Actuator used for thermal control complete equipment and treatment technology thereof

A complete set of equipment and actuator technology, applied in coatings, anti-corrosion coatings, rubber derivative coatings, etc., can solve the problems of surface speed cracking and rusting, unfavorable long-term production, shortened service life, etc., to delay pulverization and use range The effect of widening and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

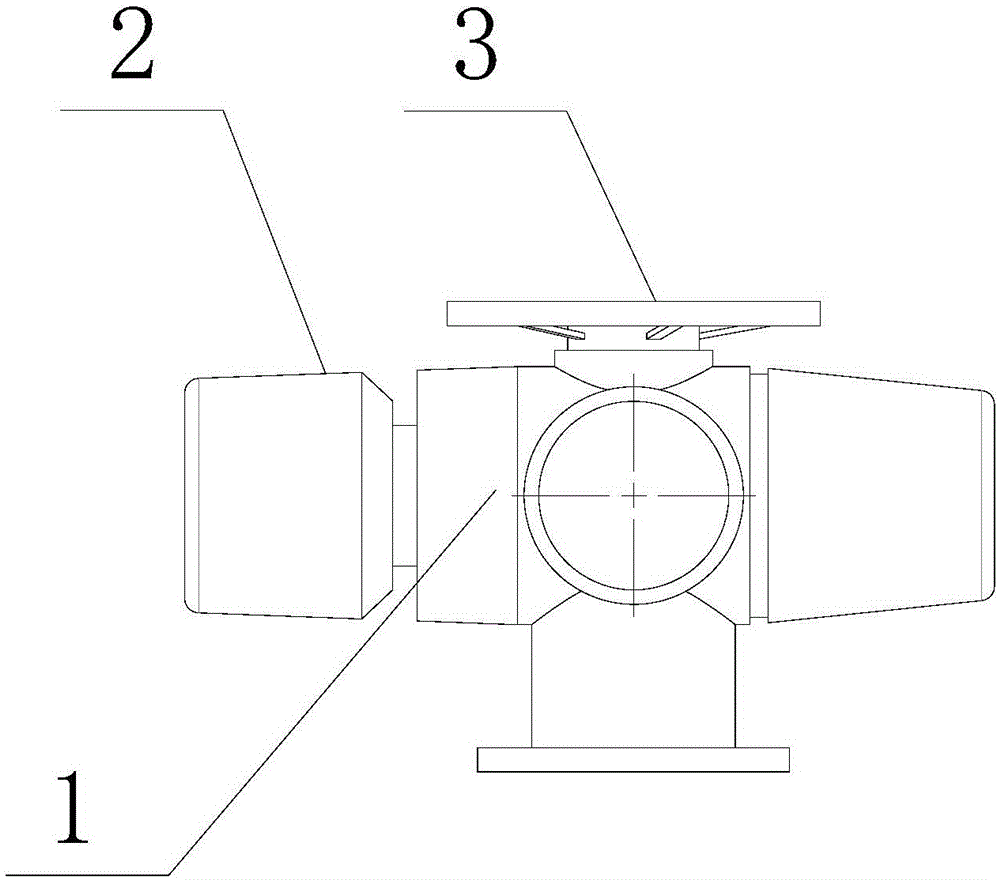

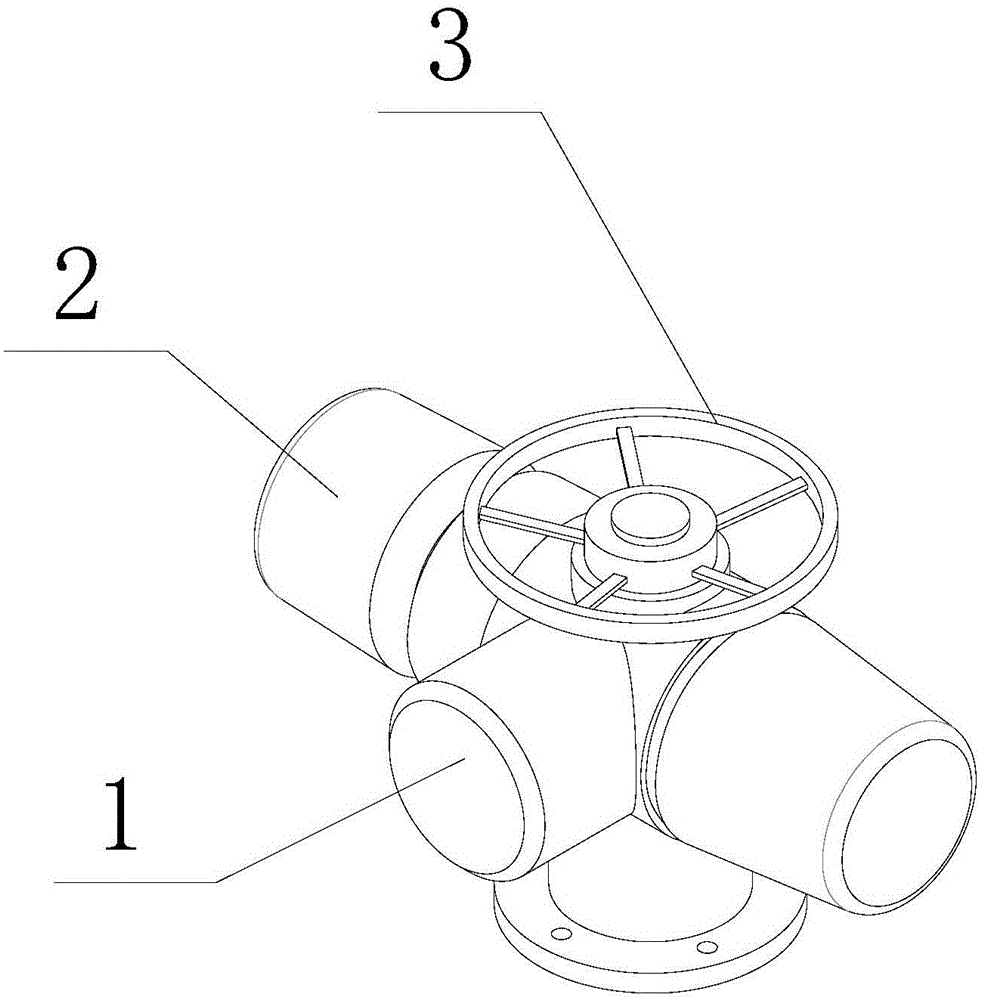

[0027] This embodiment provides an actuator for a complete set of thermal control equipment. The actuator is composed of a main body 1, a servo motor 2, and a hand wheel 3. The hand wheel 3 is set on the upper end of the main body 1, and the servo motor 2 is set at one end along the length direction of the main body 1. The surface of the main body 1, the servo motor 2 and the hand wheel 3 are all coated with corrosion-resistant paint;

[0028] The corrosion-resistant paint components are calculated in parts by weight: epoxy modified silicone resin: 40 parts, hydrogenated nitrile rubber: 12 parts, bisphenol A epoxy resin: 12 parts, mica powder: 5 parts, talcum powder: 14 parts, polyvinyl butyral: 8 parts, benzyl silicone resin: 4 parts, dioctyl phthalate: 2 parts, copper powder: 10 parts, rutile titanium dioxide: 2 parts, iron phosphorus powder : 1 part, deionized water: 20 parts, ethyl silicate: 2 parts, benzoic acid: 5 parts, rare earth: 1 part, additives: 1 part;

[0029] T...

Embodiment 2

[0036] This embodiment provides an actuator for a complete set of thermal control equipment. The actuator is composed of a main body 1, a servo motor 2, and a hand wheel 3. The hand wheel 3 is set on the upper end of the main body 1, and the servo motor 2 is set at one end along the length direction of the main body 1. The surface of the main body 1, the servo motor 2 and the hand wheel 3 are all coated with corrosion-resistant paint;

[0037] The corrosion-resistant paint components are calculated in parts by weight: epoxy modified silicone resin: 60 parts, hydrogenated nitrile rubber: 14 parts, bisphenol A epoxy resin: 18 parts, mica powder: 7 parts, talcum powder: 16 parts, polyvinyl butyral: 10 parts, benzyl silicone resin: 6 parts, dioctyl phthalate: 7 parts, copper powder: 12 parts, rutile titanium dioxide: 4 parts, iron phosphorus powder : 3 parts, deionized water: 25 parts, ethyl silicate: 4 parts, benzoic acid: 7 parts, rare earth: 3 parts, additives: 3 parts;

[003...

Embodiment 3

[0045] This embodiment provides an actuator for a complete set of thermal control equipment. The actuator is composed of a main body 1, a servo motor 2, and a hand wheel 3. The hand wheel 3 is set on the upper end of the main body 1, and the servo motor 2 is set at one end along the length direction of the main body 1. The surface of the main body 1, the servo motor 2 and the hand wheel 3 are all coated with corrosion-resistant paint;

[0046] The corrosion-resistant paint components are calculated in parts by weight: epoxy modified silicone resin: 50 parts, hydrogenated nitrile rubber: 13 parts, bisphenol A epoxy resin: 15 parts, mica powder: 6 parts, talcum powder: 15 parts, polyvinyl butyral: 9 parts, benzyl silicone resin: 5 parts, dioctyl phthalate: 4 parts, copper powder: 11 parts, rutile titanium dioxide: 3 parts, iron phosphorus powder : 2 parts, deionized water: 24 parts, ethyl silicate: 3 parts, benzoic acid: 6 parts, rare earth: 2 parts, additives: 2 parts;

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com