Environment-friendly single-component industrial anti-corrosion coating and preparation method thereof

An anti-corrosion coating and industrial technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor water resistance, corrosion resistance and weather resistance, unsatisfactory drying performance, slow drying of water-based alkyd coatings, etc., to improve salt spray resistance. and corrosion resistance, excellent corrosion resistance, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

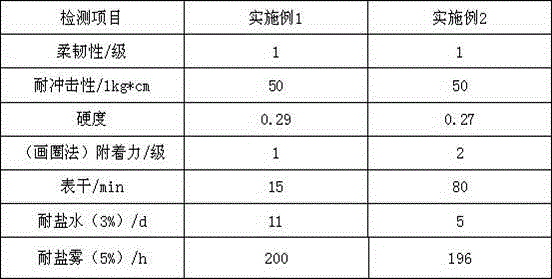

Examples

Embodiment 1

[0027] A kind of water-based industrial anticorrosion paint, is made up of following component and weight percentage:

[0028] Modified water-based acrylic resin 45%, antirust pigment 10%, filler 5%, solvent 35.9%, additive 2%, water-based drier 0.5%, thinner 0.6%, thickener 0.6%.

[0029] The modified water-based acrylic resin is an epoxy resin modified water-based acrylic resin.

[0030] The antirust pigment is microcapsule modified embedded iron oxide red and aluminum tripolyphosphate.

[0031] The filler is heavy calcium.

[0032] The solvent is water.

[0033] The auxiliary agent is composed of water-based dispersant, water-based defoamer, water-based surface wetting agent, leveling agent and anti-sedimentation agent.

[0034] The water-based dispersant adopts commercially available A4100 dispersant.

[0035] The water-based defoamer adopts commercially available BYK-024 defoamer.

[0036] The anti-settling agent adopts commercially available BYK-410 anti-settling ag...

Embodiment 2

[0047] A kind of water-based industrial anticorrosion paint, is made up of following component and weight percentage:

[0048] Modified water-based acrylic resin 50%, antirust pigment 9%, filler 6%, solvent 32%, additive 2%, water-based drier 0.5%, thinner 0.8%, thickener 0.5%.

[0049] The modified water-based acrylic resin is polyurethane modified water-based acrylic resin.

[0050] The antirust pigment is microcapsule modified and embedded aluminum tripolyphosphate / zinc phosphate and rutile titanium dioxide.

[0051] The solvent is water.

[0052] The filler is heavy calcium.

[0053] The auxiliary agent is composed of water-based dispersant, water-based defoamer, water-based surface wetting agent, leveling agent and anti-sedimentation agent.

[0054] The aqueous dispersant adopts commercially available BYK-750 dispersant.

[0055] The defoamer adopts commercially available BYK-024 defoamer.

[0056] The anti-settling agent adopts commercially available BYK-410 anti-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com