the induction cooker is improved.

Owner:JOYOUNG CO LTD

Cleaning method for automobile parts

InactiveCN108971075AImprove paint qualityGuarantee the quality of paintingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater rinsingEngineering

The invention discloses a cleaning method for automobile parts. The cleaning method mainly comprises the following steps that step 1, the surfaces of the automobile parts are subjected to high pressure cleaning and dust removal; step 2, the parts after high pressure washing are subjected to ultrasonic cleaning; step 3, the parts after ultrasonic cleaning are subjected to water rinsing; step 4, theparts after ultrasonic cleaning are dried; and step 5, the parts after drying in the step 4 are subjected to rust-proof treatment, and then conventional spraying is carried out using spraying. By adopting the cleaning method, oil stains and impurities on the surfaces of the automobile parts can be thoroughly removed, the paint spraying quality of the parts after paint spraying can be significantly improved, the appearance is kept complete and attractive, phenomena such as paint film discoloration, cracking, bubbling and falling off do not exist, and meanwhile, the high temperature resistanceand rust resistance of a paint film after paint spraying of the parts are improved.

Owner:江苏法瑞德专用汽车有限公司

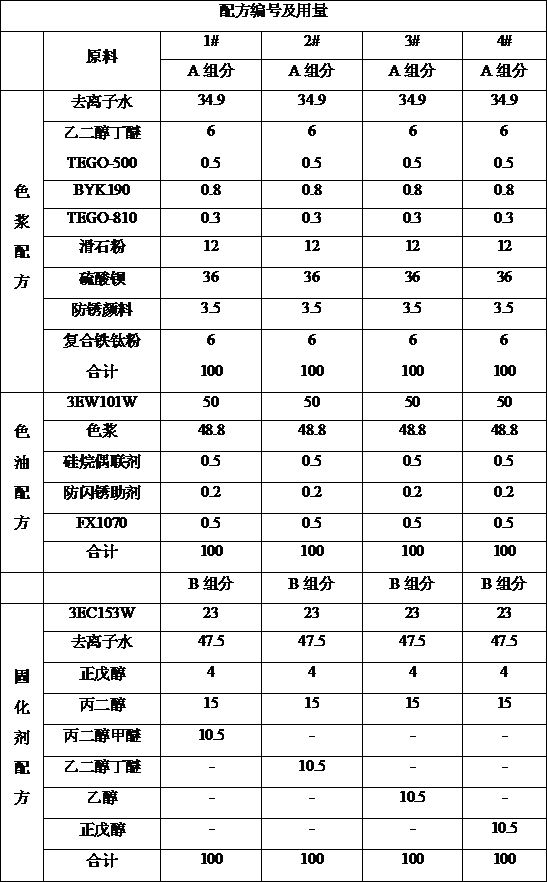

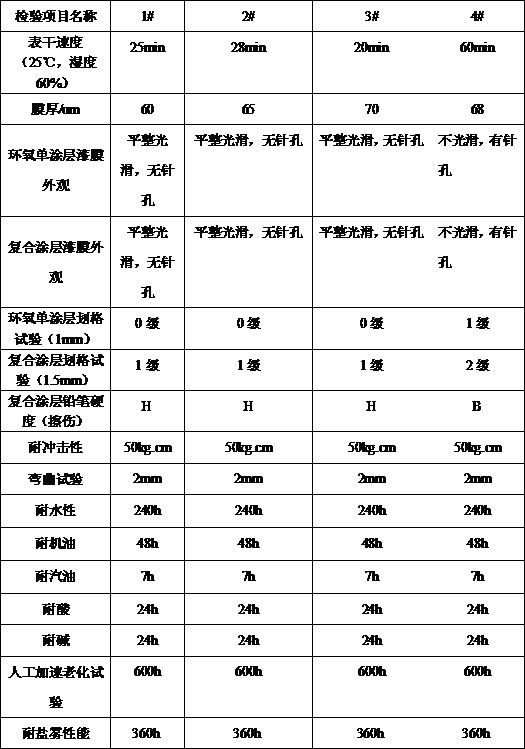

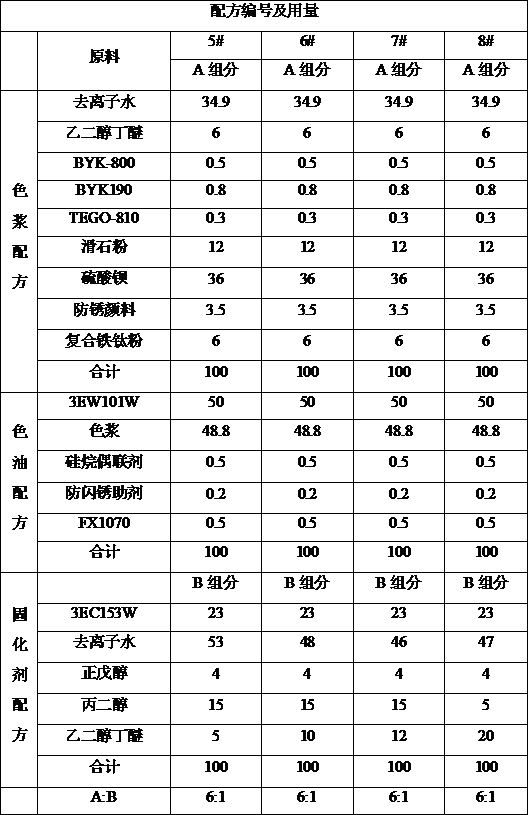

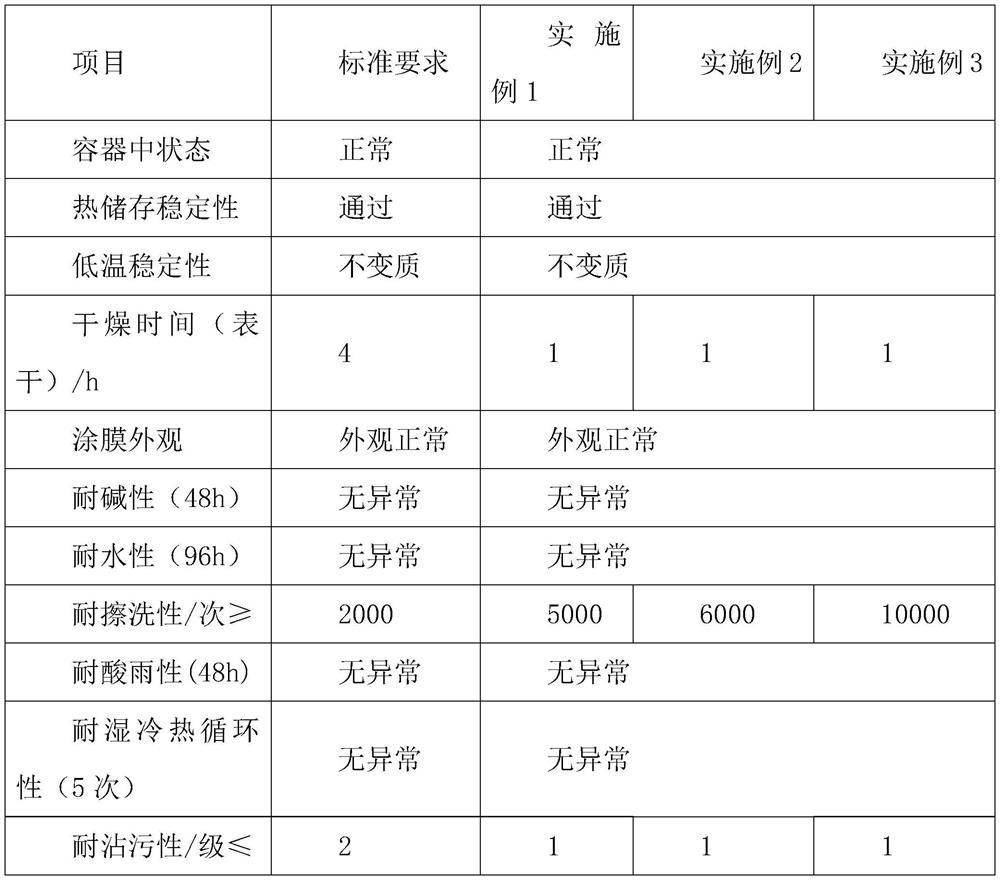

Water-based epoxy primer for wet-to-wet process and preparation method of water-based epoxy primer

InactiveCN112552777AHigh hardnessImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEmulsion

The invention relates to the field of water-based industrial coatings, in particular to a water-based epoxy primer for a wet-to-wet process and a preparation method of the water-based epoxy primer. The water-based epoxy primer mainly comprises a primer component A and a primer component B. The primer component A is composed of water-based resin emulsion, water slurry, a silane coupling agent, an anti-flash-rust additive, a thickener and the like, and the primer component B is a curing agent part. The preparation process comprises preparation of color paste, preparation of colored paint and preparation of the curing agent. The water-based epoxy primer can completely satisfy the high-film-thickness wet-to-wet spraying technique, has the characteristics of no sagging, no foaming, favorable adhesive force, high hardness and the like, and the property of a primer film is up to the standard.

Owner:GUANGDONG YATU CHEM

Manufacture method of water-soaking-resistant wicker products

InactiveCN109049216AGood mechanical propertiesImprove waterproof performanceWood treatment detailsReed/straw treatmentBlistersMoisture

The invention discloses a manufacture method of water-soaking-resistant wicker products. The manufacture method includes the following operation steps that firstly, after the wicker products formed through weaving are dried till the moisture content is 3% to 10%, modification liquid is sprayed on the surfaces of the wicker products; and secondly, after the wicker products processed in the first step are naturally dried in the air for 2 to 3 days, the surfaces of the wicker products are coated with wicker waterproof paint. The manufacture method of the water-soaking-resistant wicker products iseasy to operate, low in cost, green and environment-friendly, all mechanical properties of the manufactured wicker products are excellent, especially the manufactured wicker products have excellent waterproof performance, and after the wicker products are soaked in water, the paint on the surfaces of the wicker products cannot fall or blister.

Owner:阜南县大喜柳编工艺品有限公司

Preparation method of high-humidity-adhesion liquid granite coating

The invention relates to the field of water-based paint preparation, in particular to high-humidity-adhesion liquid granite paint. The components are metered in percentage by mass: 10-20% of a protective glue solution, 8-15% of an emulsion, 0.5-1% of a cross-linking agent, 62-80% of a dispersed phase (color point), 1-1.5% of a surfactant, 0.5-1% of an initiator, 0.5-1% of an accelerant, 0.5-1% of a softening agent, 0.5-1% of special resin, 0.5-1% of a rheological additive, 0.5-1% of magnesium oxide, 0.5-1% of water-based isocyanate and 2-4% of a separant. 62-80% of the dispersion phase (color point) is prepared from the following raw materials in percentage: 5-12% of water, 0.5-0.8% of a wetting dispersant, 1-1.5% of a mildew-proof preservative, 0.5-1.2% of a defoaming agent, 2-3% of an anti-freezing agent, 1-1.5% of a coalescing agent, 1-1.5% of a pH regulator, 2-5% of calcined kaolin, 3-7% of coarse whiting, 2-5% of titanium dioxide, 2-4% of cellulose, 2-4% of a protective glue solution and 40-55% of sand. The liquid granite coating has the beneficial effects that the cross-linking agent is added into the liquid granite coating, so that a dispersion medium forms secondary cross-linking, the compactness of a paint film is further improved, and the paint film still has high wet adhesion under the condition that the granite coating is washed by rainwater.

Owner:河北三棵树涂料有限公司

Construction method of building exterior wall coating

The invention provides a construction method of a building exterior wall coating. The construction method comprises the following six steps: first step, carrying out foundation treatment or base layerreconstruction; second step, painting a wall surface homogeneous foundation or base layer by using water; third step, applying putty; fourth step, painting a primer coating; fifth step, painting an intermediate coating; and sixth step, painting a finish coating. The construction method of the building exterior wall coating is used for building exterior wall coating construction.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

A two-component interfacially bonded silicone tie paint matching fouling-release antifouling paint

ActiveCN106336799BNo blisteringImprove adhesionAntifouling/underwater paintsPaints with biocidesCavitationSolvent

The invention discloses bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint. The bi-component interfacial bonding organosilicone connection paint is prepared from a first component and a second component according to the weight ratio of 10:1. The first component is prepared from organosilicone, pigments and filler, a solvent and a thixotropic agent. The second component is prepared from a high-toughness curing agent and a reaction promoter. The bi-component interfacial bonding organosilicone connection paint is prepared from the first component including, by weight, 35-55% of organosilicone, 20-40% of pigments and filler, 15-30% of solvent and 0-5% of thixotropic agent and the second component including, by weight, 10-20% of high-toughness curing agent and 0.01-0.03% of reaction promoter. According to the connection paint, the problem that pollution release type anti-fouling paint and anti-rusting paint are poor in adhesive force is solved, the adhesive strength to an anticorrosion coating reaches 2.2 MPa or above, the connection strength for an anti-fouling coating reaches 1.3 MPa or above, and 100% cohesive failure is shown; after being scoured by 50 sections of high-speed flow for 1,000 hours, the coatings are free of bubbling, disengaging and cavitation damage, and have good adhesive performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Hot melt adhesive

ActiveCN102719207BHigh degree of automationNo pollution in the processEster polymer adhesivesWaxPolymer science

The invention discloses a hot melt adhesive and aims to provide the hot melt adhesive which can not be foamed or layered under the condition of high temperatures after being bonded; and the invention has the technical key points that the hot melt adhesive comprises the following components in parts by weight: 1-70 parts of methyl methacrylate-butyl acrylate copolymer,1-40 parts of styrene-butadiene-isoprene segmented copolymer, 1-40 parts of thickening agent, 1-10 parts of filling agent, 1-5 parts of stabilizing agent and 5-10 parts of wax; and the hot melt adhesive belongs to the technical field of colloid preparation.

Owner:广州市豪特粘接材料有限公司

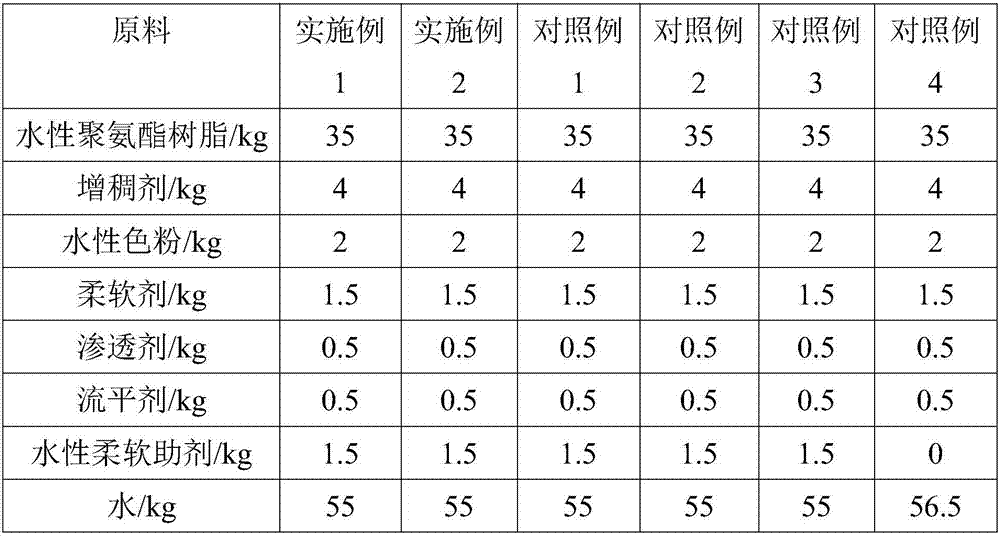

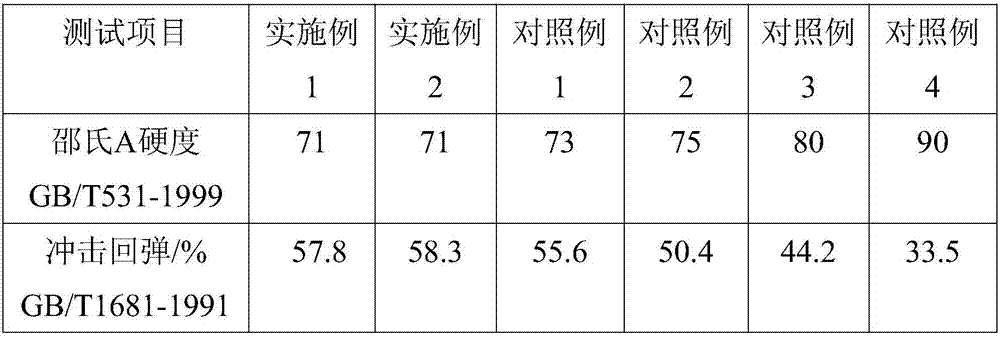

Ultra-flexible and ultra-soft rebound synthetic leather fabric and preparation method thereof

InactiveCN110948971AImprove fitImprove heat and cold resistanceLamination ancillary operationsSynthetic resin layered productsPolymer scienceLacquer

The invention discloses an ultra-flexible and ultra-soft rebound synthetic leather fabric. The fabric comprises a base cloth layer, a warm-keeping layer, fuzzing cloth, a surface layer and a highlightpolyurethane layer. The invention also discloses a preparation method of the ultra-flexible and ultra-soft rebound synthetic leather fabric. The preparation method comprises the following steps: S1,carrying out textile treatment on the base cloth; S2, sewing the base cloth layer and the warm-keeping layer; S3, treating the fuzzing cloth; S4, soaking in a softening auxiliary agent; S5, applying the highlight polyurethane layer in a spray-coating manner; and S6, post-processing. The purpose of changing the surface performance of the synthetic leather lacquer leather is achieved, the heat and cold resistance can be enhanced, the surface is highlighted, and the fabric feels soft. Meanwhile, the treatment process is changed, the treated material is better attached to the bottom layer, cracking and color migration phenomena are not likely to happen, and the fabric feels soft. The synthetic leather product is endowed with the soft and smooth hand feeling, the surface of the synthetic leather cannot bubble, and therefore, pinholes of the synthetic leather product are avoided.

Owner:QINGYUAN QILI SYNTHETIC LEATHER

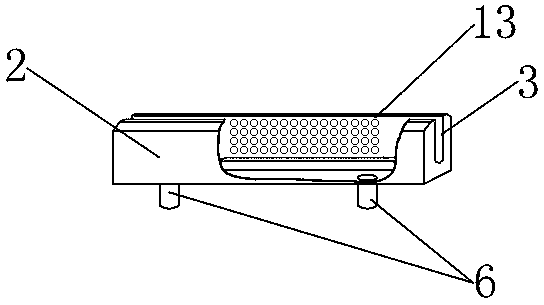

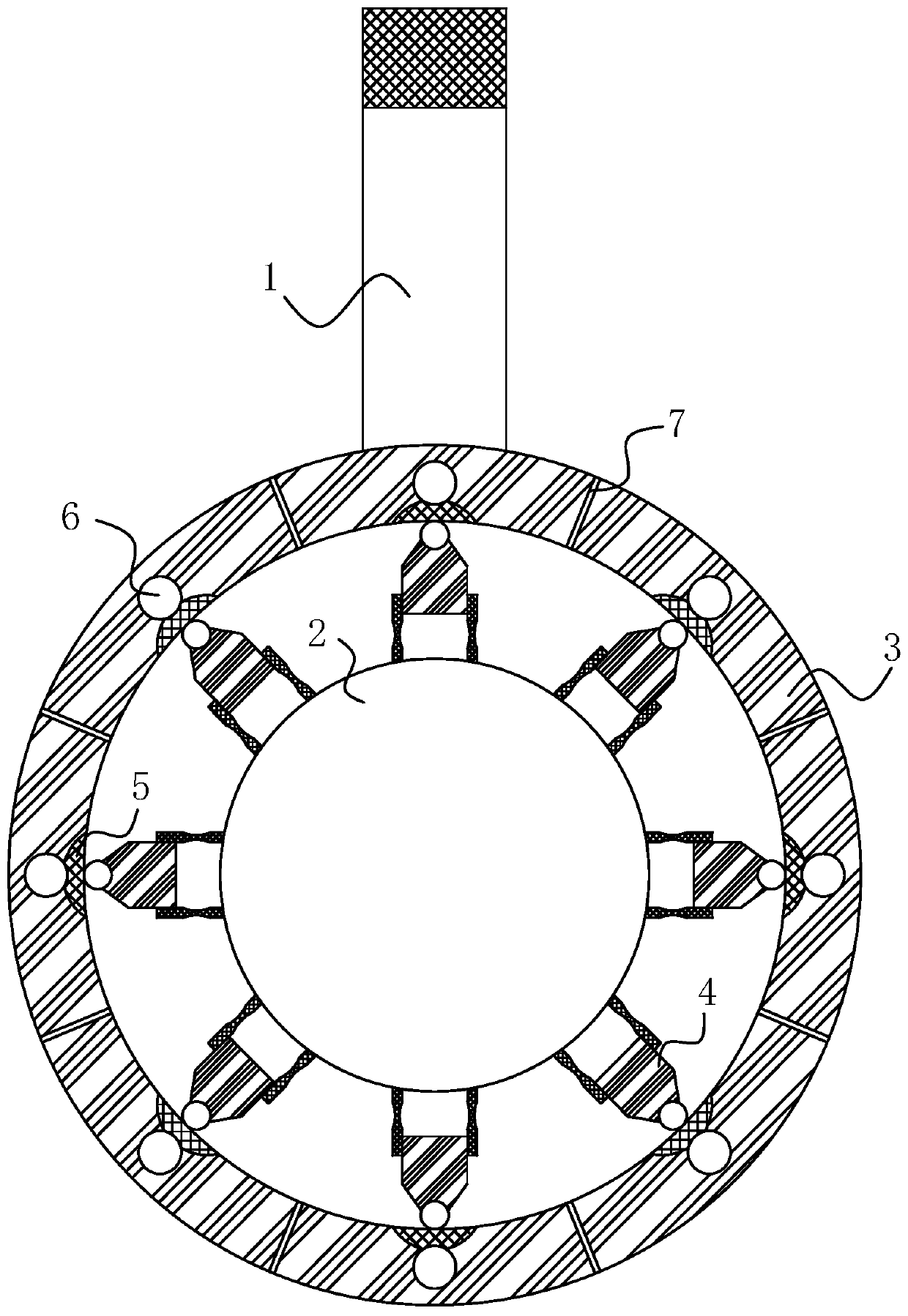

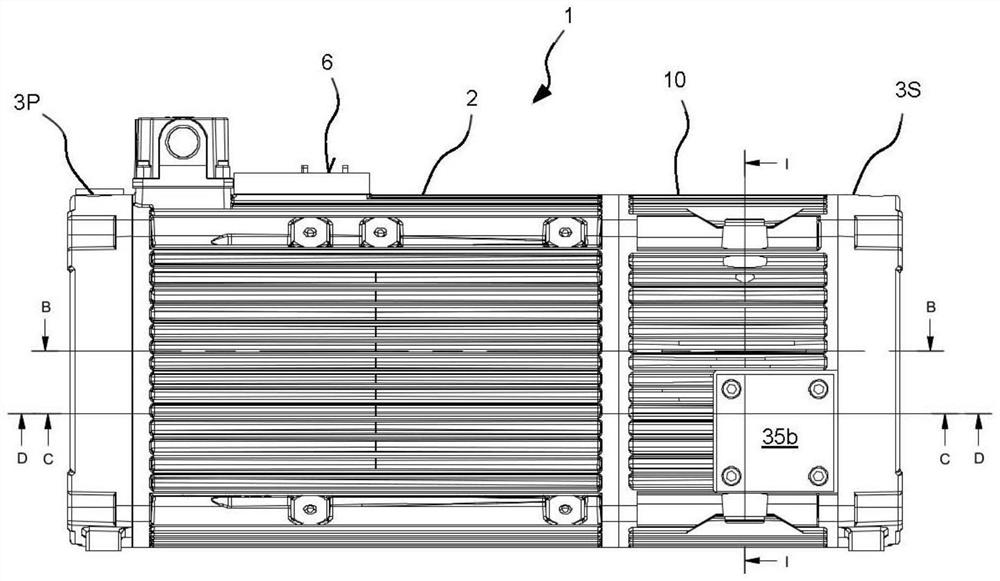

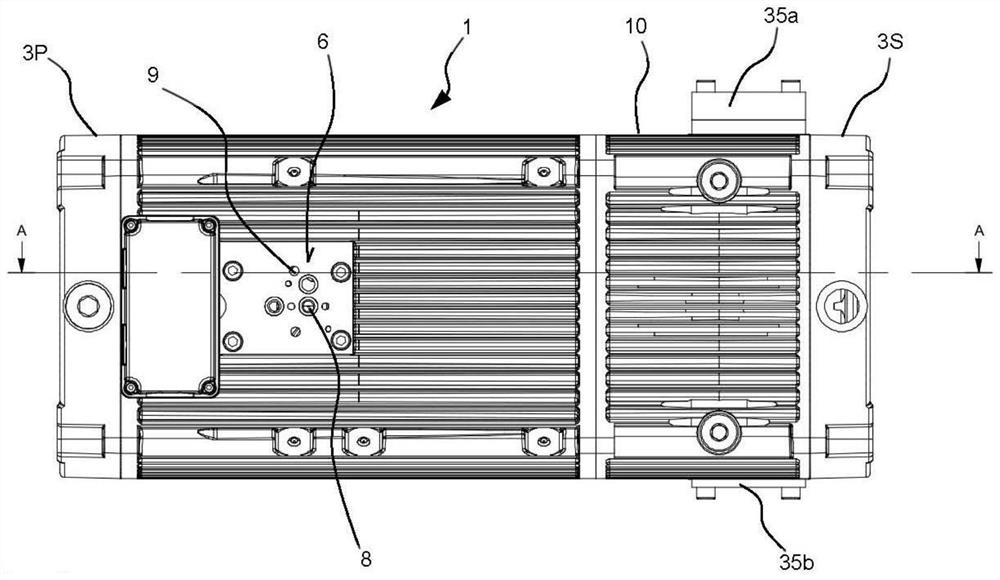

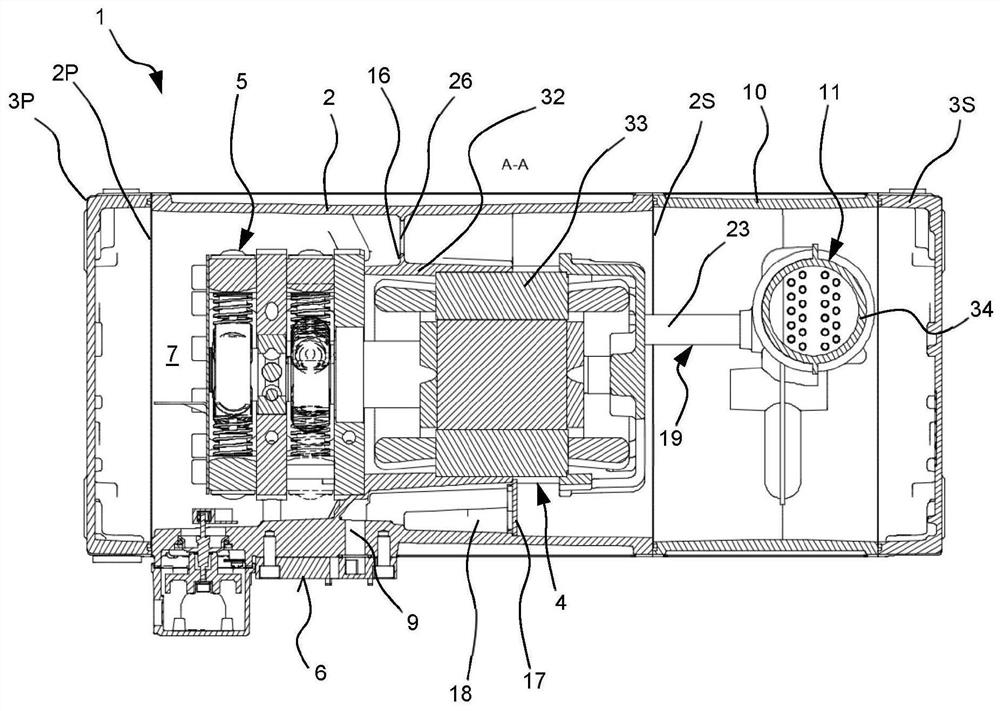

Modular Motor Pump Unit

ActiveCN110863981BFlexible structureEasy to assemblePositive displacement pump componentsPump controlElectric machineryHydraulic fluid

The invention relates to a modular motor pump unit (1) comprising: an outer housing (2) having two open ends (2S, 2P) and two a housing cover (3S, 3P); at least one electric motor (4) arranged in said outer housing (2); at least one pump element (5) arranged in said outer housing (2) and which can be provided by said outer housing (2) driven by the motor (4); and at least one connecting portion (6) arranged on the outer side of the outer casing (2). The outer housing (2) forms a hydraulic fluid reservoir (7), and a pressure channel (8) extends from the pump element (5) to the connecting portion (6). A return channel (9) extends from the connecting portion (6) to the interior of the outer housing (2). An additional housing (10) is arranged between the outer housing (2) and at least one housing cover (3S, 3P). A heat exchanger element (11) is arranged in said additional housing (10), and said return channel (9) is connected to said additional housing (10), and said additional housing (10) is connected to said hydraulic fluid reservoir (7).

Owner:ハーヴェーハイドローリックエスイー

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com