Bi-component interfacial bonding organosilicone connection paint matched with pollution release type anti-fouling paint

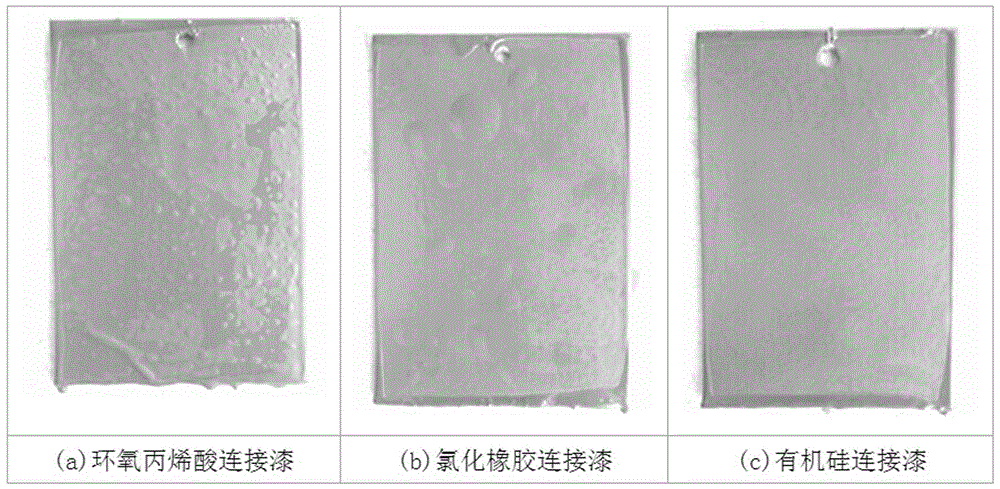

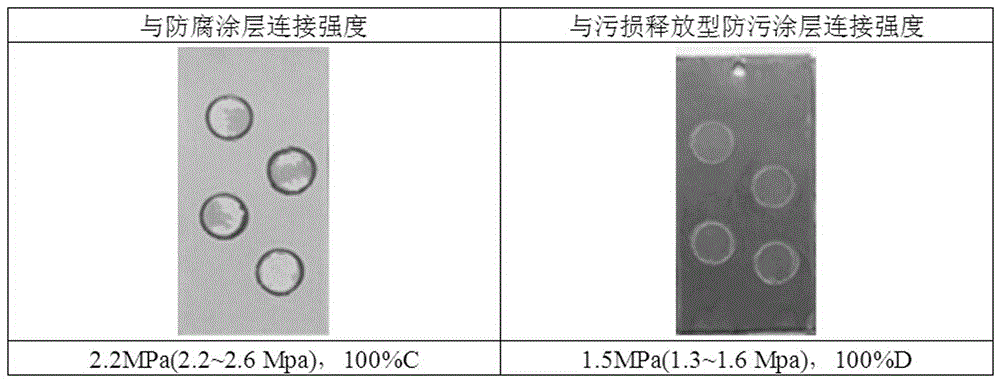

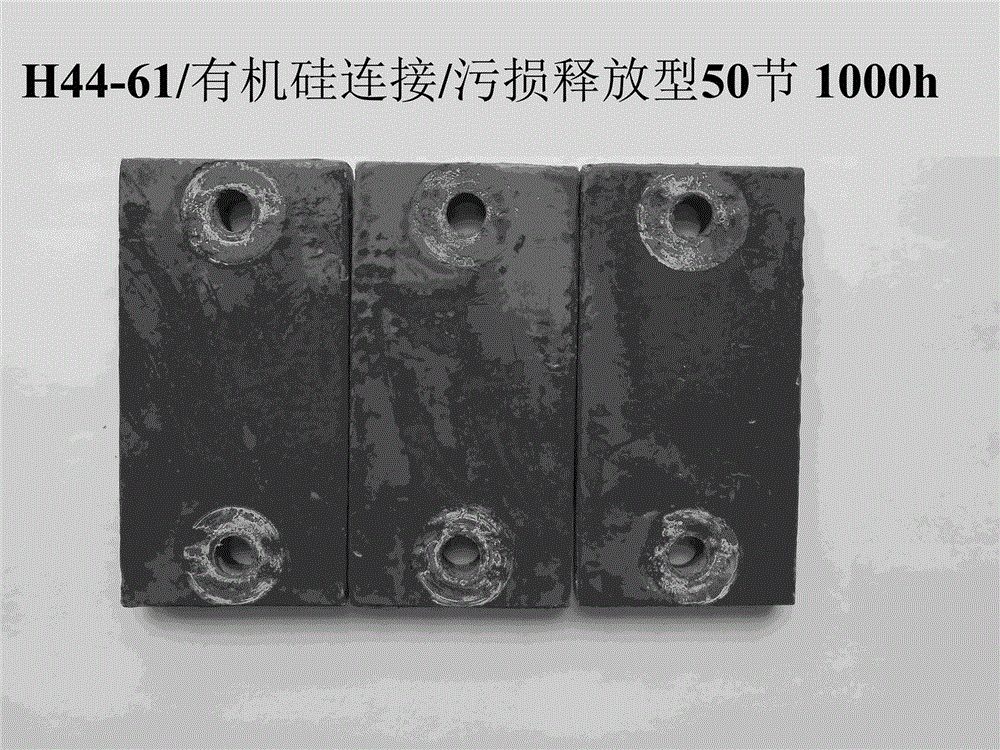

A technology of organic silicon and antifouling paint, which is applied in the direction of antifouling/underwater paint, anticorrosion paint, paint containing biocide, etc. It can solve the problems of poor adhesion between fouling release antifouling paint and antirust paint, etc. achieve a good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific examples 1-4.

[0022] A two-component interfacially bonded silicone tie paint supporting fouling-release antifouling paint, made of component A and component B at a weight ratio of 10:1, the component A is composed of silicone, pigment Composed of filler, solvent and thixotropic agent, component B of high toughness curing agent and reaction accelerator, the dosage of each component in terms of weight percentage is 35~55% of component A silicone, 20~40% of pigment and filler, and 15% of solvent ~30% and 0~5% of thixotropic agent and 10~20% of component B high toughness curing agent and 0.01~0.03% of reaction accelerator.

[0023] The organosilicon is a mixture of hydroxyl silicone oil and epoxy silicone oil, and the weight ratio of hydroxyl silicone oil and epoxy silicone oil is 1:0.6-1.5. The high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com