Preparation method of high-humidity-adhesion liquid granite coating

A granite coating and liquid technology, applied in the coating and other directions, to achieve the effects of good wear resistance, improved quality, and improved adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

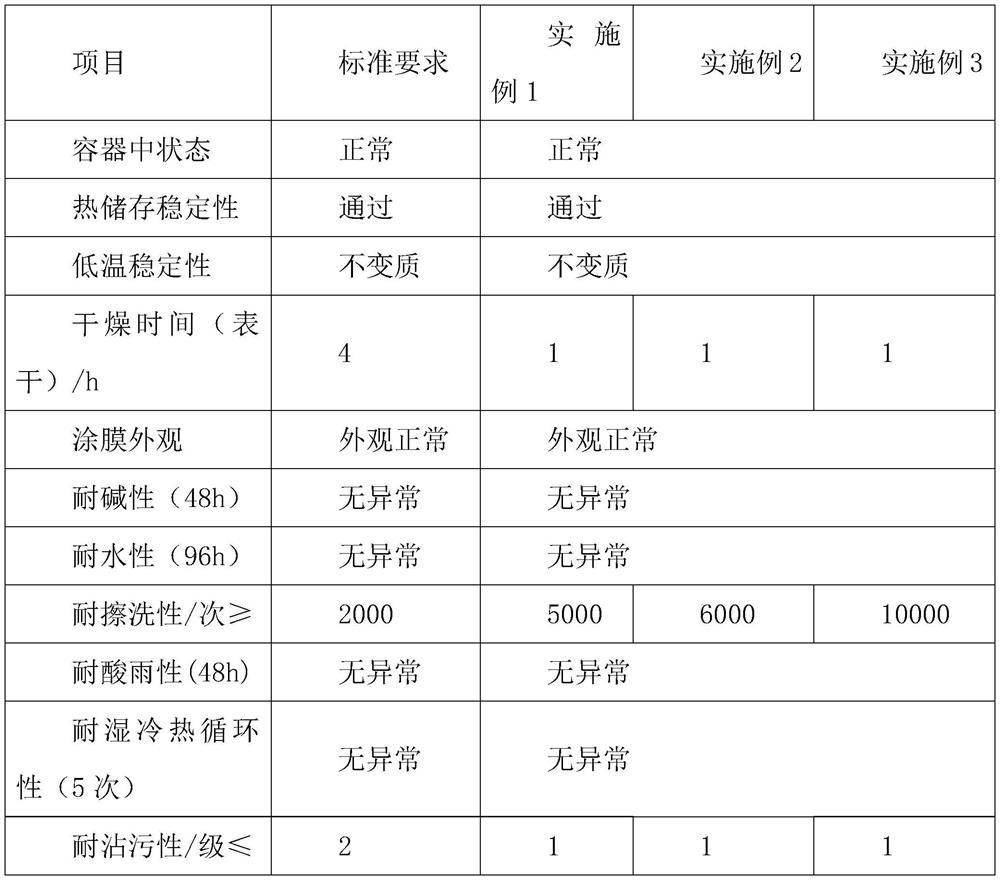

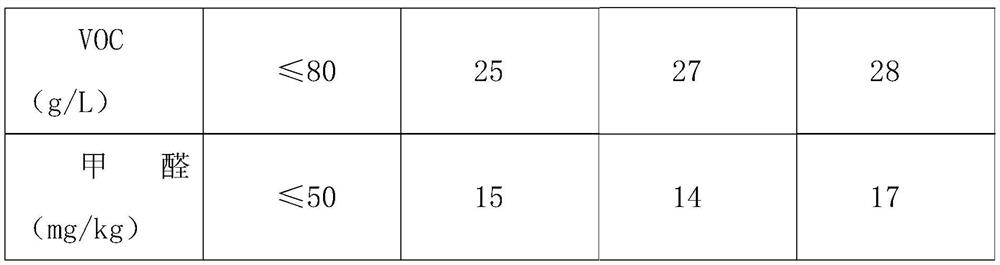

Examples

Embodiment 1

[0032]A high-humidity adhesion liquid granite coating is composed of the following materials, each component is measured according to mass percentage: 10% of protective glue, 10% of emulsion, 0.5% of crosslinking agent, 70.5% of dispersed phase (color point), surfactant 1.5%, initiator 0.5%, accelerator 0.5%, softener 1%, special resin 0.5%, rheological additive 0.5%, magnesium oxide 0.5%, water-based isocyanate 1%, release agent 3%;

[0033] Disperse phase (color dot) 70.5% is prepared from the following raw materials according to the percentage: water 10%, wetting and dispersing agent 0.5%, anti-mold and preservative 1%, defoamer 1%, antifreeze 2%, film-forming aid 1%, pH regulator 1%, calcined kaolin 3%, heavy calcium 4%, titanium dioxide 3%, cellulose 3%, protective glue 2%, sand 40%.

[0034] Among them, the wetting and dispersing agent is Nopco SN5040; the anti-mold preservative is a mixture of Lonza PROXEL CMC and Lonza PROXEL 160 with a mass ratio of 2:1; the defoamer ...

Embodiment 2

[0044] A high-humidity adhesion liquid granite coating is composed of the following materials, each component is measured according to mass percentage: 10% of protective glue, 9% of emulsion, 1% of crosslinking agent, 70.5% of dispersed phase (color point), surfactant 1.5%, initiator 0.5%, accelerator 1%, softener 1%, special resin 1%, rheological additive 0.5%, magnesium oxide 1%, water-based isocyanate 1%, release agent 2%;

[0045] Disperse phase (color dot) 70.5% is prepared from the following raw materials according to the percentage: water 10%, wetting and dispersing agent 0.5%, anti-mold and preservative 1%, defoamer 1%, antifreeze 2%, film-forming aid 1%, pH regulator 1%, calcined kaolin 3%, heavy calcium 4%, titanium dioxide 3%, cellulose 3%, protective glue 2%, sand 40%.

[0046] Among them, the wetting and dispersing agent is Nopco SN5040; the anti-mold preservative is a mixture of Lonza PROXEL CMC and Lonza PROXEL 160 with a mass ratio of 2:1; the defoamer is Haich...

Embodiment 3

[0056] A high-humidity adhesion liquid granite coating is composed of the following materials, each component is measured according to mass percentage: 10.5% of protective glue, 8% of emulsion, 1% of crosslinking agent, 70.5% of dispersed phase (color point), surfactant 1.5%, initiator 1%, accelerator 1%, softener 1%, special resin 1%, rheological additive 0.5%, magnesium oxide 1%, water-based isocyanate 1%, release agent 2%;

[0057] Disperse phase (color dot) 70.5% is prepared from the following raw materials according to the percentage: water 10%, wetting and dispersing agent 0.5%, anti-mold and preservative 1%, defoamer 1%, antifreeze 2%, film-forming aid 1%, pH regulator 1%, calcined kaolin 3%, heavy calcium 4%, titanium dioxide 3%, cellulose 3%, protective glue 2%, sand 40%.

[0058] Among them, the wetting and dispersing agent is Nopco SN5040; the anti-mold preservative is a mixture of Lonza PROXEL CMC and Lonza PROXEL 160 with a mass ratio of 2:1; the defoamer is Haich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com