Preparation method of novel single-component water-cured polyurethane waterproof coating

A polyurethane waterproof, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of environmental protection, low use value, long hair cycle, etc., and achieve excellent aging resistance and mechanical properties , The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

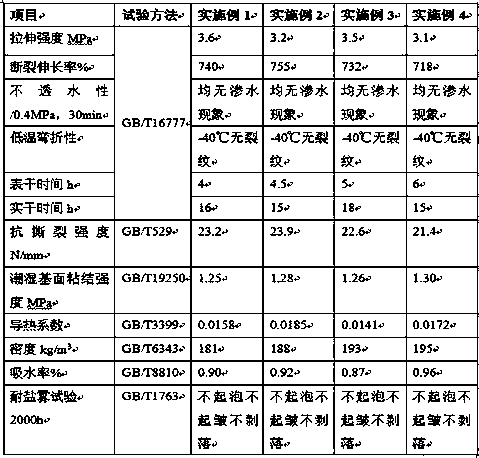

Examples

Embodiment 1

[0044] Embodiment 1 A kind of preparation method of novel single-component water-cured polyurethane waterproof coating

[0045] The preparation method of described novel one-component water-cured polyurethane waterproof coating comprises the following steps:

[0046] 1. Dry

[0047] The polyether diol and the polyether triol are respectively vacuum dehydrated to a moisture content of 0.11%;

[0048] 2. mix

[0049] Mix polyether diol and polyether triol according to the ratio of mass ratio 15:2, stir, and add benzoyl chloride in the reactor;

[0050] The add-on of described benzoyl chloride is 0.1% of polyether glycol and polyether trihydric alcohol gross weight;

[0051] 3. Prepolymerization

[0052] Nitrogen was passed under normal pressure for 20 minutes, the air in the reactor was removed, and MDI was added under the protection of nitrogen atmosphere to raise the temperature to 80°C for prepolymerization for 4 hours to obtain a prepolymer;

[0053] The add-on of descr...

Embodiment 2

[0067] Embodiment 2 A kind of preparation method of novel single-component water-cured polyurethane waterproof coating

[0068] The preparation method of described novel one-component water-cured polyurethane waterproof coating comprises the following steps:

[0069] 1. Dry

[0070] The polyether diol and polyether triol are vacuum dehydrated respectively to a moisture content of 0.2%;

[0071] 2. mix

[0072] Mix polyether diol and polyether triol according to the ratio of mass ratio 7:1, stir, add benzoyl chloride in the reactor;

[0073] The add-on of described benzoyl chloride is 0.09% of polyether glycol and polyether trihydric alcohol gross weight;

[0074] 3. Prepolymerization

[0075] Nitrogen was passed under normal pressure for 20 minutes, the air in the reactor was removed, and MDI was added under the protection of nitrogen atmosphere to raise the temperature to 78°C for prepolymerization for 3 hours to obtain a prepolymer;

[0076] The add-on of described MDI,...

Embodiment 3

[0090] Embodiment 3 A kind of preparation method of novel single-component water-cured polyurethane waterproof coating

[0091] The preparation method of described novel one-component water-cured polyurethane waterproof coating comprises the following steps:

[0092] 1. Dry

[0093] The polyether diol and the polyether triol are respectively vacuum dehydrated to a moisture content of 0.08%;

[0094] 2. mix

[0095] Mix polyether diol and polyether triol according to the ratio of mass ratio 8:1, stir, and add benzoyl chloride to the reactor;

[0096] The add-on of described benzoyl chloride is 0.1% of polyether glycol and polyether trihydric alcohol gross weight;

[0097] 3. Prepolymerization

[0098] Nitrogen was passed under normal pressure for 20 minutes, the air in the reactor was removed, and MDI was added under the protection of nitrogen atmosphere to raise the temperature to 82°C for prepolymerization for 4 hours to obtain a prepolymer;

[0099] The add-on of descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com