Construction method of building exterior wall coating

A construction method and technology for building exterior walls, applied in the direction of architecture, building structure, covering/lining, etc., can solve the problems of unsightly appearance, poor effect, peeling, etc., and achieve good effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

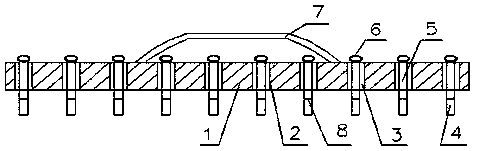

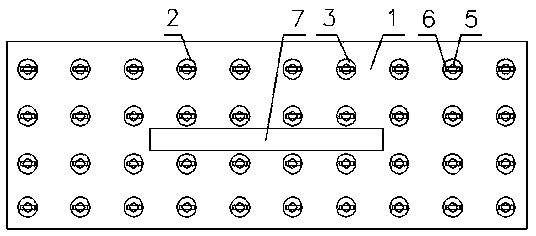

Image

Examples

Embodiment 1

[0021] A construction method for building exterior wall coatings. The construction method includes six steps. The first step is to carry out foundation treatment or transformation of the base, the second step is to paint the wall surface with water for a homogeneous foundation or base, the third step is to scrape putty, and the fourth step The first step is to apply the primer, the fifth step is to apply the middle paint, and the sixth step is to apply the top coat.

Embodiment 2

[0023] The construction method of a kind of building exterior wall coating described in embodiment 1, described basic treatment is to remove dirt, floating sand on the wall surface at first, and concrete wall surface is smoothed with cement mortar, requires that the whole wall surface is smooth, without Check the gap with a ruler and a level ruler, and the flatness error is 1-2mm; at the same time, clean up the sundries near the door and window frames, seal and level the door and window frames, and dry the cement mortar for 4-8 days, and the moisture content after drying is less than 10 %, the next step is to check whether there are potholes on the wall, and level it with secondary cement mortar. The drying period is 3-6 days.

[0024] The effect of wall cleaning is good, which can improve the quality of putty and the quality of the whole wall.

Embodiment 3

[0026] The construction method of a kind of building exterior wall coating described in embodiment 2, described grass-roots transformation is that the existing finish paint of wall surface is polished clean with emery wheel, and wall surface is drenched with water, and one layer is smeared with cement mortar, Then leveling requires the overall wall surface to be flat and free of gaps. Check with a ruler and a level ruler. The flatness error is 1-2mm; the drying time of cement mortar is 4-8 days, and the moisture content after drying is less than 10%.

[0027] Grinding the existing wall surface with a grinding wheel to ensure that the wall surface is clean and thorough, and the cleaning speed is fast, and the bonding force with the cement mortar is good, ensuring that there will be no gap between the wall surface and the cement mortar, and the bonding effect is good. Strong adhesion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com