Modular Motor Pump Unit

A motor pump, modular technology, applied in pump components, pumps, multi-cylinder pumps, etc., can solve complex problems and achieve the effects of easy integration, simplified assembly, and sufficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

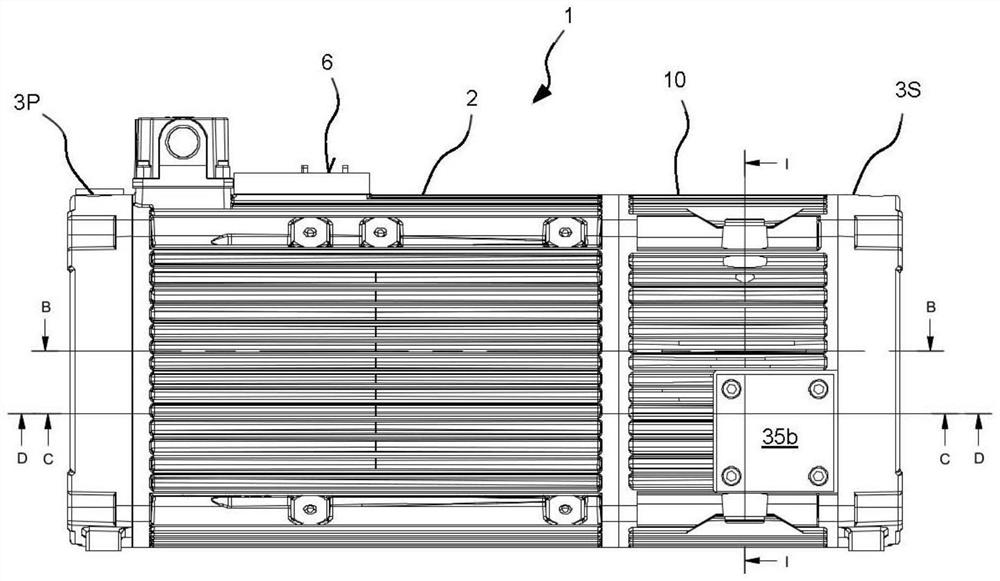

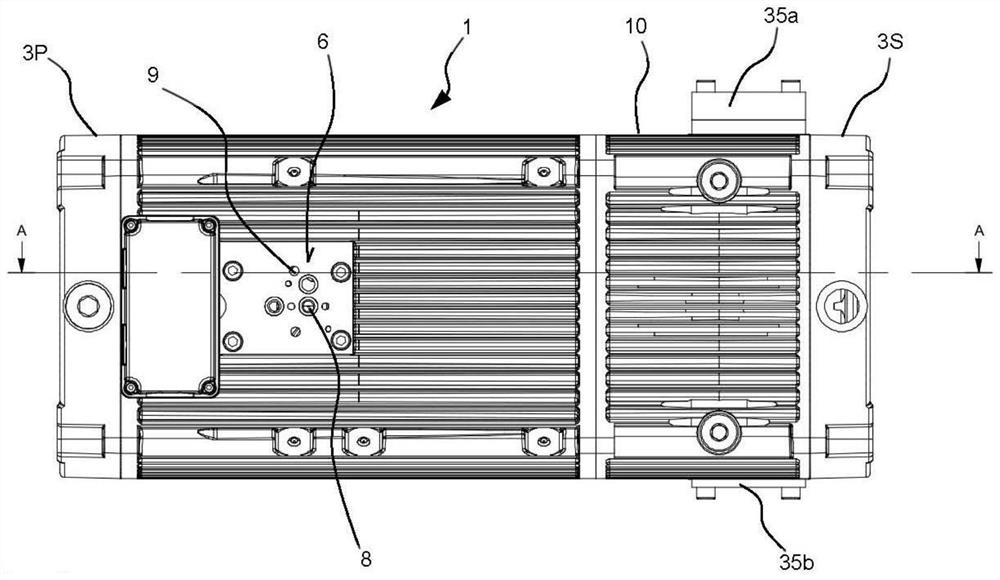

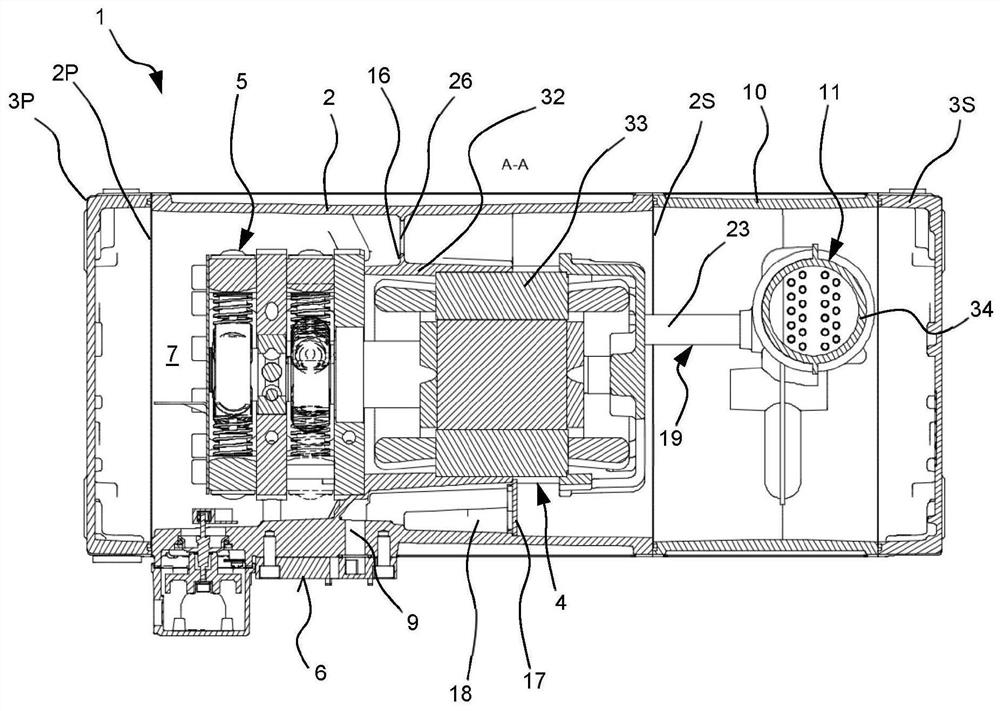

[0058] Figure 1 to Figure 11 A modular motor-pump unit 1 according to a first embodiment is shown. Figure 13 to Figure 22 A modular motor pump unit 100 according to a second embodiment is shown. Hereinafter, first, the modular motor pump unit 1 will be described in detail according to the first embodiment.

[0059] The motor pump unit 1 according to the first embodiment has an outer housing 2 with a connecting portion 6 on the outer periphery. The connection part 6 has a pressure connection and a return hydraulic fluid connection. The outer housing 2 is, for example, a gravity die-cast part made of light metal, such as aluminum or an aluminum alloy. A transverse wall 16 with a plurality of axial through holes 26 is arranged in the outer housing 2 having a stator plug seat 32 to accommodate a stator 33 of the electric motor 4 . The electric motor 4 drives a pump element 5 fixed in the outer housing 2 in a conventional manner, so that hydraulic fluid is pumped from a hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com