Lining cloth and making method thereof

A production method and interlining technology, which is applied in the field of clothing, can solve problems such as rigid hand feeling, poor dimensional stability, and insufficient washability, and achieve the effect of soft hand feeling, good elasticity, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

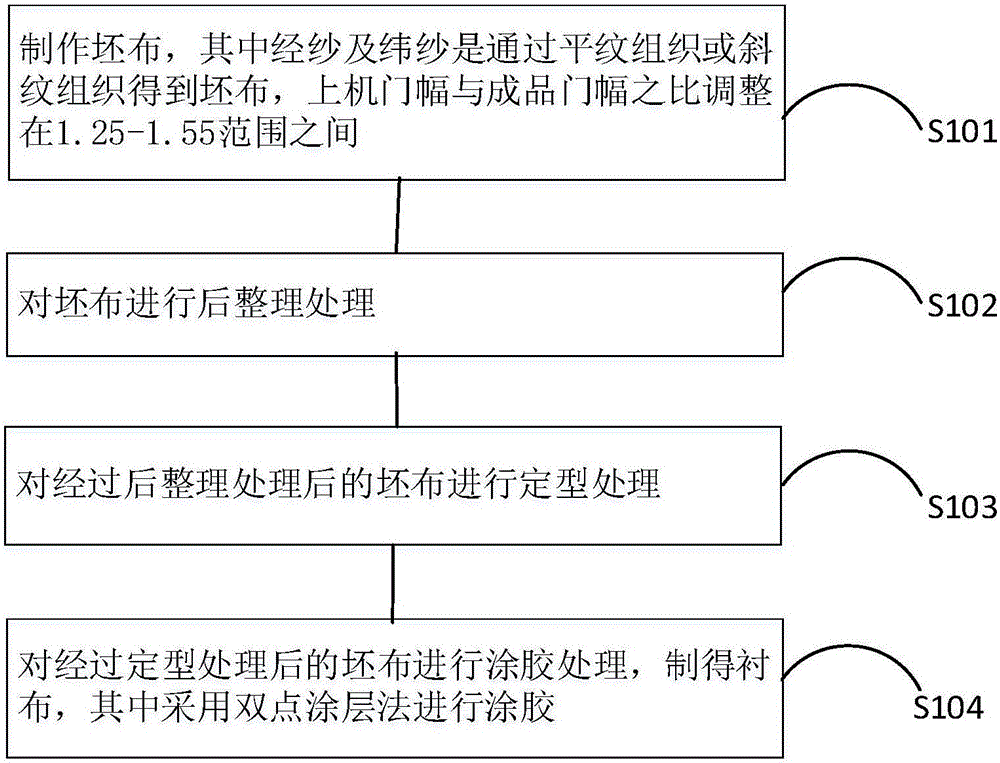

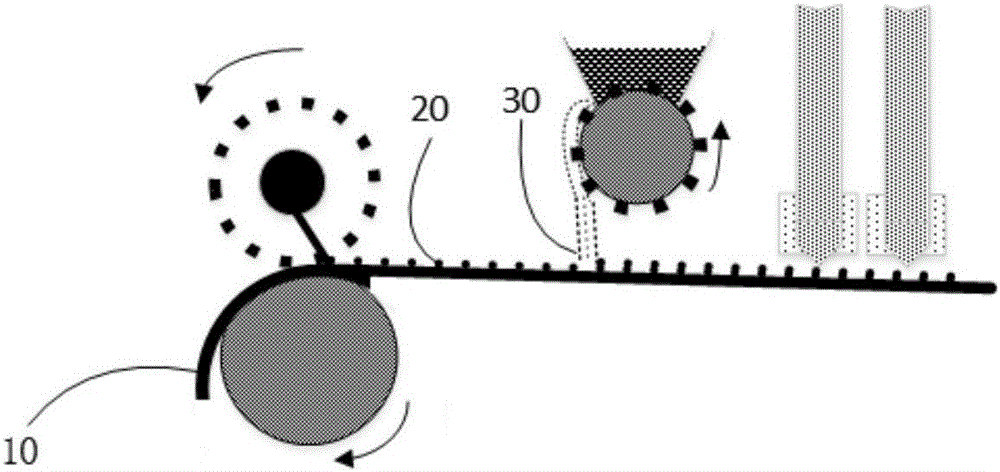

Method used

Image

Examples

Embodiment 1

[0067] Example 1: T4552-05H

[0068] Choose an air-jet loom to make gray fabric, in which twill 2 / 2 weave is selected, the warp material is PA66DTY material, the specification is micro mesh 15D / 5F, the weft material is PA6 DTY material, the specification is 150D / 48F, and the warp and weft density on the machine is 29x13 .5 pcs / cm, the door width on the machine is 230cm.

[0069] After finishing the gray cloth. Arrange the billet in the steam pre-shrinking machine, the temperature is 135°C, the speed is 20m / min, and the pre-shrinking is carried out under the condition of no tension, and the door width shrinks from about 205cm to about 140cm.

[0070] The pre-shrunk billet is further arranged in an overflow dyeing machine for refining and oil removal, so as to further pre-shrink and expand. Specifically: place the pre-shrunk gray cloth in an overflow dyeing machine at 90°C, heat it up to 115°C at a heating rate of 1.5°C / min for dyeing, and keep it warm for 25 minutes; then dra...

Embodiment 2

[0077] Example 2: T4560-06H

[0078] Choose an air-jet loom to make gray fabric, in which twill 2 / 2 weave is selected, the warp material is PA6DTY material, the specification is micro mesh 75D / 24F, the weft material is PA6 DTY material, the specification is 150D / 48F, and the warp and weft density on the machine is 20x10 root / cm, the door width on the machine is 225cm.

[0079] After finishing the gray cloth. Arrange the billet in the steam pre-shrinking machine, the temperature is 140°C, the speed is 15m / min, and the pre-shrinking is carried out under the condition of no tension, and the door width shrinks from about 205cm to about 140cm.

[0080] The pre-shrunk billet is further arranged in an overflow dyeing machine for refining and oil removal, so as to further pre-shrink and expand. Specifically: place the pre-shrunk gray cloth in an overflow dyeing machine at 90°C, heat it up to 115°C at a heating rate of 1.5°C / min for dyeing, and keep it warm for 25 minutes; then drain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com