Patents

Literature

52results about How to "High adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

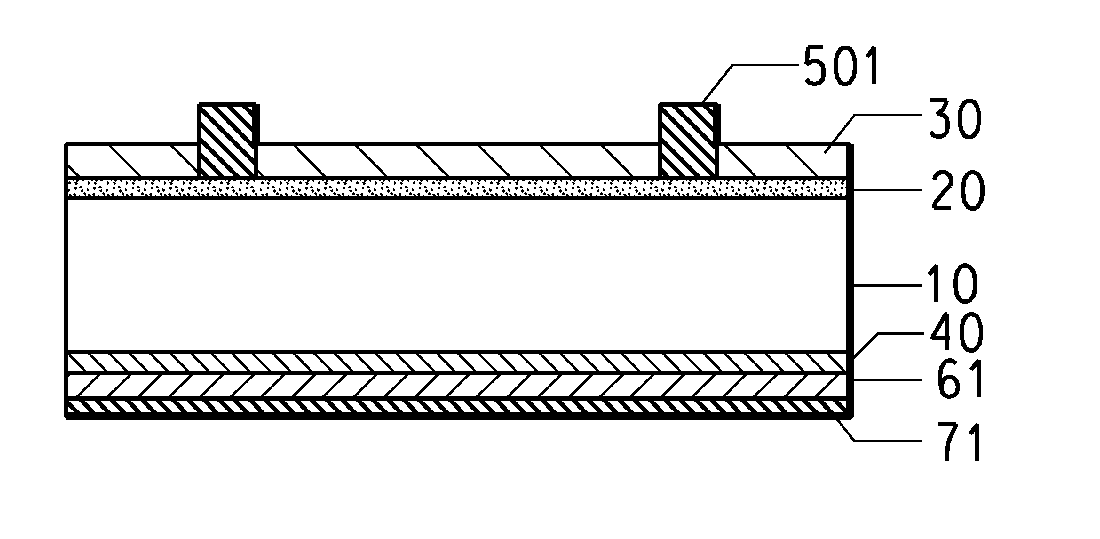

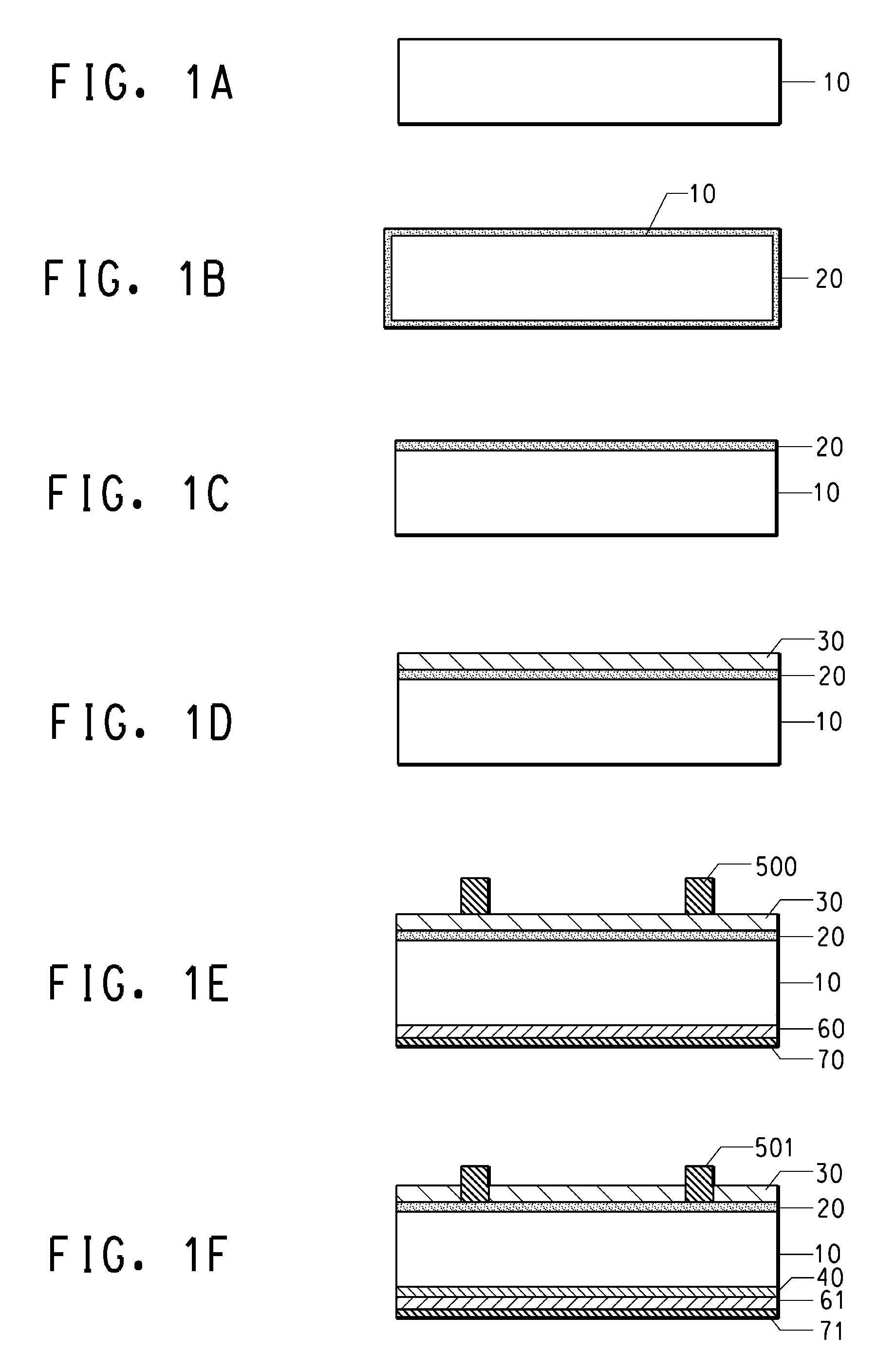

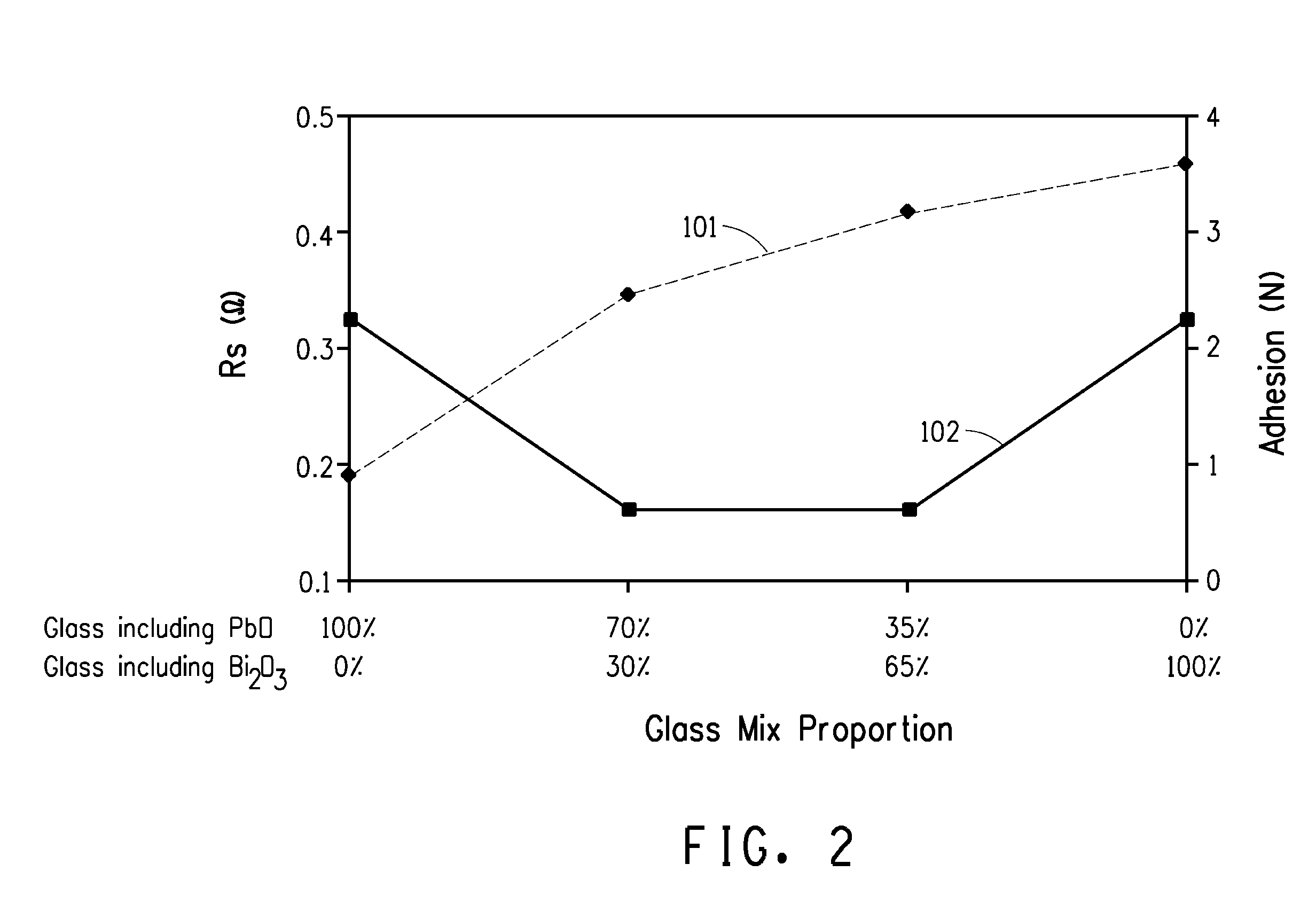

Conductive paste for solar cell electrode

ActiveUS20100126565A1Low resistanceHigh adhesionConductive materialSemiconductor/solid-state device manufacturingSolar cellHigh adhesion

To obtain low resistance and high adhesion at the same time in a solar cell electrode, a conductive paste is offered. A conductive paste for solar cell electrode contains conductive powder, organic medium and glass frit which is mixture of more than one kind of glass frit such as a mixture of glass frit containing at least PbO and glass frit containing at least Bi2O3.

Owner:SOLAR PASTE LLC

Composite reinforcer sheathed with a layer of polymer that is self-adhesive to rubber

ActiveUS20140045983A1Ensures adhesionHigh adhesionLiquid surface applicatorsConductive materialCarbon steelEpoxide

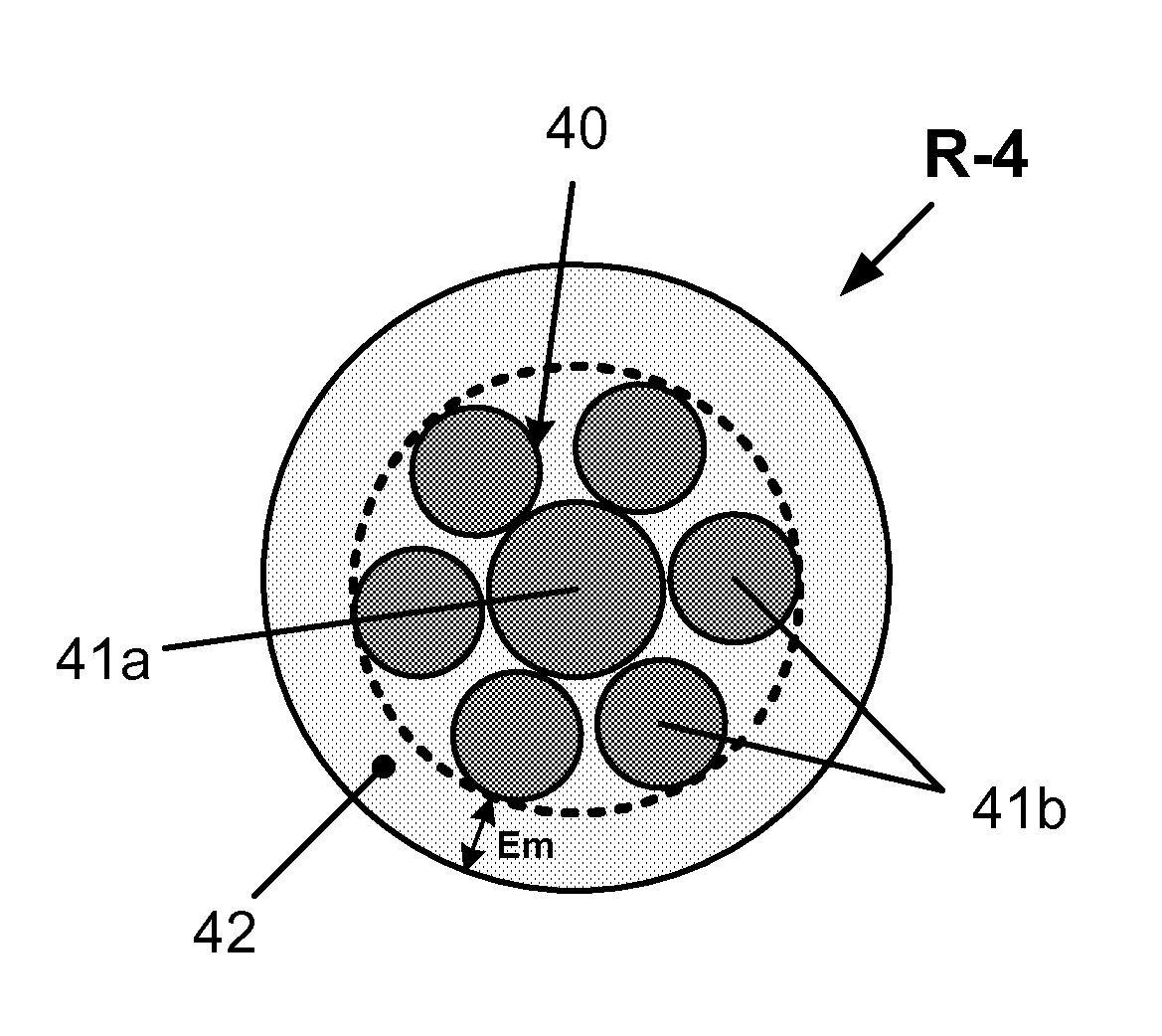

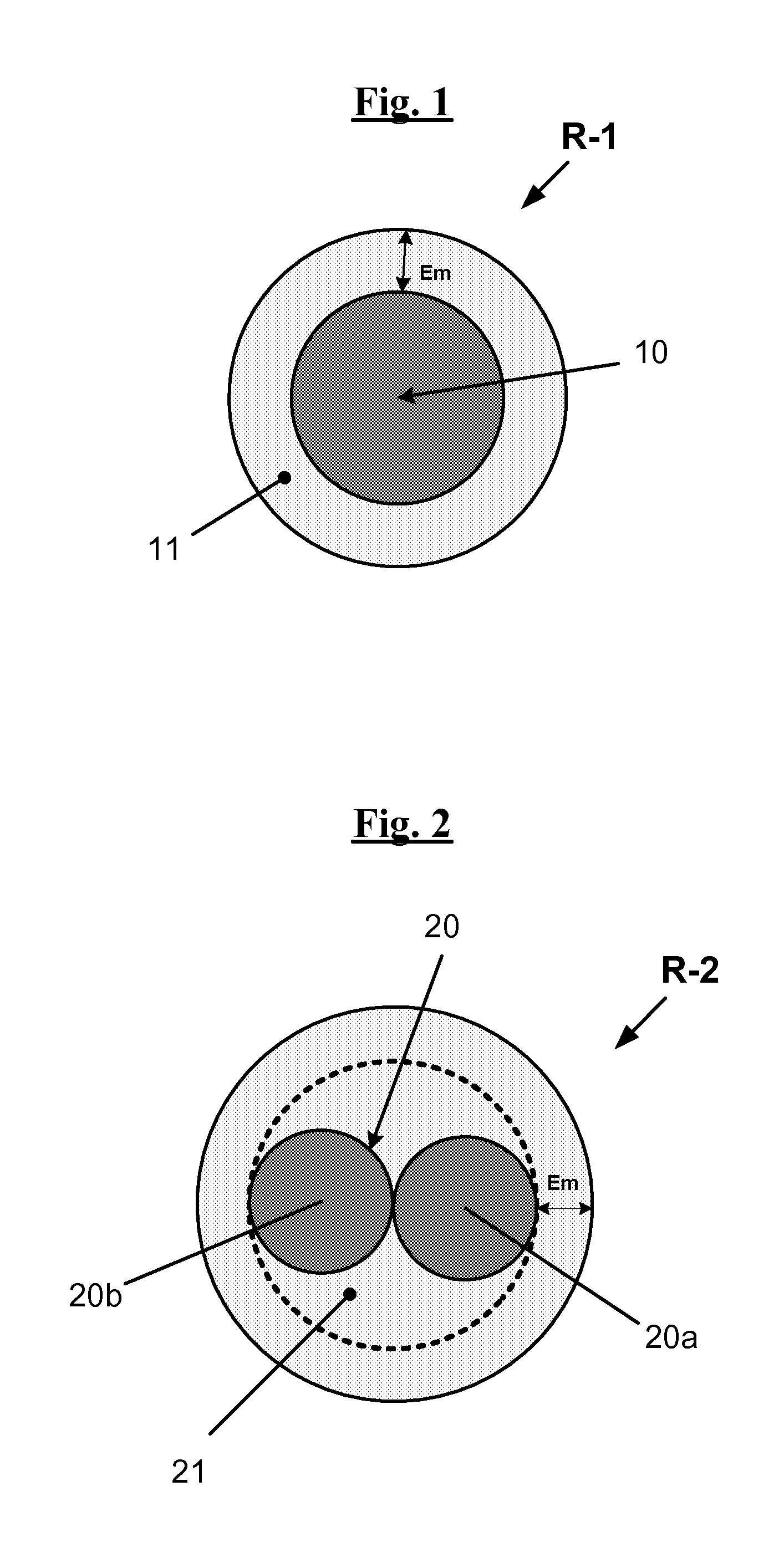

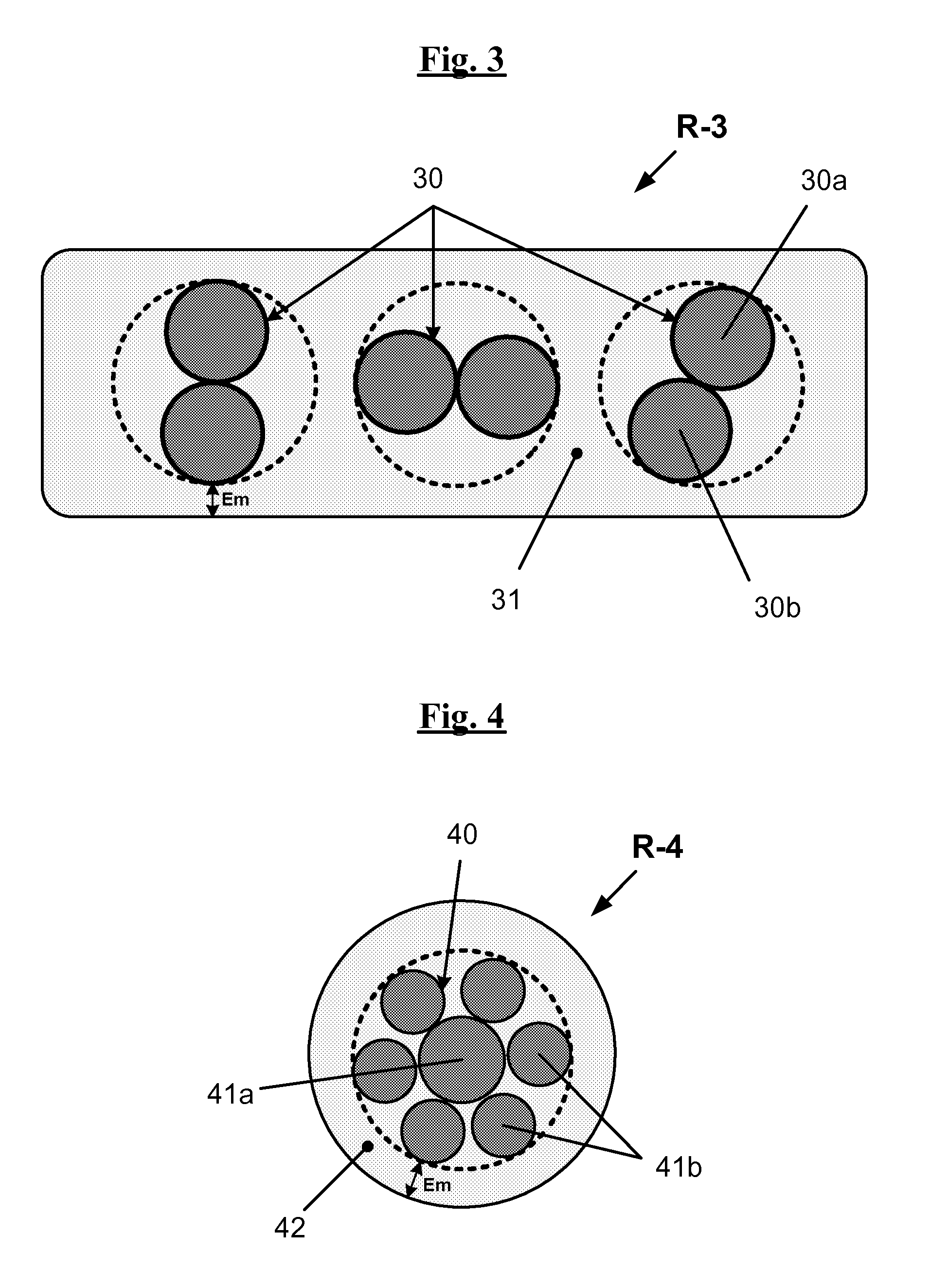

Composite reinforcer (R-2) capable of adhering directly to a diene rubber matrix, which can be used as a reinforcing element for a pneumatic tyre, comprising:one or more reinforcing thread(s) (20), for example a carbon steel cord;covering said thread, individually each thread or collectively several threads, a layer of a thermoplastic polymer composition comprising at least one thermoplastic polymer, the glass transition temperature of which is positive, a poly(p-phenylene ether) (PPE) and a functionalized unsaturated thermoplastic styrene (TPS) elastomer, the glass transition temperature of which is negative, said TPS elastomer bearing functional groups selected from epoxide, carboxyl and acid anhydride or ester groups.Process for manufacturing such a composite reinforcer and rubber article or semi-finished product, especially a pneumatic tyre, incorporating such a composite reinforcer.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

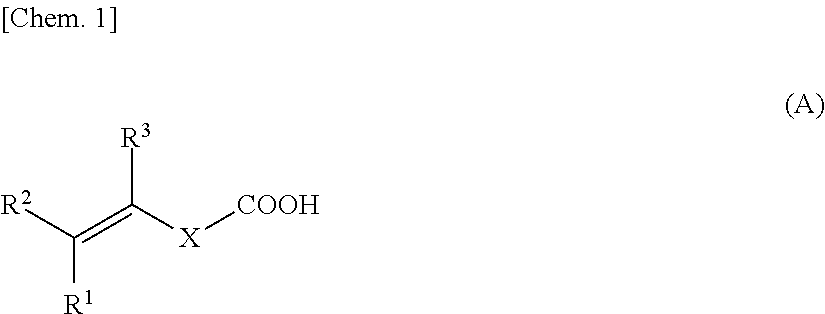

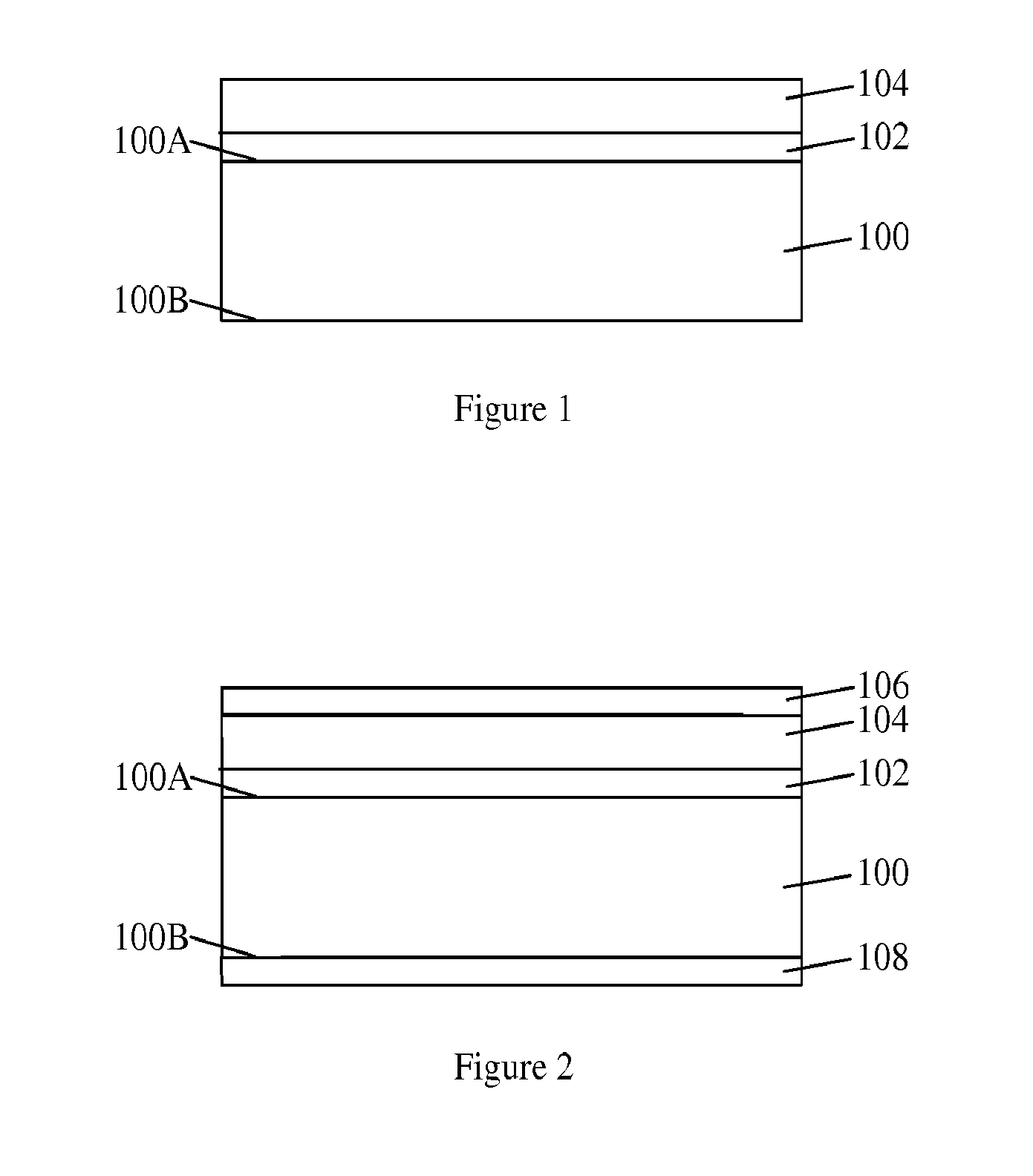

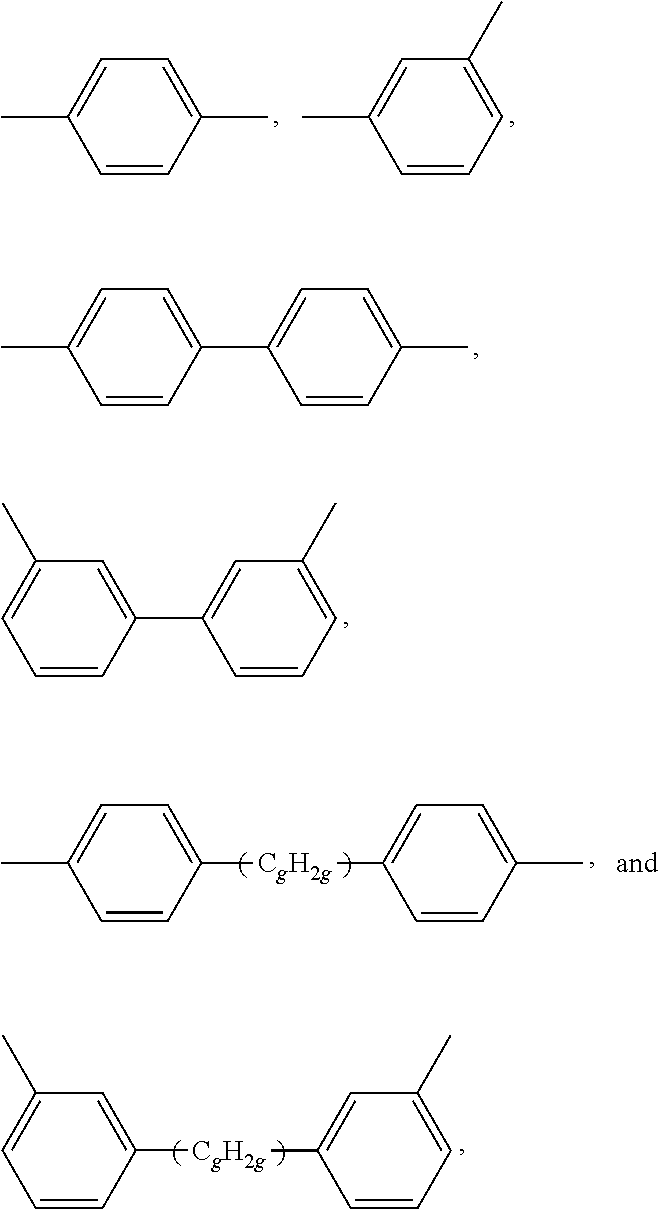

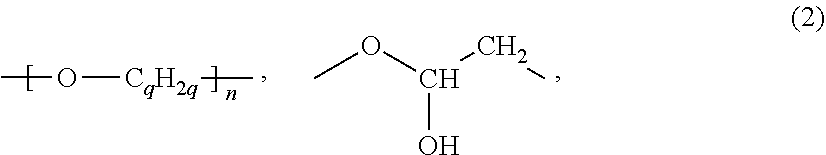

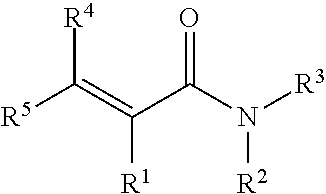

Vinylidene Fluoride Copolymers and Uses of the Copolymers

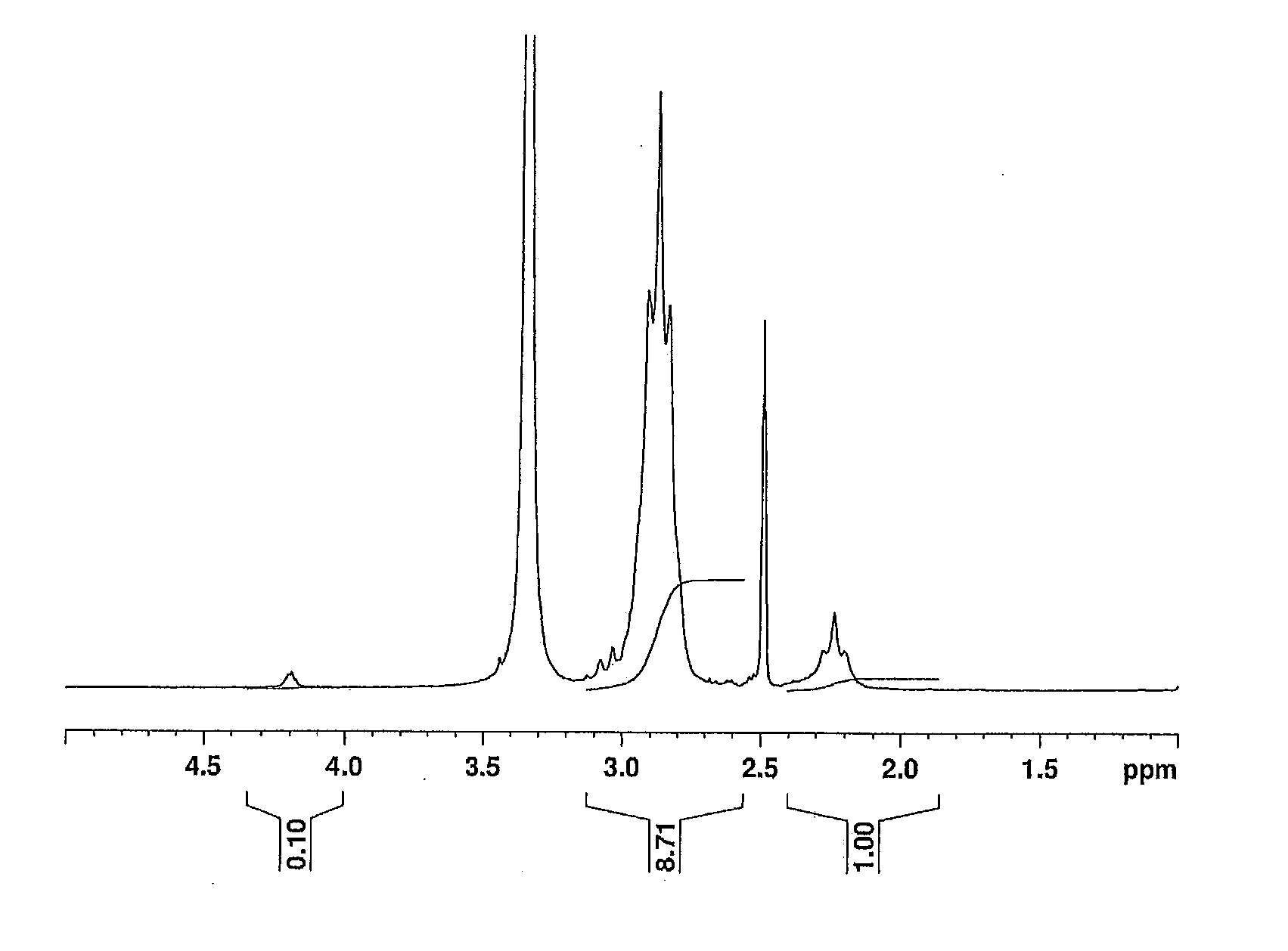

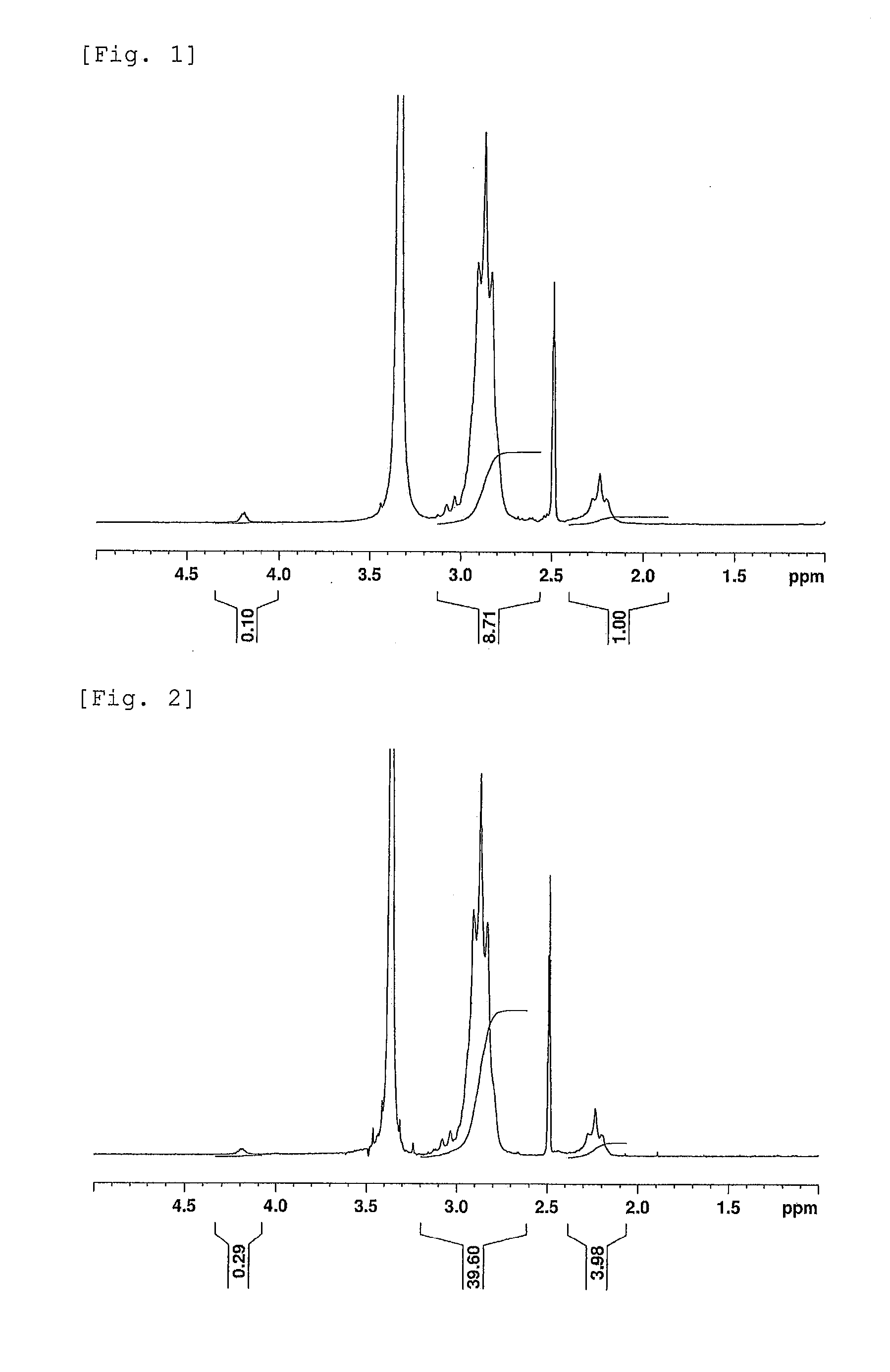

ActiveUS20130273424A1High adhesionGood productivityFinal product manufactureNon-aqueous electrolyte accumulator electrodesMetal foilHigh adhesion

Provided are vinylidene fluoride copolymers exhibiting higher adhesion with respect to metal foils than do conventional vinylidene fluoride copolymers, and to provide uses of the vinylidene fluoride copolymers. The vinylidene fluoride copolymers are obtained by copolymerizing vinylidene fluoride with a compound represented by Formula (A). In Formula (A), R1, R2 and R3 are each independently a hydrogen atom, a chlorine atom or an alkyl group; and X is an atomic group with a molecular weight of not more than 500 containing a heteroatom and having a main chain composed of 1 to 20 atoms, or is a heteroatom.

Owner:KUREHA KAGAKU KOGYO KK

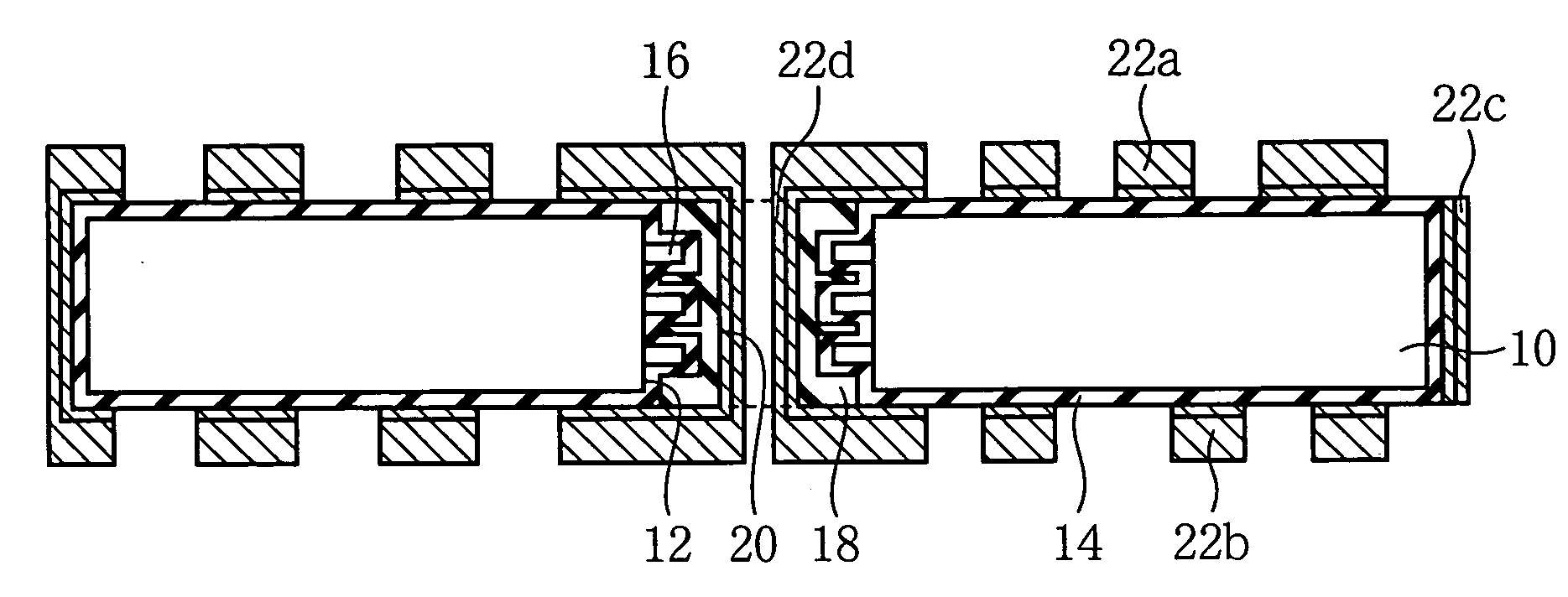

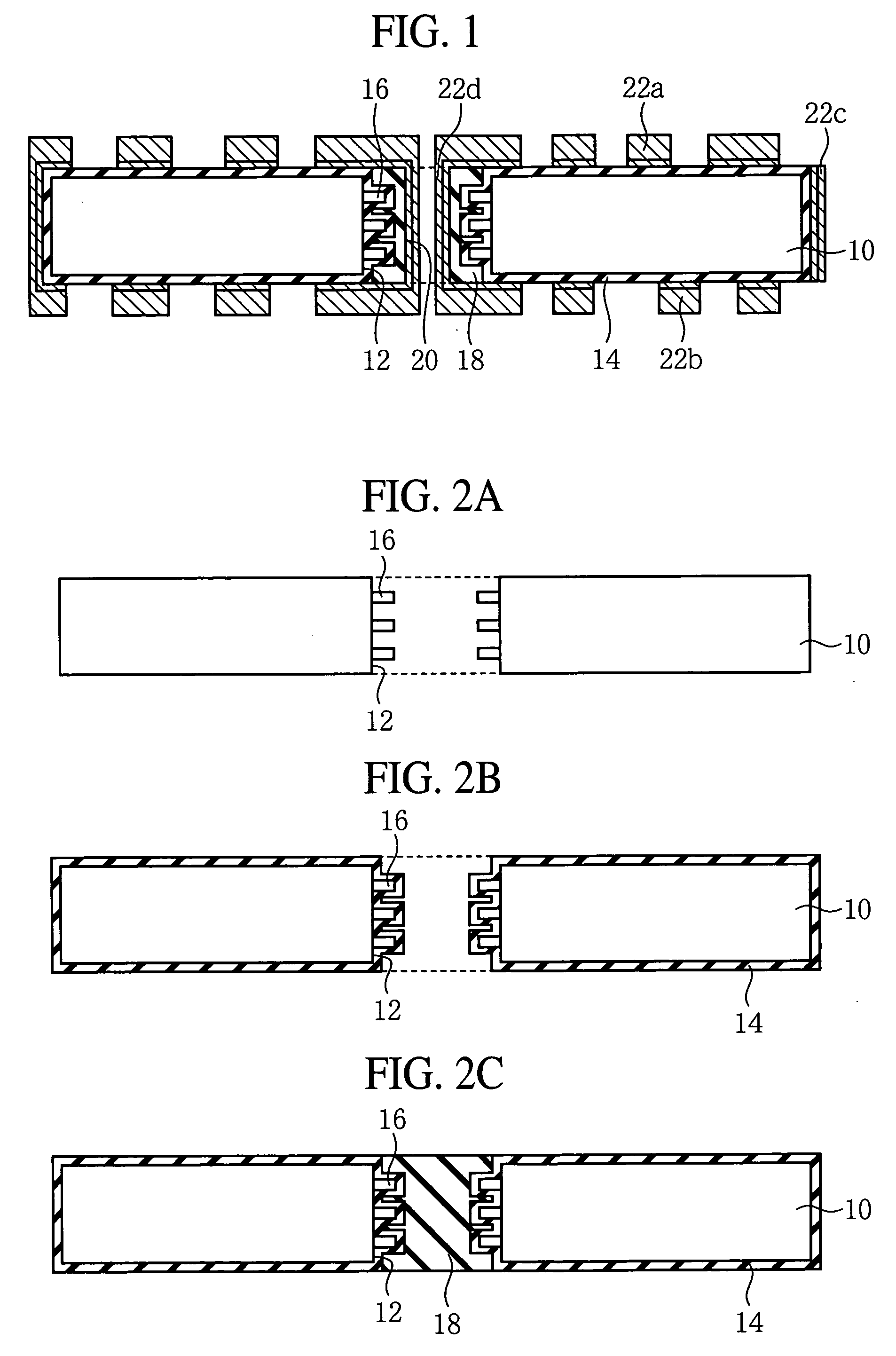

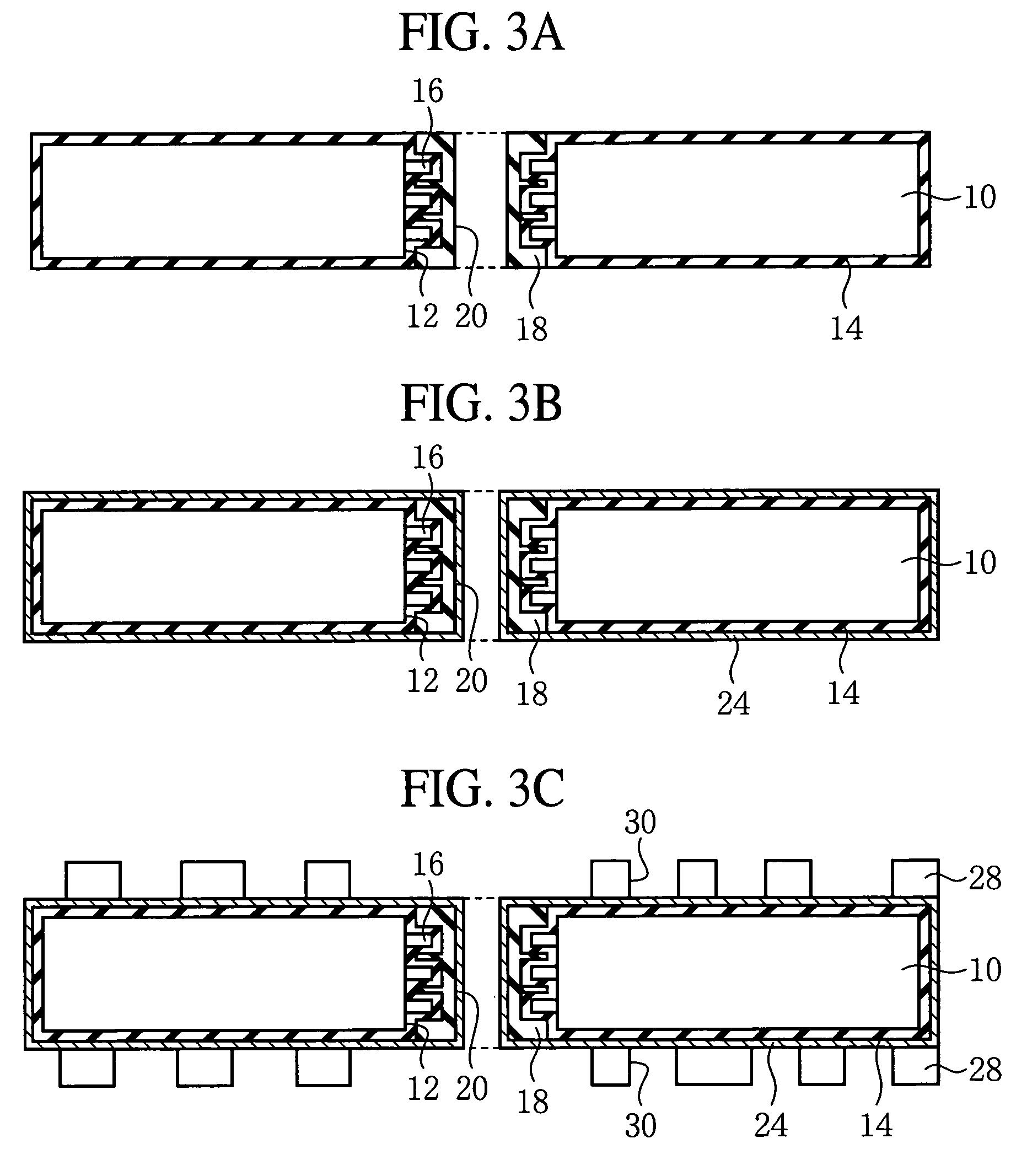

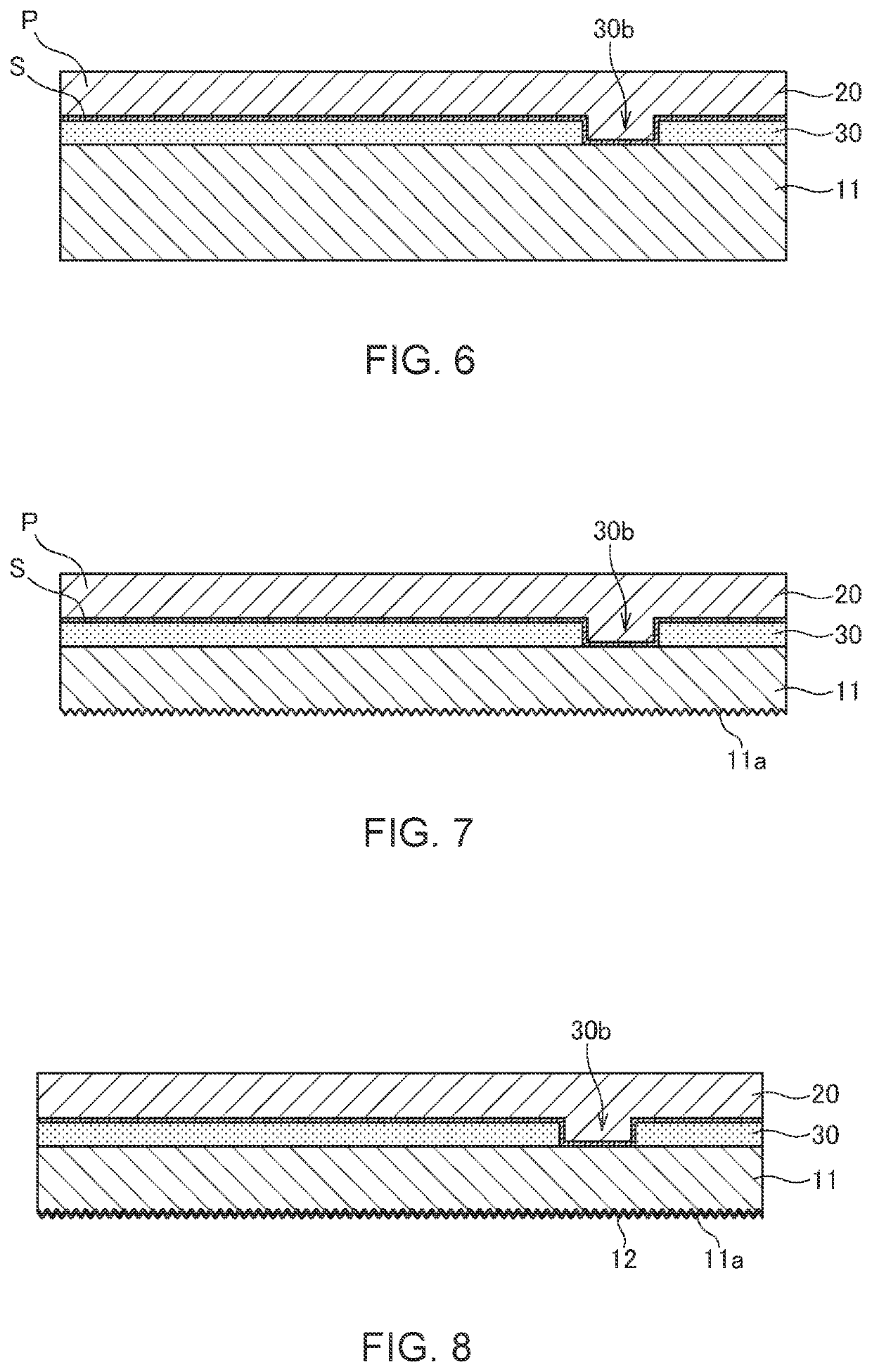

Wiring board and method for fabricating the same

ActiveUS20060175084A1High reliabilityHigh adhesionLine/current collector detailsPrinted circuit aspectsElectrical and Electronics engineeringInsulation layer

The wiring board comprises a plate-shaped conductive core material 10 with a through-hole 12 formed in, an insulation layer 14 formed on the surface of the conductive core material 10 and on the inside wall of the through-hole 12, a resin 18 buried in the through-hole 12 with the insulation layer 14 formed in, wirings 22a, 22b formed on the upper surface and the undersurface of the conductive core material 10 with the insulation layer 14 formed on, and an wiring 22d formed in the through-hole 20 formed in the resin 18 and electrically connected to the wirings 22a, 22b.

Owner:FUJITSU LTD

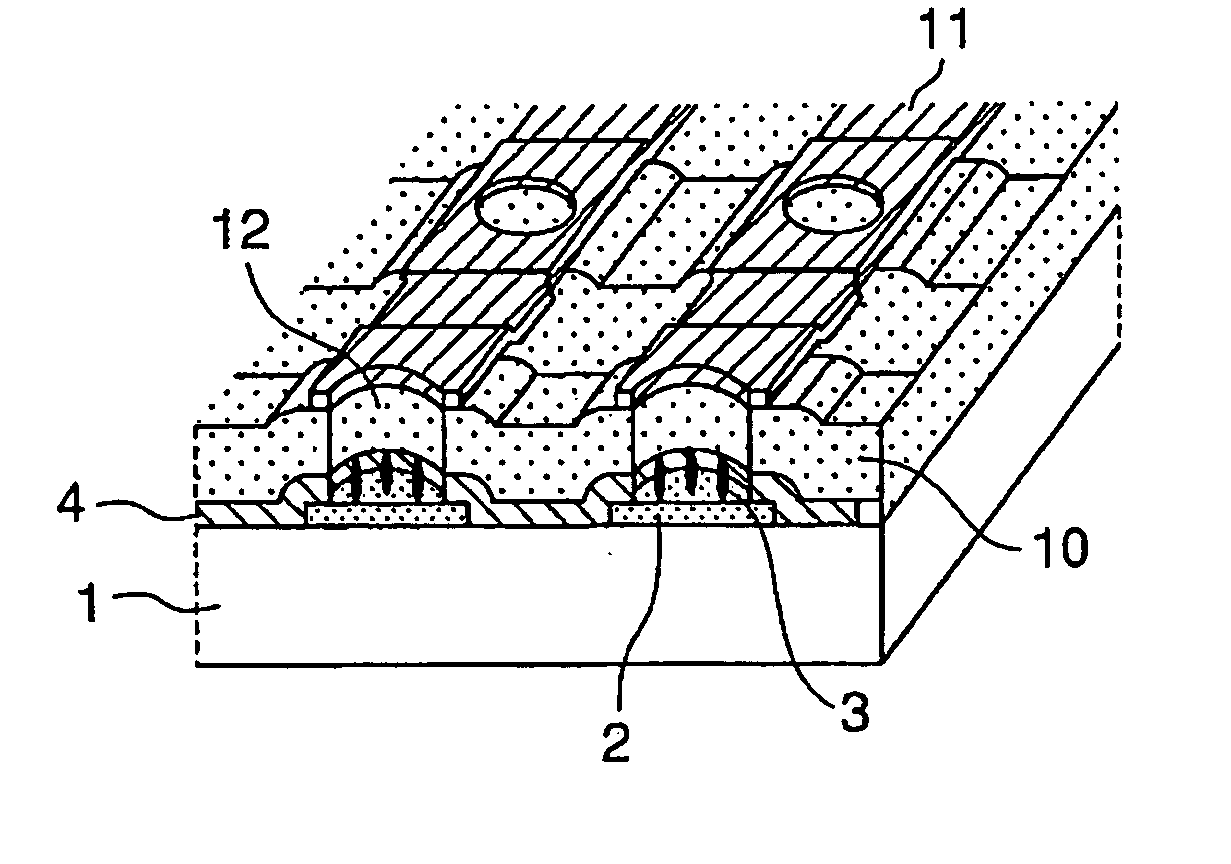

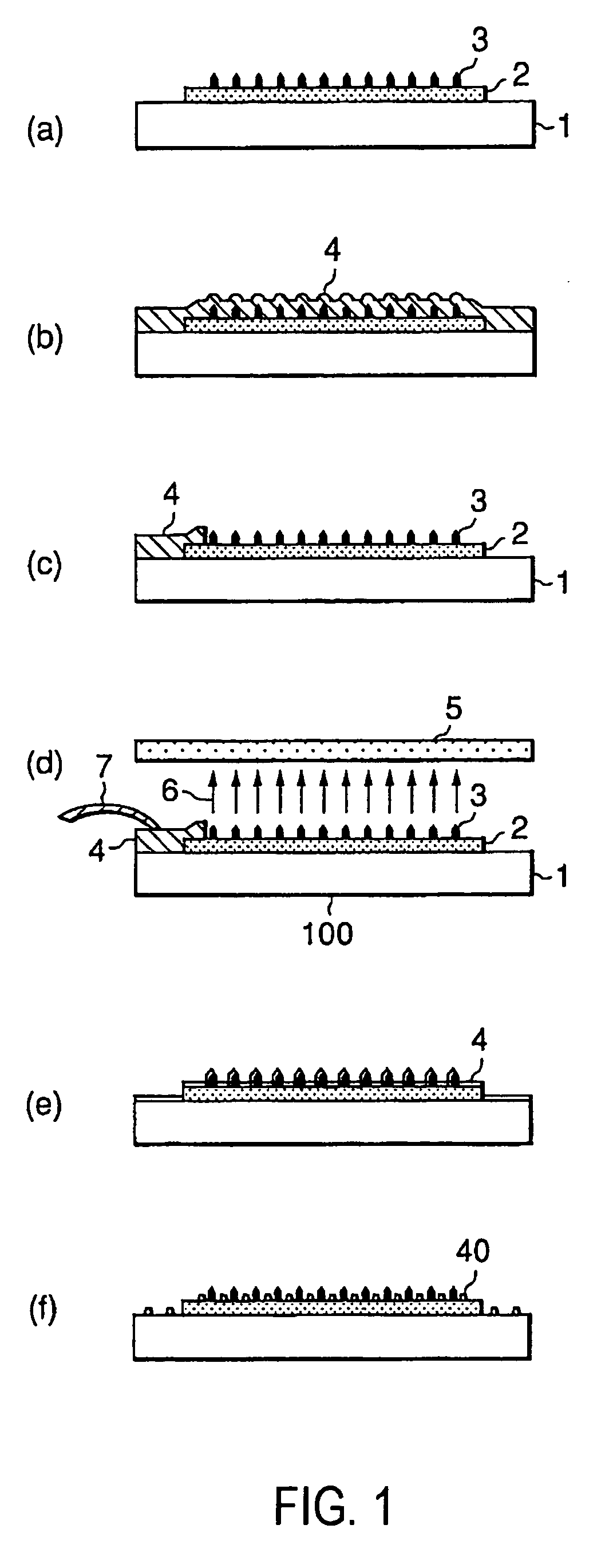

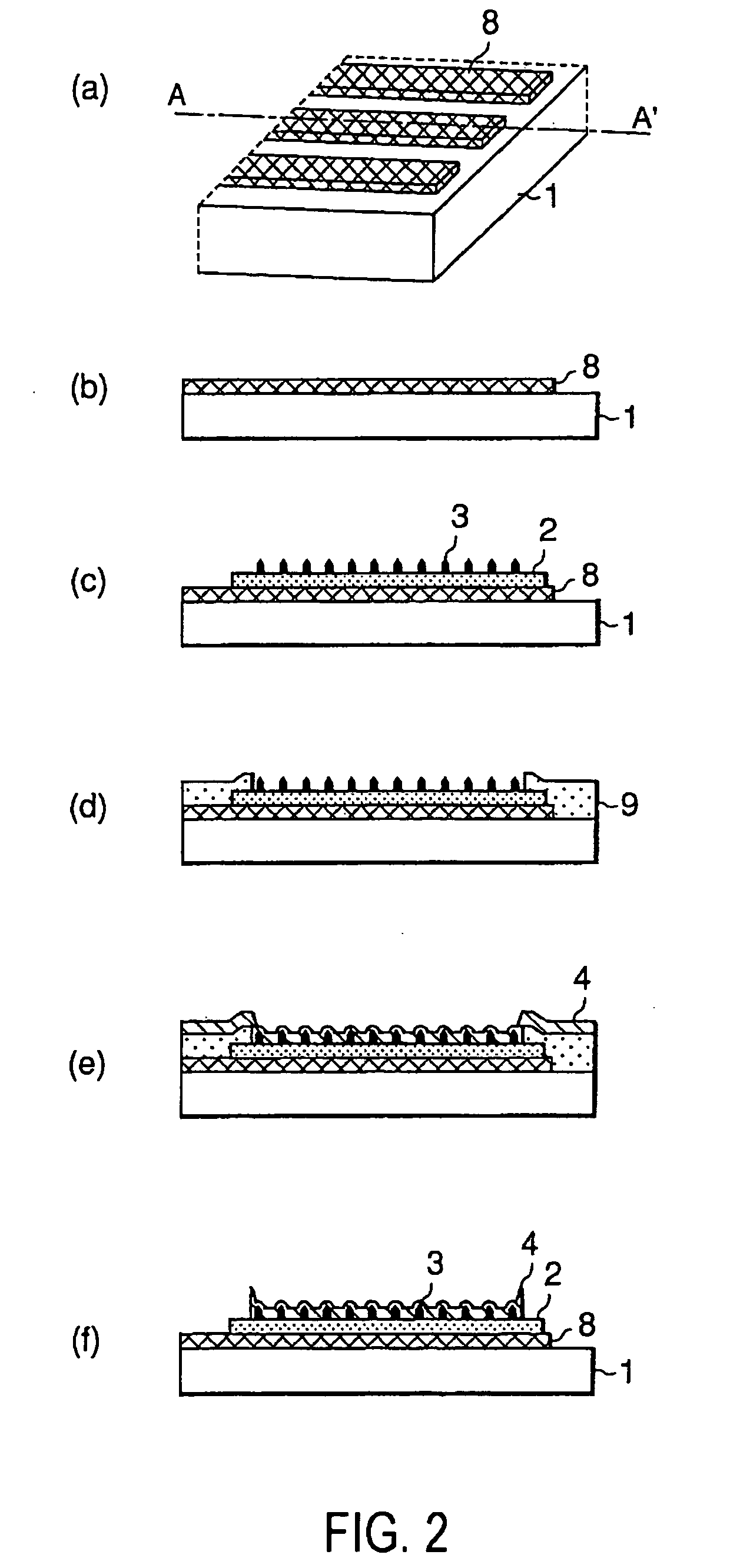

Field electron emission apparatus and method for manufacturing the same

InactiveUS20040036401A1High adhesionHigh resolutionNanoinformaticsThermionic cathodesAluminiumLower threshold

To provide a method for manufacturing a high-performance field electron emission apparatus, wherein occurrence of damage to a CNT during a manufacturing step is prevented, and thereby, the CNT can adequately keep an inherent electron emission characteristic of exhibiting a large current density with a low threshold value. This method for manufacturing a field electron emission apparatus is related to the manufacture of a field electron emission apparatus using the CNT as an electron source. In the method, a protective film formation step is performed in order to form an aluminum film 4 as the protective film on the surface of the CNT film 2 during a manufacturing process of at least a part of the apparatus. The CNT surface structure is protected with this conductive protective film (aluminum film 4, 40), while the structure significantly affects the electron emission characteristic. Consequently, the electron emission characteristic inherent in the CNT can be adequately ensured and be exhibited.

Owner:NEC CORP

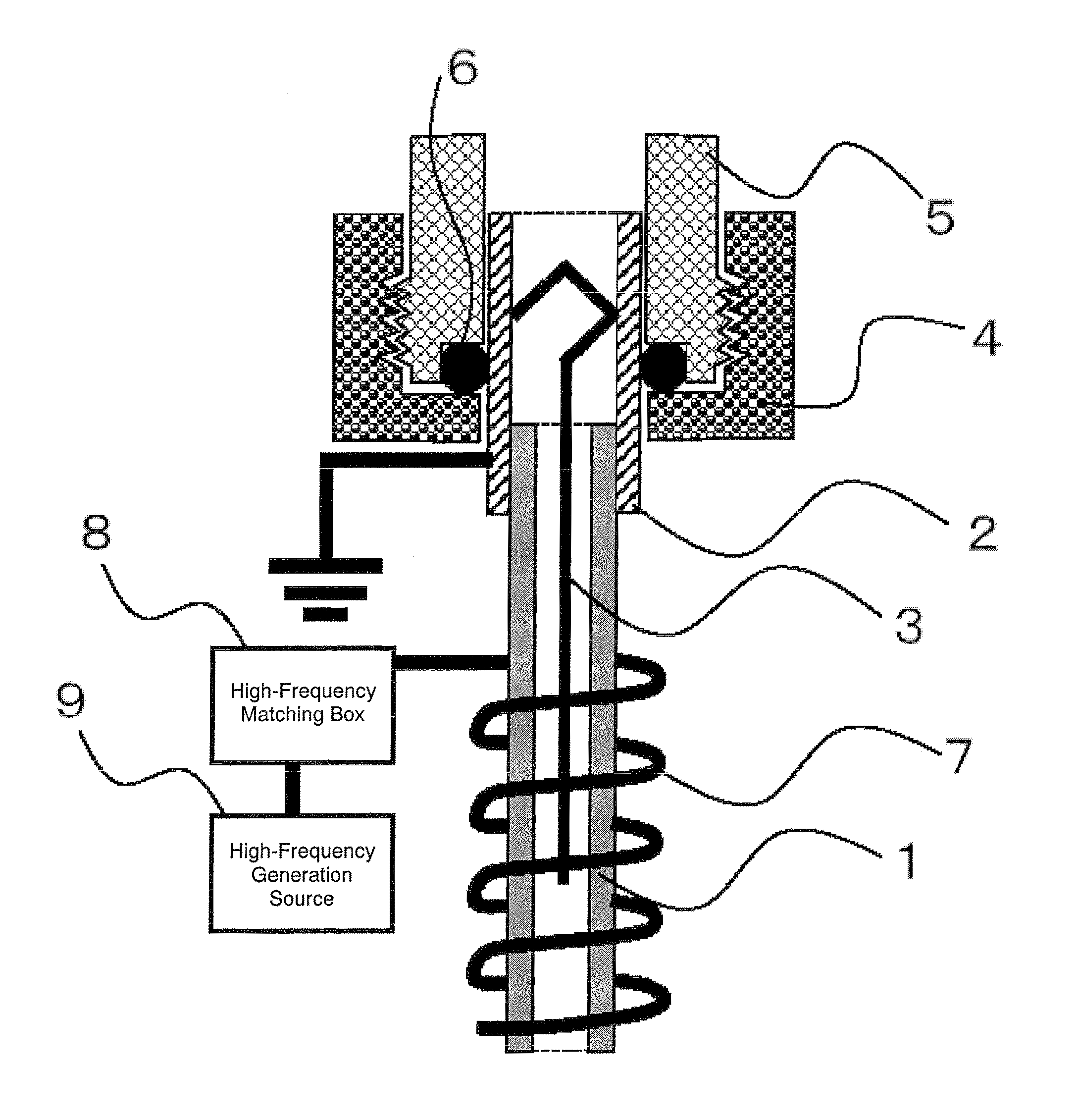

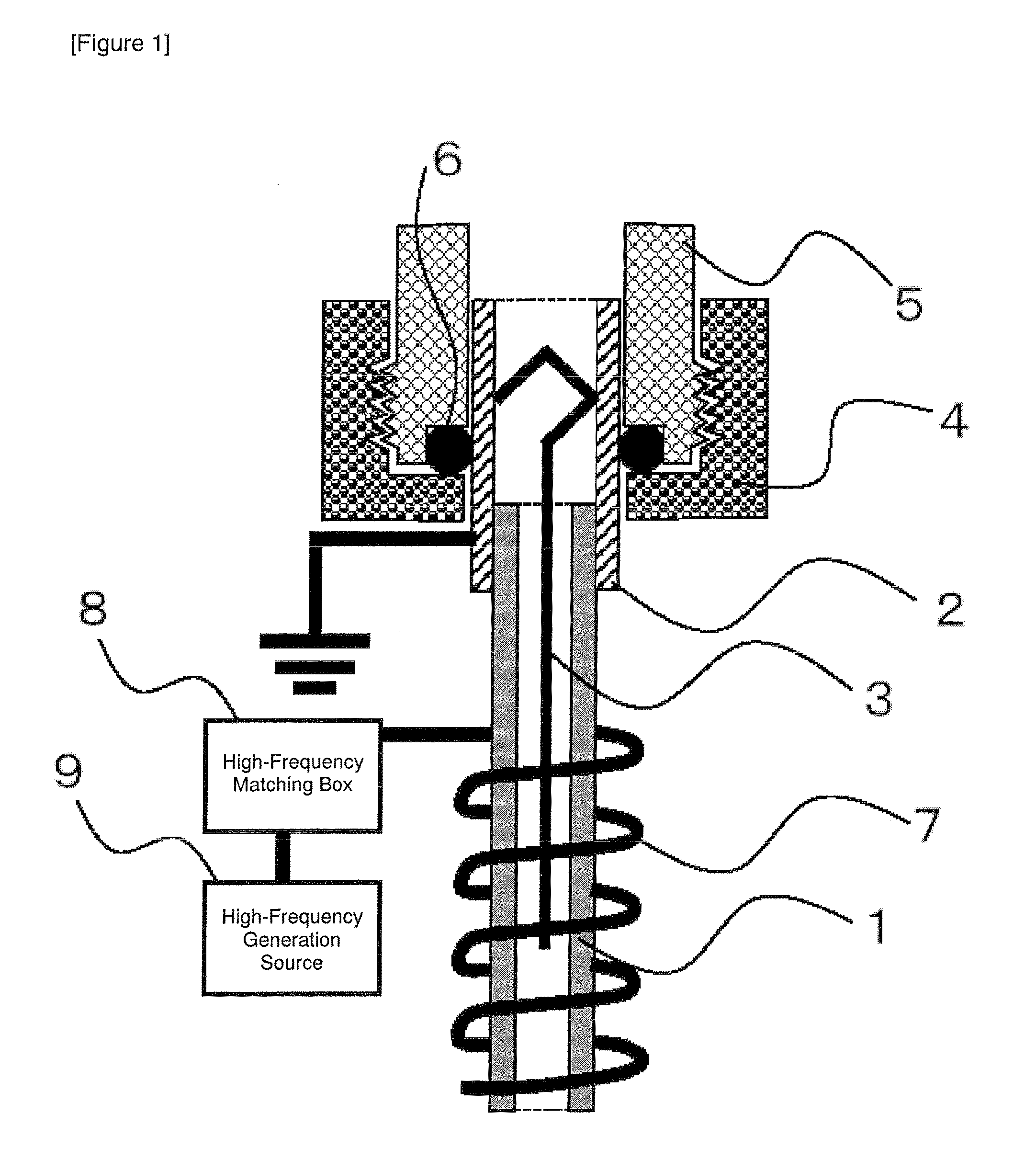

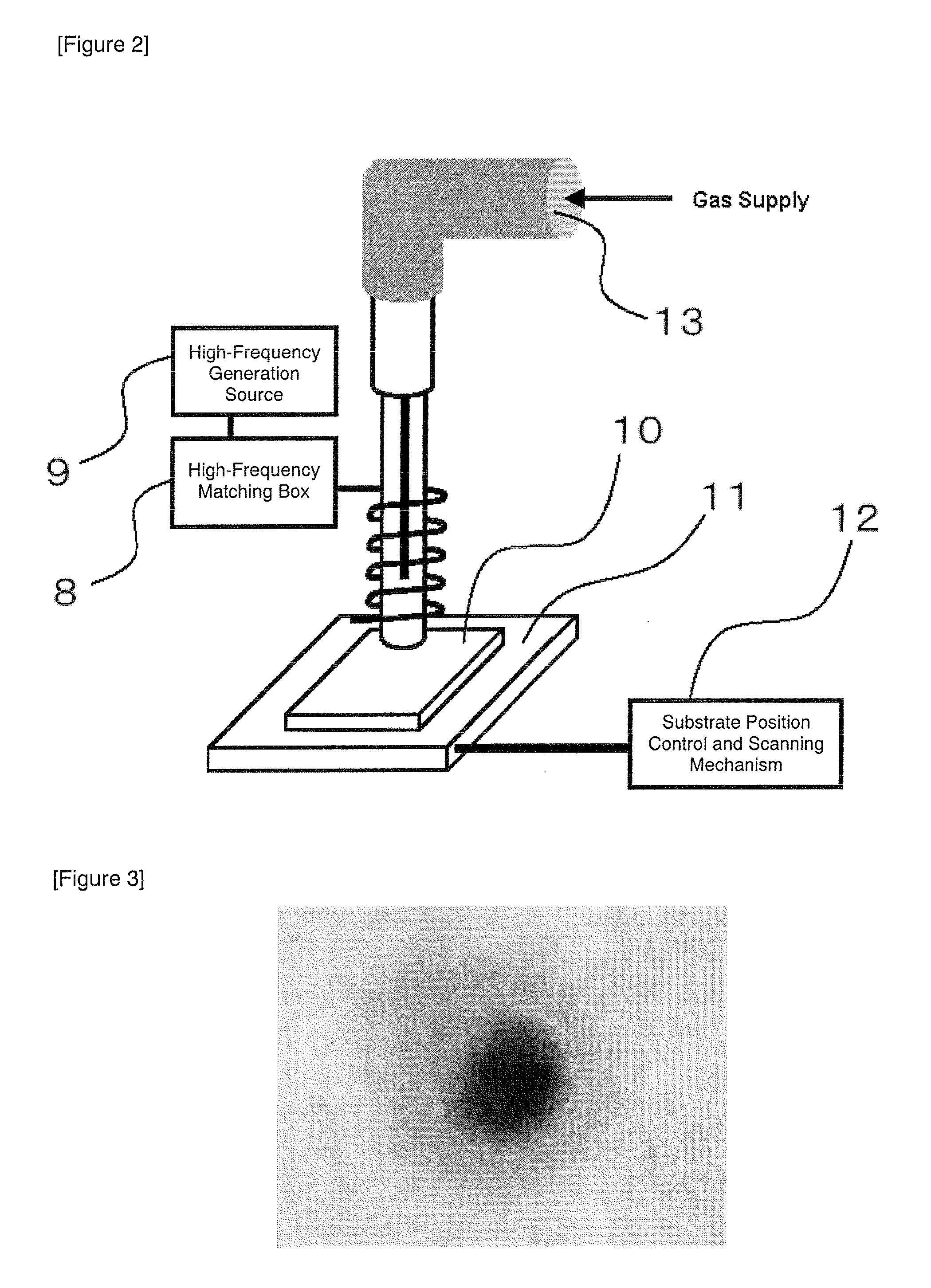

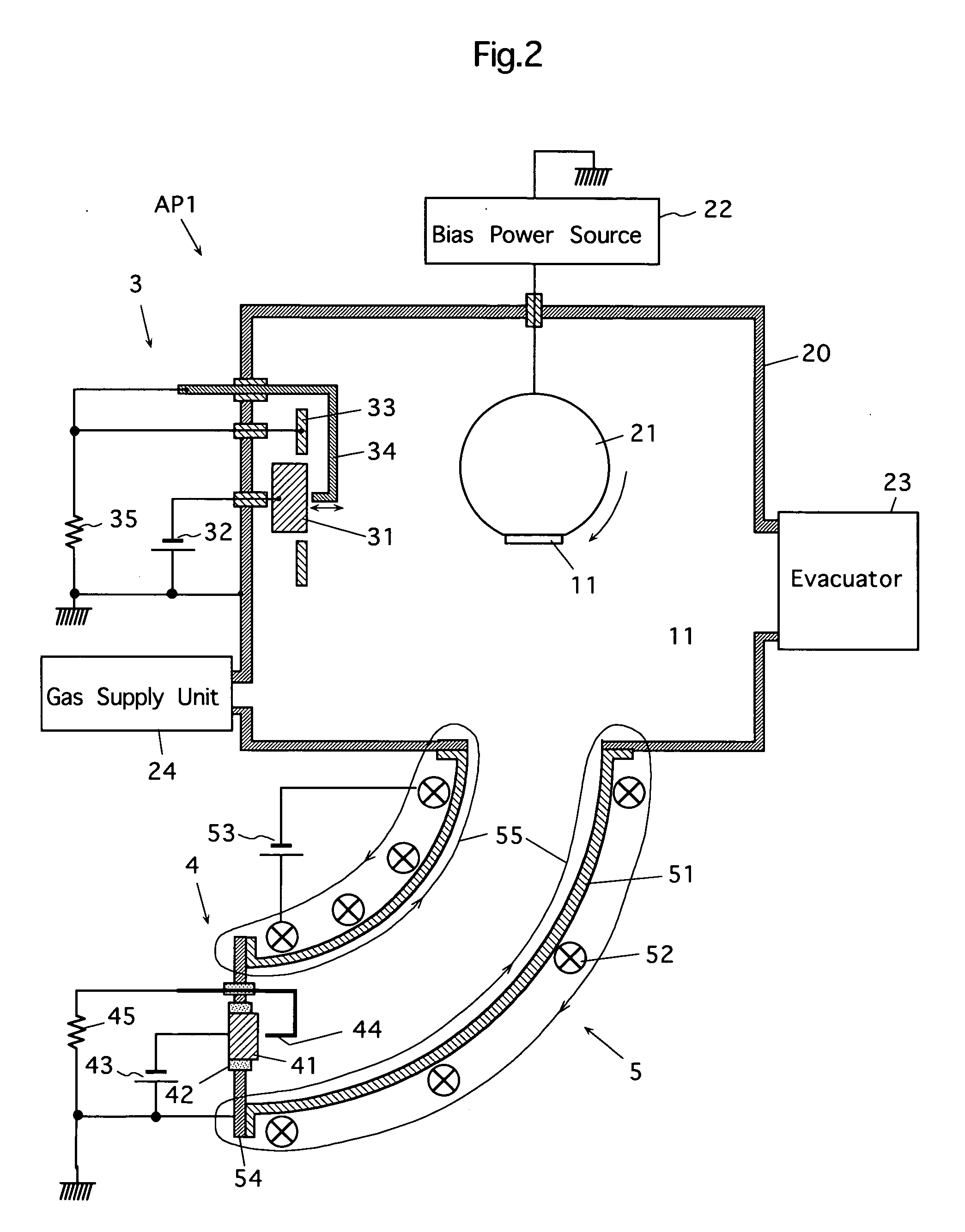

Method of Fabricating Thin Film by Microplasma Processing and Apparatus for Same

InactiveUS20120021132A1High adhesionReduce necessityLiquid surface applicatorsMolten spray coatingIonVoltage

Provided is a method of fabricating, with satisfactory adhesion, a thin film of a metal or a metallic-compound, such as a metal oxide or nitride, on a substrate made of a high-melting-point material such as silicon or ceramics by using a metal or metallic-compound target as the primary raw material so as to eliminate the necessity of using harmful gases such as organometallic gas, and by using an atmospheric-pressure plasma generated under atmospheric pressure as a reaction field and also as a heat source. Additionally provided is an apparatus for fabricating the thin film. The thin-film fabrication method by microplasma processing includes the steps of disposing a raw material for thin-film fabrication in one or more tubes (A) having a uniform inner diameter throughout, introducing an inert gas and applying a high-frequency voltage to the narrow tubes (A) to generate high-frequency plasma in the narrow tubes (A), heating / evaporating the raw material while maintaining the flow rate of the plasma gas in the narrow tubes (A) and maintaining the plasma gas temperature high, ejecting the evaporated material from the narrow tubes (A) to spray it onto the substrate, heating the substrate with the plasma, and depositing the sprayed material on the substrate under atmospheric pressure.

Owner:NAT INST OF ADVANCED IND SCI & TECH

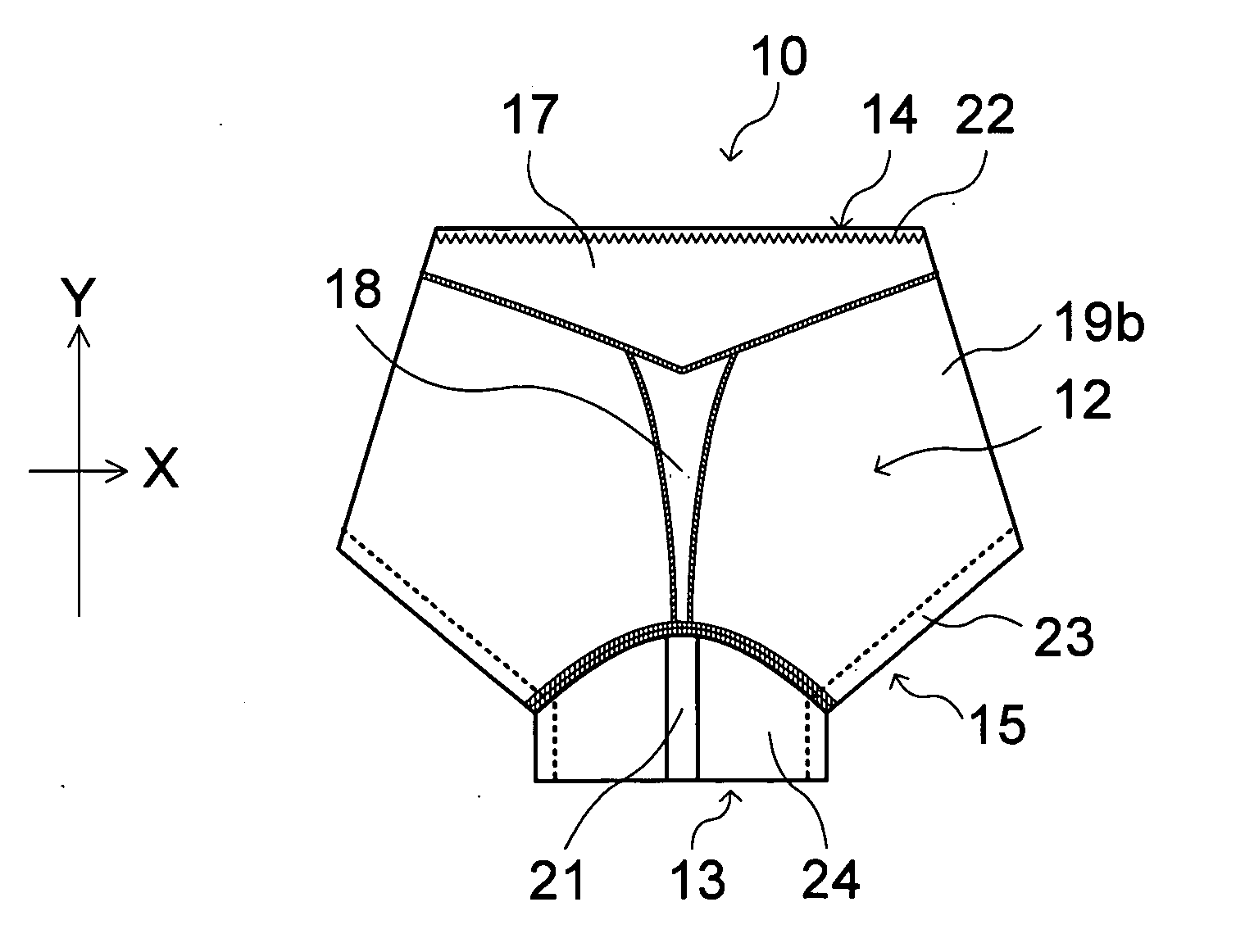

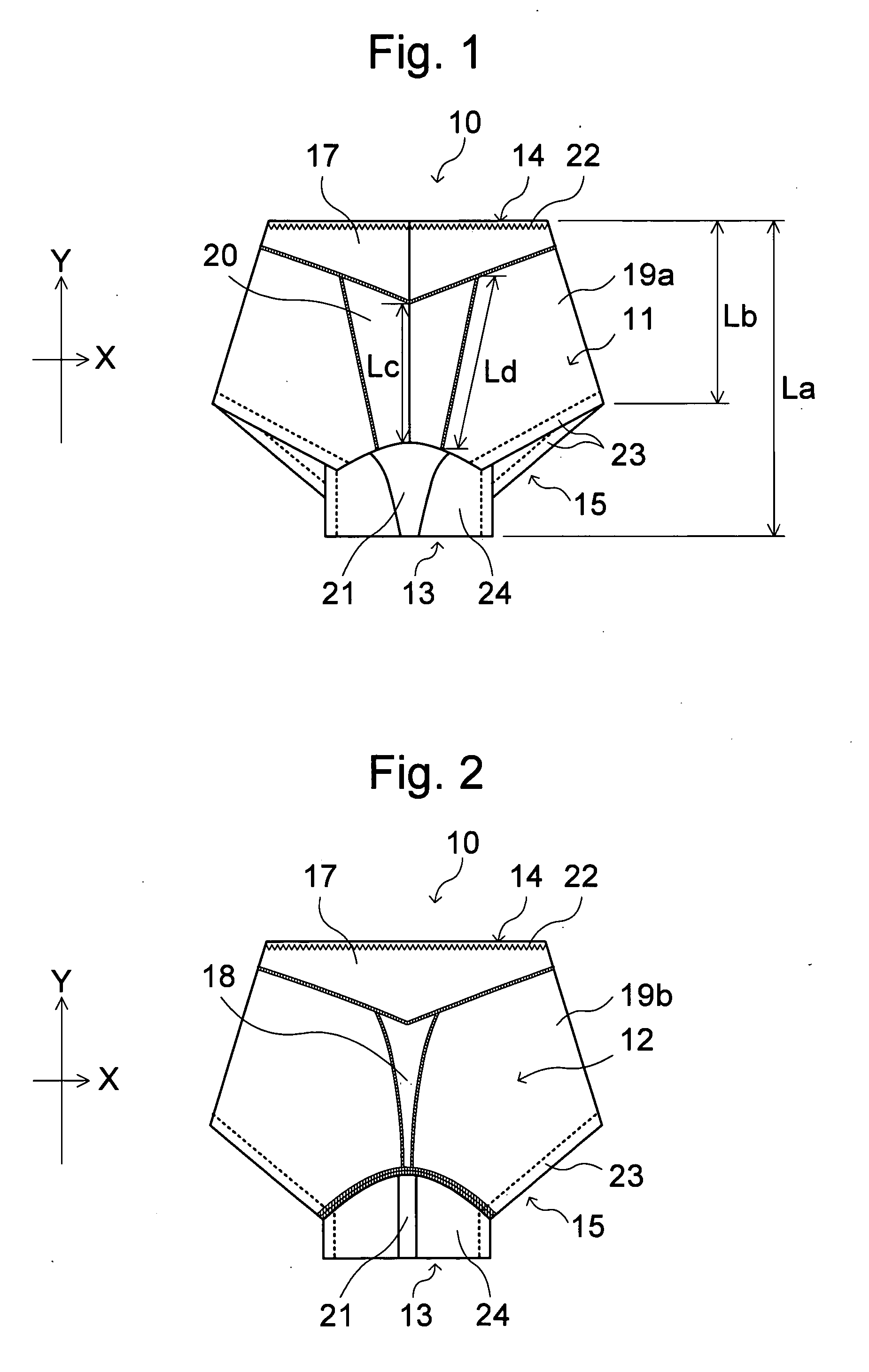

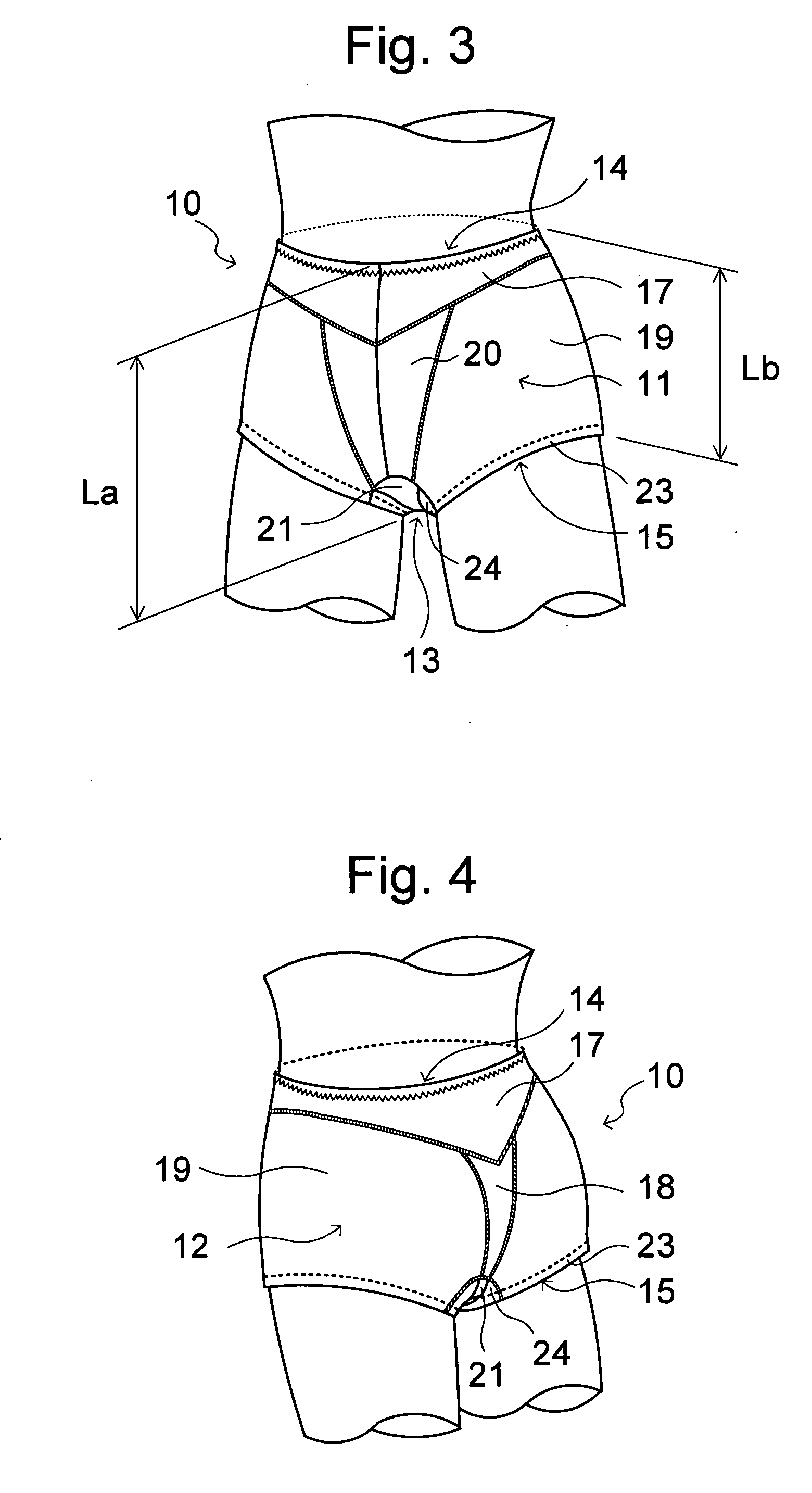

Panty

The invention provides a panty realizing easy fit of a sanitary napkin for night use to a crotch portion, preventing the napkin from shifting out of position, alleviating digging into the crotch portion, and thus being comfortable to wear without giving feeling of constriction to the wearer. The panty includes a front part, a back part, a crotch part provided so as to bridge between the front part and the back part, a slightly elastic member is provided at the substantially center area of the back part, a highly elastic member is provided from a back parts lifting member to the entire area of the front part except for the waist hold part, a fixing member is provided on the substantially center area of the front part, a crotch lifting member is provided at the substantially center area of the crotch part.

Owner:UNI CHARM CORP

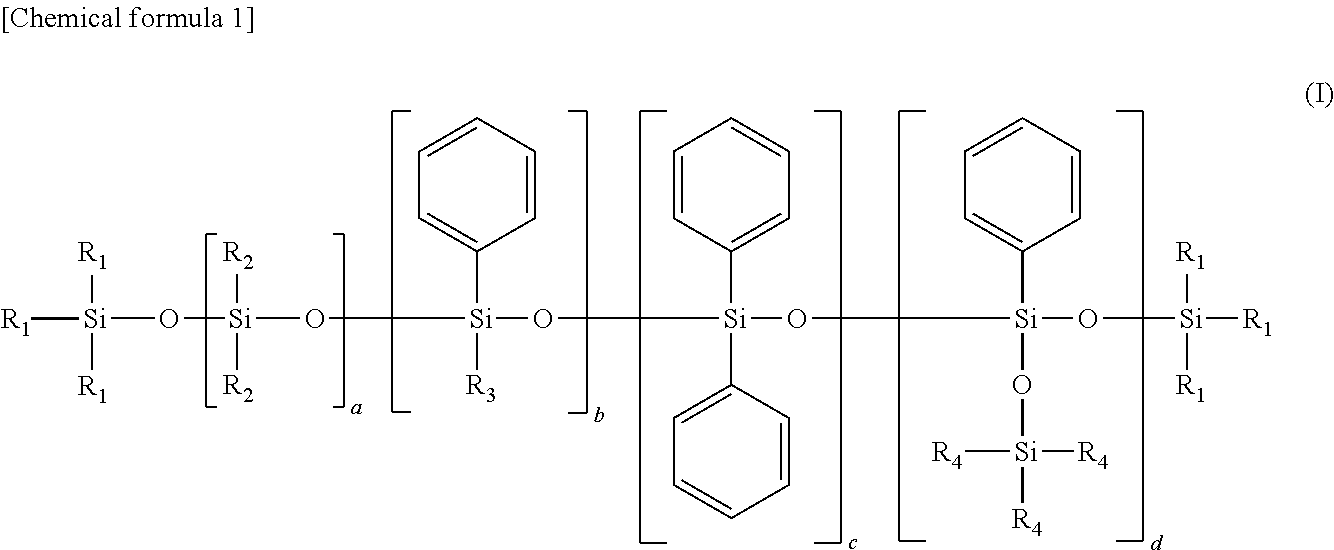

Silicone Composition, Silicone Adhesive, Coated and Laminated Substrates

InactiveUS20120052309A1High adhesionLow flammabilitySynthetic resin layered productsGlass/slag layered productsSilicone resinSilorane Resins

A filled silicone composition comprising a curable silicone composition comprising at least one silicone resin, and a low-melting inorganic glass filler having a glass transition temperature not greater than 700° C. and a softening point not greater than 800° C.; a silicone adhesive comprising a cured product of at least one silicone resin, and a low-melting inorganic glass filler; and a coated substrate and a laminated substrate, each comprising the silicone adhesive.

Owner:DOW CORNING CORP

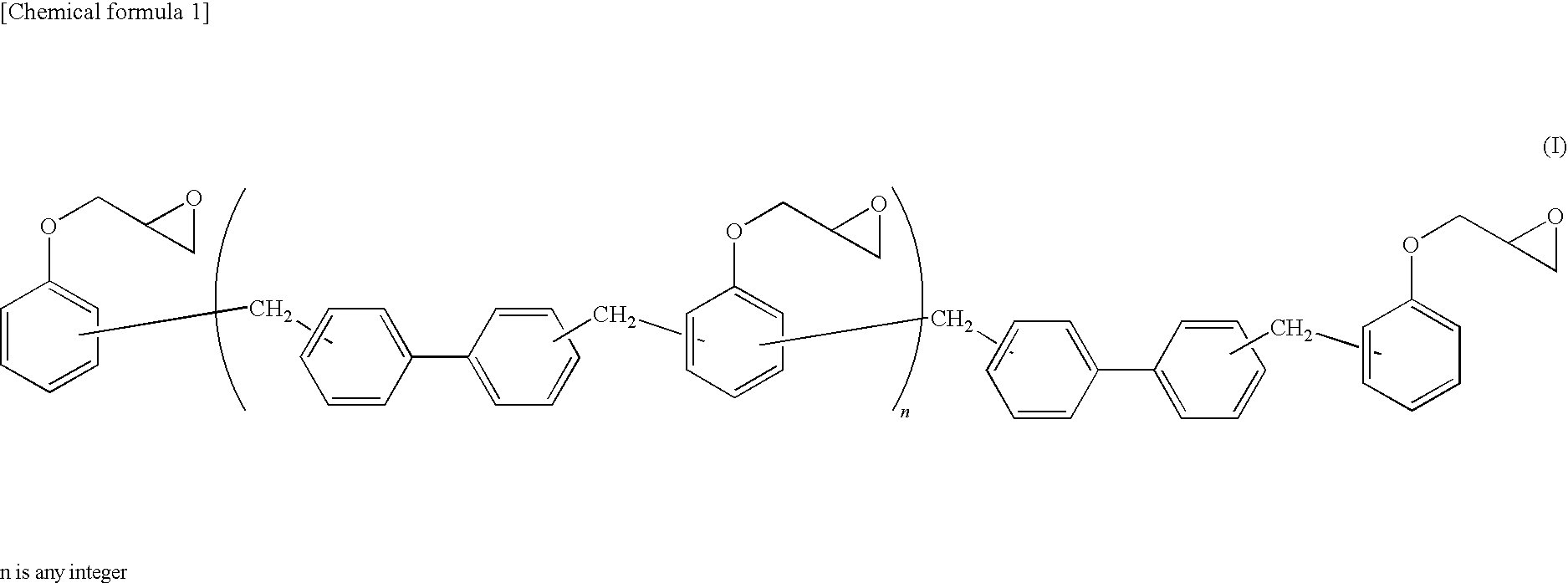

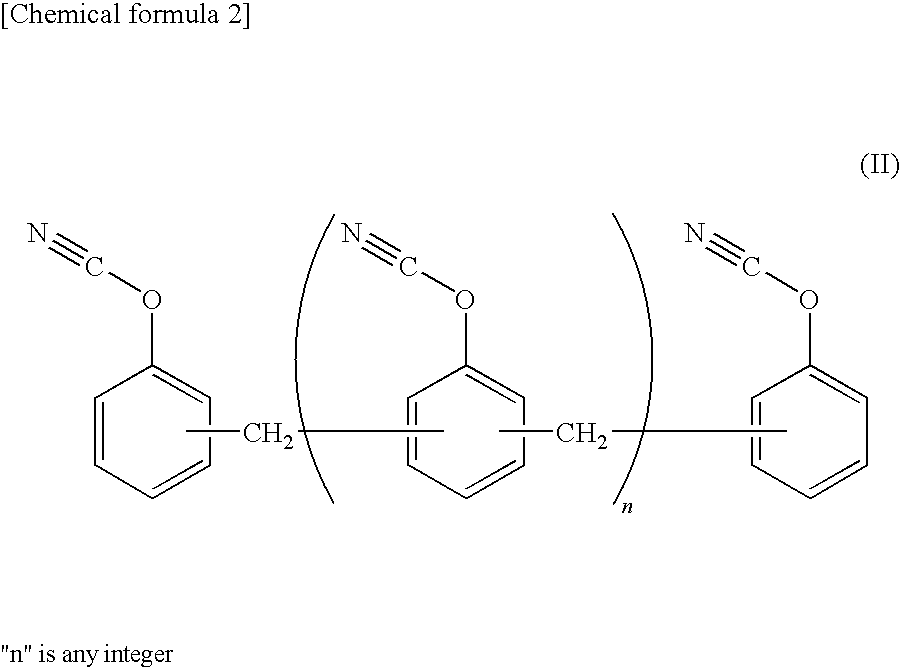

Resin composition, insulating sheet with base, prepreg, multilayer printed wiring board and semiconductor device

InactiveUS20100065315A1High adhesionHigh heat resistancePrinted circuit detailsSemiconductor/solid-state device detailsThermal shockEngineering

The present invention provides a resin composition which can produce a multilayer printed wiring board not causing peeling and crack in a thermal shock test such as a cooling / heating cycle, and having high heat resistance and low-thermal expansion characteristics, when the resin composition is used for an insulating layer of the multilayer printed wiring board; and also an insulating sheet provided on a base, a prepreg, a multilayer printed wiring board and a semiconductor device using thereof. The resin composition is used for forming an insulating layer of the multilayer printed wiring board, wherein a surface roughness parameter Rvk value of the insulating layer is from 0.1 μm to 0.8 μm, measured after the insulating layer being formed with the resin composition, and subject to roughening treatment.

Owner:SUMITOMO BAKELITE CO LTD

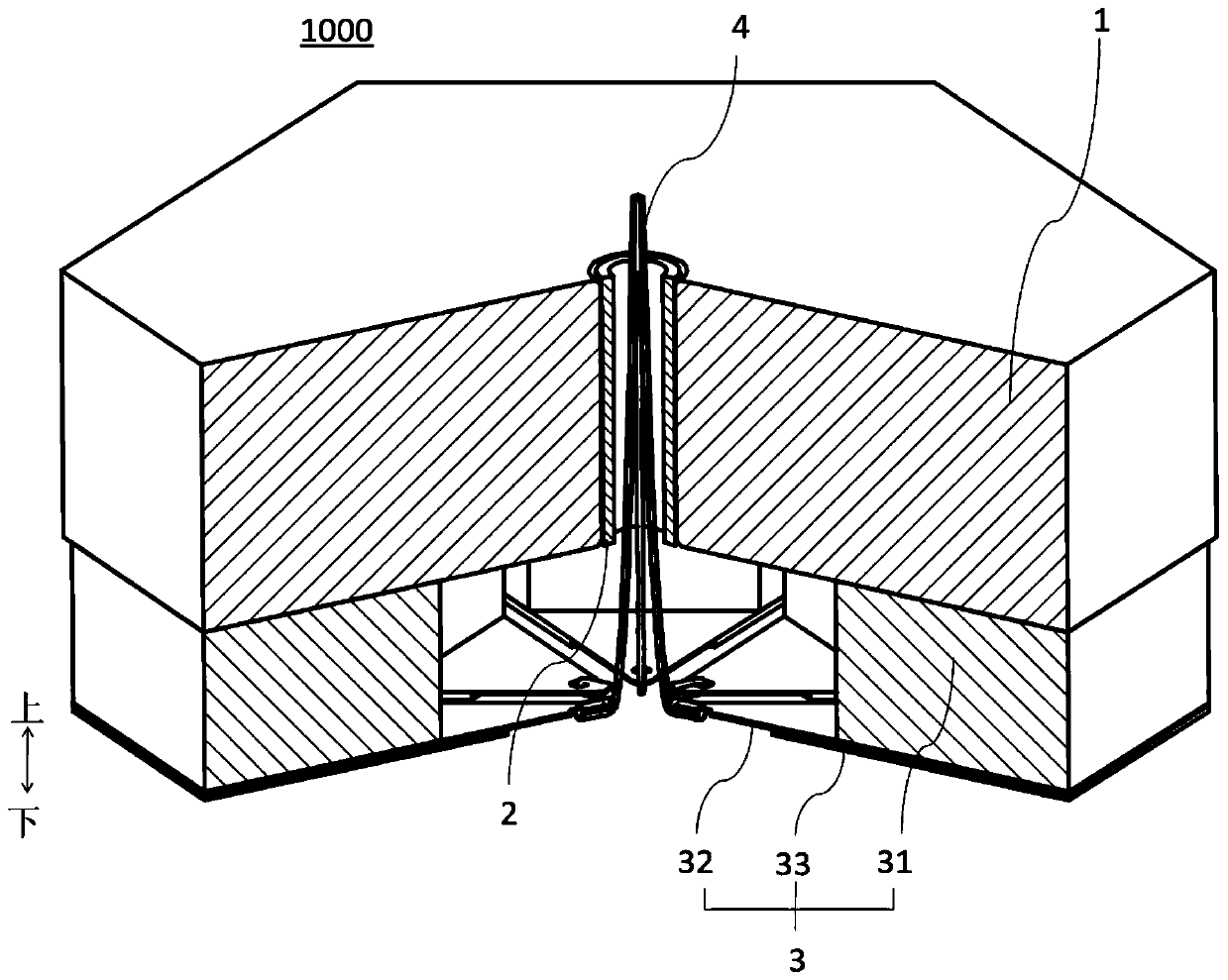

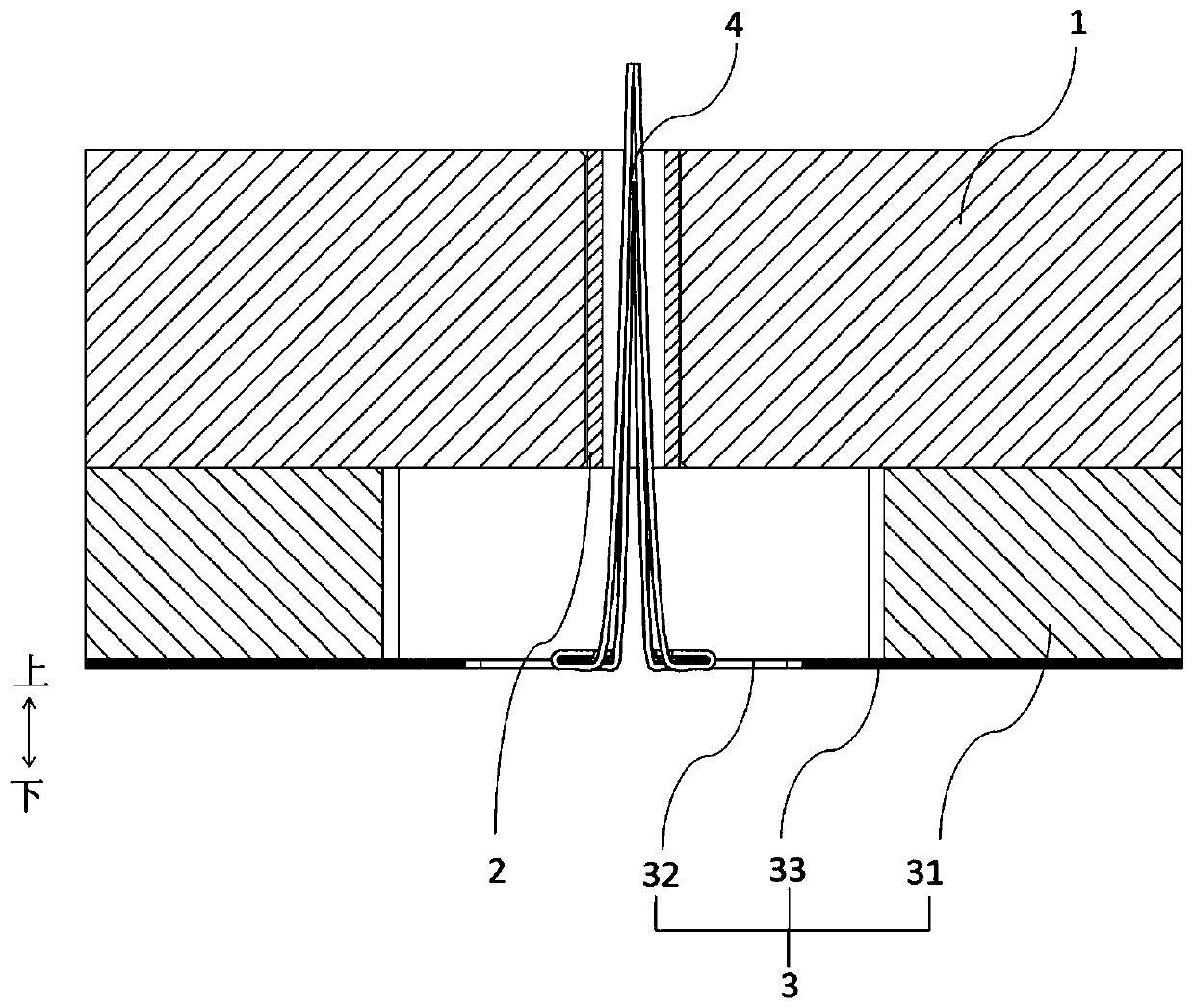

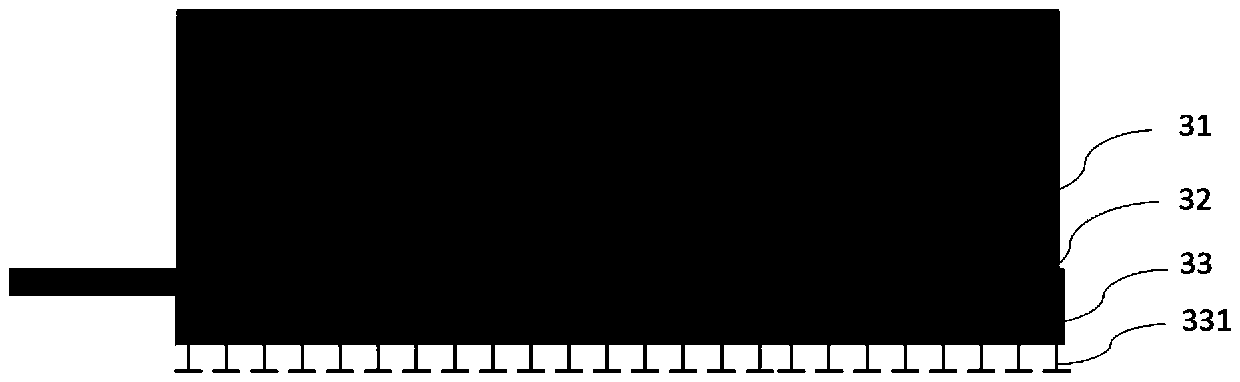

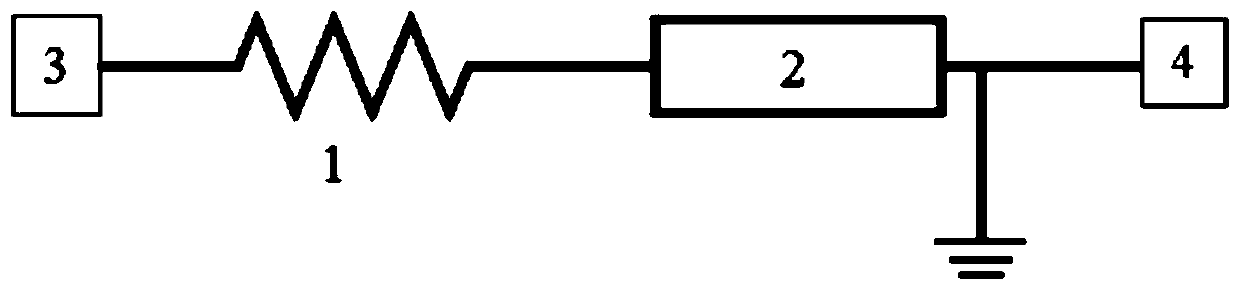

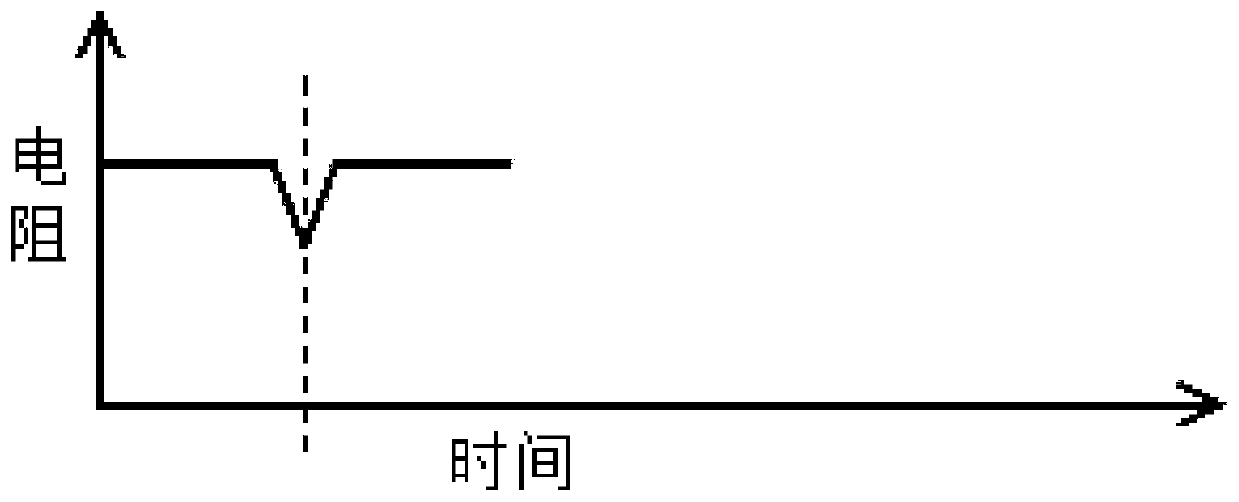

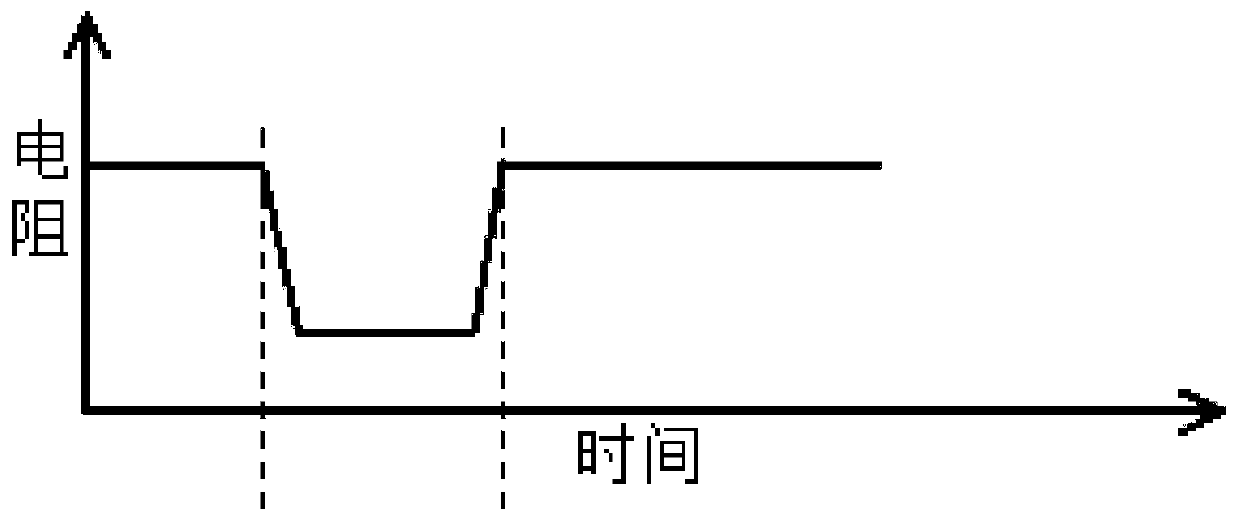

An adhesion and desorption control device

ActiveCN110524563ALow costSimple structureProgramme-controlled manipulatorGripping headsDesorptionEngineering

The invention discloses an adhesion and desorption control device which comprises a base, an actuator and a movement mechanism, wherein the actuator is mounted on the base; the movement mechanism comprises a bearing unit, a stripping unit and an adhesion unit; the bearing unit is compressible but tensile, and the upper surface of the bearing unit is fixed to the lower surface of the base; the stripping unit is a thin plate with high elasticity modulus and is provided with a first side and a second side which are opposite to each other; the upper surface of the stripping unit is fixed to the lower surface of the bearing unit; the actuator is fixed to the first side of the stripping unit; the adhesion unit is arranged on the lower surface of the stripping unit; the stripping unit is bent andelastically deformed from the first side to the second side under the action of the actuator, so that the adhesion unit synchronously moves to realize desorption release; and the stripping unit is ina plane state after elastic deformation is recovered so as to realize adhesion grabbing. The control device can achieve rapid, reliable and stable high-strength adhesion and desorption control, and is low in cost, simple in structure, convenient to operate and good in repeatability.

Owner:TSINGHUA UNIV

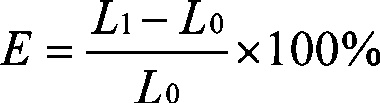

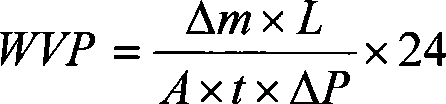

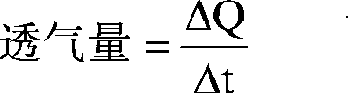

Degradable non-poisonous seed-coating agent and preparation method thereof

InactiveCN101416650AHigh adhesionSeed coat capacity is goodBiocideAnimal repellantsChemistryApparent viscosity

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Marking Ink for Covered Electrical Conductor

InactiveUS20090182080A1High adhesionExcellent productivityInksConductor/cable markingMarking InkPolyolefin

The present invention provides a marking ink for a covered electrical conductor utilized for a wire harness of a motor vehicle. The marking ink is printed on the covered conductor formed with polyolefin such as polyethylene and provides a high adherence (coloring), high wear resistance, high productivity, fast drying, and moderate spreading. The marking ink for the covered electrical conductor contains an acrylate resin with molecular weight of 10,500-93,000.

Owner:YAZAKI CORP

Acidic treatment liquid and method of treating copper surfaces

InactiveUS7153449B2High adhesionEasily carry outInsulating substrate metal adhesion improvementHeat-exchange elementsPhenyl groupMicrostructure

The present invention relates to a solution and to a method of treating copper surfaces, the copper surfaces being brought into contact with an acidic treatment liquid which contains hydrogen peroxide and at least one five-membered heterocyclic compound as well as additionally at least one microstructure modifying agent selected from the group comprising thioles A, disulfides B, sulfides C and thioamides D having the following respective general formulae:wherein R1 and R2=alkyl, alkenyl, aryl, aralkyl, especially benzyl, cycloalkyl and the derivatives thereof and R3=R1, R1—O, R1—S, amino or substituted amino, wherein R1 and R2 may especially be phenyl or substituted phenyl.

Owner:ATOTECH DEUT GMBH

Preparation method and application of high-strength superhydrophobic composite material taking block-like organosilicone/epoxy hybrid resin as matrix

The invention provides a preparation method of a superhydrophobic composite material taking two chemically-bonded silanized epoxy resin and block-like organosilicone / epoxy hybrid resin as a matrix. The silanized epoxy resin is prepared by utilizing a reaction of trimethoxysilane and high-purity allyl epoxy resin, the block-like organosilicone / epoxy hybrid resin is prepared by utilizing a reactionof double-hydrogen-terminated organosilicone and the high-purity allyl epoxy resin; and the two organosilicone / epoxy resin hybrid systems and micro-nano particles are blended and compounded to form asuspension, then an epoxy resin curing agent is added for matching, and the generated suspension can be sprayed, brushed or dip-coated on the surfaces of various base materials to obtain a superhydrophobic surface with high adhesive force and high mechanical strength. The preparation method has the advantages of simplicity, easiness in operation and extremely high process stability, and the formedsuperhydrophobic composite material is firm and reliable, still has the superhydrophobic characteristic after being abraded, and has very high practical values.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Carbon film-coated article and method of producing the same

InactiveUS20050186424A1High adhesionElectric discharge tubesVacuum evaporation coatingCarbon filmTungsten film

This invention is directed to a carbon film-coated article comprising a substrate; a mixed layer formed on at least a part of the substrate, and composed of an element(s) constituting the substrate and tungsten; a tungsten film formed on the mixed layer; and a carbon film formed on the tungsten film. The invention provides a method of producing the carbon film-coated article, the method comprising the steps of: forming a mixed layer on at least a part of the substrate, the mixed layer being composed of an element(s) constituting the substrate and tungsten, forming a tungsten film on the mixed layer, and forming a carbon film on the tungsten film, wherein at least one of the mixing layer, the tungsten film and the carbon film is formed using a cathode material evaporated by arc discharge in a vacuum arc deposition apparatus having a vacuum arc evaporation source including the cathode.

Owner:NISSIN ELECTRIC CO LTD

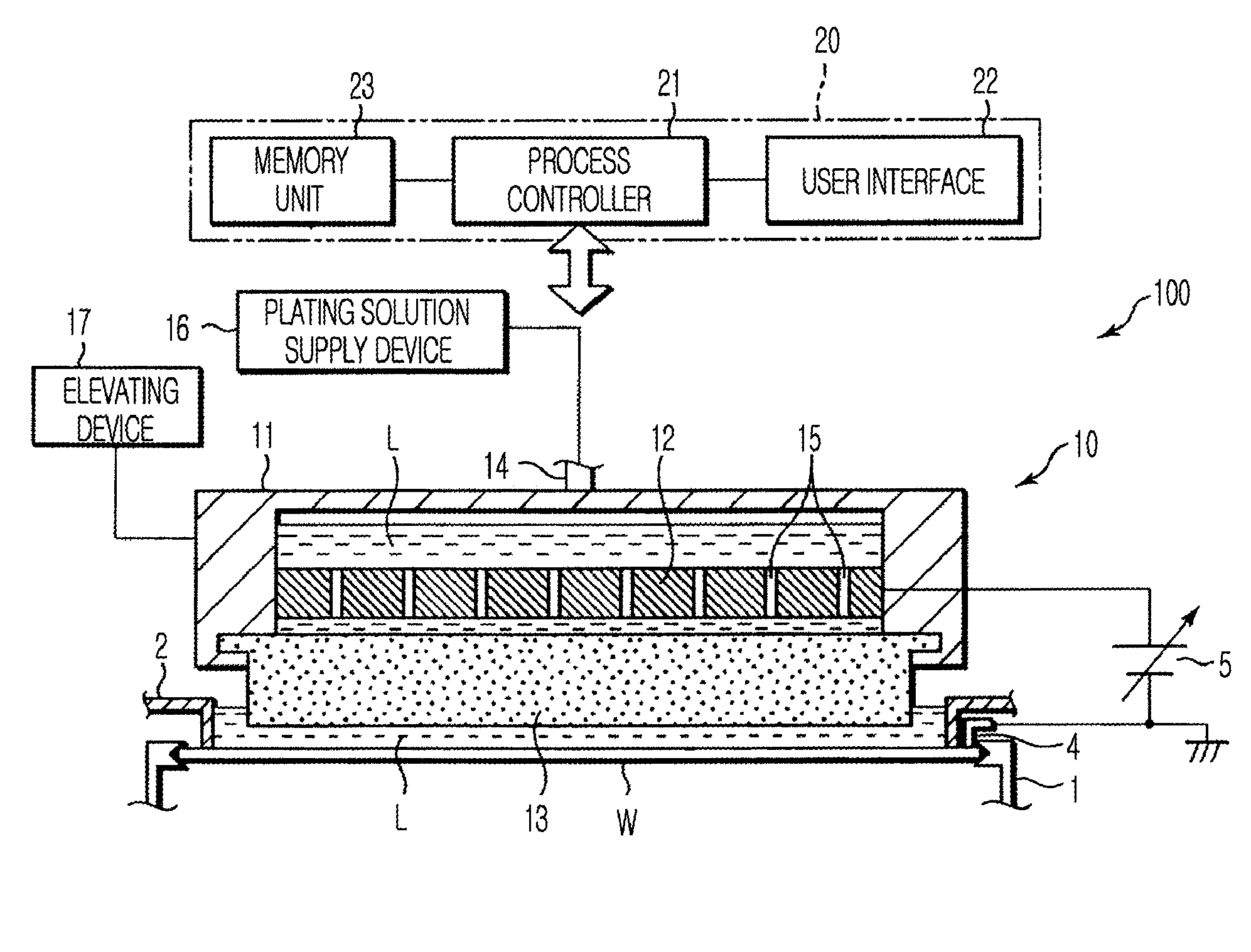

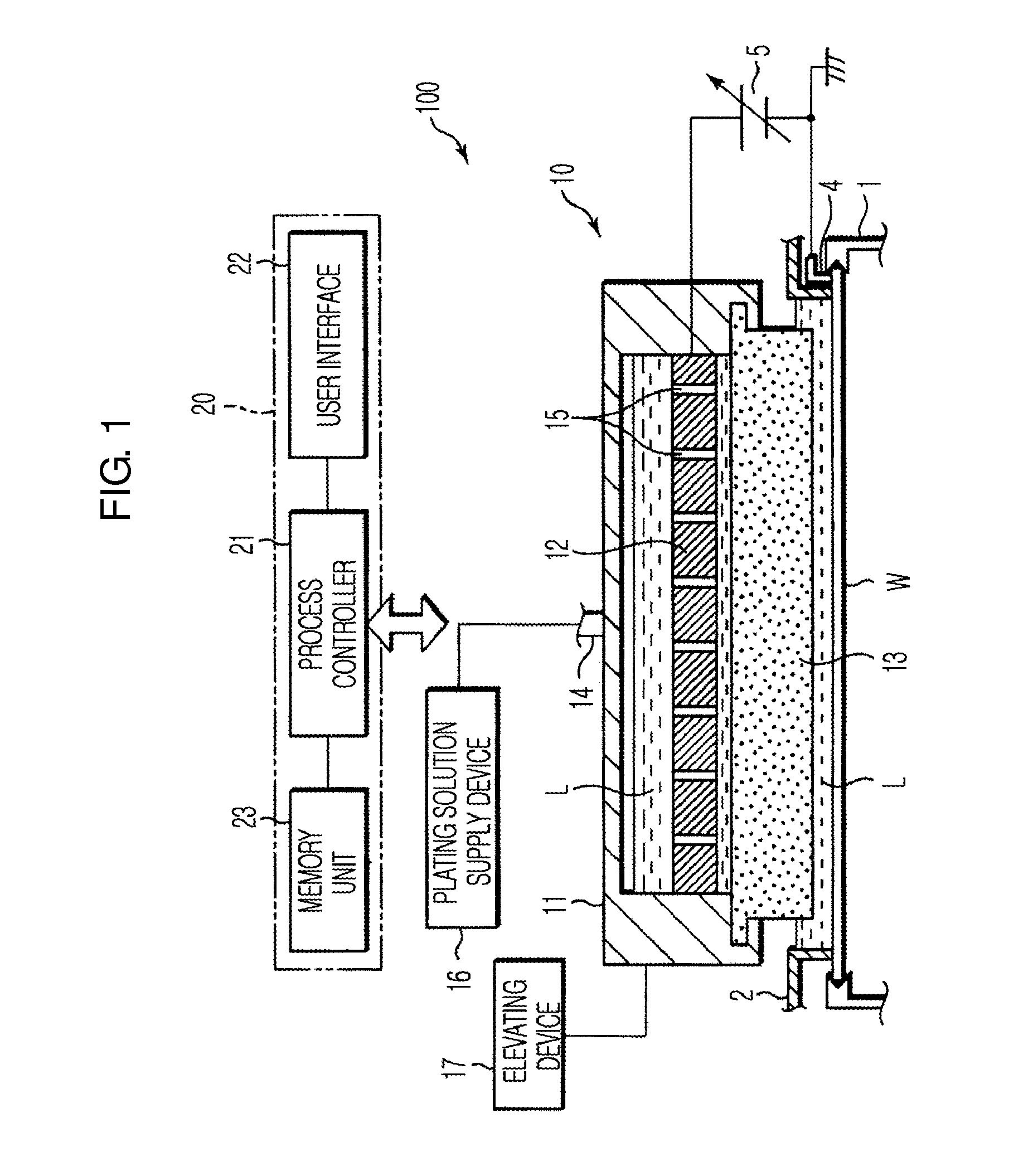

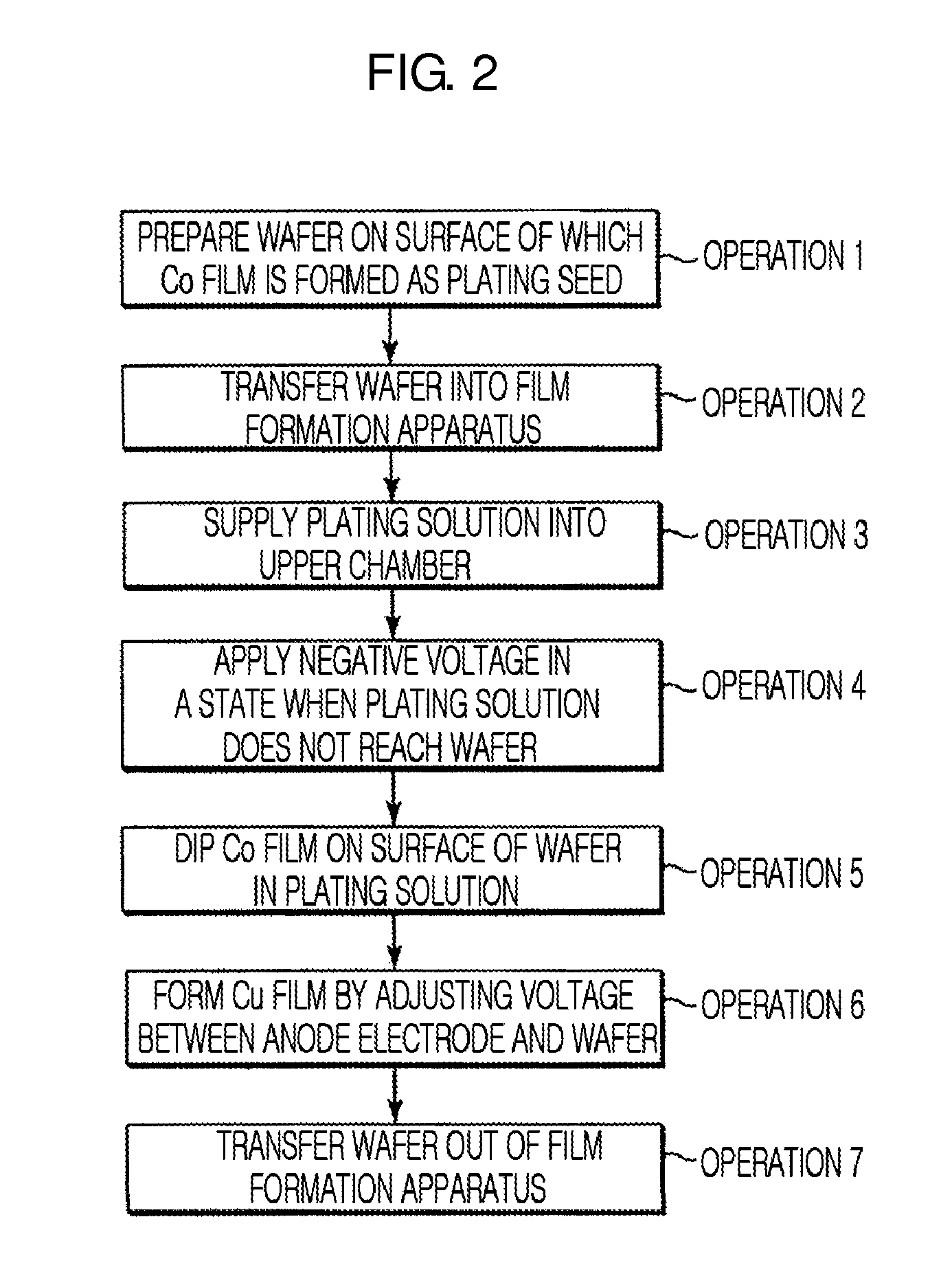

Film formation method and storage medium

InactiveUS20110174630A1High uniformityHigh adhesionCellsSemiconductor/solid-state device manufacturingOptoelectronicsElectroplating

A film formation method includes preparing a substrate formed a Co film as a seed layer on a surface of the substrate, applying a negative voltage to the substrate such that a surface potential of Co is lower than an oxidation potential of the Co, and in a state when the negative voltage is applied to the substrate, dipping the Co film in a plating solution mainly containing copper sulfate solution, thereby a Cu film is formed on the Co film of the substrate by electroplating.

Owner:TOKYO ELECTRON LTD

Pressure sensor, preparation method and application thereof, and wearable intelligent fabric comprising the pressure sensor

ActiveCN110606981AIncrease loadImprove adhesionForce measurement using piezo-resistive materialsEngineeringGraphene

The invention provides a pressure sensor, a preparation method and application thereof, and a wearable intelligent fabric comprising the pressure sensor. The pressure sensor is made of graphene modified polyurethane foam; wherein on the basis that the total mass of the graphene modified polyurethane foam is 100%, the mass percentage of the graphene is 0.8-2.5%. The wearable intelligent fabric prepared by the sensor provided by the invention is a wearable platform completely based on the fabric, and has a wide application value.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

High-adhesion powder coating

InactiveCN104231871AThe recipe is simpleReduce manufacturing costPowdery paintsEpoxy resin coatingsWaxEpoxy

The invention relates to a powder coating, and in particular relates to a high-adhesion powder coating which comprises the following components in parts by weight: 560-620 parts of outdoor polyester resin, 42-45 parts of a curing agent TGIC, 8-10 parts of a universal leveling agent, 3 parts of benzoin, 5-10 parts of a curing accelerant, 3-5 parts of micro powder wax, 5-10 parts of a dispersing agent aid, 20-50 parts of epoxy resin, 5-250 parts of pigment and 80-350 parts of packing. The power coating provided by the invention is simple in formula, low in production cost, high in adhesion and relatively high in scraping resistance.

Owner:JIANGSU CHANGSONG SCI & TECH DEV

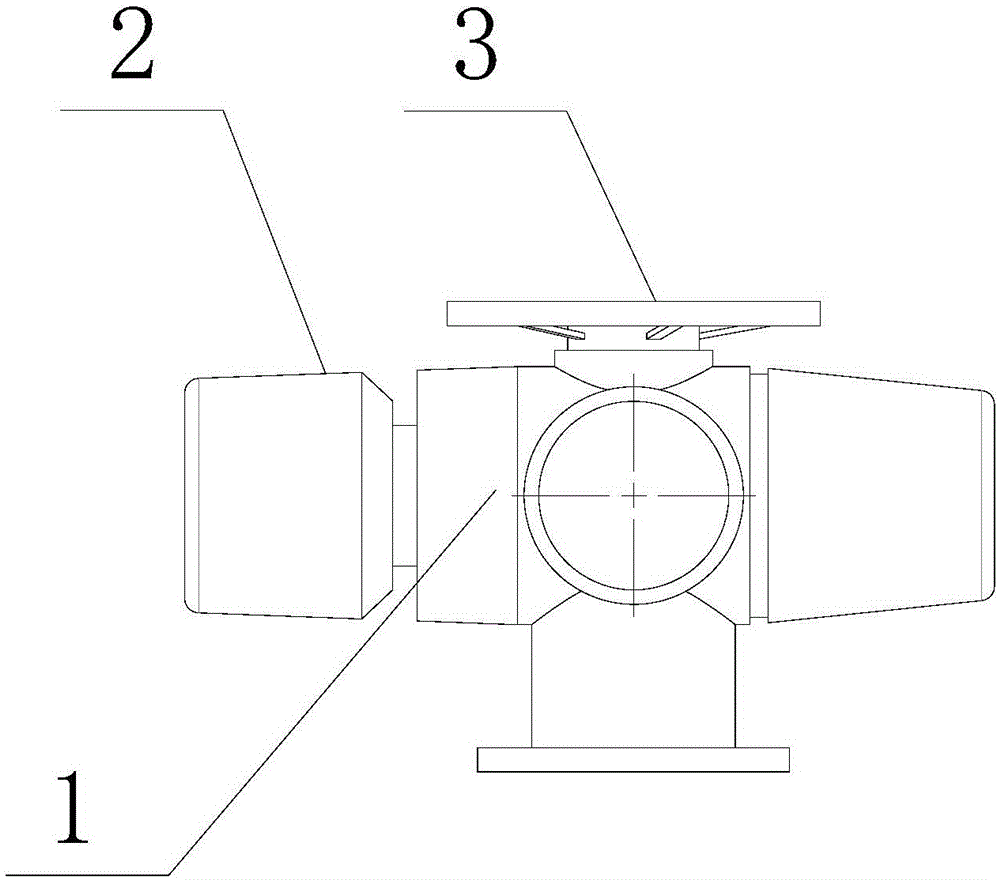

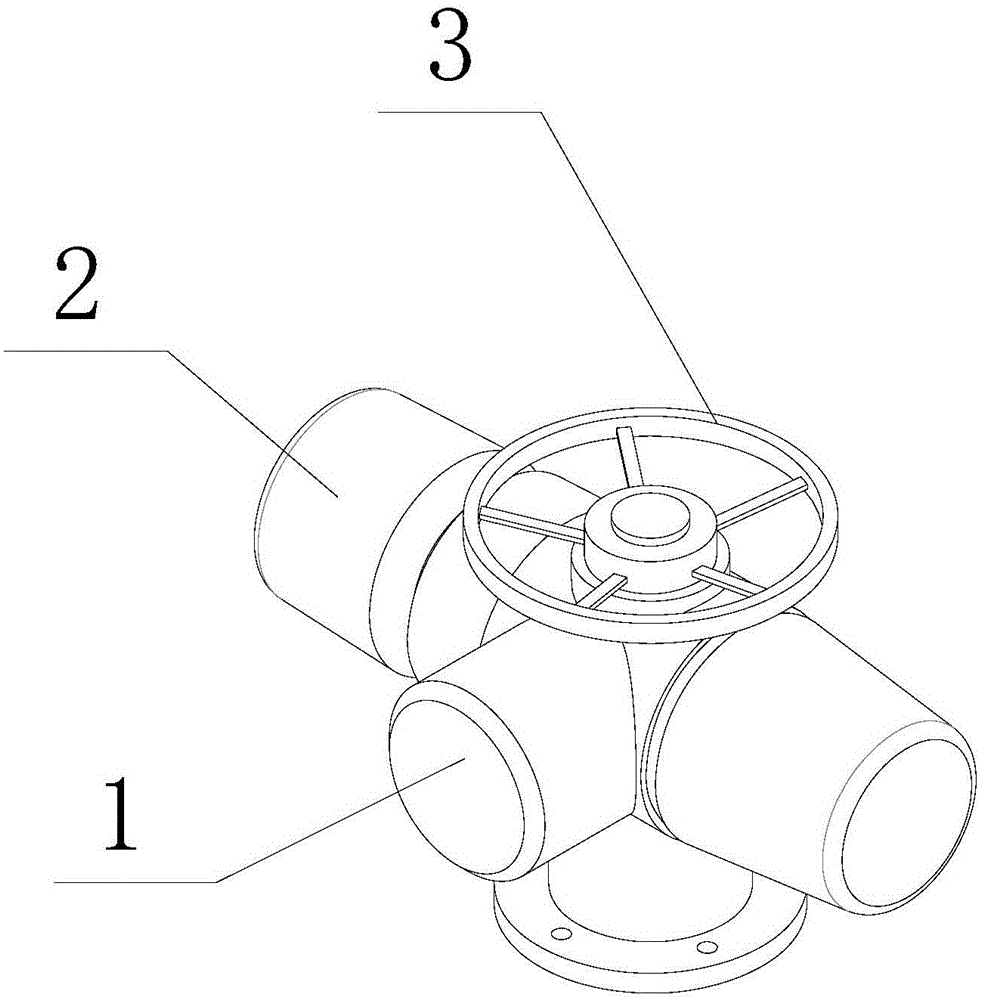

Actuator used for thermal control complete equipment and treatment technology thereof

InactiveCN105131687AImprove surface friction resistanceExtended service lifeRubber derivative coatingsAnti-corrosive paintsBenzoic acidPolyvinyl alcohol

The invention discloses an actuator used for thermal control complete equipment and a treatment technology thereof. The actuator is composed of a body, a servo motor and a hand wheel. The hand wheel is arranged at the upper end of the body, the servo motor is arranged at one end, in the length direction, of the body, and the surfaces of the body, the servo motor and the hand wheel are coated with anti-corrosion paint. The anti-corrosion paint is prepared from, by weight, 40-60 parts of epoxy-modified silicone resin, 12-14 parts of hydrogenated butadiene-arylonitrile rubber, 12-18 parts of bisphenol A epoxy resin, 5-7 parts of mica powder, 14-16 parts of talcum powder, 8-10 parts of polyvinyl butyral, 4-6 parts of benzyl silicon resin, 2-7 parts of dioctyl phthalate, 10-12 parts of copper powder, 2-4 parts of rutile titanium dioxide, 1-3 parts of ferro-phosphorus powder, 20-25 parts of deionized water, 2-4 parts of ethyl silicate, 5-7 parts of benzoic acid, 1-3 parts of rare earth and 1-3 parts of auxiliaries.

Owner:WUXI HUAHONG INFORMATION TECH

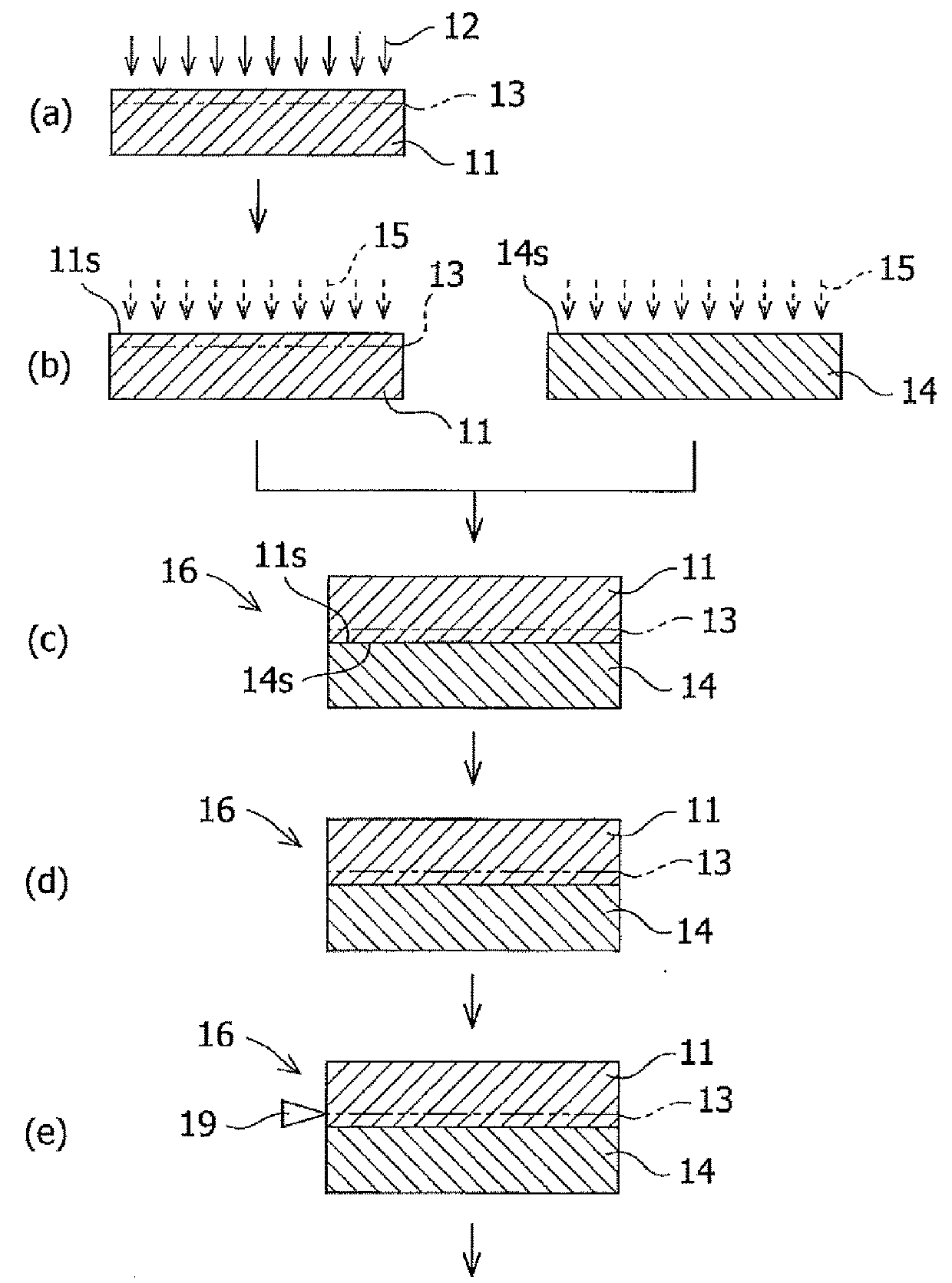

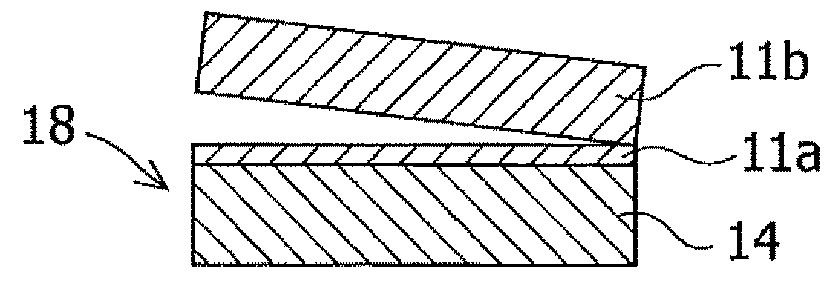

Method for producing composite wafer having oxide single-crystal film

ActiveUS20180166622A1High adhesionCost reductionSolid-state devicesSemiconductor/solid-state device manufacturingOxideOptoelectronics

A composite wafer having an oxide single-crystal film transferred onto a support wafer, the film being a lithium tantalate or lithium niobate film, and the composite wafer being unlikely to have cracking or peeling caused in the lamination interface between the film and the support wafer. More specifically, a method of producing the composite wafer, including steps of: implanting hydrogen atom ions or molecule ions from a surface of the oxide wafer to form an ion-implanted layer inside thereof, subjecting at least one of the surface of the oxide wafer and a surface of the support wafer to surface activation treatment; bonding the surfaces together to obtain a laminate; heat-treating the laminate at 90° C. or higher at which cracking is not caused; and applying a mechanical impact to the ion-implanted layer of the heat-treated laminate to split along the ion-implanted layer to obtain the composite wafer.

Owner:SHIN ETSU CHEM CO LTD

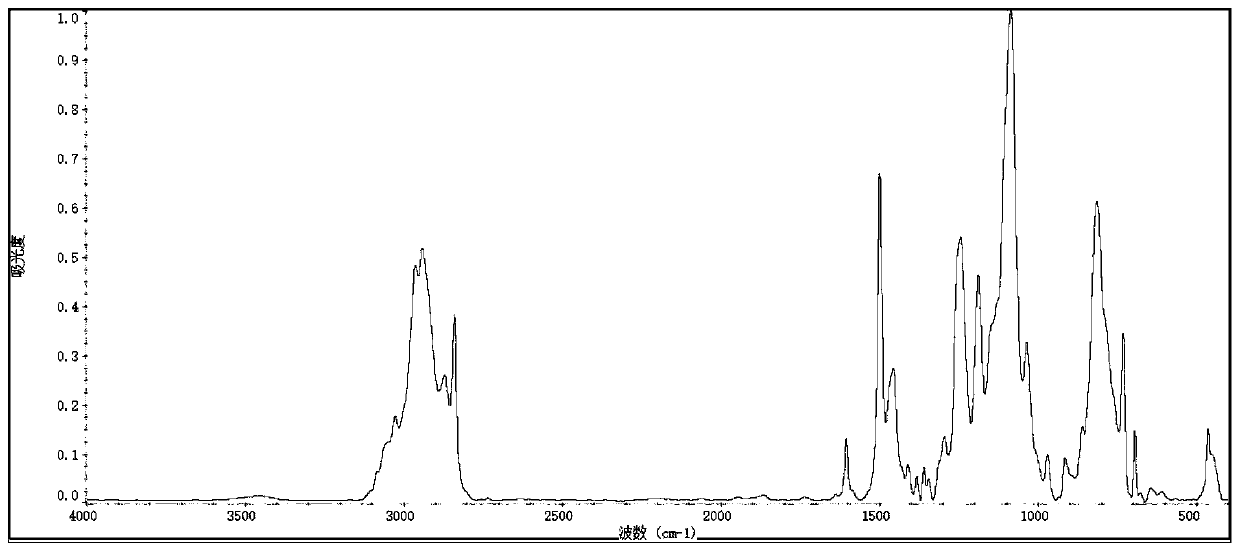

Adhesive resin composition, and laminate using the same

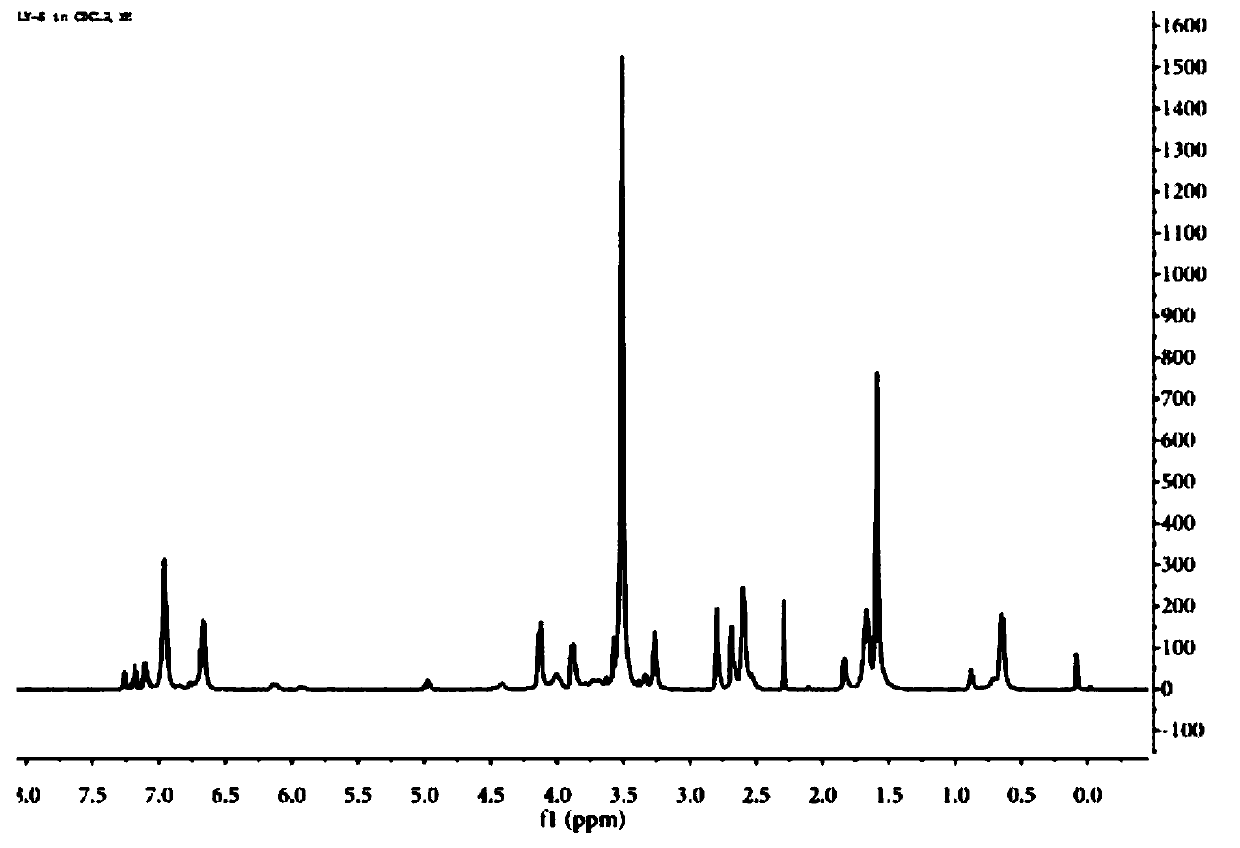

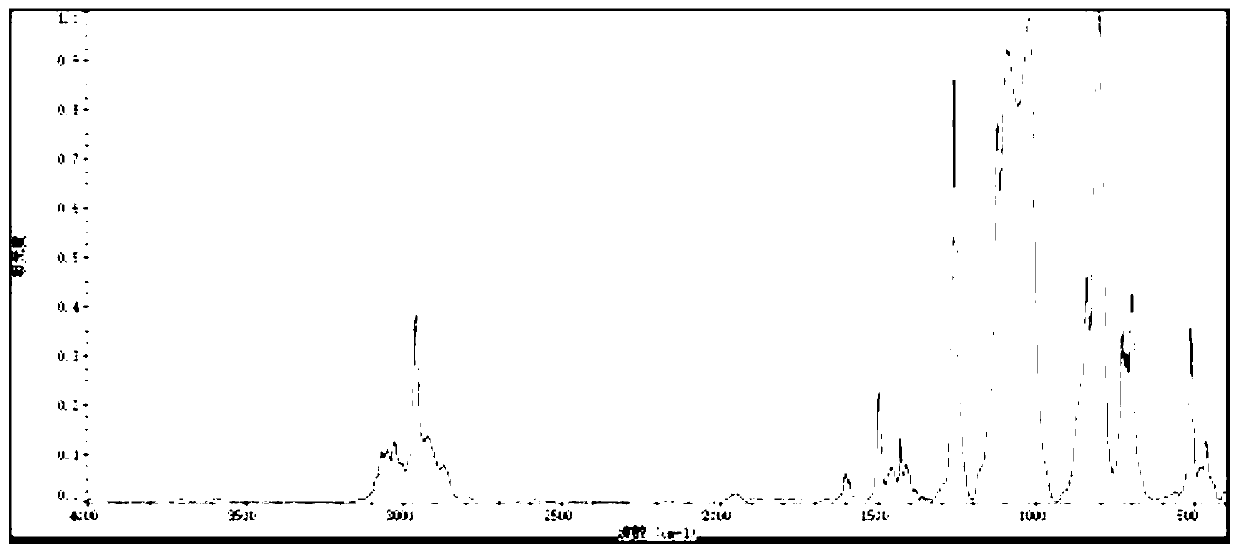

ActiveUS20100119856A1High adhesionImprove adhesionSynthetic resin layered productsDomestic containersChemistryInfrared

This invention provides an adhesive resin having sufficient adhesion with a polar resin in any applications at normal temperature and applications for boiling and retort processing, a resin composition comprising the adhesive resin, and further a laminate with polyolefin / polar resin including the resin composition as an intermediate layer. An adhesive resin composition (A) for a polar resin is produced by mixing a resin having a carboxylic acid anhydride or derivative thereof component (a1) with a ring-opening polymer or condensation polymer component (a2) having a hydroxyl group or an amino group at both ends or at one end; or graft-reacting the (a2) component with the (a1) component, and wherein an amount of the (a1) component is such that an acid value of the adhesive resin composition (A) is from 0.1 to 50 mg KOH / g with a potassium hydroxide / ethanol solution, and an amount of the (a2) component is such that y / (x+y)*100 is 10 or more, where x is a sum of peak heights of peaks (1713 cm−1, 1780 cm−1) derived from an acid anhydride group and y is a height of a peak (1740 cm−1) derived from an ester group, all peaks determined by infrared ray (IR) absorption spectrum measurement after melt-kneading the adhesive resin composition (A) at 220° C. for 5 minutes and then cooling to room temperature.

Owner:KURARAY CO LTD

Coating composition for back protection layer of diffusion membrane and diffusion membrane

InactiveCN108047781AHigh adhesionImprove scratch resistanceDiffusing elementsCoatingsChemical treatmentOligomer

The invention relates to the technical field of high-performance coating materials, and particularly relates to a diffusion coating composition for a back protection layer of a diffusion membrane andthe diffusion membrane. In order to solve the problem of poor scratch resistance of the back protection layer of an existing diffusion membrane, the invention provides the coating composition for theback protection layer of the diffusion membrane and the diffusion membrane. The coating composition is prepared from 10%-30% of polyol copolymer, 1%-3% of a curing agent, 10%-20% of polyurethane acrylate oligomer, 5%-10% of monomers, 0.15%-1.5% of a photoinitiator, 0.2%-0.3% of diffusion particles and 36%-60% of a diluting agent. The coating composition provided by the invention is applied to a common substrate which is subjected to non-chemical treatment, and the back protection layer formed by curing has good scratch resistance and has good adhesive force with the substrate.

Owner:NINGBO EXCITON TECH

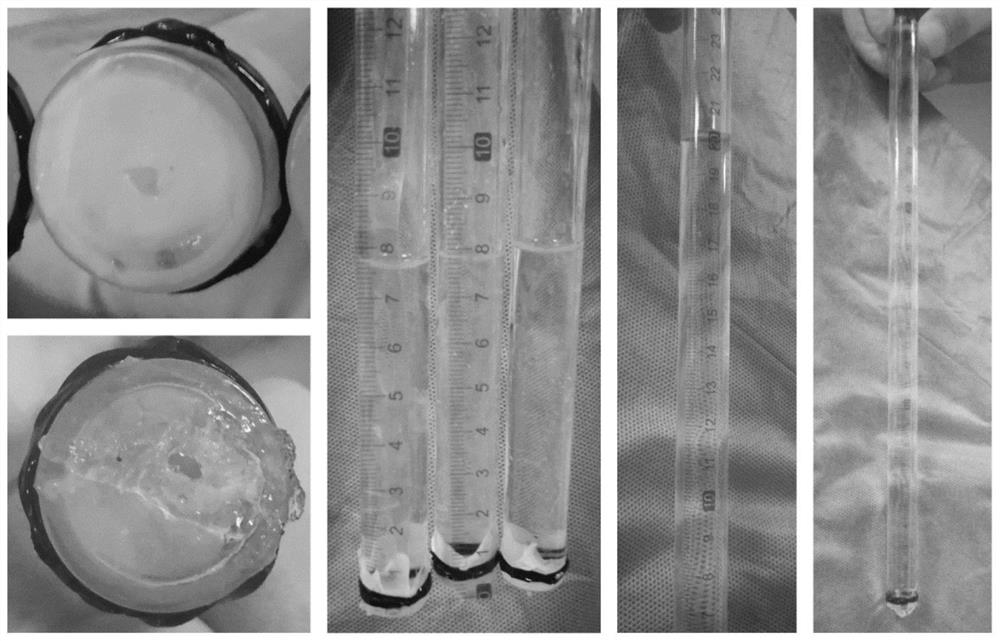

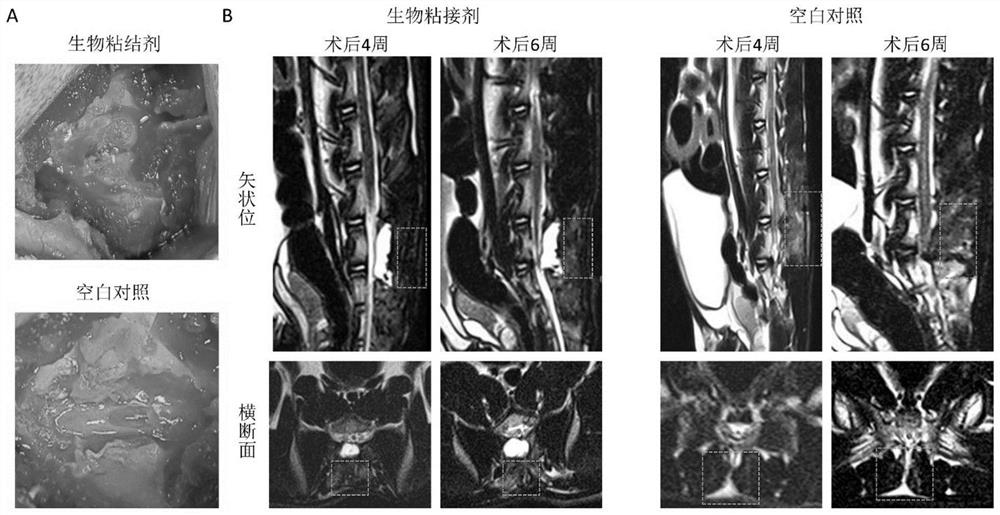

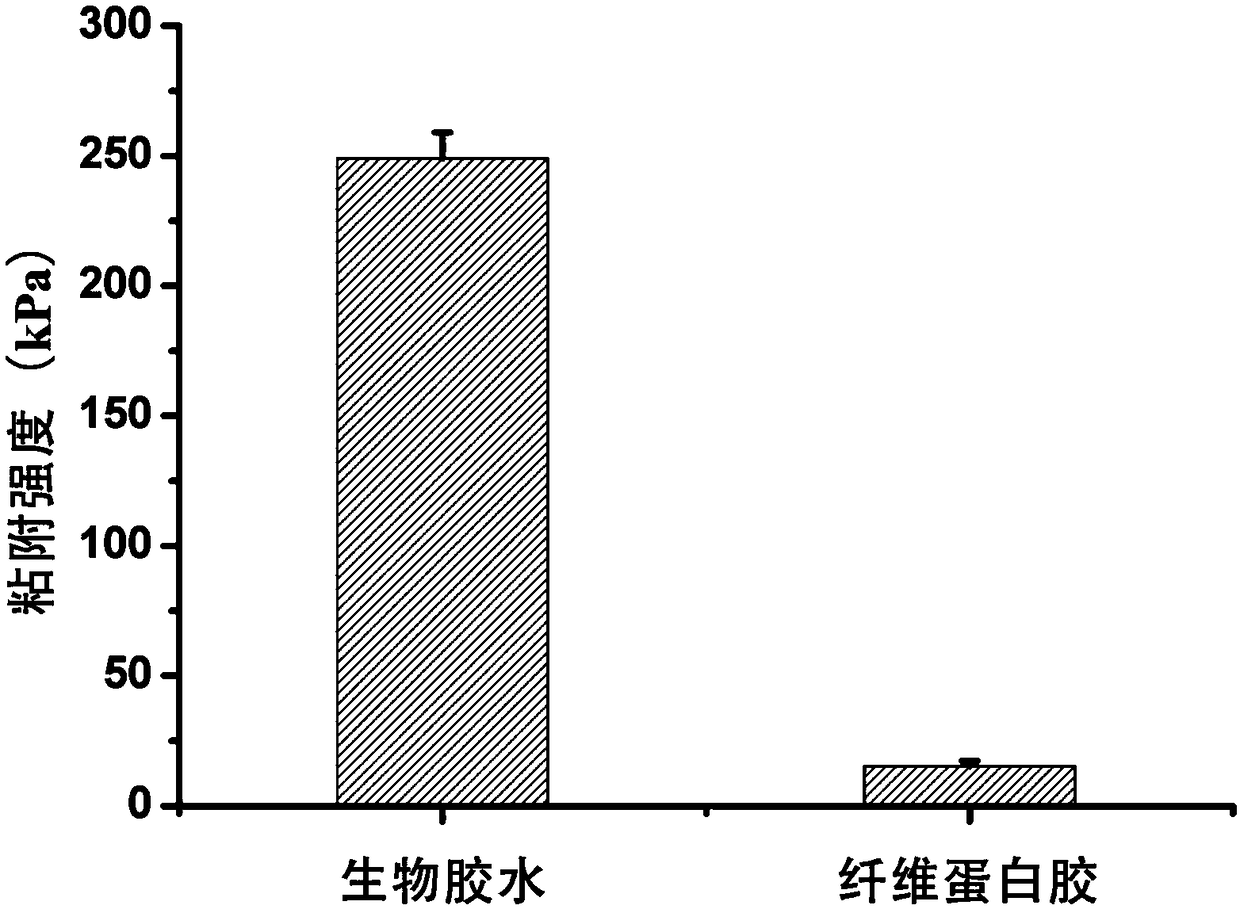

Biological adhesive and preparation method and application thereof

The invention discloses a biological adhesive and a preparation method and application thereof. The biological adhesive comprises 4-arm polyethylene glycol amine and 4-arm polyethylene glycol succinimide succinate according to the mass ratio of 1: (0.1-10). The biological adhesive disclosed by the invention has the advantages of good biocompatibility, degradability and relatively high adhesive capacity, and is enough to tolerate the pressure of cerebrospinal fluid after being adhered to the spinal dura mater. Moreover, the biological adhesive disclosed by the invention is convenient to operatein an operation, can be independently used and does not need to be sutured, so that the operation time is greatly shortened and the operation risk is reduced. The biological adhesive disclosed by theinvention can be used for dura mater injuries of a special part which cannot be effectively sutured by a conventional method, such as injuries in front of and on the side of the dura mater and injuries in the positions of nerve root sleeves, can effectively reduce complications of cerebrospinal fluid leakage after a spinal operation, and improves prognosis of a patient.

Owner:BEIJING NATON INST OF MEDICAL TECH CO LTD

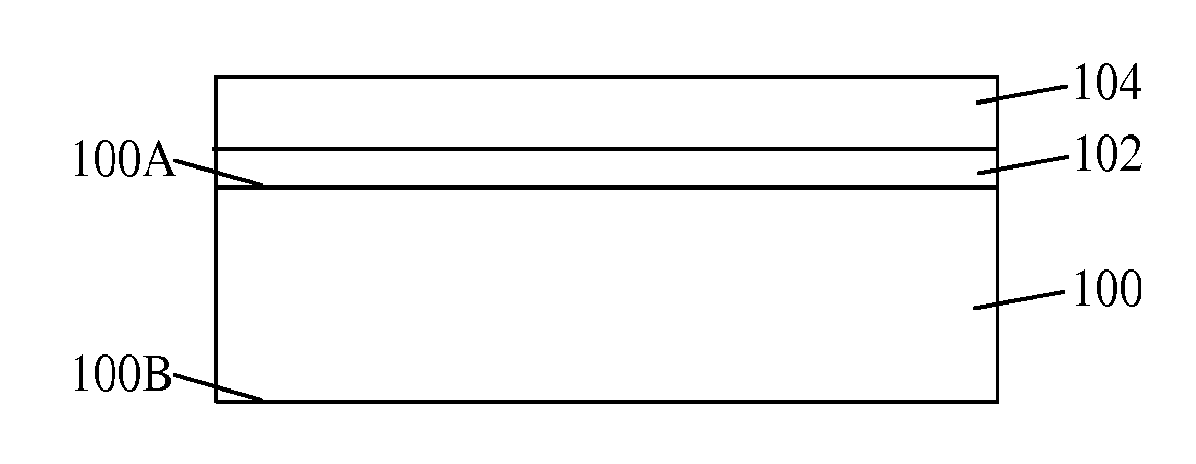

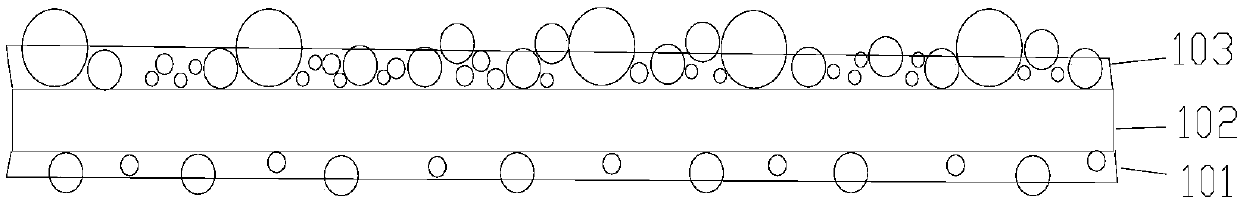

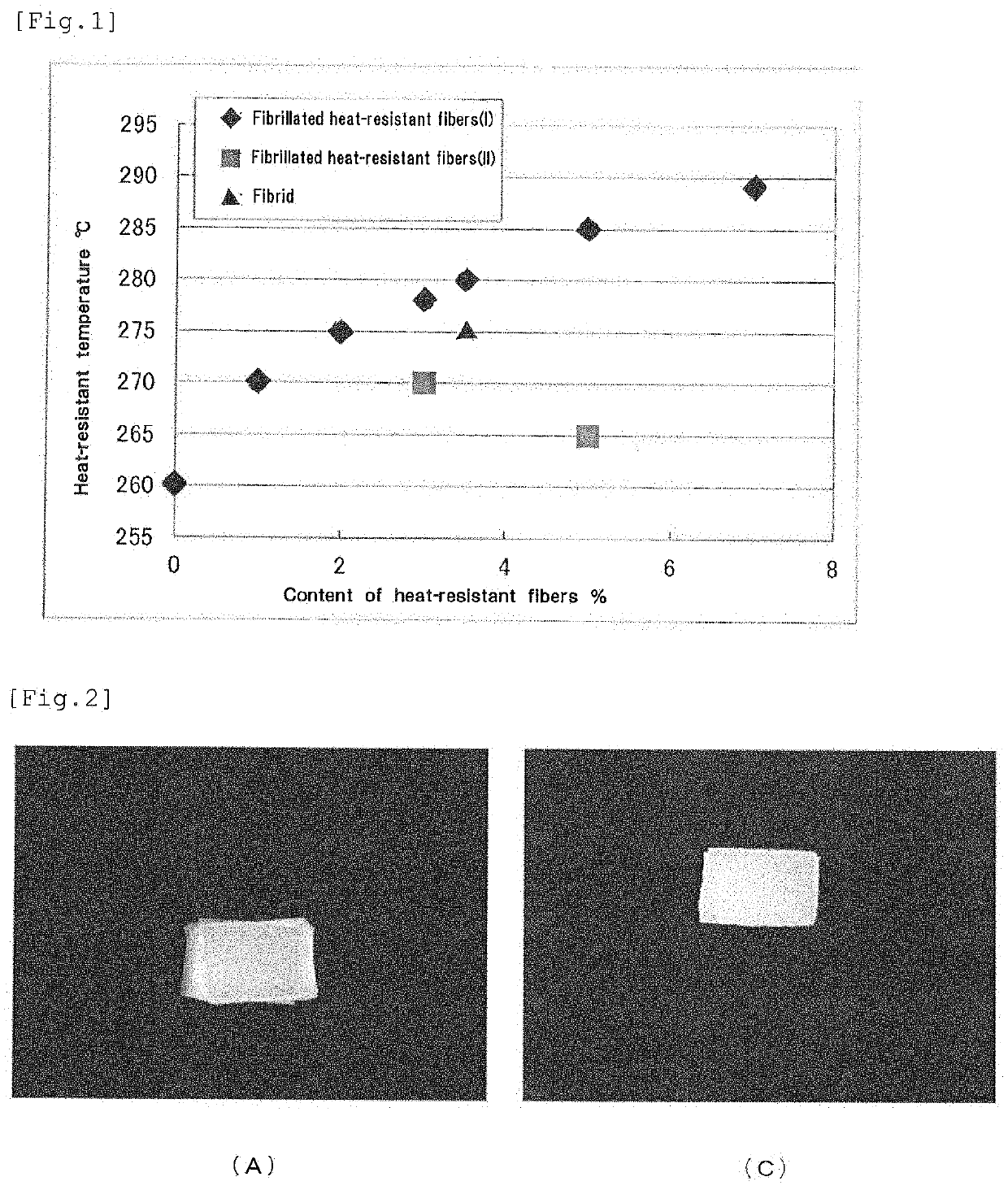

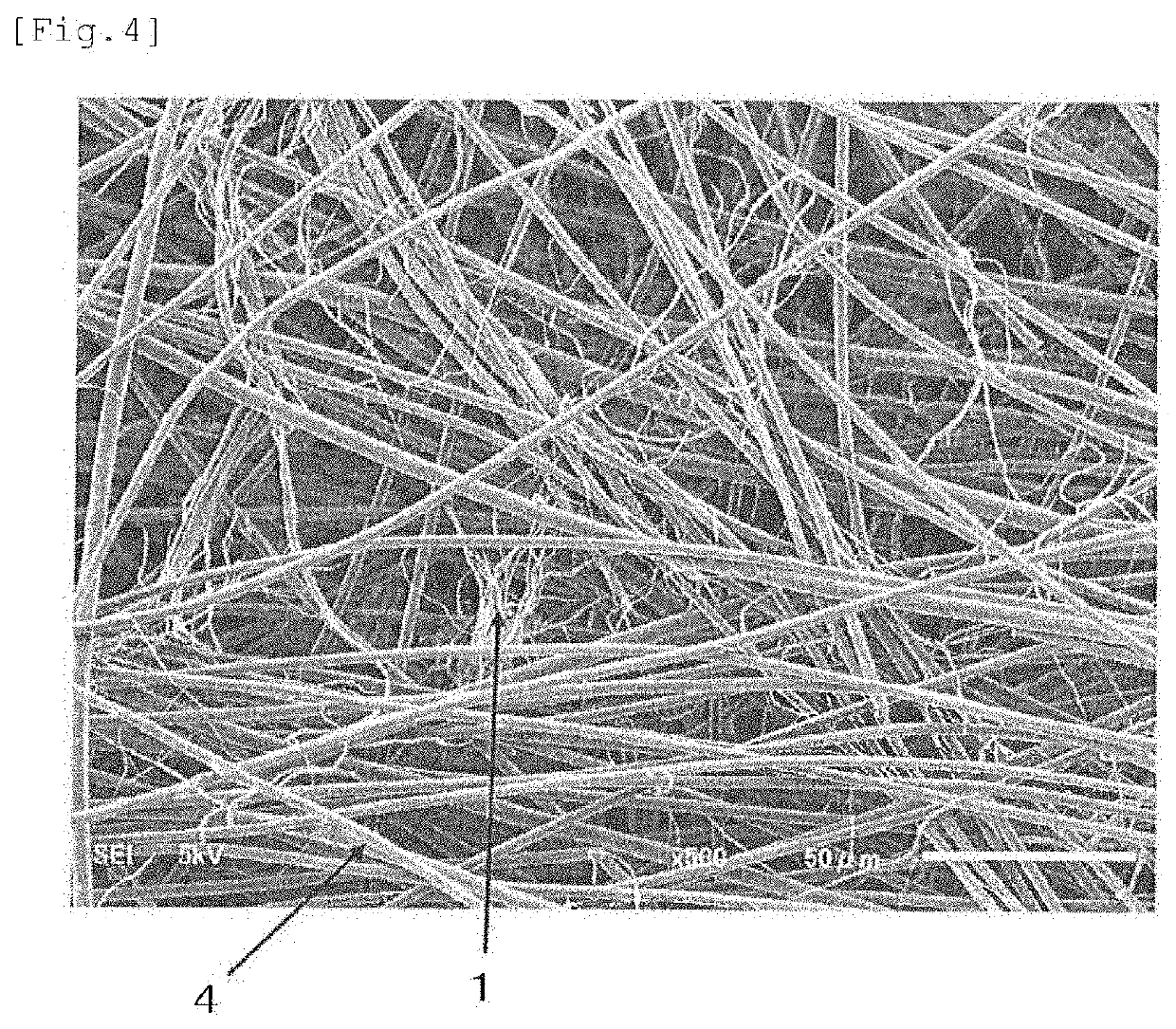

Substrate for lithium ion battery separators and lithium ion battery separator

ActiveUS20210288382A1Excellent in tensile strength and cuttabilityHigh adhesionLayered productsSecondary cellsLithium electrodeFiber

It is an object of the present invention to provide a substrate for lithium ion battery separators which has high adhesion to an inorganic particle layer, can be made thin and is excellent in tensile strength and cuttability and a lithium ion battery separator including the substrate for lithium ion battery separators. The substrate for lithium ion battery separators which contains heat-resistant fibers and synthetic resin short fibers contains fibrillated heat-resistant fibers having a modified freeness of not more than 300 ml as the heat-resistant fibers and has a content of the fibrillated heat-resistant fibers having a modified freeness of not more than 300 ml of not less than 1.0 mass % to less than 5.0 mass % based on the total of all the fiber components contained in the substrate. The modified freeness is a value measured in accordance with JIS P8121-2:2012 except that an 80-mesh wire net having a wire diameter of 0.14 mm and an opening of 0.18 mm is used as a screening plate and the concentration of a sample is 0.1%.

Owner:MITSUBISHI PAPER MILLS LTD

Bonding composition and board

InactiveUS20140011042A1High adhesionImprove adhesionNon-macromolecular adhesive additivesWater-repelling agents additionHigh adhesionCarboxylic acid

The purpose of the present invention is to provide a bonding composition having high adhesion, from which formaldehyde is hardly released. The present invention relates to a bonding composition cured through heating and pressing. The bonding composition contains a polyvalent carboxylic acid.

Owner:PANASONIC CORP

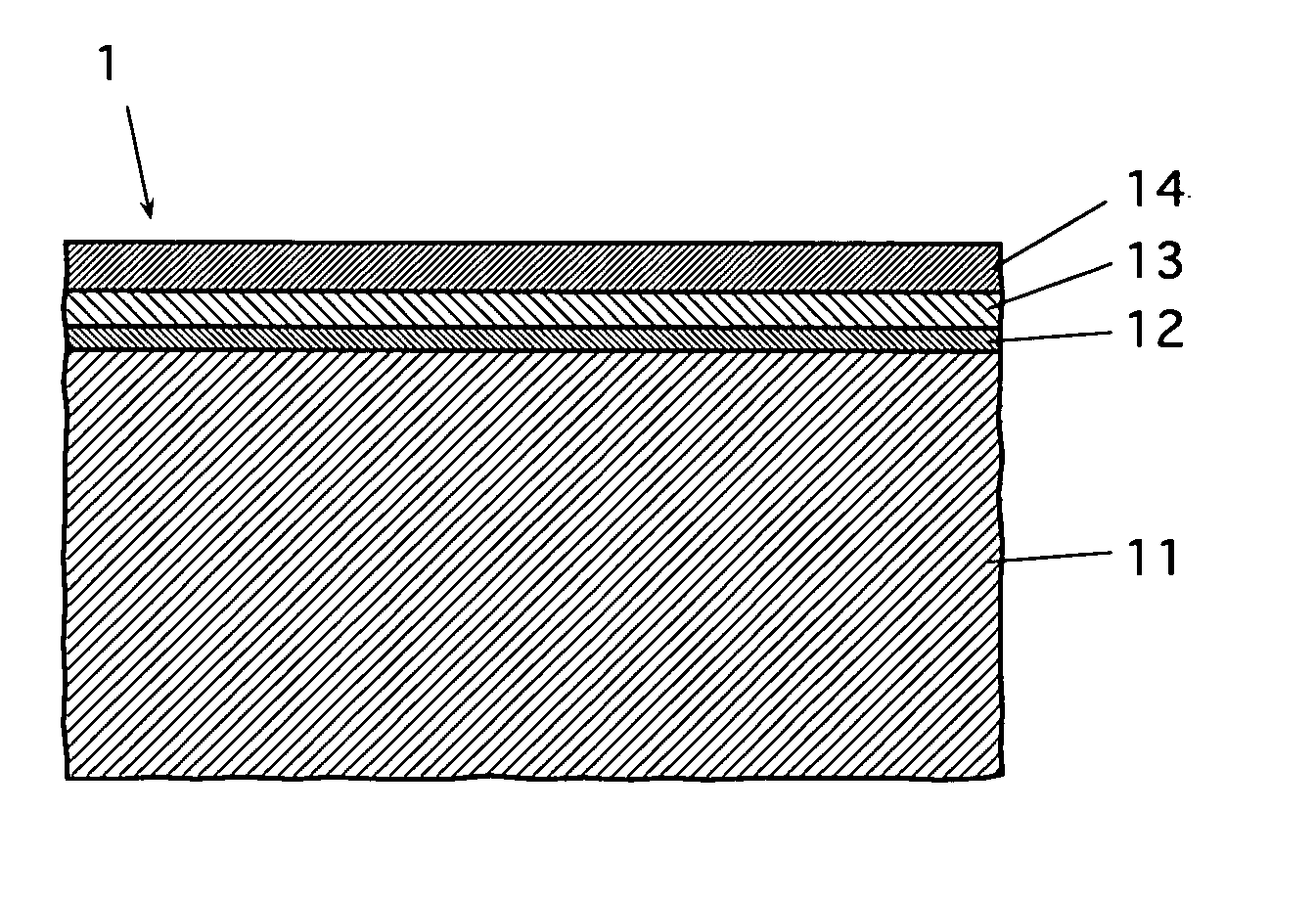

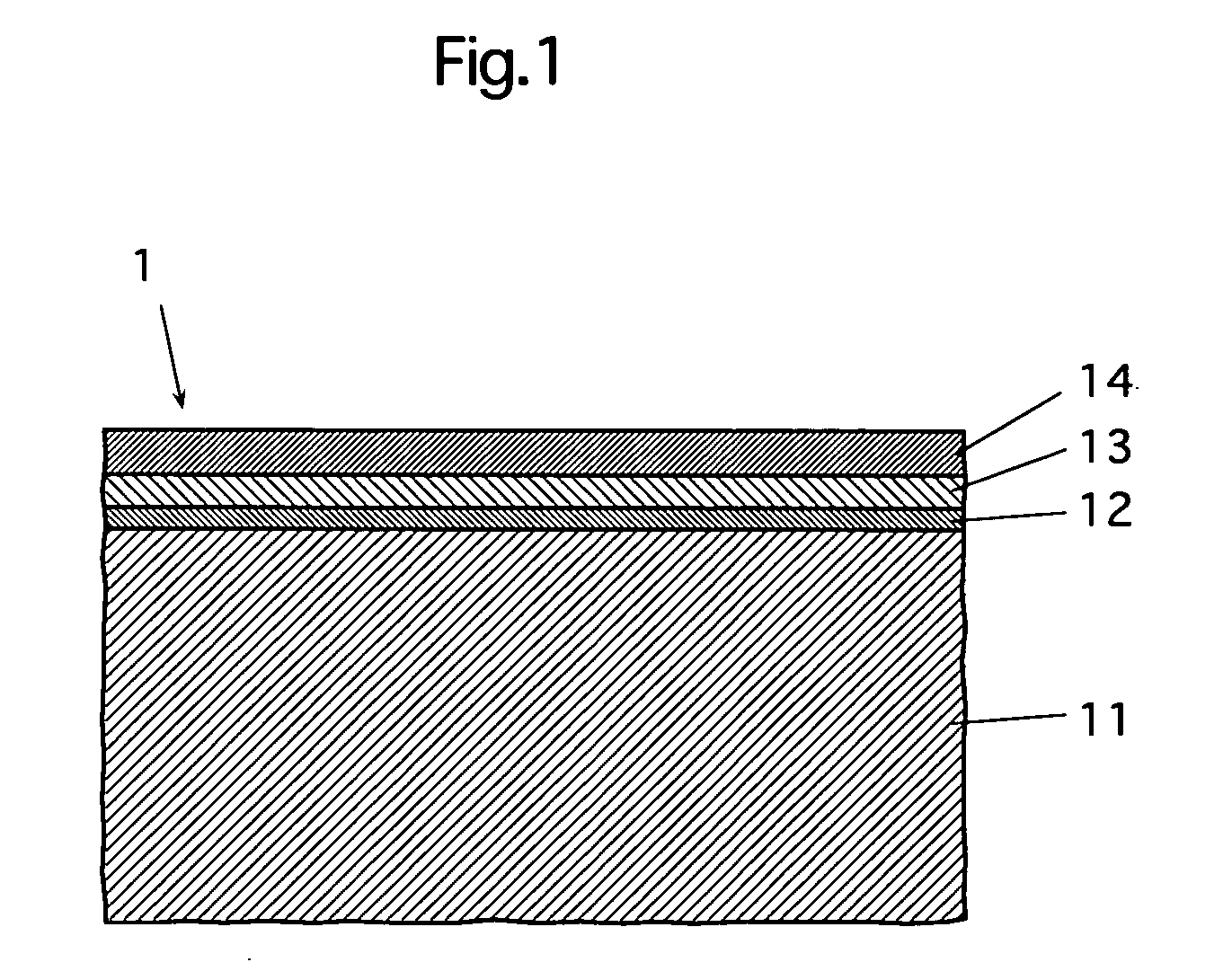

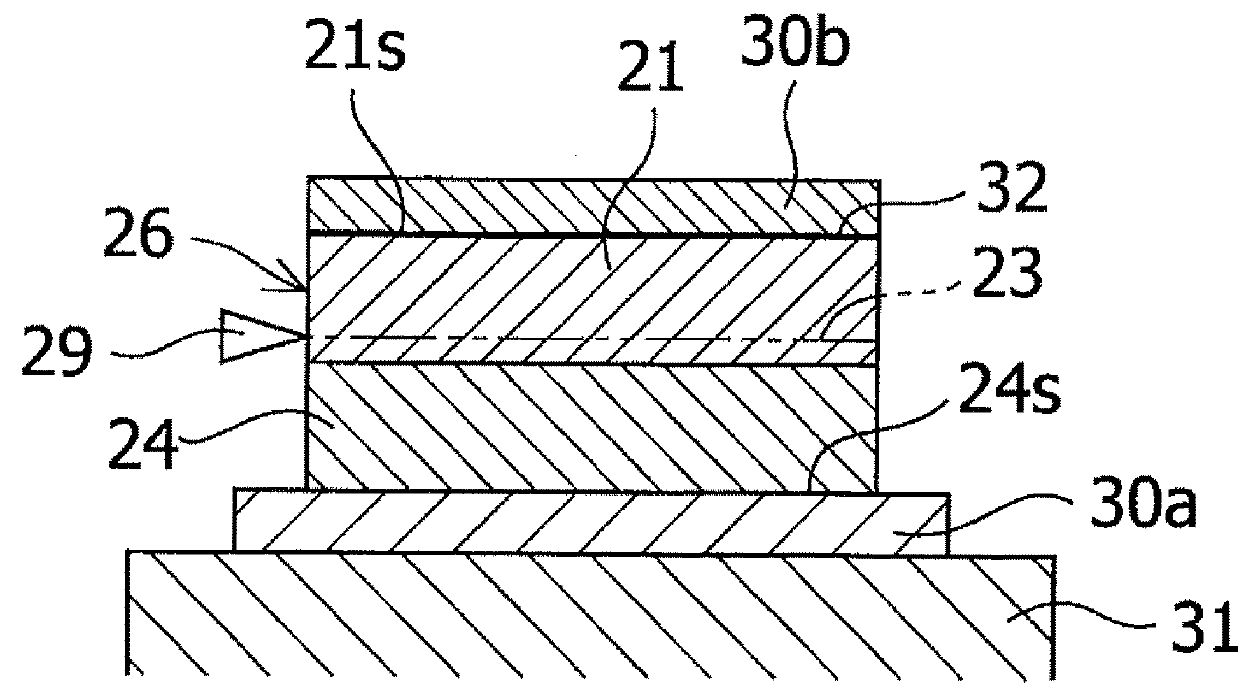

Thin film capacitor, circuit board incorporating the same, and thin film capacitor manufacturing method

ActiveUS20210257164A1Enhance adhesionHigh adhesionInsulating substrate metal adhesion improvementThin/thick film capacitorPhysicsFilm capacitor

Disclosed herein a thin film capacitor that includes a lower electrode layer, an upper electrode layer, and a dielectric layer disposed between the lower electrode layer and the upper electrode layer. The lower electrode layer includes a first metal layer positioned on a side facing the dielectric layer and a second metal layer positioned on a side facing away from the dielectric layer. The first metal layer has a first surface positioned on a side facing the second metal layer and a second surface positioned on a side facing the dielectric layer. The first surface has a surface roughness higher than that of the second surface. The second metal layer reflects a surface property of the first surface.

Owner:TDK CORPARATION

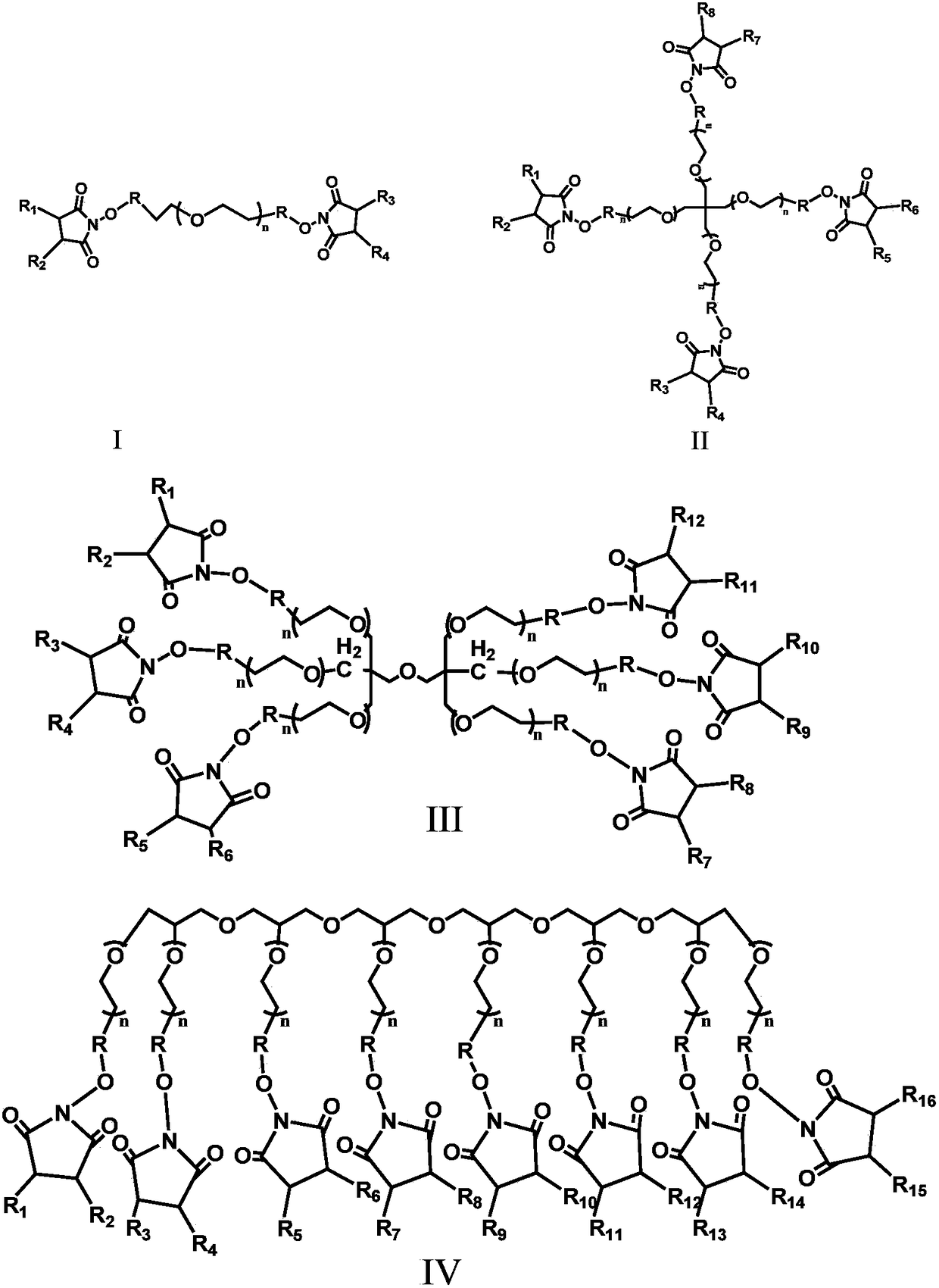

Injectable biologic glue having high-strength adhesion property and preparation method and applications thereof

ActiveCN108525002AHigh adhesionGood biocompatibilitySurgical adhesivesPharmaceutical delivery mechanismPolyethylene glycolHigh adhesion

The invention discloses an injectable biologic glue having a high-strength adhesion property and a preparation method and applications thereof. The injectable biologic glue is formed by the hydrogen bond interaction of a polyethylene glycol derivative (polyethylene glycol succinimide ester) and tannic acid. The preparation method of the injectable biologic glue includes (1) preparing a solution 1of the polyethylene glycol derivative; (2) preparing a solution 2 of the tannic acid; and (3) mixing the solution 1 and the solution 2 to obtain a sediment through centrifugation. The injectable biologic glue has potential applications in the following fields: surgical wound adhesion; drug delivery and release systems; medical implants; and surface coatings of medical implants; The beneficial effects of the injectable biologic glue are that the injectable biologic glue can be formed by the interaction of two substances which are the PEG derivative and the tannic acid through a physical effect(the hydrogen bond); the injectable biologic glue has high adhesion capability; and the injectable biologic glue can be used by single-tube injectors so that the usage is more convenient.

Owner:深圳宁聚生物新材料科技有限公司

Makeup cosmetic and makeup kit comprising the makeup cosmetic and a top coating agent

ActiveUS20120312316A1Good feeling of useHigh adhesionCosmetic preparationsMake-upRelative massPolyprenol

Provided is a makeup cosmetic which has a good feeling of use, without showing tautness or stiffness as in the case of using a silicone-based resin film or an offensive odor as in the case of using polyisoprene, and exhibits a good effect of preventing color migration. This makeup cosmetic is characterized by comprising polyisobutylene having a relative mass of 30,000-100,000 and a volatile hydrocarbon oil. Also provided are a top coating agent, which can be appropriately applied on the aforesaid makeup cosmetic, imparts glossiness and shows little color migration or blurring, a makeup kit comprising the aforesaid makeup cosmetic and the top coating agent, and a makeup method using the makeup kit.

Owner:SHISEIDO CO LTD

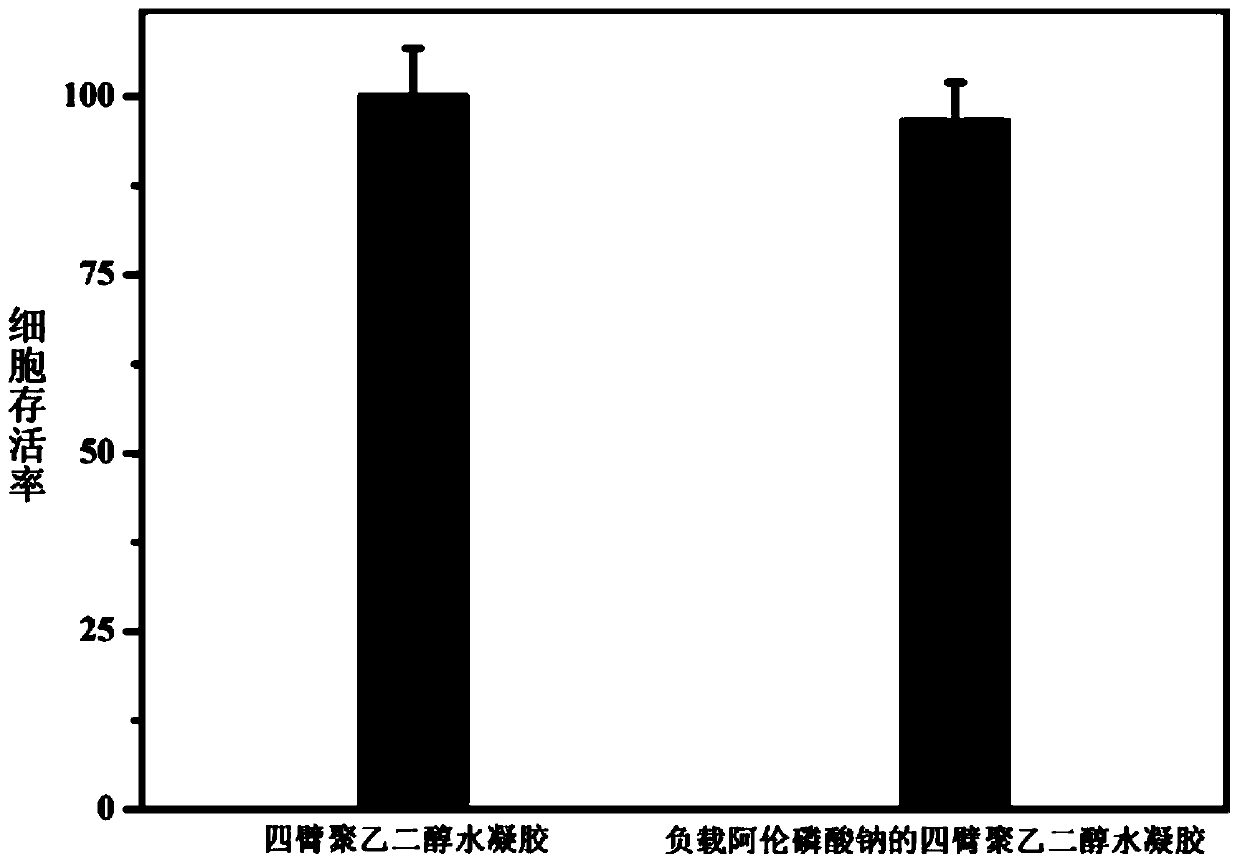

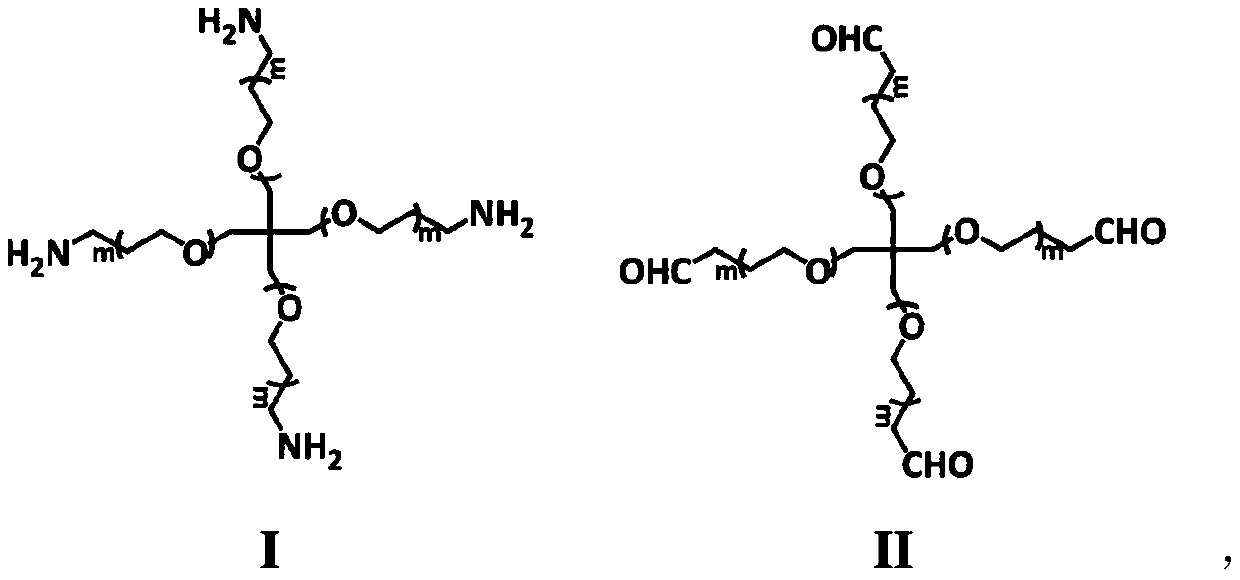

Preparation method of injectable polyethylene glycol hydrogel loaded with alendronate sodium and application thereof

InactiveCN111557902ARegular structureGood mechanical propertiesOrganic active ingredientsAerosol deliveryPolymer scienceCollagenan

The invention discloses a preparation method of an injectable polyethylene glycol preparation loaded with alendronate sodium and an application thereof. The preparation at least comprises two independent solutions, wherein a solution 1 is prepared from four-arm-polyethylene glycol-aldehyde group; a solution 2 containsg four arms-polyethylene glycol-amino groups; the hydrogel is dissolved in the solution 1 or the solution 2, or is independently dissolved to form a solution 3; wherein the pH value of the mixed solution of the preparation obtained by mixing the solutions is 4.0-9.0. The four-arm-polyethylene glycol-aldehyde groups and four-arm-polyethylene glycol-amino groups are adopted for in-situ gelling through Schiff base bonds, intraoperative operation is convenient, and the gelling speed is high. Meanwhile, amino on collagen on the surface of the tissue and alendronate sodium in the solution can be quickly and chemically bonded with the four-arm-polyethylene glycol-aldehyde group through a Schiff base bond.

Owner:GENERAL HOSPITAL OF PLA

Binder aqueous solution for lithium-ion battery electrode, slurry for lithium-ion battery electrode, lithium-ion battery electrode, and lithium-ion battery

PendingUS20210075019A1Good stabilityHigh adhesionElectrode collector coatingNon-aqueous electrolyte accumulator electrodesWater soluble polymersMethacrylamide

Provided are a binder aqueous solution for a lithium-ion battery electrode, a slurry for a lithium-ion battery electrode, a lithium-ion battery electrode, and a lithium-ion battery. The binder aqueous solution for a lithium-ion battery electrode contains a water-soluble polymer (A). The water-soluble polymer (A) is a polymer of a monomer group containing, with respect to 100 mol % of the monomer group, 5 mol % to 80 mol % of a hydroxyl group-containing vinyl ether (a). In one embodiment, the monomer group contains 20 mol % to 95 mol % of a (meth)acrylamide group-containing compound (b).

Owner:ARAKAWA CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com