Film formation method and storage medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

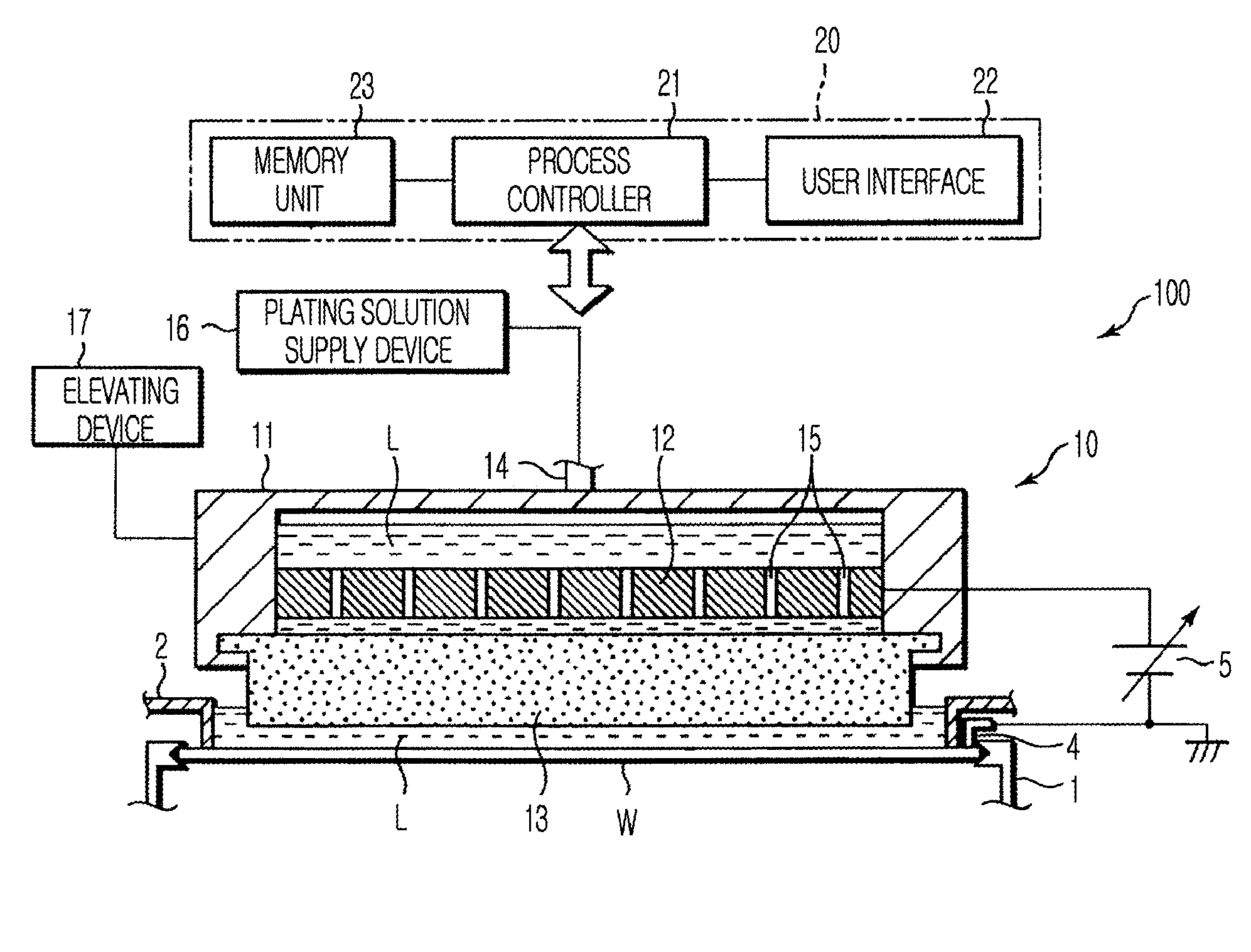

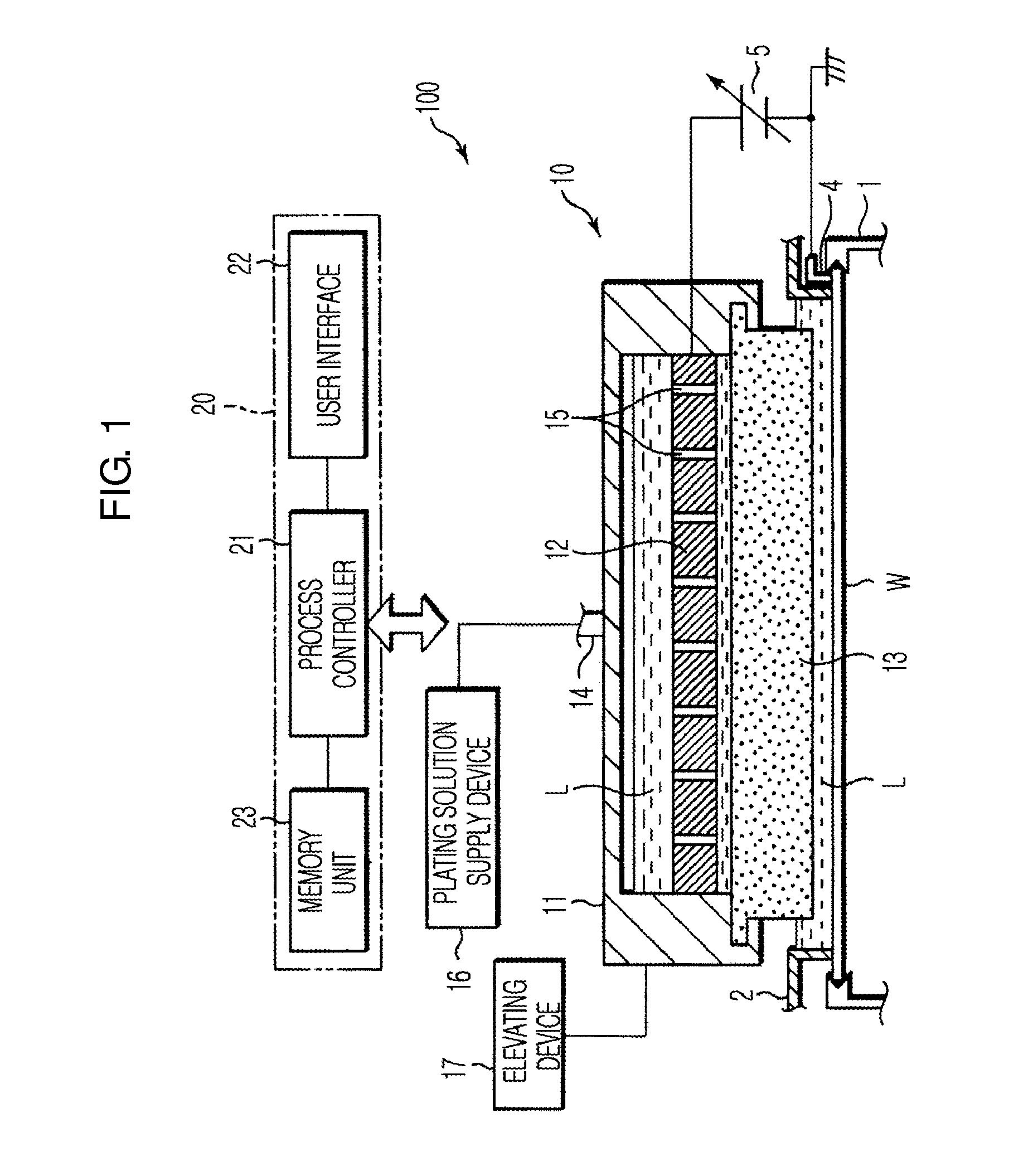

Image

Examples

embodiments

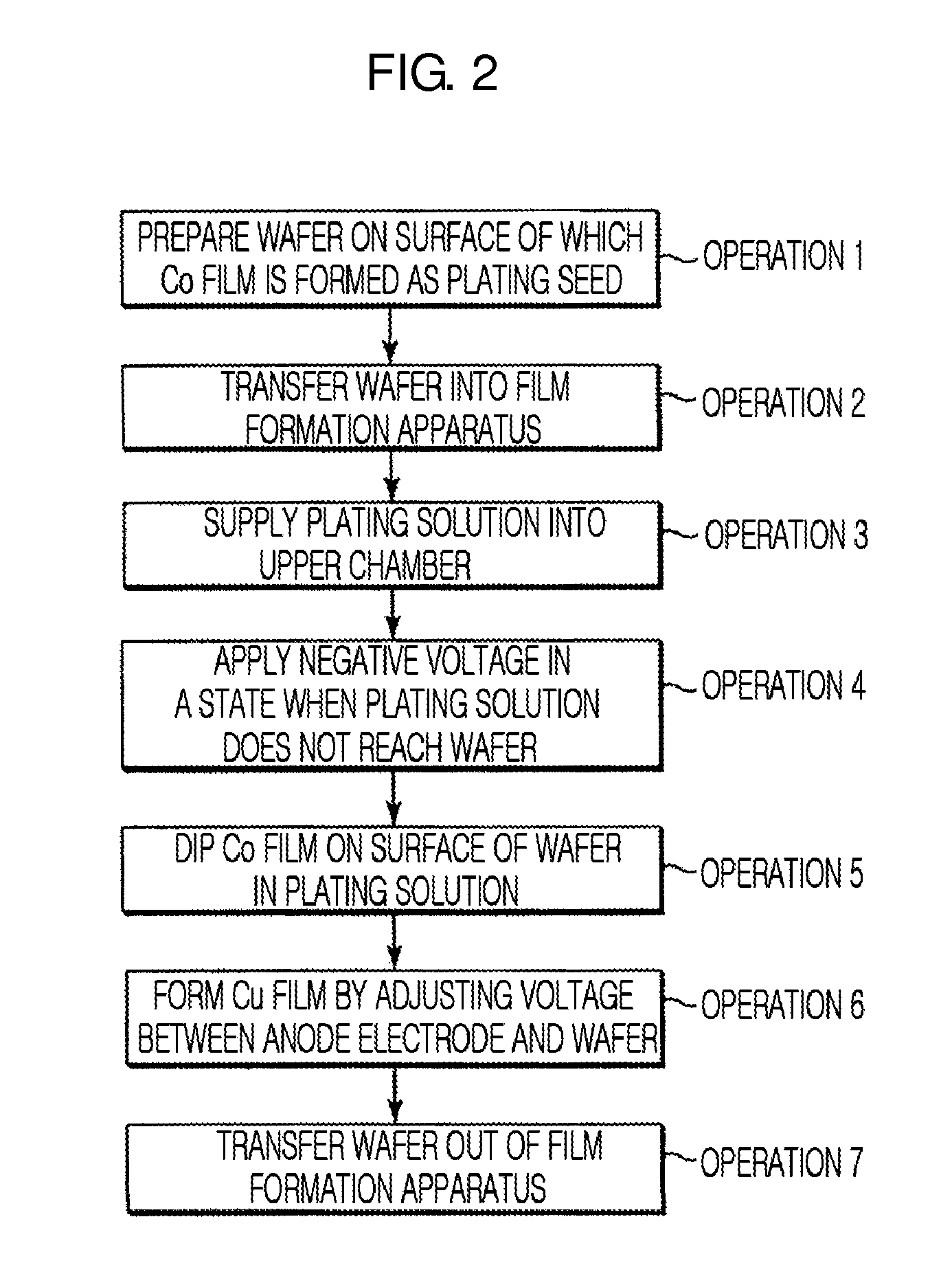

[0054]Next, embodiments will be explained.

[0055]A sample in which a Co film was formed as a plating seed to a thickness of 10 nm on a substrate and two samples in each of which a Co film was formed as a plating seed to a thickness of 5 nm on a substrate were prepared. First, no voltage was applied to the sample in which the Co film was formed to the thickness of 10 nm and one of the samples in which the Co film was formed to the thickness of 5 nm before the samples were dipped in plating solutions, and Cu films are formed by electroplating. Also, a voltage of −20 V was applied to the other sample in which the Co film was formed to the thickness of 5 nm before the sample was dipped in a plating solution, thereby a Cu film is formed by electroplating.

[0056]FIG. 7 are photographs showing plating states of the samples as time passes. As shown in FIG. 7, it was found that in the sample in which the Co film was formed to the thickness of 10 nm, the Cu film was formed satisfactorily althou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Surface potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com