Water-based epoxy primer for wet-to-wet process and preparation method of water-based epoxy primer

A water-based epoxy, wet-on-wet technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems affecting the final effect of the paint film, product use limitations, poor hardness of composite coatings, etc., to achieve high Wet-on-wet process of film thickness, high resistance to salt spray and aging performance, and the effect of avoiding shrinkage cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

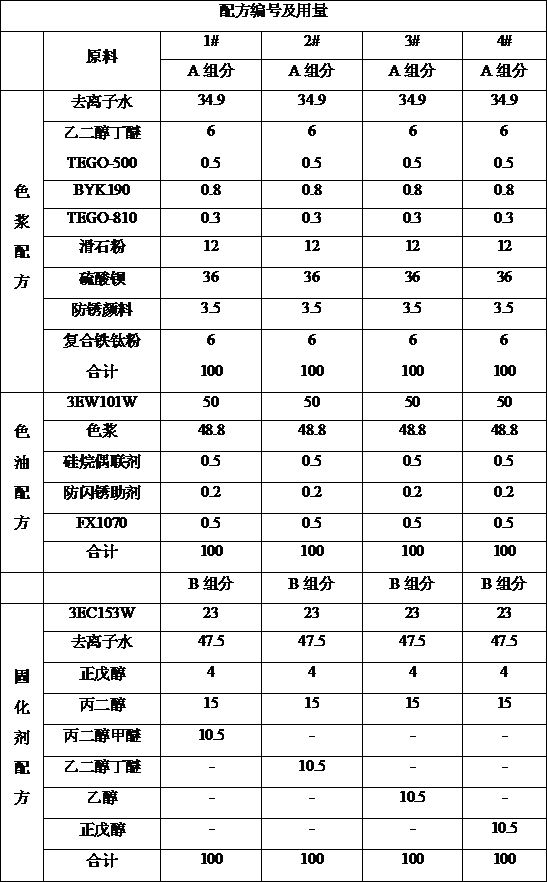

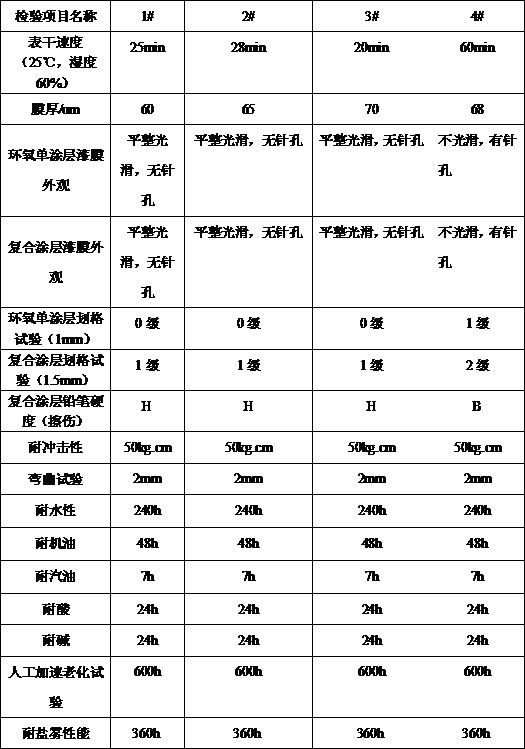

Embodiment 1

[0025] A water-based epoxy primer of a wet-on-wet process, the preparation method of which is:

[0026] 1) Water slurry preparation method

[0027] After dispersing water, color paste co-solvent, substrate wetting agent, dispersant and defoamer evenly, add talcum powder, barium sulfate, anti-rust pigment and iron-titanium powder while stirring at a linear speed of 3-5m / s. After dispersing for 20-30 minutes, use a grinder to grind to a fineness of 15-25 μm, and discharge;

[0028] 2) Preparation of component A of epoxy primer

[0029] Slowly add water slurry to the water-based epoxy emulsion during stirring at a line speed of 8-12m / s. After 15-30min, add silane coupling agent, anti-flash rust additive and thickener while stirring at a line speed of 3-5m / s. Then use deionized water to adjust the viscosity (coat -4 cups, 50-100s, 25°C), and stir well to obtain component A of the water-based epoxy primer;

[0030] 3) Preparation of Epoxy Primer B Component

[0031] Mix the pol...

Embodiment 2

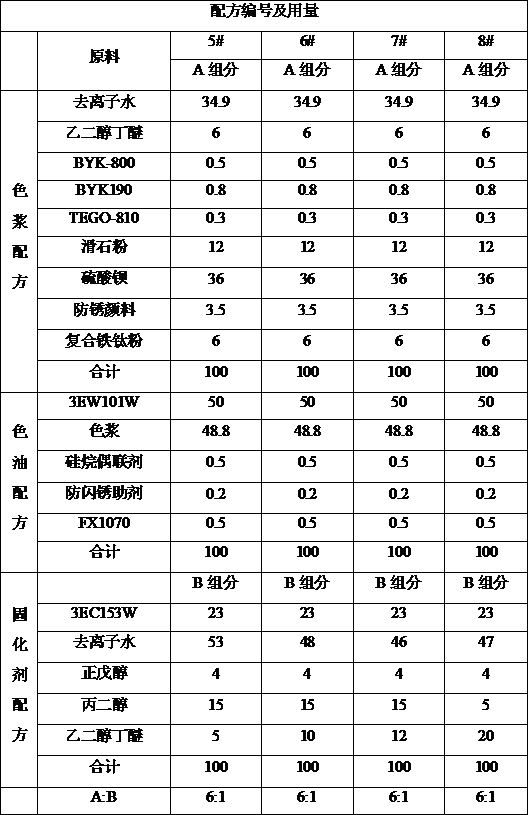

[0041] Table 3 shows the process of preparing color paste and color paint according to Example 1 by changing the amount of curing agent co-solvent, numbered 5#, 6#, 7#, and 8# in Example 2 while keeping other materials unchanged. , and prepare the paint film.

[0042] Table 4 is the paint film performance detection of embodiment 2. The curing agent co-solvent is mixed with n-amyl alcohol, propylene glycol and ethylene glycol butyl ether solvent. The paint film performance of 6# and 7# is normal, but there are abnormalities such as pinholes in 5# and 8#. This is because the solvent ethylene glycol butyl ether with low heat of evaporation accounts for 20% and 80% of the hydrophilic solvent respectively, and the low heat of evaporation solvent in the 5# side is too small, resulting in slow moisture volatilization. In the wet-on-wet process, there is also A large amount of water remains, during baking, the volatilization of water causes abnormalities such as pinholes in the paint...

Embodiment 3

[0048] Table 5 shows that in Example 3, under the condition that other materials remain unchanged, the amount of talcum powder and barium sulfate in the color paste is changed, and the numbers are 9#, 10#, 11#, 12#, and the color paste, The process of color paint and the preparation of paint film.

[0049] Table 6 is the paint film property detection of embodiment 3, know by table, change the amount of talcum powder and barium sulfate, 10# and 11# square paint film performance and every index of paint film appearance are all qualified, 9# square paint film The hardness of the talcum powder decreased, the flexibility of the 12# square decreased, and the appearance of the paint film was normal. This is because in this formula system, the talcum powder is a monoclinic crystal system and forms a dense leaf shape. When the amount is large, it is beneficial to increase the paint film. flexibility, but it will reduce the hardness of the paint film. Excessive barium sulfate is not con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com