Ultra-flexible and ultra-soft rebound synthetic leather fabric and preparation method thereof

A synthetic leather and fabric technology, applied in the field of synthetic leather, can solve the problems of insufficient surface gloss, poor cold and heat resistance, and insufficient lightness and softness, so as to achieve excellent wear resistance, enhanced heat and cold resistance, and soft hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

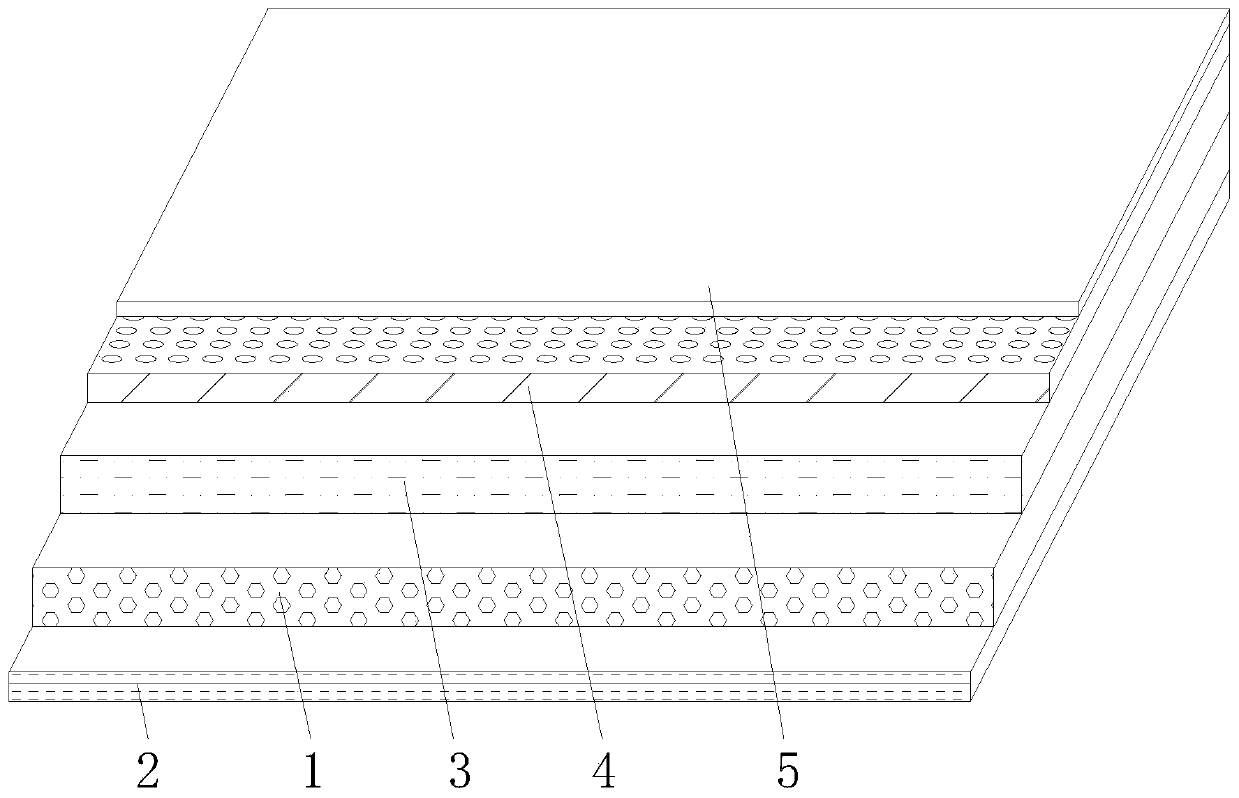

[0034] This embodiment provides a kind of extra soft and extra soft resilient synthetic leather fabric, comprising base cloth layer 1, warm layer 2, raised cloth 3, surface layer 4 and high-gloss polyurethane layer 5, passing between base cloth layer 1 and warm layer 2 Knitting and sewing are connected together, the raised cloth 3 is positioned above the base cloth layer 1, and the raised cloth 3 and the base cloth layer 1 are fixedly connected by an adhesive, the surface layer 4 is positioned above the raised cloth 3, and the surface layer 4 and the raised cloth 3 are fixedly connected by an adhesive, and the high-gloss polyurethane layer 5 is sprayed on the surface of the surface layer 4 .

[0035] The base fabric layer 1 is woven into a fine mesh structure by nylon 56. At the same time, fibrous or powdery hot-melt adhesive reinforcement materials are added to both sides of the nylon mesh. After the fiber mesh is heated and melted, it is cooled and reinforced to form a bottom...

Embodiment 2

[0051] The extra-soft and extra-soft rebound synthetic leather fabric provided in this embodiment comprises a base cloth layer 1, a warm-keeping layer 2, a raised cloth 3, a surface layer 4 and a high-gloss polyurethane layer 5, and the base cloth layer 1 and the warm-keeping layer 2 are knitted The stitching is connected together, the raised cloth 3 is positioned above the base cloth layer 1, the raised cloth 3 and the base cloth layer 1 are fixedly connected by an adhesive, the surface layer 4 is positioned above the raised cloth 3, the surface layer 4 and the raised cloth 3 They are fixedly connected by an adhesive, and the high-gloss polyurethane layer 5 is sprayed on the surface of the surface layer 4 .

[0052] The base fabric layer 1 is woven into a fine mesh structure by nylon 56. At the same time, fibrous or powdery hot-melt adhesive reinforcement materials are added to both sides of the nylon mesh. After the fiber mesh is heated and melted, it is cooled and reinforced...

Embodiment 3

[0068] The extra-soft and extra-soft rebound synthetic leather fabric provided in this embodiment comprises a base cloth layer 1, a warm-keeping layer 2, a raised cloth 3, a surface layer 4 and a high-gloss polyurethane layer 5, and the base cloth layer 1 and the warm-keeping layer 2 are knitted The stitching is connected together, the raised cloth 3 is positioned above the base cloth layer 1, the raised cloth 3 and the base cloth layer 1 are fixedly connected by an adhesive, the surface layer 4 is positioned above the raised cloth 3, the surface layer 4 and the raised cloth 3 They are fixedly connected by an adhesive, and the high-gloss polyurethane layer 5 is sprayed on the surface of the surface layer 4 .

[0069] The base fabric layer 1 is woven into a fine mesh structure by nylon 56. At the same time, fibrous or powdery hot-melt adhesive reinforcement materials are added to both sides of the nylon mesh. After the fiber mesh is heated and melted, it is cooled and reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com