Continuous production method for temporary protective layer of hot-rolled strip steel and hot-rolled strip steel

A technology of hot-rolled steel strip and production method, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., which can solve the problems of welding and coating influence, complicated process, excessive protection, etc., and achieve simplified production Process and process requirements, shortening process length, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

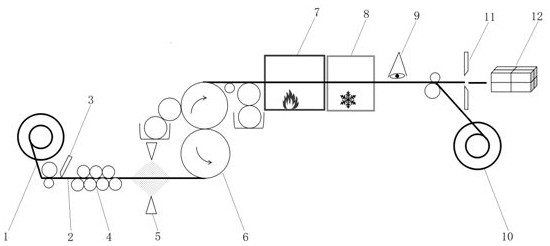

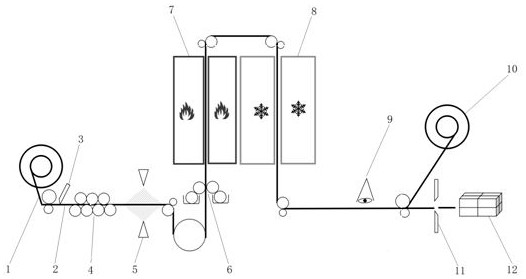

[0035] see figure 1 A method for continuous production of a temporary protective layer for hot-rolled steel strips, comprising the steps of:

[0036] Step 1, uncoiling and straightening: the head of the strip to be processed 1 and the tail of the pre-coiled strip 2 are welded and connected by the welding device 3, and the strip to be processed 1 is opened and sent to the straightening machine 4 for straightening. The plate shape of the treated strip is optimized to ensure that the surface flatness of the strip meets the requirements of subsequent surface treatment operations.

[0037] Step 2, surface cleaning: the surface cleaning device 5 is used to clean the floating ash, oxide particles and oil stains on the surface of the straightened steel strip, so as to ensure that the cleanliness of the steel strip surface meets the surface treatment requirements. In this step, there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com