Preparation method and application of high-strength superhydrophobic composite material taking block-like organosilicone/epoxy hybrid resin as matrix

A technology of composite materials and epoxy resin, applied in the direction of coating, etc., can solve the problems of low mechanical strength and adhesion, and achieve the effects of short preparation cycle, stable super-hydrophobic performance, high mechanical strength and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

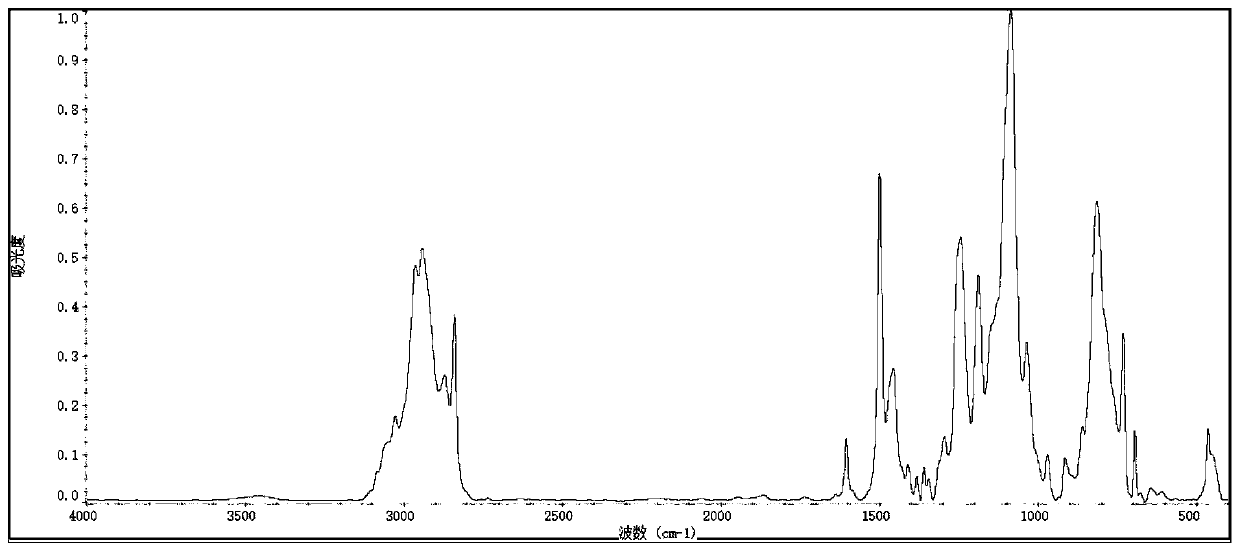

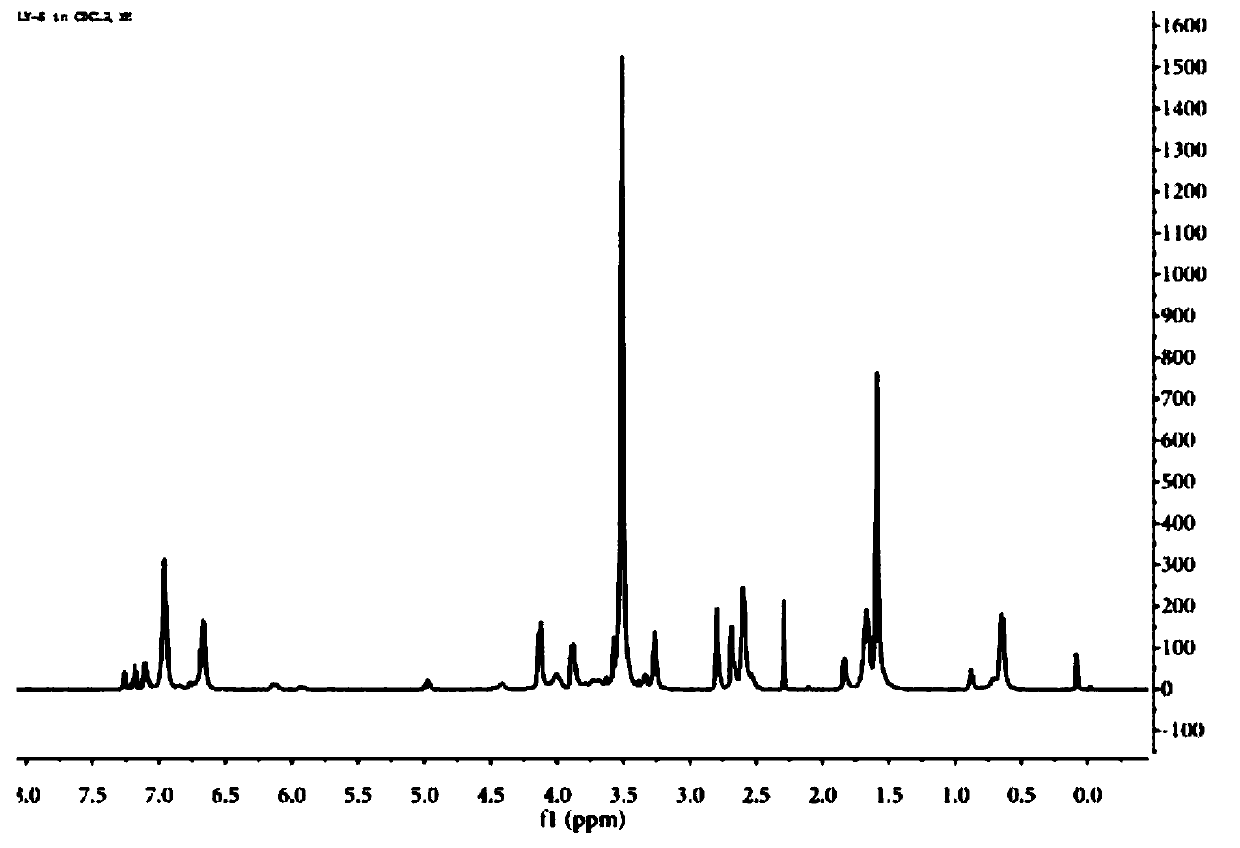

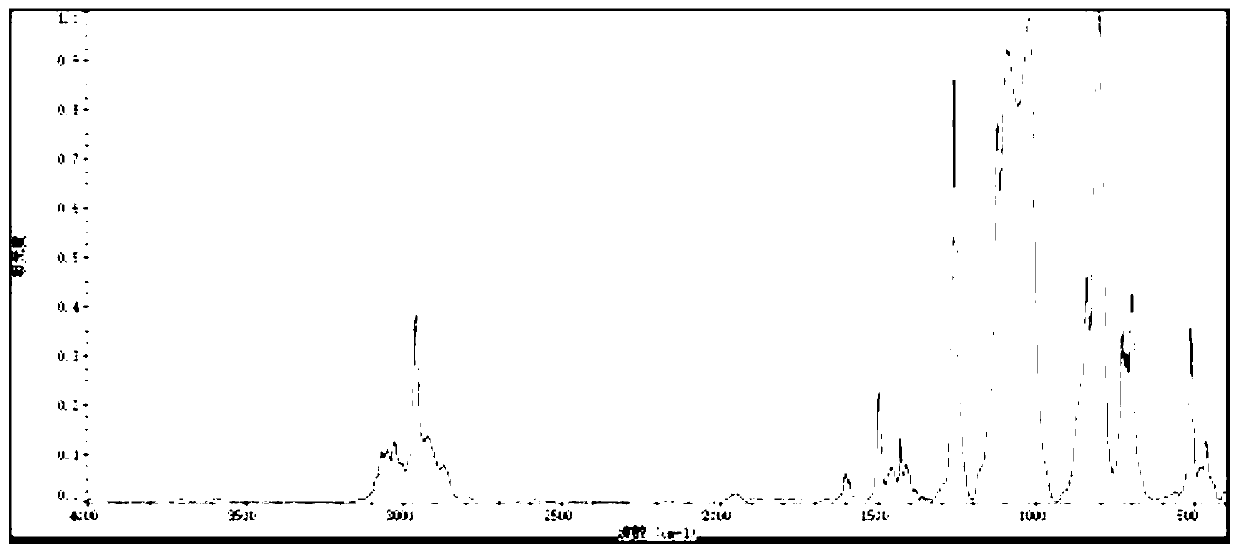

[0040](1) Add 20g of allyl epoxy resin, 35g of double-terminal hydrogen silicone and 160g of dry toluene into a 500ml four-necked bottle, and add 0.28g of 1,3-divinyl- 1,1,3,3-Tetramethyldisiloxane platinum (0) catalyst, heat up to 65°C for 4 hours, and remove the solvent toluene by rotary evaporation to obtain Si-EP 1 . The infrared spectra of the reaction products and 1 H-NMR spectrum see respectively figure 1 and figure 2 . Add 35g of allyl epoxy resin, 8.7g of double-terminal hydrogen silicone and 140g of dry toluene into a 250ml four-necked flask, and add 0.15g of 1,3-divinyl-1 under 40°C and stir for 30min with nitrogen , 1,3,3-Tetramethyldisiloxane platinum (0) catalyst, heated up to 110 ° C for 4 hours, and the solvent toluene was removed by rotary evaporation to obtain Si-EP 2 . The infrared spectra of the reaction products and 1 H-NMR spectrum see respectively image 3 and Figure 4 .

[0041] (2) Disperse 6g of silica powder with a particle size of 50nm a...

Embodiment 2

[0053] (1) Add 10g of allyl epoxy resin, 17.3g of double-ended hydrogen silicone and 120g of dry toluene into a 250ml four-necked flask, fill with nitrogen at room temperature and stir for 30min, then add 0.18g of chloroplatinic acid-xylene catalyst , heated up to 60°C for 4 hours, and the solvent toluene was removed by rotary evaporation to obtain Si-EP 1 . Add 35g of allyl epoxy resin, 8.7g of double-ended hydrogen silicone and 140g of dry toluene into a 250ml four-neck flask, fill with nitrogen and stir for 30min at 40°C, then add 0.21g of chloroplatinic acid-xylene catalyst, and heat up Reaction at 100°C for 4h, and the solvent toluene was removed by rotary evaporation to obtain Si-EP 2 .

[0054] (2) Disperse 4g of silica powder with a particle size of 50nm and a particle size of 2g with a particle size of 500nm after KH560 treatment into 30g of ethanol and sonicate for 10min, and then continue to add 5g of Si-EP 1 , 1.25g Si-EP 2 Add to the above ethanol suspension, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com